ASTM E1755-01(2007)

(Test Method)Standard Test Method for Ash in Biomass

Standard Test Method for Ash in Biomass

SIGNIFICANCE AND USE

The ash content is an approximate measure of the mineral content and other inorganic matter in biomass.

The ash content is used in conjunction with other assays to determine the total composition of biomass samples.

SCOPE

1.1 This test method covers the determination of ash, expressed as the mass percent of residue remaining after dry oxidation (oxidation at 575 ± 25°C), of hard and soft woods, herbaceous materials (such as switchgrass and sericea), agricultural residues (such as corn stover, wheat straw, and bagasse), wastepaper (such as office waste, boxboard, and newsprint), acid and alkaline pretreated biomass, and the solid fraction of fermentation residues. All results are reported relative to the 105°C oven-dried mass of the sample. For particulate wood fuels, Test Method E 1534 should be used.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1755 − 01(Reapproved 2007)

Standard Test Method for

Ash in Biomass

This standard is issued under the fixed designation E1755; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This test method covers the determination of ash, 4.1 The ash content is an approximate measure of the

expressed as the mass percent of residue remaining after dry mineral content and other inorganic matter in biomass.

oxidation (oxidation at 575 6 25°C), of hard and soft woods,

4.2 The ash content is used in conjunction with other assays

herbaceous materials (such as switchgrass and sericea), agri-

to determine the total composition of biomass samples.

cultural residues (such as corn stover, wheat straw, and

bagasse), wastepaper (such as office waste, boxboard, and

5. Apparatus

newsprint), acid and alkaline pretreated biomass, and the solid

5.1 Ashing Crucibles, 50 mL, platinum crucibles are

fraction of fermentation residues. All results are reported

preferred, but silica or porcelain crucibles may be used.

relative to the 105°C oven-dried mass of the sample. For

5.2 Muffle Furnace, an electric furnace is recommended for

particulate wood fuels, Test Method E1534 should be used.

igniting the sample. The furnace should be fitted with an

1.2 The values stated in SI units are to be regarded as the

indicating pyrometer or thermocouple, so that the required

standard.

temperature of 575 6 25°C can be maintained.

1.3 This standard does not purport to address all of the

5.3 Analytical Balance, sensitive to 0.1 mg.

safety concerns, if any, associated with its use. It is the

5.4 Desiccator, using anhydrous calcium sulfate.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5.5 Drying Oven, with temperature control of 105 6 2°C.

bility of regulatory limitations prior to use.

6. Test Specimen

2. Referenced Documents

6.1 Test specimens suitable for analysis by this test method

are as follows:

2.1 ASTM Standards:

6.1.1 Prepared biomass samples that have been prepared

E1534 Test Method for Determination of Ash Content of

according to Practice E1757.

Particulate Wood Fuels

6.1.2 Biomass feedstocks, dried at 105°C according to Test

E1756 Test Method for Determination of Total Solids in

Method E1756,

Biomass

6.1.3 Pretreated biomass, dried at 105°C according to Test

E1757 Practice for Preparation of Biomass for Composi-

Method E1756, and

tional Analysis

6.1.4 The solids fraction of fermentation residues, dried at

105°C according to Test Method E1756.

3. Terminology

6.2 The test specimen shall consist of approximately 0.5 to

3.1 Definitions of Terms Specific to This Standard:

1.0 g of sample obtained in such a manner to ensure that it is

3.1.1 ash—the inorganic residue left after ignition at 575 6

representative of the entire lot of material being tested.

25°C.

NOTE 1—All samples should be ground or milled to reduce the size of

the large pieces to less than 1 mm in diameter. The sample is then redried

at 105°C prior to testing. Prepared biomass can be used in place of 105°C

This test method is under the jurisdiction of ASTM Committee E48 on

dried material, but the mass of the material must be corrected for its

Bioenergy and Industrial Chemicals from Biomass and is the direct responsibility of

moisturecontentbyusingTestMethodE1756,priortocalculatingtheash.

Subcommittee E48.05 on Biomass Conversion.

Current edition approved Nov. 15, 2007. Published January 2008. Originally

7. Procedure

approved in 1995. Last previous edition approved in 2001 as E1755-01. DOI:

10.1520/E1755-01R07.

7.1 Markapanorcruciblewithauniqueidentificationusing

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

a porcelain marker, place it in the muffle furnace at 575 6

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

25°C. Remove the pan or crucible from the furnace, cool to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. room temperature in a desiccator, and weigh to the nearest 0.1

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1755 − 01 (2007)

mg. For an aluminum pan, two hours of heating at 575 6 25°C provided that the test specimen has already been analyzed for

will be sufficient to bring the pan to constant mass. With a mass percent total solids at 105°C using Test Method E1756.

crucible, however, the following procedure is used: place the

m 5 m 2 m 3T/100 (2)

~ !

s ar cont

crucible in the furnace at 575 6 25°C for 3 h. Remove the

where:

crucible and place in a desiccator.Allow the crucible to cool to

m = mass of moisture-free solids in the prepared biomass

room temperature and then weigh the crucible to the nearest

s

0.1 mg. Record this mass. After weighing, return the crucible sample, g,

m = initial mass of prepared biomass sample and

to the furnace for1hat575 6 25°C, cool again in the

ar

container, g,

desiccator, and reweigh. Repeat this step until the mass of the

m = tare mass of container, g, and

cruciblevariesbylessthan0.3mgfromthepreviousweighing. cont

T = mass percent of total solids in sample, as determined

Recordthisfinalmassasthecrucibletaremass, m .Keepthe

cont

by Test Method E1756.

pan or crucible in a desiccator until used.

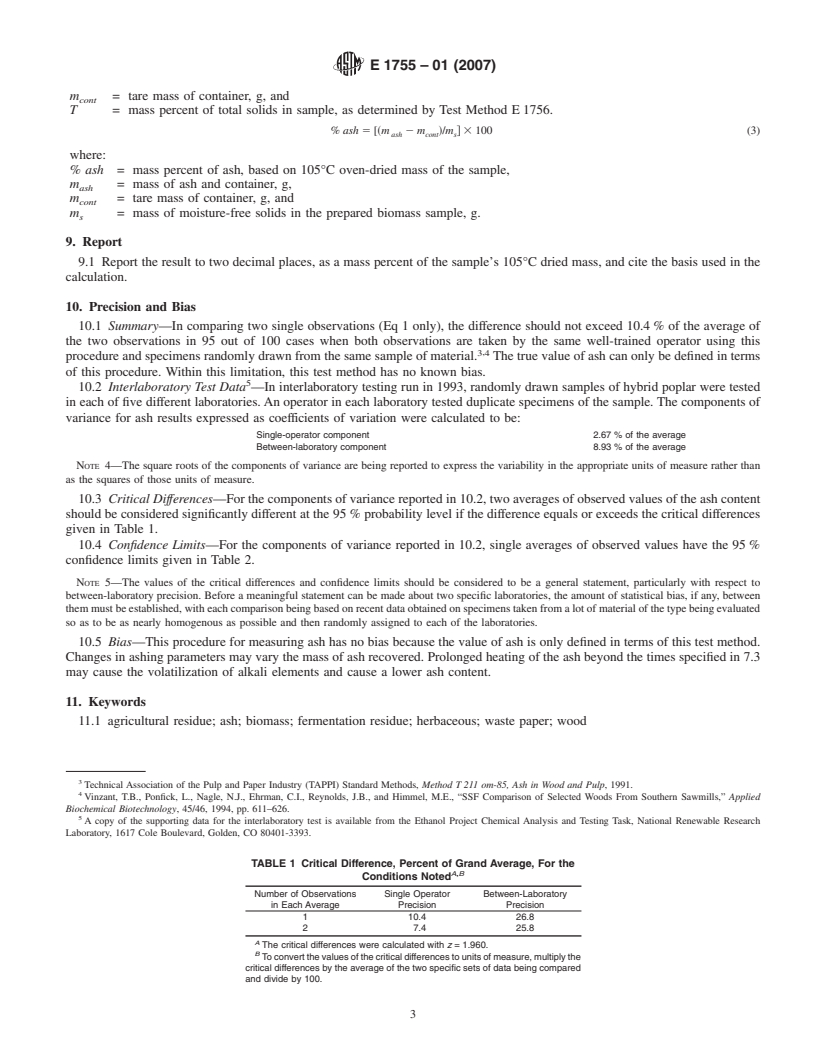

% ash 5 @~m 2 m !/m # 3100 (3)

7.2 Weigh approximately 0.5 to 1.0 g, to the nearest 0.1 mg, ash cont s

of a test specimen into the tared pan or crucible. If the sample

where:

being analyzed is a test specimen dried at 105°C, the sample

% ash = mass percent of ash, based on 105°C oven-dried

should be stored in a desiccator until use. For a 105°C dried

mass of the sample,

test sample, record the mass (container plus sample mass) as

m = mass of ash and container, g,

ash

the initial mass, m . For prepared biomass samples prepped

od

m = tare mass of container, g, and

cont

according to Practice E1757, record the mass (container plus

m = mass of moisture-free solids in the prepared bio-

s

sample mass) as the initial mass, m .

ar mass sample, g.

NOTE 2—For prepared biomass samples, it is recommend that samples

9. Report

for moisture determination should be weighed out at the same time as the

samples for the ash determination. If this is done at a later time it can

9.1 Report the result to two decimal places, as a mass

introduce an error in the calculation because ground biomass can rapidly

percent of the sample’s 105°C dried mass, and cite the basis

gain or lose moisture when exposed to the atmosphere.

used in the calculation.

7.3 Place

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E1755–95 Designation: E 1755 – 01 (Reapproved 2007)

Standard Test Method for

Ash in Biomass

This standard is issued under the fixed designation E 1755; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of ash, expressed as the mass percent of residue remaining after dry oxidation

(oxidation at 575 6 25°C), of hard and soft woods, herbaceous materials (such as switchgrass and sericea), agricultural residues

(such as corn stover, wheat straw, and bagasse), wastepaper (such as office waste, boxboard, and newsprint), acid and alkaline

pretreated biomass, and the solid fraction of fermentation residues.All results are reported relative to the 105°C oven-dried mass

of the sample. For particulate wood fuels, Test Method E 1534 should be used.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E 1534 Test Method for Determination of Ash Content of Particulate Wood Fuels

E 1756 Test Method for the Determination of Total Solids in Biomass

E 1757 Practice for Preparation of Biomass for Compositional Analysis

3. Terminology

3.1 Descriptions of Terms Specific to This Standard:

3.1.1 ash—the inorganic residue left after ignition at 5756 25°C.

4. Significance and Use

4.1 The ash content is an approximate measure of the mineral content and other inorganic matter in biomass.

4.2 The ash content is used in conjunction with other assays to determine the total composition of biomass samples.

5. Apparatus

5.1 Aluminum Weighing Pans or Crucibles, 50 mL, if crucibles are used, platinum crucibles are preferred, but silica or porcelain

crucibles may be used. Ashing Crucibles, 50 mL, platinum crucibles are preferred, but silica or porcelain crucibles may be used.

5.2 Muffle Furnace, an electric furnace is recommended for igniting the sample. The furnace should be fitted with an indicating

pyrometer or thermocouple, so that the required temperature of 575 6 25°C can be maintained.

5.3 Analytical Balance, sensitive to 0.1 mg.

5.4 Desiccator, using anhydrous calcium sulfate.

5.5 Drying Oven, with temperature control of 105 6 2°C.

6. Test Specimen

6.1 Test specimens suitable for analysis by this test method are as follows:

6.1.1 Prepared biomass samples that have been preppedprepared according to Practice E 1757.

6.1.2 Biomass feedstocks, dried at 105°C according to Test Method E 1756,

6.1.3 Pretreated biomass, dried at 105°C according to Test Method E 1756, and

6.1.4 The solids fraction of fermentation residues, dried at 105°C according to Test Method E 1756.

This test method is under the jurisdiction ofASTM Committee E-48 on Biotechnology and is the direct responsibility of Subcommittee E48.05 on Biomass Conversion.

Current edition approved Oct. 10, 1995. Published December 1995.

This test method is under the jurisdiction ofASTM Committee E48 on Biotechnology and is the direct responsibility of Subcommittee E48.05 on Biomass Conversion.

Current edition approved Nov. 15, 2007. Published January 2008. Originally approved in 1995. Last previous edition approved in 2001 as E 1755-01.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 11.05.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 1755 – 01 (2007)

6.2 The test specimen shall consist of approximately 0.5 to 1.0 g of sample obtained in such a manner to ensure that it is

representative of the entire lot of material being tested. For 105°C dried

NOTE 1—All samples containing large particles or chunks, it is recommended that the sampleshould be ground or milled to reduce the size of the large

pieces to less than 1 mm in diameter.The sample is then redried at 105°C prior to testing. Prepared biomass can be used in place of 105°C dried material,

but the mass of the material must be corrected for its moisture content by using Test Method E 1756, prior to calculating the ash.

7. Procedure

7.1Mark a pan or crucible with a unique identification using a porcelain marker, place it in the muffle furnace, and bring to

constant mass by igniting at 575 6 25°C. Remove the pan or crucible from the furnace, cool to room temperature in a desiccator,

and weigh to the nearest 0.1 mg. Record this mass as the tare mass,

7.1 Mark a pan or crucible with a unique identification using a porcelain marker, place it in the muffle furnace at 575 6 25°C.

Remove the pan or crucible from the furnace, cool to room temperature in a desiccator, and weigh to the nearest 0.1 mg. For an

aluminum pan, two hours of heating at 575 6 25°C will be sufficient to bring the pan to constant mass. With a crucible, however,

the following procedure is used: place the crucible in the furnace at 5756 25°C for 3 h. Remove the crucible and place in a

desiccator. Allow the crucible to cool to room temperature and then weigh the crucible to the nearest 0.1 mg. Record this mass.

After weighing, return the crucible to the furnace for1hat575 6 25°C, cool again in the desiccator, and reweigh. Repeat this

step until the mass of the crucible varies by less than 0.3 mg from the previous weighing. Record this final mass as the crucible

tare mass, m . Keep the pan or crucible in a desiccator until used. Note1—For an aluminum pan, two hours of heating at 575

cont

6 25°C will be sufficient to bring the pan to constant mass. With a crucible, however, the following procedure is used: place the

crucible in the furnace at 5756 25°C for 3 h. Remove the crucible and place in a desiccator. Allow the crucible to cool to room

temperature and then weigh the crucible to the nearest 0.1 mg. Record this mass.After weighing, return the crucible to the furnace

for1hat575 6 25°C, cool again in the desiccator, and reweigh. Repeat this step until the mass of the crucible varies by less than

0.3 mg from the previous weighing. Record this final mass as the crucible tare mass, m .

cont

7.2 Weighapproximately0.5to1.0g,tothenearest0.1mg,ofatestspecimenintothetaredpanorcrucible.Ifthesamplebeing

analyzed is a test specimen dried at 105°C, the sample should be stored in a desiccator until use. For a 105°C dried test sample,

recordthemass(containerplussamplemass)astheinitialmass, m .ForpreparedbiomasssamplespreppedaccordingtoPractice

od

E 1757, record the mass (container plus sample mass) as the initial mass, m .

ar

NOTE 2—For prepared biomass samples, it is recommend that samples for moisture determination should be weighed out at the same time as the

samples for the ash determination. If this is done at a later time it can introduce an error in the calculation because ground biomass can rapidly gain or

lose mo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.