ASTM F2711-19

(Test Method)Standard Test Methods for Bicycle Frames

Standard Test Methods for Bicycle Frames

SIGNIFICANCE AND USE

5.1 These tests are used to verify the durability and strength of a bicycle frame.

SCOPE

1.1 These test methods establish procedures for conducting tests to determine the structural performance properties of bicycle frames.

1.2 These test methods describe mechanical tests for determining the following performance properties:

1.2.1 Frame Fatigue – Horizontal Loading

1.2.2 Frame Fatigue – Vertical Loading

1.2.3 Falling Mass – Horizontal Loading

1.2.4 Falling Frame – Vertical Loading

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2711 − 19 An American National Standard

Standard Test Methods for

1

Bicycle Frames

This standard is issued under the fixed designation F2711; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1.1 Discussion—Theforktransmitssteeringtorquefrom

the handlebars to the front wheel.

1.1 These test methods establish procedures for conducting

tests to determine the structural performance properties of 3.1.2 bicycle frame, n—structural member that supports the

bicycle frames. seat with rear connection for the rear wheel, front connection

via the head tube for the fork and lower connection for the

1.2 These test methods describe mechanical tests for deter-

crank/pedal assembly.

mining the following performance properties:

1.2.1 Frame Fatigue – Horizontal Loading 3.1.3 bottom bracket shell, n—structural member of the

1.2.2 Frame Fatigue – Vertical Loading frame that houses the assembly that supports the bearings,

1.2.3 Falling Mass – Horizontal Loading which support the cranks.

1.2.4 Falling Frame – Vertical Loading

3.1.4 crank, n—lever arm that receives human energy as

1.3 The values stated in SI units are to be regarded as torque to convert into bicycle motion.

standard. No other units of measurement are included in this

3.1.5 crown race seat, n—position on the fork where the

standard.

lower steering axis bearing sits.

1.4 This standard does not purport to address all of the

3.1.6 down tube, n—lower structural connection between

safety concerns, if any, associated with its use. It is the

the head tube and the bottom bracket shell.

responsibility of the user of this standard to establish appro-

3.1.7 dropout centerline, n—hub-mounting axis that passes

priate safety, health, and environmental practices and deter-

through both right and left dropouts.

mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor-

3.1.8 front dropout, n—area where the front wheel hub

dance with internationally recognized principles on standard-

connects to the fork.

ization established in the Decision on Principles for the

3.1.9 head tube, n—forward most structural member of the

Development of International Standards, Guides and Recom-

frame, which provides an interface through top, and bottom

mendations issued by the World Trade Organization Technical

bearings for the fork.

Barriers to Trade (TBT) Committee.

3.1.9.1 Discussion—The head tube is connected to the seat

tube through the top tube and the down tube.

2. Referenced Documents

2

3.1.10 initial running displacement, n—average displace-

2.1 ASTM Standards:

ment between approximately 500 and 1000 cycles during a

E4 Practices for Force Verification of Testing Machines

durability fatigue test.

3. Terminology

3.1.11 normal attitude, n—intended position of the bicycle

3.1 Definitions of Terms Specific to This Standard: framewhenincontinuousstraight-linemotiononaflatsurface.

3.1.1 bicycle fork, n—structural connection between the

3.1.12 rake, n—straight-line distance from the front axle

front wheel and the frame.

center to the perpendicular of the steering axis.

3.1.13 rear dropout, n—area where the rear wheel hub

1

These test methods are under the jurisdiction of ASTM Committee F08 on connects to the lower rear and the upper rear frame members.

Sports Equipment, Playing Surfaces, and Facilities and are the direct responsibility

3.1.14 sag, n—amount of compression in a suspension unit,

of Subcommittee F08.10 on Bicycles.

Current edition approved Oct. 1, 2019. Published November 2019. Originally given in a percentage.

approved in 2008. Last previous edition approved in 2012 as F2711 - 08 (2012).

3.1.15 seat post, n—structural component that connects the

DOI: 10.1520/F2711-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or seat to the seat tube.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.1.16 seat tube, n—structural member of the frame into

Standardsvolume information, refer to the standard’s Document Summary page on

the ASTM website. which the seat post inserts.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

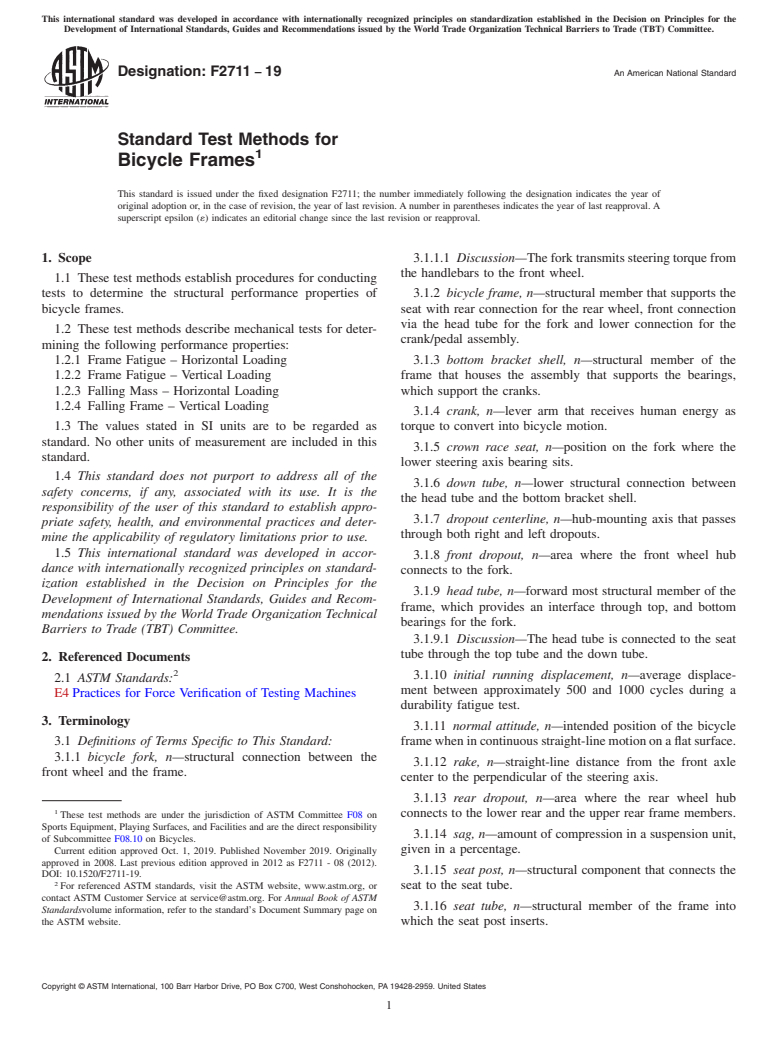

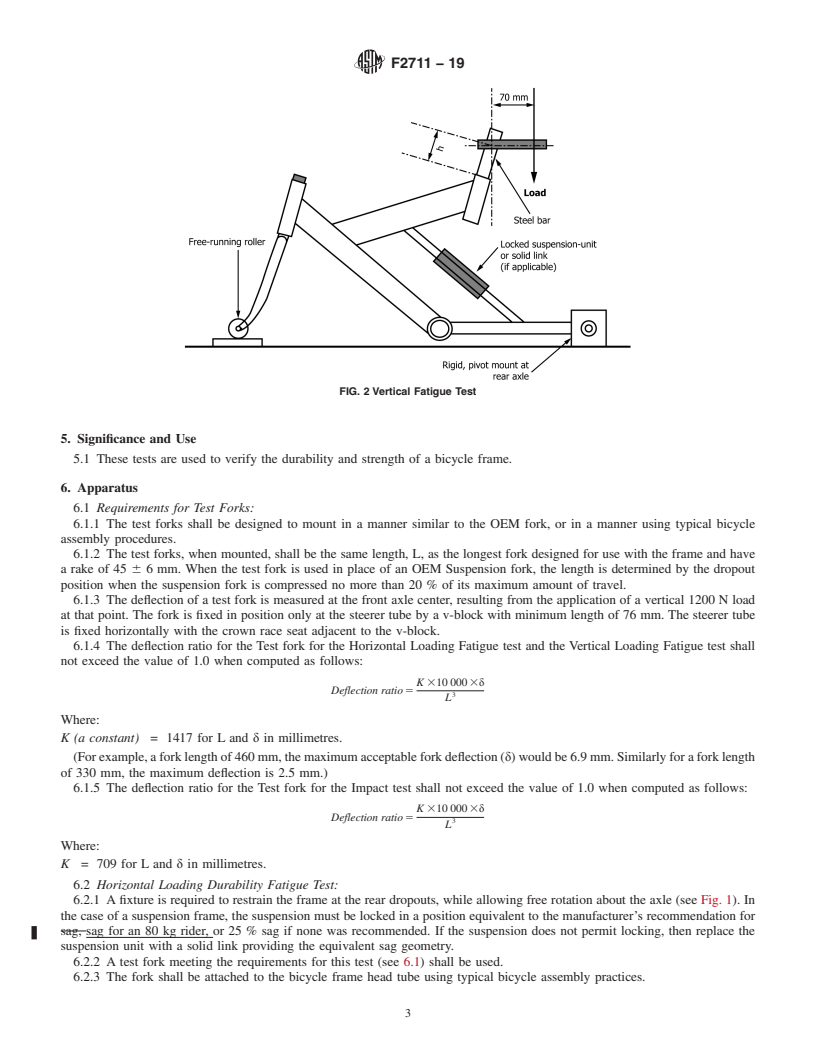

F2711 − 19

3.1.17 steerer tube, n—section of the bicycle fork that is 6.1.1 The test forks shall be designed to mount in a manner

housed within the head tube a

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2711 − 08 (Reapproved 2012) F2711 − 19 An American National Standard

Standard Test Methods for

1

Bicycle Frames

This standard is issued under the fixed designation F2711; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods establish procedures for conducting tests to determine the structural performance properties of bicycle

frames.

1.2 These test methods describe mechanical tests for determining the following performance properties:

1.2.1 Frame Fatigue—Horizontal Loading,Fatigue – Horizontal Loading

1.2.2 Frame Fatigue—Vertical Loading, andFatigue – Vertical Loading

1.2.3 Falling Mass – Horizontal Loading

1.2.4 Frame Impact Strength.Falling Frame – Vertical Loading

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E4 Practices for Force Verification of Testing Machines

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 bicycle, n—two-wheeled, single track, articulated vehicle that is solely human powered.

3.1.1 bicycle fork, n—structural connection between the front wheel and the frame.

3.1.1.1 Discussion—

The fork transmits steering torque from the handlebars to the front wheel.

3.1.2 bicycle frame, n—structural member that supports the seat with rear connection for the rear wheel, front connection via

the head tube for the fork and lower connection for the crank/pedal assembly.

3.1.3 bottom bracket shell, n—structural member of the frame that houses the assembly that supports the bearings, which

support the cranks.

3.1.4 crank, n—lever arm that receives human energy as torque to convert into bicycle motion.

3.1.5 crown race seat, n—position on the fork where the lower steering axis bearing sits.

3.1.6 down tube, n—lower structural connection between the head tube and the bottom bracket shell.

1

ThisThese test method ismethods are under the jurisdiction of ASTM Committee F08 on Sports Equipment, Playing Surfaces, and Facilities and isare the direct

responsibility of Subcommittee F08.10 on Bicycles.

Current edition approved Nov. 1, 2012Oct. 1, 2019. Published December 2012November 2019. Originally approved in 2008. Last previous edition approved in 20082012

as F2711 – 08. DOI: 10.1520/F2711-08.- 08 (2012). DOI: 10.1520/F2711-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standardsvolume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2711 − 19

3.1.7 dropout centerline, n—hub-mounting axis that passes through both right and left dropouts.

3.1.8 front dropout, n—area where the front wheel hub connects to the fork.

3.1.9 head tube, n—forward most structural member of the frame, which provides an interface through top, and bottom bearings

for the fork.

3.1.9.1 Discussion—

The head tube is connected to the seat tube through the top tube and the down tube.

3.1.10 initial running displacement, n—average displacement between approximately 500 and 1000 cycles during a durability

fatigue test.

3.1.11 normal attitude, n—intended position of the bicycle frame when in continuous straight-line motion on a flat surface.

3.1.12 rake, n—straight-line distance from the front axle center to the perpendicular of the steering axis.

3.1.13 rear dropout, n—area where the rear wheel hub connects to the lower rear and the upper rear f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.