ASTM D139-12

(Test Method)Standard Test Method for Float Test for Bituminous Materials

Standard Test Method for Float Test for Bituminous Materials

SIGNIFICANCE AND USE

4.1 The float test characterizes the flow behavior or consistency of certain bituminous materials.

4.2 This test method is useful in determining the consistency of bitumen as one element in establishing the uniformity of certain shipments or sources of supply.

SCOPE

1.1 This test method covers the float test for bituminous materials.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 Warning—Mercury has been designated by EPA and many state agencies as a hazardous material that can cause central nervous system, kidney, and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury-containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website (http://www.epa.gov/mercury/faq.htm) for additional information. Users should be aware that selling mercury or mercury-containing products, or both, in your state may be prohibited by state law.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific precaution statement, see 6.1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D139 − 12

Standard Test Method for

1

Float Test for Bituminous Materials

This standard is issued under the fixed designation D139; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 IEC Standard:

IEC 60854Methods of Measuring the Performance of Ul-

1.1 This test method covers the float test for bituminous

3

trasonic Pulse-Echo Diagnostic Equipment

materials.

1.2 The values stated in SI units are to be regarded as the

3. Summary of Test Method

standard. The values given in parentheses are for information

3.1 A plug of bitumen is cast in a tapered collar. The

only.

assembled float and collar is then floated in the testing bath at

1.3 Warning—Mercury has been designated by EPA and the specified temperature. The time, in seconds, between

many state agencies as a hazardous material that can cause

placing the apparatus on the water and the water breaking

central nervous system, kidney, and liver damage. Mercury, or through the material shall be taken as a measure of the

its vapor, may be hazardous to health and corrosive to

consistency of the material under examination.

materials.Cautionshouldbetakenwhenhandlingmercuryand

4. Significance and Use

mercury-containing products. See the applicable product Ma-

terial Safety Data Sheet (MSDS) for details and EPA’s website

4.1 The float test characterizes the flow behavior or consis-

(http://www.epa.gov/mercury/faq.htm) for additional informa-

tency of certain bituminous materials.

tion. Users should be aware that selling mercury or mercury-

4.2 This test method is useful in determining the consis-

containingproducts,orboth,inyourstatemaybeprohibitedby

tency of bitumen as one element in establishing the uniformity

state law.

of certain shipments or sources of supply.

1.4 This standard does not purport to address all of the

5. Apparatus

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

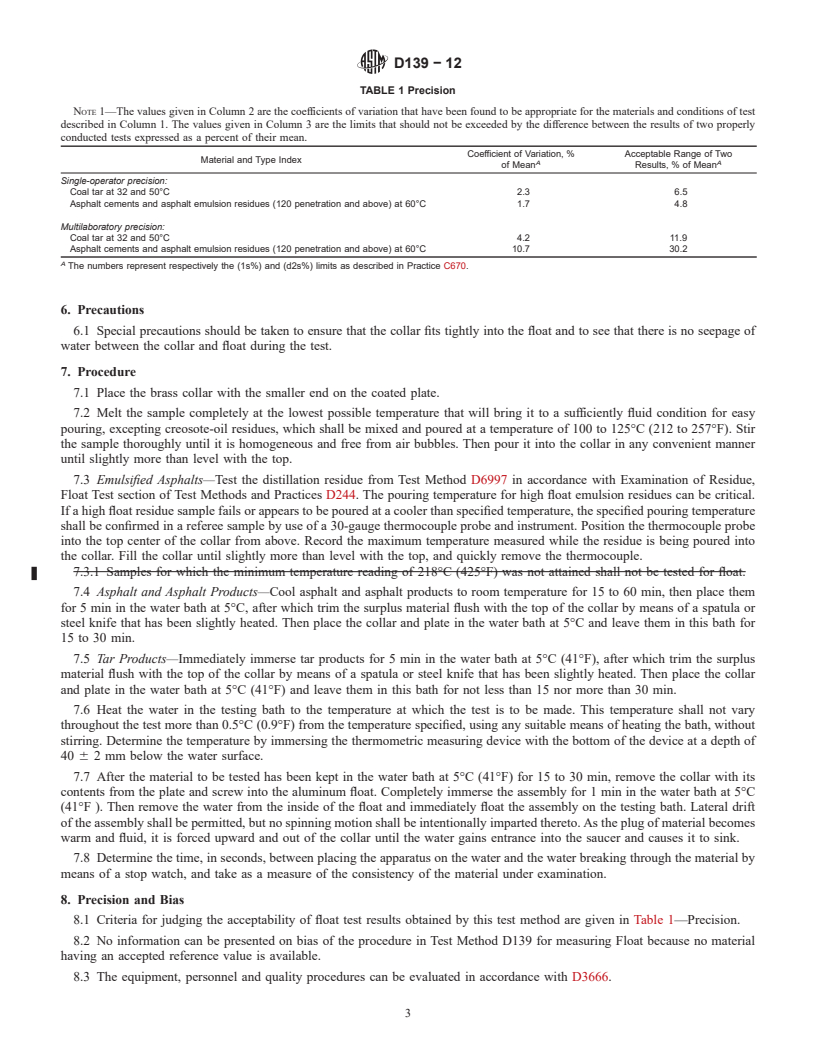

5.1 Float—The float (Fig. 1) shall be made of aluminum or

priate safety and health practices and determine the applica-

aluminum alloy and shall be in accordance with the following

bility of regulatory limitations prior to use. For a specific

requirements:

precaution statement, see 6.1.

Min Normal Max

Mass of float, g 37.70 37.90 38.10

2. Referenced Documents

Total height of float, mm 34.0 35.0 36.0

Height of rim above lower 26.5 27.0 27.5

2

2.1 ASTM Standards:

side of shoulder, mm

C670Practice for Preparing Precision and Bias Statements

Thickness of shoulder, mm 1.3 1.4 1.5

Diameter of opening, mm 11.0 11.1 11.2

for Test Methods for Construction Materials

D244Test Methods and Practices for Emulsified Asphalts 5.2 Collar—The collar (Fig. 1) shall be made of brass and

shall be in accordance with the following requirements:

D3666Specification for Minimum Requirements for Agen-

cies Testing and Inspecting Road and Paving Materials

Min Normal Max

Mass of collar, g 9.60 9.80 10.00

D6997Test Method for Distillation of Emulsified Asphalt

Over-all height of collar, mm 22.3 22.5 22.7

E1Specification for ASTM Liquid-in-Glass Thermometers

Inside diameter at bottom, mm 12.72 12.82 12.92

Inside diameter at top, mm 9.65 9.70 9.75

The top of the collar shall screw up tightly against the lower

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

side of the shoulder.

and Paving Materials and is the direct responsibility of Subcommittee D04.44 on

Rheological Tests.

5.3 Verification of Assembly—The assembled float and

Current edition approved Dec. 1, 2012. Published December 2012. Originally

collar,withthecollarfilledflushwiththebottomandweighted

approved in 1922. Last previous edition approved in 2007 as D139–07. DOI:

toatotalmassof53.2g,shallfloatuponwaterwiththerim8.5

10.1520/D0139-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D139 − 12

bituminousmaterialfromadheringtoit.Asuitabletreatmentis

to coat the plate just before use with a thin layer of a mixture

of glycerin and dextrin, talc, or kaolin (china clay). Other

plates or coatings, or both, may be used, providing similar

results are achieved.

6. Pre

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D139 − 07 D139 − 12

Standard Test Method for

1

Float Test for Bituminous Materials

This standard is issued under the fixed designation D139; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the float test for bituminous materials.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 Warning—Mercury has been designated by EPA and many state agencies as a hazardous material that can cause central

nervous system, kidney, and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution

should be taken when handling mercury and mercury-containing products. See the applicable product Material Safety Data Sheet

(MSDS) for details and EPA’s website (http://www.epa.gov/mercury/faq.htm) for additional information. Users should be aware

that selling mercury or mercury-containing products, or both, in your state may be prohibited by state law.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For a specific precaution statement, see 6.1.

2. Referenced Documents

2

2.1 ASTM Standards:

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

D244 Test Methods and Practices for Emulsified Asphalts

D3666 Specification for Minimum Requirements for Agencies Testing and Inspecting Road and Paving Materials

D6997 Test Method for Distillation of Emulsified Asphalt

E1 Specification for ASTM Liquid-in-Glass Thermometers

2.2 IEC Standard:

3

IEC 60854 Methods of Measuring the Performance of Ultrasonic Pulse-Echo Diagnostic Equipment

3. Summary of Test Method

3.1 A plug of bitumen is cast in a tapered collar. The assembled float and collar is then floated in the testing bath at the specified

temperature. The time, in seconds, between placing the apparatus on the water and the water breaking through the material shall

be taken as a measure of the consistency of the material under examination.

4. Significance and Use

4.1 The float test characterizes the flow behavior or consistency of certain bituminous materials.

4.2 This test method is useful in determining the consistency of bitumen as one element in establishing the uniformity of certain

shipments or sources of supply.

5. Apparatus

5.1 Float—The float (Fig. 1) shall be made of aluminum or aluminum alloy and shall be in accordance with the following

requirements:

1

This test method is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.44 on Rheological

Tests.

Current edition approved Dec. 1, 2007Dec. 1, 2012. Published December 20072012. Originally approved in 1922. Last previous edition approved in 20012007 as

ε1

D139 – 95 (2001)D139 – 07. . DOI: 10.1520/D0139-07.10.1520/D0139-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D139 − 12

FIG. 1 Float Test Apparatus

Min Normal Max

Mass of float, g 37.70 37.90 38.10

Total height of float, mm 34.0 35.0 36.0

Height of rim above lower 26.5 27.0 27.5

side of shoulder, mm

Thickness of shoulder, mm 1.3 1.4 1.5

Diameter of opening, mm 11.0 11.1 11.2

5.2 Collar—The collar (Fig. 1) shall be made of brass and shall be in accordance with the following requirements:

Min Normal Max

Mass of collar, g 9.60 9.80 10.00

Over-all height of collar, mm 22.3 22.5 22.7

Inside diameter at bottom, mm 12.72 12.82 12.92

Inside diameter at top, mm 9.65 9.70 9.75

The top of the collar shall screw up tightly against the lower side of the shoulder.

5.3 Verification of Assembly—The assembl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.