ASTM D4014-89(1995)

(Specification)Standard Specification for Plain and Steel-Laminated Elastomeric Bearings for Bridges

Standard Specification for Plain and Steel-Laminated Elastomeric Bearings for Bridges

SCOPE

1.1 This specification covers bearings, which consist of all elastomer or of alternate laminates of elastomer and steel, when the function of the bearings is to transfer loads or accommodate relative movement between a bridge superstructure and its supporting structure, or both.

1.2 The values stated in SI units are to be regarded as the standard. Note 1-The words "elastomer" or "elastomeric" will be used interchangeably with the word "rubber" in this specification.

1.3 The following safety hazards caveat pertains only to the test methods portion, Section B, of this specification: This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4014 – 89 (Reapproved 1995)

Standard Specification for

Plain and Steel-Laminated Elastomeric Bearings for

Bridges

This standard is issued under the fixed designation D 4014; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1418 Practice for Rubber and Rubber Latices—

Nomenclature

1.1 This specification covers bearings, which consist of all

D 2000 Classification System for Rubber Products in Auto-

elastomer or of alternate laminates of elastomer and steel,

motive Applications

when the function of the bearings is to transfer loads or

D 2137 Test Methods for Rubber Property—Brittleness

accommodate relative movement between a bridge superstruc-

Point of Flexible Polymers and Coated Fabrics

ture and its supporting structure, or both.

D 2240 Test Method for Rubber Property—Durometer

1.2 The values stated in SI units are to be regarded as the

Hardness

standard.

D 3183 Practice for Rubber—Preparation of Pieces for Test

NOTE 1—The words “elastomer” or “elastomeric” will be used inter-

Purposes from Products

changeably with the word “rubber” in this specification.

E 4 Practices for Force Verification of Testing Machines

1.3 The following safety hazards caveat pertains only to the

3. Terminology

test methods portion, Section B, of this specification: This

standard does not purport to address all of the safety concerns,

3.1 Definitions:

if any, associated with its use. It is the responsibility of the user

3.1.1 design load—the mean compressive stress applied to

of this standard to establish appropriate safety and health

the area of the steel laminate.

practices and determine the applicability of regulatory limita-

3.1.2 external load plate—a steel plate bonded to the top or

tions prior to use.

bottom elastomeric surface of a bearing, or both.

3.1.3 lot—unless otherwise specified in the contract or

2. Referenced Documents

purchase order, a lot shall consist of a single type of bearing, of

2.1 ASTM Standards:

the same design and material, submitted for inspection at the

A 36/A36M Specification for Structural Steel

same time.

D 395 Test Methods for Rubber Property—Compression

3.1.4 plain elastomeric bearing pad—a bearing that con-

Set

sists only of elastomeric material.

D 412 Test Methods for Vulcanized Rubber and Thermo-

3.1.5 plain elastomeric sandwich bearing—a bearing that

plastic Rubbers and Thermoplastic Elastomers in Tension

consists of a single layer of elastomeric material bonded to one

D 518 Test Method for Rubber Deterioration—Surface

or two external load plates (3.1.2).

Cracking

3.1.6 steel-laminated elastomeric bearing—a bearing

D 573 Test Method for Rubber—Deterioration in an Air

molded of elastomeric material with one or more steel lami-

Oven

nates embedded in and bonded to it, and to which one or two

D 832 Practice for Rubber Conditioning for Low-

external load plates (3.1.2) may be bonded.

Temperature Testing

4. Classification

D 1149 Test Method for Rubber Deterioration Surface

Ozone Cracking in a Chamber

4.1 The bearings are furnished in four types as follows:

D 1415 Test Method for Rubber Property—International

4.1.1 Plain Elastomeric Bearing Pad.

Hardness

4.1.2 Plain Elastomeric Sandwich Bearing.

4.1.3 Steel-Laminated Elastomeric Bearing.

4.1.4 Steel-Laminated Elastomeric Bearing with External

This specification is under the jurisdiction of ASTM Committee D-4 on Road

Load Plate(s).

and Paving Materials and is the direct responsibility of Subcommittee D04.32 on

Bridges and Structures.

Current edition approved Oct. 27, 1989. Published December 1989. Orginally

published as D 4014 – 81. Last previous edition D 4014 – 87.

2 4

Annual Book of ASTM Standards, Vol 01.04. Annual Book of ASTM Standards, Vol 09.02.

3 5

Annual Book of ASTM Standards, Vol 09.01. Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4014 – 89 (1995)

NOTE 2—Examples of the types of elastomeric bearing construction are

4.3.1 Grade 0—Suitable for continuous use down to + 5°C.

given in Fig. 1.

4.3.2 Grade 2—Sub-zero temperatures occur at night and

NOTE 3—The adjective elastomeric is omitted in this specification

occasionally persist for no more than 1 or 2 days.

when referring to bearing types.

4.3.3 Grade 3—Same as 2 but occasional periods of up to 2

4.2 The elastomer for the manufacture of the bearing is

weeks continuously below zero.

furnished in two types as follows:

4.3.4 Grade 5—Sub-zero temperatures down to − 40°C per-

4.2.1 Type CR—Chloroprene rubber.

sisting for several months each year with up to 2 months

4.2.2 Type NR—Natural rubber.

continuously below − 15°C.

4.2.3 If none is specified then the manufacturer shall use one

4.3.5 If a grade is not specified Grade 0 shall be furnished.

of those types.

An elastomer of a higher grade number may be substituted for

any lower grade.

NOTE 4—Appendix X1 relates to elastomeric materials which do not

have fully documented in-service records or sufficiently widespread use or

NOTE 6—A discussion of low-temperature properties of elastomeric

both.

materials is given in Practice D 832.

NOTE 5—The abbreviations for the elastomer types are taken from

NOTE 7—The grade numbers for the low-temperature properties corre-

Practice D 1418.

spond to those in Table 5 of Classification D 2000.

4.3 The elastomer for the manufacture of the bearing is

5. Ordering Information

furnished in four grades of low-temperature properties. The

grades and typical operating temperature conditions for each 5.1 Orders for each type of bearing under this specification

grade are as follows: shall include the following:

FIG. 1 Examples of the Construction of Elastomeric Bearings

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4014 – 89 (1995)

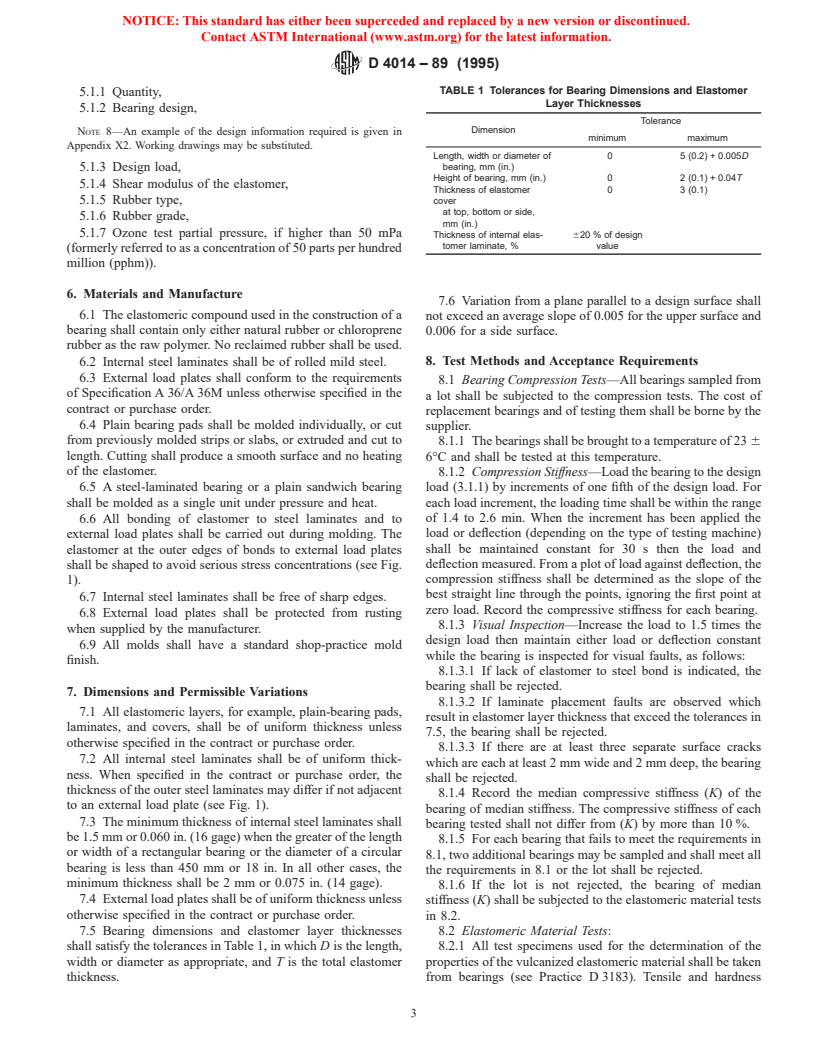

TABLE 1 Tolerances for Bearing Dimensions and Elastomer

5.1.1 Quantity,

Layer Thicknesses

5.1.2 Bearing design,

Tolerance

Dimension

NOTE 8—An example of the design information required is given in

minimum maximum

Appendix X2. Working drawings may be substituted.

Length, width or diameter of 0 5 (0.2) + 0.005D

bearing, mm (in.)

5.1.3 Design load,

Height of bearing, mm (in.) 0 2 (0.1) + 0.04T

5.1.4 Shear modulus of the elastomer,

Thickness of elastomer 0 3 (0.1)

5.1.5 Rubber type,

cover

at top, bottom or side,

5.1.6 Rubber grade,

mm (in.)

5.1.7 Ozone test partial pressure, if higher than 50 mPa

Thickness of internal elas- 620 % of design

tomer laminate, % value

(formerly referred to as a concentration of 50 parts per hundred

million (pphm)).

6. Materials and Manufacture

7.6 Variation from a plane parallel to a design surface shall

6.1 The elastomeric compound used in the construction of a

not exceed an average slope of 0.005 for the upper surface and

bearing shall contain only either natural rubber or chloroprene

0.006 for a side surface.

rubber as the raw polymer. No reclaimed rubber shall be used.

8. Test Methods and Acceptance Requirements

6.2 Internal steel laminates shall be of rolled mild steel.

6.3 External load plates shall conform to the requirements

8.1 Bearing Compression Tests—All bearings sampled from

of Specification A 36/A 36M unless otherwise specified in the

a lot shall be subjected to the compression tests. The cost of

contract or purchase order.

replacement bearings and of testing them shall be borne by the

6.4 Plain bearing pads shall be molded individually, or cut

supplier.

from previously molded strips or slabs, or extruded and cut to

8.1.1 The bearings shall be brought to a temperature of 23 6

length. Cutting shall produce a smooth surface and no heating

6°C and shall be tested at this temperature.

of the elastomer.

8.1.2 Compression Stiffness—Load the bearing to the design

6.5 A steel-laminated bearing or a plain sandwich bearing load (3.1.1) by increments of one fifth of the design load. For

shall be molded as a single unit under pressure and heat.

each load increment, the loading time shall be within the range

of 1.4 to 2.6 min. When the increment has been applied the

6.6 All bonding of elastomer to steel laminates and to

load or deflection (depending on the type of testing machine)

external load plates shall be carried out during molding. The

shall be maintained constant for 30 s then the load and

elastomer at the outer edges of bonds to external load plates

deflection measured. From a plot of load against deflection, the

shall be shaped to avoid serious stress concentrations (see Fig.

compression stiffness shall be determined as the slope of the

1).

best straight line through the points, ignoring the first point at

6.7 Internal steel laminates shall be free of sharp edges.

zero load. Record the compressive stiffness for each bearing.

6.8 External load plates shall be protected from rusting

8.1.3 Visual Inspection—Increase the load to 1.5 times the

when supplied by the manufacturer.

design load then maintain either load or deflection constant

6.9 All molds shall have a standard shop-practice mold

while the bearing is inspected for visual faults, as follows:

finish.

8.1.3.1 If lack of elastomer to steel bond is indicated, the

bearing shall be rejected.

7. Dimensions and Permissible Variations

8.1.3.2 If laminate placement faults are observed which

7.1 All elastomeric layers, for example, plain-bearing pads,

result in elastomer layer thickness that exceed the tolerances in

laminates, and covers, shall be of uniform thickness unless

7.5, the bearing shall be rejected.

otherwise specified in the contract or purchase order.

8.1.3.3 If there are at least three separate surface cracks

7.2 All internal steel laminates shall be of uniform thick-

which are each at least 2 mm wide and 2 mm deep, the bearing

ness. When specified in the contract or purchase order, the

shall be rejected.

thickness of the outer steel laminates may differ if not adjacent

8.1.4 Record the median compressive stiffness (K)ofthe

to an external load plate (see Fig. 1).

bearing of median stiffness. The compressive stiffness of each

7.3 The minimum thickness of internal steel laminates shall

bearing tested shall not differ from (K) by more than 10 %.

be 1.5 mm or 0.060 in. (16 gage) when the greater of the length

8.1.5 For each bearing that fails to meet the requirements in

or width of a rectangular bearing or the diameter of a circular

8.1, two additional bearings may be sampled and shall meet all

bearing is less than 450 mm or 18 in. In all other cases, the

the requirements in 8.1 or the lot shall be rejected.

minimum thickness shall be 2 mm or 0.075 in. (14 gage).

8.1.6 If the lot is not rejected, the bearing of median

7.4 External load plates shall be of uniform thickness unless

stiffness (K) shall be subjected to the elastomeric material tests

otherwise specified in the contract or purchase order.

in 8.2.

7.5 Bearing dimensions and elastomer layer thicknesses 8.2 Elastomeric Material Tests:

shall satisfy the tolerances in Table 1, in which D is the length, 8.2.1 All test specimens used for the determination of the

width or diameter as appropriate, and T is the total elastomer properties of the vulcanized elastomeric material shall be taken

thickness. from bearings (see Practice D 3183). Tensile and hardness

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4014 – 89 (1995)

specimens for the quality control tests in 8.2.3, specimens for 8.2.4 Shear Modulus—The shear modulus of the elastomer

the ozone resistance test in 8.2.5, and strips for the low- determined in accordance with Annex A1 shall not differ by

temperature brittleness test in 8.2.6.1, if applicable, shall more than 615 % from the required shear modulus of the

include an outer surface of a bearing. All other specimens shall elastomer.

be taken from within the middle one third of a bearing. 8.2.5 Ozone Resistance—An ozone resistance test shall be

Compression set specimens shall be as specified in Test carried out on test strips mounted in accordance with procedure

Methods D 395, Method B, Type 1. A of Test Method D 518. The test shall be carried out in

8.2.2 The temperature at which the tests shall be carried out accordance with Test Method D 1149 at 20 % strain and at 40

shall be 23 6 2°C except where otherwise specified in this 6 2°C for 100 h. The ozone test partial pressure shall be 50 6

specification. 5 mPa formerly referred to as a concentration of 50 6 5 pphm

8.2.3 Quality Control Properties—The quality control prop- unless a higher test partial pressure has been specified. The test

erties of the elastomer shall meet the requirements of Table 2 strips shall be examined for cracks using a 73 magnification

for the hardness and type of rubber used. lens. The elastomer has adequate ozone resistance if no

perpendicular cracks are observed on that surface of the strip

corresponding to the outer surface of the bearing.

TABLE 2 Quality Control Properties of Elastomer

8.2.6 Low-Temperature Grade Tests:

Rubber NR CR

8.2.6.1 When Low-Temperature Grade 2, 3 or 5 is specified,

Hardness limits (Test 45 to 75 45 to 75

a low-temperature brittleness test shall be carried out in

Methods D 1415 or

accordance with Test Methods D 2137, Method A using five

D 2240)

test strips. The temperature at which the strips shall be

Physical properties

(Test Methods D 412):

conditioned and tested shall be − 10°C for Grade 2, − 25°C for

Tensile strength, 15.5 (2250) 15.5 (2250)

Grade 3 and − 40°C for Grade 5. To meet the requirements of

min, MPa (psi)

this specification, none shall fail.

Ultimate elongation:

45 to 55 400 400

9. Sampling

hardness, min, %

56 to 65 400 350

9.1 Unless otherwise specified in the contract or purchase

hardness, min, %

order, sampling shall consist of the following.

66 to 75 300 300

hardness, min, %

9.1.1 For acceptance purposes, bearing from within the lot

High-temperature

shall be selected at random as samples for inspection and

resistance (Test

testing.

Methods D 573)

Aging time, h 168 70

9.1.2 A minimum of three bearings shall be taken from the

Aging 70 100

lot for testing. If the number of bearings in the lot exceeds 50

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.