ASTM D4745-11ae1

(Specification)Standard Specification for Filled Compounds of Polytetrafluoroethylene (PTFE) Molding and Extrusion Materials

Standard Specification for Filled Compounds of Polytetrafluoroethylene (PTFE) Molding and Extrusion Materials

ABSTRACT

This specification covers polytetrafluoroethylene(PTFE) filled molding compounds made with virgin PTFE resins defined in a certain specification except Types I, IV, V, and VI. PTFE compounds are classified into two types which are Type I as the nonpelletized material use for general purpose compression molding and Type II as the pelletized or free-flowing material use for molding, automatic molding or ram extrusion. Each type is further classified into thirteen grades distinguished by the nature of the filler. Different tests shall be conducted in order to determine the following properties: filler content, bulk density, specific gravity, and tensile properties.

SCOPE

1.1 This specification covers polytetrafluoroethylene (PTFE) filled molding compounds made with virgin PTFE resins defined in Specification D4894, as Types II and III.

Note 1—This specification can be used as a model for other PTFE compounds having particulate fillers that can survive the sintering temperatures of PTFE as can those listed in this specification. This specification is restricted to virgin PTFE base resin for technical reasons. Recycled or reprocessed material cannot be processed successfully.

Note 2—The properties measured on commercially fabricated parts may differ from the listed values for samples prepared by the procedures given in this specification, depending on part geometry and processing parameters.

1.2 The values stated in SI units are to be regarded as standard.

1.3 The following statement applies to the test method portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Note 5 for a specific warning statement.

Note 3—There is no known ISO equivalent to this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:D4745 −11a

StandardSpecification for

Filled Compounds of Polytetrafluoroethylene (PTFE)

1

Molding and Extrusion Materials

This standard is issued under the fixed designation D4745; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Editorially corrected the text in Fig. 2 in January 2012.

1. Scope* D1708TestMethodforTensilePropertiesofPlasticsbyUse

of Microtensile Specimens

1.1 This specification covers polytetrafluoroethylene

D3892Practice for Packaging/Packing of Plastics

(PTFE) filled molding compounds made with virgin PTFE

D4894 Specification for Polytetrafluoroethylene (PTFE)

resins defined in Specification D4894, as Types II and III.

Granular Molding and Ram Extrusion Materials

NOTE 1—This specification can be used as a model for other PTFE

IEEE/ASTM SI-10Standard for Use of the International

compounds having particulate fillers that can survive the sintering

3

System of Units (SI): The Modern Metric System

temperatures of PTFE as can those listed in this specification. This

specification is restricted to virgin PTFE base resin for technical reasons.

3. Terminology

Recycled or reprocessed material cannot be processed successfully.

NOTE 2—The properties measured on commercially fabricated parts

3.1 Definitions—The terminology given in Terminology

may differ from the listed values for samples prepared by the procedures

D883 is applicable to this specification unless otherwise

given in this specification, depending on part geometry and processing

specified.

parameters.

3.2 Definitions of Terms Specific to This Standard:

1.2 The values stated in SI units are to be regarded as

3.2.1 bulk density, n—themassinkilogramspercubicmetre

standard.

of resin compound measured under the conditions of the test.

1.3 The following statement applies to the test method

3.2.2 filled compound, n—blendofPTFEresinasthematrix

portion, Section 11, of this specification: This standard does

and particulate fillers, generally glass, other inorganic,

not purport to address all of the safety concerns, if any,

metallic, or polymeric materials that withstand the sintering

associated with its use. It is the responsibility of the user of this

temperature of PTFE (327 to 380°C).

standard to establish appropriate safety and health practices

and determine the applicability of regulatory limitations prior 3.2.3 free-flow resins (pelletized), n—generally made by

to use. See Note 5 for a specific warning statement. treatment of finely divided resins to produce free-flowing

agglomerates.

NOTE 3—There is no known ISO equivalent to this standard.

3.2.4 lot, n—one production run.

2. Referenced Documents

3.2.5 pigmented compound, n—a compound in which a

2

2.1 ASTM Standards: pigment is added for colorant purposes only.

D792Test Methods for Density and Specific Gravity (Rela-

3.2.6 standard flow resins (nonpelletized), n—finely divided

tive Density) of Plastics by Displacement

resin with an average particle size less than 100 µm.

D883Terminology Relating to Plastics

3.3 Abbreviations—Abbreviations are in accordance with

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

Terminology D1600. PTFE is the acronym for polytetrafluo-

tics

roethylene.

4. Classification

1

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

4.1 This specification covers the following two types of

Materials.

PTFE compounds:

Current edition approved Dec. 1, 2011. Published December 2011. Originally

4.1.1 Type I—Standard flow resins (nonpelletized) material,

approved in 1991. Last previous edition approved in 2011 as D4745-11. DOI:

10.1520/D4745-11A.

for general-purpose compression molding.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from ASTM International Headquarters, 100 Barr Harbor Drive,

the ASTM website. West Conshohocken, PA 19428

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D4745−11a

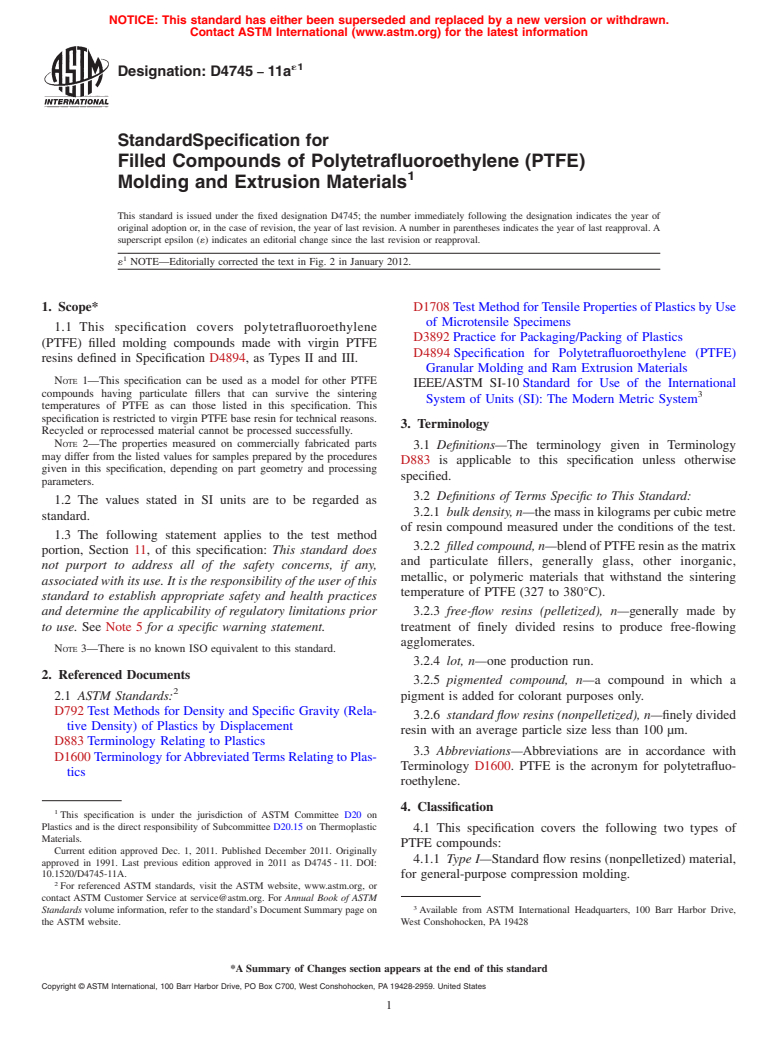

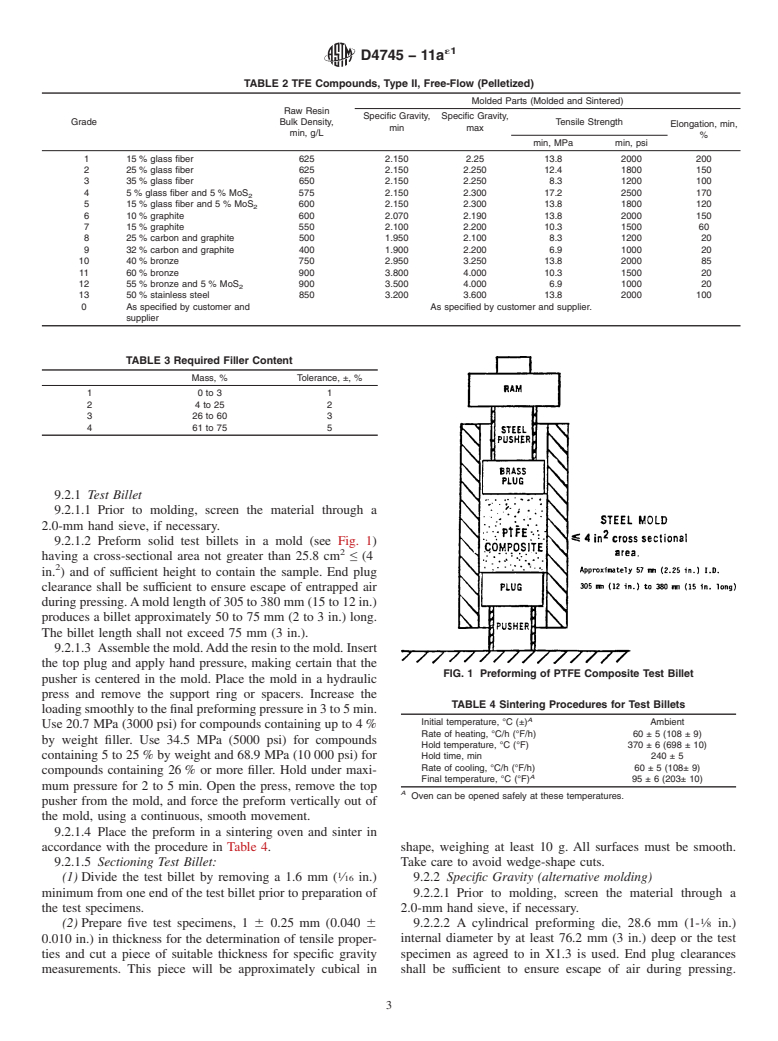

TABLE 1 TFE Compounds, Type I, Standard Flow (Nonpelletized)

Molded Parts (Molded and Sintered)

Raw Resin

Specific Gravity, Specific Gravity,

Grade Bulk Density, Tensile Strength

Elongation, min,

min max

min, g/L

%

min, MPa min, psi

1 15 % glass fiber 400 2.150 2.250 19.6 2840 220

2 25 % glass fiber 425 2.150 2.25

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.