ASTM C1257-15(2023)

(Test Method)Standard Test Method for Accelerated Weathering of Solvent-Release-Type Sealants

Standard Test Method for Accelerated Weathering of Solvent-Release-Type Sealants

SIGNIFICANCE AND USE

5.1 It is difficult to establish a precise correlation between laboratory accelerated and natural weathering because of (1) geographical climatic variations, local weather variation from normal, and local pollutants and (2) the fact that the acceleration factor is material dependent, varying with the type of material as well as its formulation. This test method is used to determine the resistance of a sealant to laboratory accelerated weathering and, if a control material with known outdoor weathering performance is used, the relative weathering performance of the sealant against that of the control material.

5.2 This test method is conducted using aluminum channels. Other substrate materials may show different results.

SCOPE

1.1 This test method includes two laboratory accelerated exposure procedures for predicting the effects of ultraviolet or ultraviolet/visible radiation, heat, and moisture on color, chalking, cracking, and adhesion of solvent-release sealants.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The committee with jurisdiction over this standard is not aware of any comparable standards published by other organizations.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1257 − 15 (Reapproved 2023)

Standard Test Method for

Accelerated Weathering of Solvent-Release-Type Sealants

This standard is issued under the fixed designation C1257; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Lamp Apparatus for Exposure of Materials

G155 Practice for Operating Xenon Arc Lamp Apparatus for

1.1 This test method includes two laboratory accelerated

Exposure of Materials

exposure procedures for predicting the effects of ultraviolet or

ultraviolet/visible radiation, heat, and moisture on color,

3. Terminology

chalking, cracking, and adhesion of solvent-release sealants.

3.1 Definitions:

1.2 The values stated in SI units are to be regarded as the

3.1.1 Refer to Terminology C717 and G113 for definitions

standard. The values given in parentheses are for information

of terms used in this test method: standard conditions.

only.

4. Summary of Test Method

1.3 The committee with jurisdiction over this standard is not

aware of any comparable standards published by other orga-

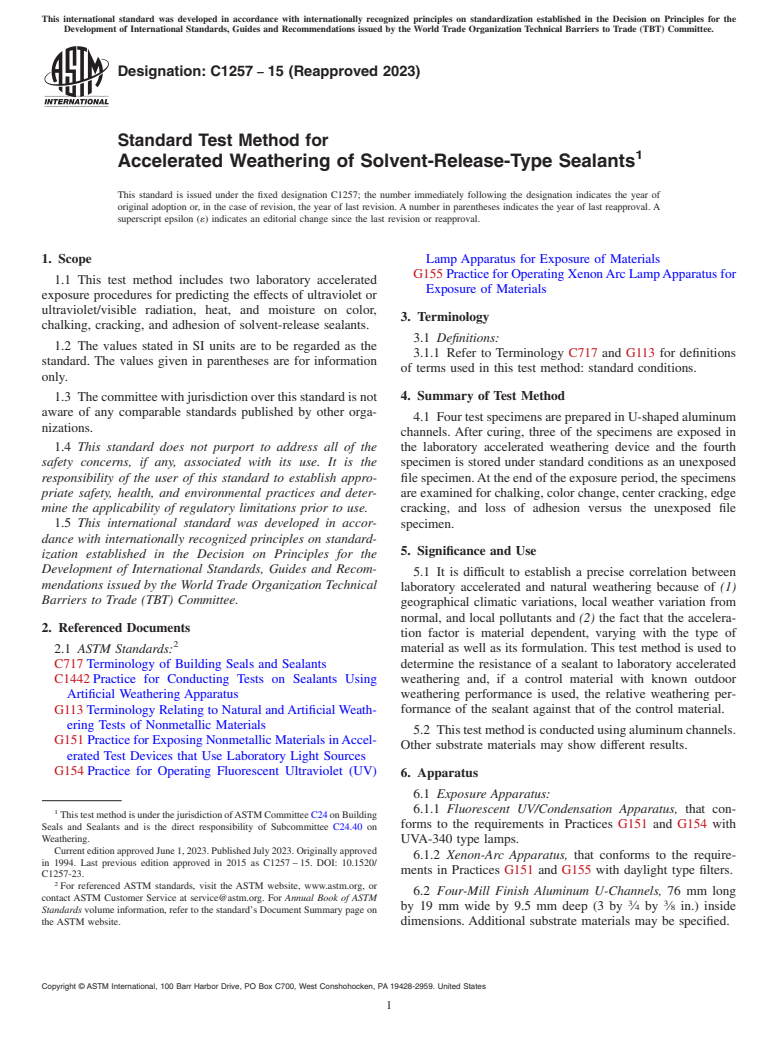

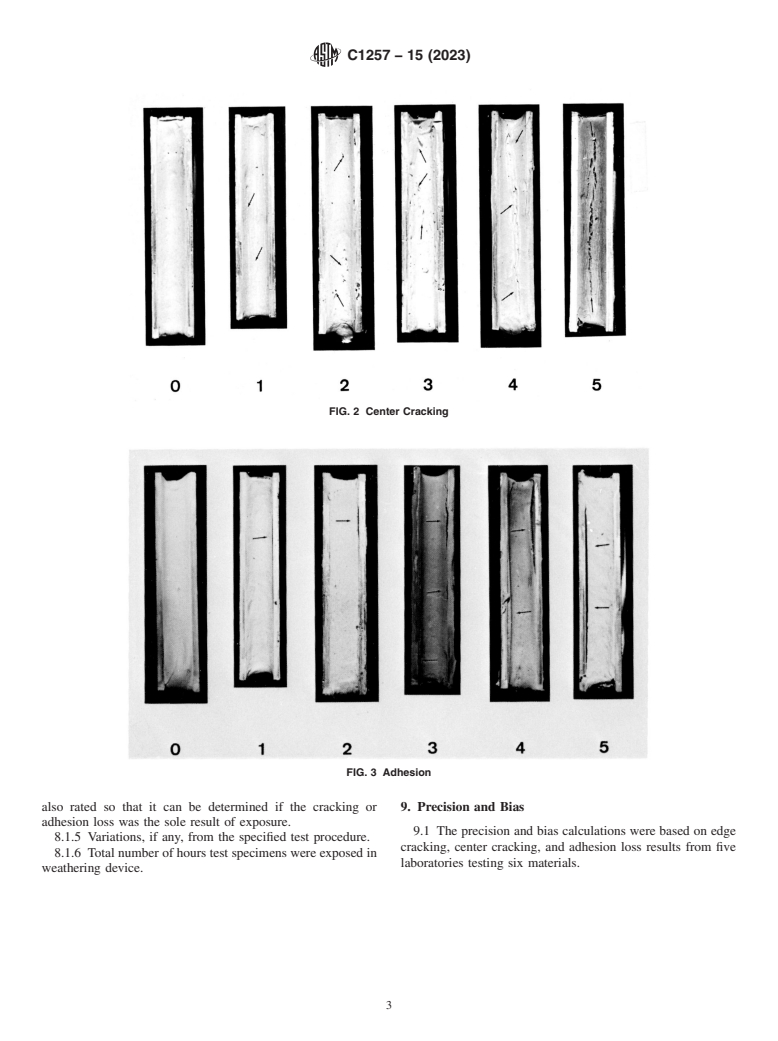

4.1 Four test specimens are prepared in U-shaped aluminum

nizations.

channels. After curing, three of the specimens are exposed in

1.4 This standard does not purport to address all of the the laboratory accelerated weathering device and the fourth

safety concerns, if any, associated with its use. It is the specimen is stored under standard conditions as an unexposed

responsibility of the user of this standard to establish appro- file specimen. At the end of the exposure period, the specimens

priate safety, health, and environmental practices and deter- are examined for chalking, color change, center cracking, edge

mine the applicability of regulatory limitations prior to use. cracking, and loss of adhesion versus the unexposed file

1.5 This international standard was developed in accor- specimen.

dance with internationally recognized principles on standard-

5. Significance and Use

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

5.1 It is difficult to establish a precise correlation between

mendations issued by the World Trade Organization Technical

laboratory accelerated and natural weathering because of (1)

Barriers to Trade (TBT) Committee.

geographical climatic variations, local weather variation from

normal, and local pollutants and (2) the fact that the accelera-

2. Referenced Documents

tion factor is material dependent, varying with the type of

2.1 ASTM Standards: material as well as its formulation. This test method is used to

C717 Terminology of Building Seals and Sealants determine the resistance of a sealant to laboratory accelerated

C1442 Practice for Conducting Tests on Sealants Using weathering and, if a control material with known outdoor

Artificial Weathering Apparatus weathering performance is used, the relative weathering per-

G113 Terminology Relating to Natural and Artificial Weath- formance of the sealant against that of the control material.

ering Tests of Nonmetallic Materials

5.2 This test method is conducted using aluminum channels.

G151 Practice for Exposing Nonmetallic Materials in Accel-

Other substrate materials may show different results.

erated Test Devices that Use Laboratory Light Sources

G154 Practice for Operating Fluorescent Ultraviolet (UV)

6. Apparatus

6.1 Exposure Apparatus:

6.1.1 Fluorescent UV/Condensation Apparatus, that con-

This test method is under the jurisdiction of ASTM Committee C24 on Building

forms to the requirements in Practices G151 and G154 with

Seals and Sealants and is the direct responsibility of Subcommittee C24.40 on

Weathering.

UVA-340 type lamps.

Current edition approved June 1, 2023. Published July 2023. Originally approved

6.1.2 Xenon-Arc Apparatus, that conforms to the require-

in 1994. Last previous edition approved in 2015 as C1257 – 15. DOI: 10.1520/

ments in Practices G151 and G155 with daylight type filters.

C1257-23.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.2 Four-Mill Finish Aluminum U-Channels, 76 mm long

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3 3

by 19 mm wide by 9.5 mm deep (3 by ⁄4 by ⁄8 in.) inside

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. dimensions. Additional substrate materials may be specified.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1257 − 15 (2023)

6.3 Steel Spatula. faces the light source. Keep the fourth test specimen as an

unexposed file specimen of the test material and store at

7. Procedure

standard conditions.

7.4.1 Procedure for Fluorescent UV/Condensation

7.1 Condition sufficient compound in an original closed

Apparatus—Operate the device in accordance with the proce-

container for at least 24 h at standard conditions.

dure in Section 7.3 of Practice C1442. Remove the specimens

7.2 Prepare four sealant test specimens in aluminum

from the apparatus after a minimum of 1000 h of exposure.

U-channels.

7.4.2 Procedure for Xenon-Arc Apparatus—Operate the de-

7.2.1 Thoroughly clean channels using a suitable solvent

vice in accordance with the procedure in Section 7.2 of

such as methyl ethyl ketone (MEK). Allow to dry before filling

Practice C1442. When operated at the preferred irradiance

with sealant.

level of 0.51 W(m · nm) at 340 nm, remove the specimens

7.2.2 Block the ends of the U-channels with masking tape

from the apparatus after a minimum of 1000 h (1835 kJ/(m ·

and overfill the entire channel with conditioned compound

nm) at 340 nm). See Annex A1 in C1442 for determining the

from the bottom up being careful to avoid air entrapment.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.