ASTM C1756-11

(Guide)Standard Guide for Comparing Sealant Behavior to Reference Photographs

Standard Guide for Comparing Sealant Behavior to Reference Photographs

SIGNIFICANCE AND USE

This guide is intended to be used in evaluating sealant conditions that occur in service, along with other diagnostic techniques in failure analysis. These standard reference photographs have been selected and approved through ASTM's consensus balloting process to illustrate terms defined by Committee C24.

Not all of the terms illustrated here are failures, and there are other failure mechanisms that affect sealants that are not discussed in this guide. This guide is intended to be one of a number of sources of information used in the evaluation of sealant behavior.

SCOPE

1.1 This guide provides photographs that illustrate sealant behavior terms that have been defined by Committee C24.

1.2 When available, photographs that better illustrate these terms, or that illustrate additional terms defined by Committee C24, will be included in future editions of this standard. Photographs for consideration may be submitted to the committee using the form in Appendix X1.

1.3 The committee with jurisdiction over this standard is not aware of any comparable standards published by other organizations.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1756 − 11

StandardGuide for

Comparing Sealant Behavior to Reference Photographs

This standard is issued under the fixed designation C1756; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This guide provides photographs that illustrate sealant

3.1 The terms used in this guide are defined inTerminology

behavior terms that have been defined by Committee C24.

C717.

1.2 When available, photographs that better illustrate these

terms, or that illustrate additional terms defined by Committee

4. Significance and Use

C24, will be included in future editions of this standard.

4.1 This guide is intended to be used in evaluating sealant

Photographs for consideration may be submitted to the com-

conditions that occur in service, along with other diagnostic

mittee using the form in Appendix X1.

techniques in failure analysis. These standard reference photo-

1.3 Thecommitteewithjurisdictionoverthisstandardisnot

graphs have been selected and approved through ASTM’s

aware of any comparable standards published by other orga-

consensus balloting process to illustrate terms defined by

nizations.

Committee C24.

1.4 This standard does not purport to address all of the

4.2 Not all of the terms illustrated here are failures, and

safety concerns, if any, associated with its use. It is the

there are other failure mechanisms that affect sealants that are

responsibility of the user of this standard to establish appro-

not discussed in this guide. This guide is intended to be one of

priate safety and health practices and determine the applica-

a number of sources of information used in the evaluation of

bility of regulatory limitations prior to use.

sealant behavior.

2. Referenced Documents

2.1 ASTM Standards:

5. Reference Photographs

C717Terminology of Building Seals and Sealants

5.1 Figs. 1-9 present a standard reference photograph for

each of the terms defined in Terminology C717, reprinted with

ThisguideisunderthejurisdictionofASTMCommitteeC24onBuildingSeals

and Sealants and is the direct responsibility of Subcommittee C24.10 their definitions.

onSpecifications, Guides and Practices.

Current edition approved June 15, 2011. Published August 2011. DOI: 10.1520/

6. Keywords

C1756-11.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1 adhesion failure; chalking; cohesion failure; crazed; dirt

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

pick-up; elastomeric joint sealant; fluid migration; reversion;

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. rundown; sag

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1756 − 11

adhesion failure, n—in building construction, failure of the bond between a

sealant and a substrate.

Discussion—This definition pertains to interfacial adhesion failure, a lack of

bond at the interface between the materials. Interphasal adhesion failure, within

the sealant or substrate near the interface, is less common and may appear to be

cohesive failure, n—in building construction, failure characterized by rupture

inerfacial without the use of magnification.

within the sealant.

FIG. 1 Adhesion Failure

FIG. 3 Cohesive Failure

chalking, v—in building construction, formation of a powder on the surface of a

crazed, adj—in building construction, having a random network of cracks in a

sealant that is caused by the disintegration of the polymer or binding medium due

sealant surface which do not penetrate through the body of the material.

to weathering.

FIG. 4 Crazed

FIG. 2 Chalking

C1756 − 11

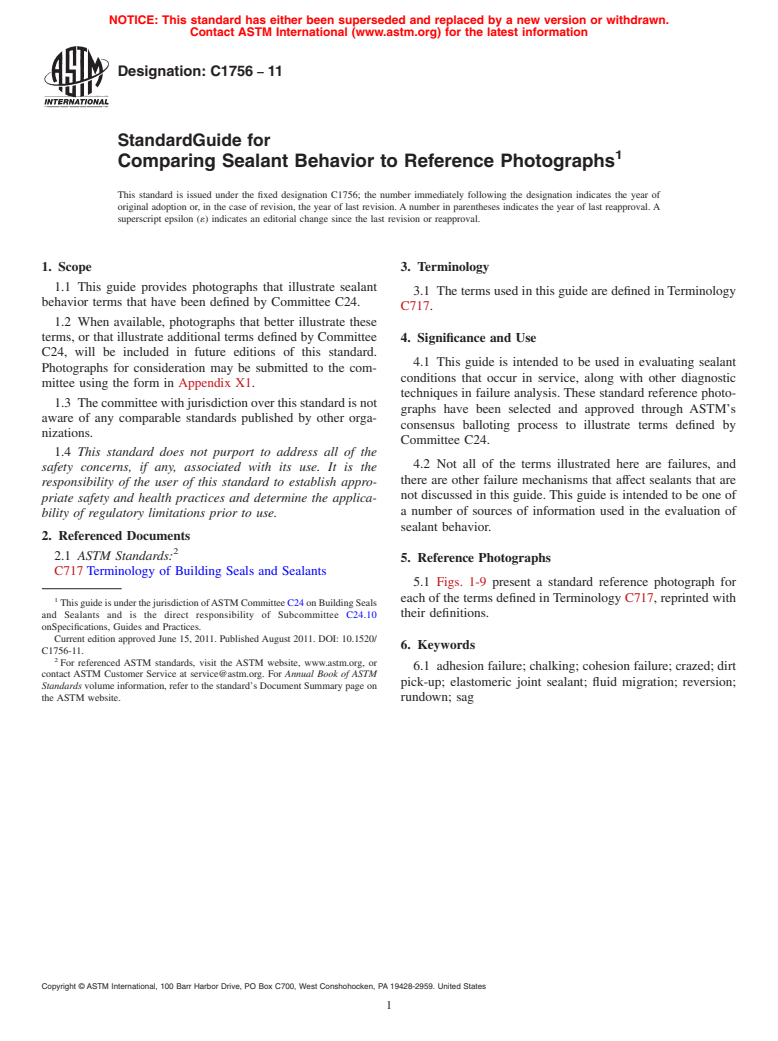

dirt pick-up, n—in building construction, soiling caused by a foreign material

other than micro-organism growth that is deposited on, adhered to, or embedded

into a sealant.

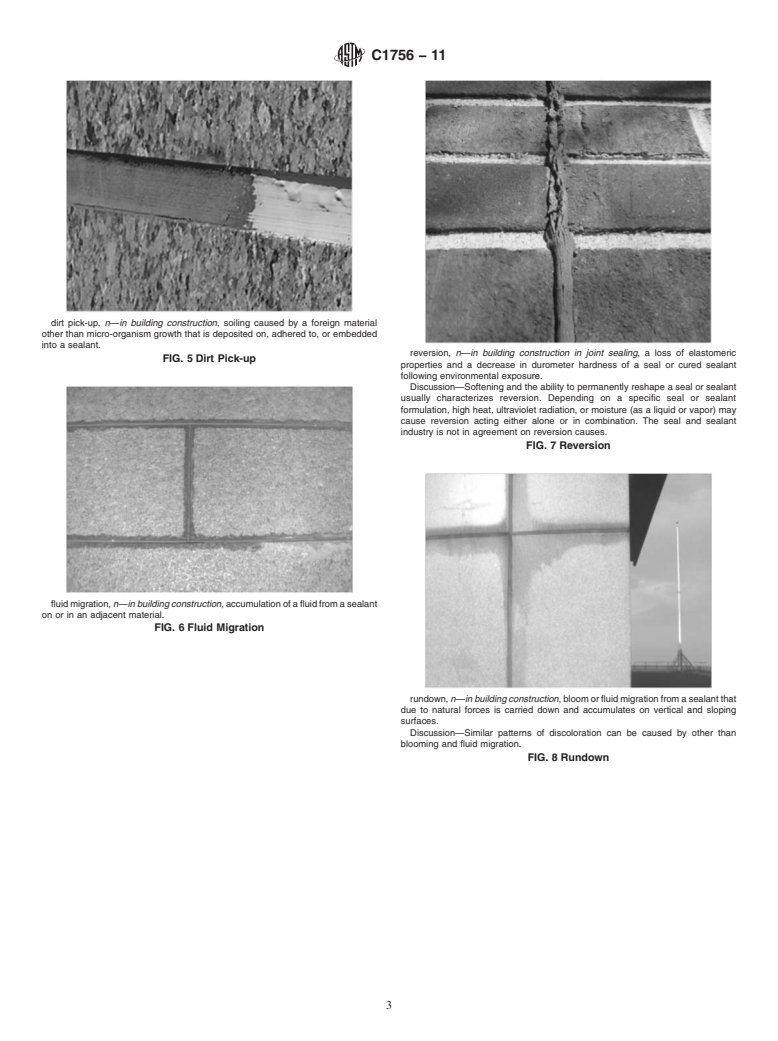

reversion, n—in building construction in joint sealing, a loss of elastomeric

FIG. 5 Dirt Pick-up

properties and a decrease in durometer hardness of a seal or cured sealant

following environmental exposure.

Discussion—Softening and the ability to permanently reshape a seal or sealant

usually characterizes reversion. Depending on a specific seal or sealant

formulation, high heat, ultraviolet radiation, or moisture (as a liquid or vapor) may

cause reversion acting either alone or in combination. The seal and sealant

industry is not in agreement on reversion causes.

FIG. 7 Reversion

fluid migration,n—inbuildingconstruction, accumulation of a fluid from a sealant

on or in an adjacent material.

FIG. 6 Fluid Migration

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.