ASTM E557-00(2006)e1

(Guide)Standard Guide for The Installation of Operable Partitions

Standard Guide for The Installation of Operable Partitions

SIGNIFICANCE AND USE

Rooms formed by operable partitions must often be isolated acoustically. Sound-isolating properties of operable partitions are specified by architects in terms of sound transmission class (STC) and so advertised by the manufacturer on the basis of laboratory tests in accordance with Test Method E90 and Classification E413.

Because normal building design and construction practices are not the same as those used in acoustical laboratories, actual field performance of operable partitions will probably be less than that of test specimens. Sound transmission between areas to be isolated will occur through all of the connecting building components in addition to the operable partition, that is, floor and ceiling slabs, ceiling plenums, common walls, etc. All possible paths between the areas being isolated should have a sound insulation performance at least equal to the operable partition. Unless good acoustical practice is followed in both building design and installation, there may be a significant discrepancy between the sound isolation expected and that achieved.

Because of the complex nature of the sound flanking paths adjacent to operable partitions, it is highly recommended that all related construction details be reviewed by a person qualified in acoustical construction.

This guide does not specify requirements. However, persons desiring to write installation and construction specifications may find the contents useful in developing requirements for the site preparation, and installation practices necessary to minimize leakage and flanking sound around the operable partition.

SCOPE

1.1 This guide describes options of intructions recommended to be considered in preparation for, and application and installation of, operable partitions and, to some extent, in the design of the building in which they are installed. Operable partitions are those that are quickly movable.

1.2 Excluded from this guide are those partitions that are classified by the building products industry as demountable. Demountable partitions are those that are designed and installed with the intent of later being taken down and re-erected by a crew over a period of time, with the components being reusable.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

´1

Designation:E557–00(Reapproved 2006)

Standard Guide for

The Installation of Operable Partitions

This standard is issued under the fixed designation E557; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—1.3, units of measure statement, was editorially inserted and Fig. 3 and 5.3.3 and 5.4 were editorially revised in May

2010.

1. Scope E497 Practice for Installing Sound-Isolating Lightweight

Partitions

1.1 This guide describes options of intructions recom-

E1155 Test Method for Determining F Floor Flatness and

F

mended to be considered in preparation for, and application

F Floor Levelness Numbers

and installation of, operable partitions and, to some extent, in L

E1155M Test Method for Determining F Floor Flatness

F

the design of the building in which they are installed. Operable

and F Floor Levelness Numbers (Metric)

partitions are those that are quickly movable. L

1.2 Excluded from this guide are those partitions that are

3. Significance and Use

classified by the building products industry as demountable.

3.1 Rooms formed by operable partitions must often be

Demountable partitions are those that are designed and in-

isolated acoustically. Sound-isolating properties of operable

stalled with the intent of later being taken down and re-erected

partitions are specified by architects in terms of sound trans-

by a crew over a period of time, with the components being

mission class (STC) and so advertised by the manufacturer on

reusable.

the basis of laboratory tests in accordance with Test Method

1.3 The values stated in inch-pound units are to be regarded

E90 and Classification E413.

as standard. The values given in parentheses are mathematical

3.2 Because normal building design and construction prac-

conversions to SI units that are provided for information only

tices are not the same as those used in acoustical laboratories,

and are not considered standard.

actual field performance of operable partitions will probably be

1.4 This standard does not purport to address all of the

less than that of test specimens. Sound transmission between

safety problems, if any, associated with its use. It is the

areas to be isolated will occur through all of the connecting

responsibility of the user of this standard to establish appro-

building components in addition to the operable partition, that

priate safety and health practices and determine the applica-

is, floor and ceiling slabs, ceiling plenums, common walls, etc.

bility of regulatory limitations prior to use.

Allpossiblepathsbetweentheareasbeingisolatedshouldhave

2. Referenced Documents a sound insulation performance at least equal to the operable

2 partition. Unless good acoustical practice is followed in both

2.1 ASTM Standards:

building design and installation, there may be a significant

E90 Test Method for Laboratory Measurement of Airborne

discrepancy between the sound isolation expected and that

Sound Transmission Loss of Building Partitions and Ele-

achieved.

ments

3.3 Because of the complex nature of the sound flanking

E336 Test Method for Measurement of Airborne Sound

paths adjacent to operable partitions, it is highly recommended

Attenuation between Rooms in Buildings

that all related construction details be reviewed by a person

E413 Classification for Rating Sound Insulation

qualified in acoustical construction.

3.4 This guide does not specify requirements. However,

This guide is under the jurisdiction ofASTM Committee E33 on Building and persons desiring to write installation and construction specifi-

EnvironmentalAcousticsandisthedirectresponsibilityofSubcommitteeE33.04on

cations may find the contents useful in developing require-

Application of Acoustical Materials and Systems.

ments for the site preparation, and installation practices nec-

Current edition approved Sept. 1, 2006. Published September 2006. Originally

essary to minimize leakage and flanking sound around the

approved in 1975. Last previous edition approved in 2000 as E557 - 00. DOI:

10.1520/E0557-00R06E01.

operable partition.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

´1

E557–00 (2006)

4. Properties of Operable Partitions

4.1 There are several types of operable partitions: hinged

panel groups, individual panel and continuously hinged parti-

tion systems. Some are supported by overhead track with or

withoutafloorguideortrack.Somearefloorsupportedwithan

overhead track to guide them. They may be manual or

power-operated. One type consists of movable panels secured

in place by vertical expansion to seal against the floor and

ceiling. Seals or gaskets are of many kinds; some consist of

resilient material that maintains continuous flexible contact

with floor or ceiling, and some include a mechanical, hydraulic

or pneumatic mechanism that maintains clearance when in

motion and a positive seal when finally closed.

4.2 Sound Leaks:

4.2.1 The seals at the top of the partitions should make

continuous contact with smooth surfaces on both sides of the

operablepartitions.Thesoundpaththroughaninsufficientseal,

up and over the track, and out on the other side through the

insufficient seal constitutes a serious sound leak.

4.2.2 When a partition consists of several panels, leaks may

occur at the vertical joints when the seals at the joint are not

tight.

4.2.3 Pass-through doors in partitions will generally reduce

the overall sound isolation of the wall. For this reason,

pass-through doors should be equipped with full perimeter

gasketing, including seals at head.

4.2.4 Trackassembliesinstalledoutsidethepartitionstorage

pocket area to form cross-through paths (90° to each other )

primarilyforthetransportofpartitionsfromonelocationtothe

other should be avoided unless a satisfactory method is

provided to reduce the flanking path created through the track

section from one side of the partition to the other.

4.3 Sound Flanking Paths—Although the operable partition

may be an adequate barrier itself, sound may pass from one

side to the other by going over, around, or under the partition.

The passage of sound by paths other than directly through the

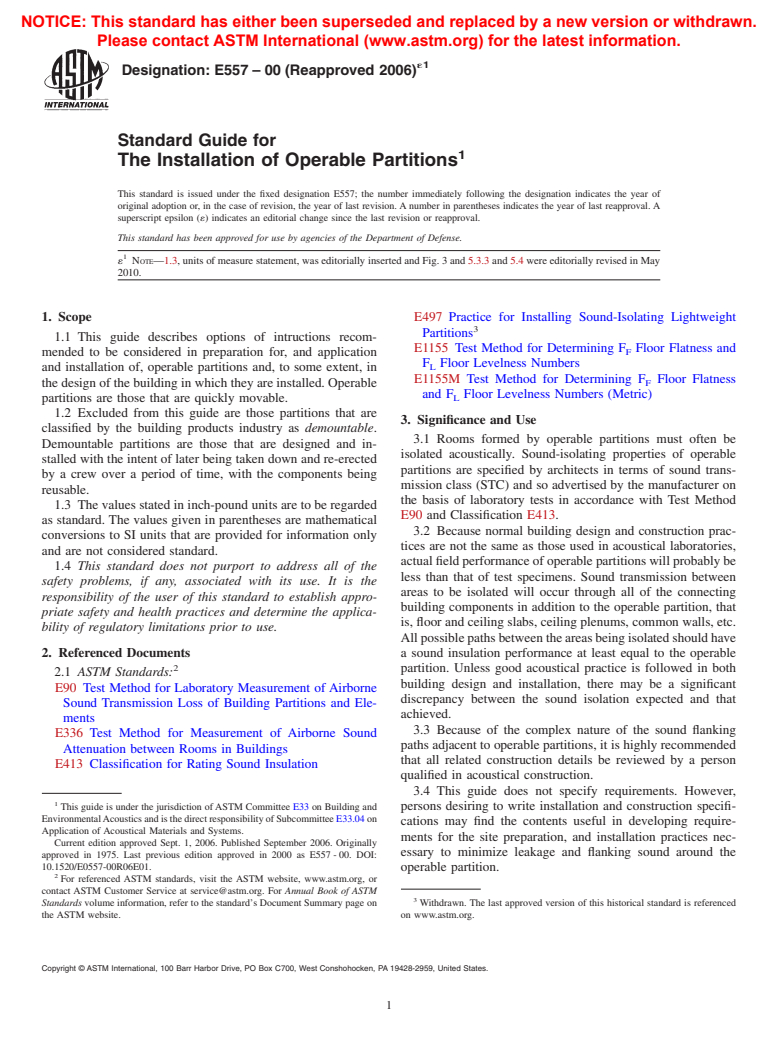

FIG. 1 Recommended Ceiling Barrier Installation

partition itself is called flanking transmission.

sound transmission loss of the duct or silencer, and the ceiling,

5. Recommendations

should be equal to or greater than the sound transmission loss

5.1 Area Above Track:

of the partition (see Fig. 2).

5.1.1 If there is a plenum above the partition, sound may

pass up through the ceiling on one side and down through the

ceiling on the other.Abarrier should be erected directly above

the operable partitions. This barrier, in conjunction with the

ceiling, should have a sound transmission loss equal to or

greater than that of the partition.The barrier is best designed as

part of the building and not added as an afterthought (see Fig.

1). Often a seemingly solid ceiling has hollows behind it, such

as spaces between the joists, or spaces in corrugated decks, that

provideaflankingpatharoundanoperablepartitionbelow.The

hollow spaces must be blocked directly above the operable

partition. The sound transmission loss provided by the block-

ing barrier should be equal to or greater than that provided by

the operable partition.

5.1.2 When a plenum is part of the air conditioning system,

a sound-attenuating duct or silencer is recommended to control

possible flanking and should be installed through the barrier

wall straddling the operable partition below. The composite FIG. 2 Recommended Sound Attenuating Duct Installation

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

´1

E557–00 (2006)

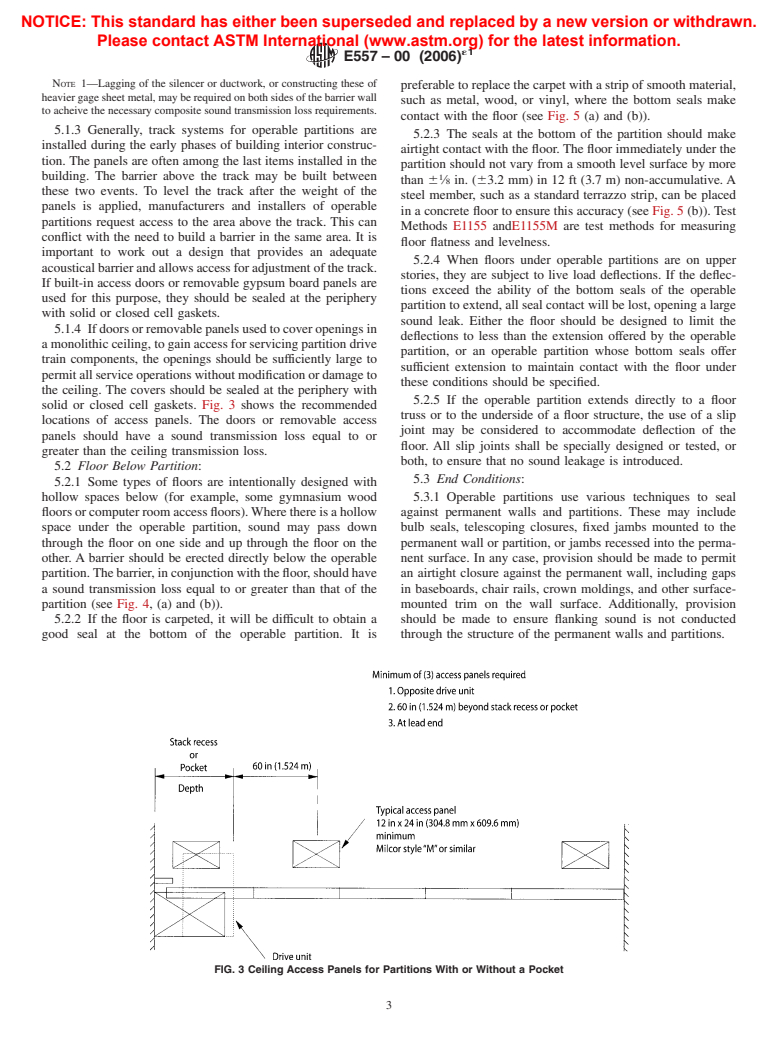

NOTE 1—Lagging of the silencer or ductwork, or constructing these of

preferable to replace the carpet with a strip of smooth material,

heavier gage sheet metal, may be required on both sides of the barrier wall

such as metal, wood, or vinyl, where the bottom seals make

to acheive the necessary composite sound transmission loss requirements.

contact with the floo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.