ASTM D1856-95a

(Test Method)Standard Test Method for Recovery of Asphalt From Solution by Abson Method

Standard Test Method for Recovery of Asphalt From Solution by Abson Method

SCOPE

1.1 This method covers the recovery by the Abson method of asphalt from a solution from a previously conducted extraction. The asphalt is recovered with properties substantially the same as those it possessed in the bituminous mixture and in quantities sufficient for further testing.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1856 – 95a

Standard Test Method for

Recovery of Asphalt From Solution by Abson Method

This standard is issued under the fixed designation D 1856; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This method covers the recovery by the Abson method 4.1 The asphalt should be extracted from the aggregate-

of asphalt from a solution from a previously conducted asphalt mixture in accordance with Method A of Test Methods

extraction. The asphalt is recovered with properties substan- D 2172 (centrifuge method) as there is some experimental

tially the same as those it possessed in the bituminous mixture evidence that the recovered asphalt may have slightly lower

and in quantities sufficient for further testing. penetration values when recovered from solutions obtained

1.2 This standard does not purport to address all of the from hot extraction methods.

safety concerns, if any, associated with its use. It is the

5. Apparatus

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 5.1 Centrifuge, batch unit capable of exerting a minimum

centrifugal force of 770 times gravity or continuous unit

bility of regulatory limitations prior to use.

capable of exerting a minimum force of 3000 times gravity.

2. Referenced Documents

(The apparatus specified in Test Methods D 96 may also be

2.1 ASTM Standards: used.)

C 670 Practice for Preparing Precision and Bias Statements 5.2 Centrifuge Tubes—A supply of wide-mouth bottles or

for Test Methods for Construction Materials centrifuge tubes as shown in Fig. 1 or Fig. 2 of Test Methods

D 96 Test Methods for Water and Sediment in Crude Oil by D 96.

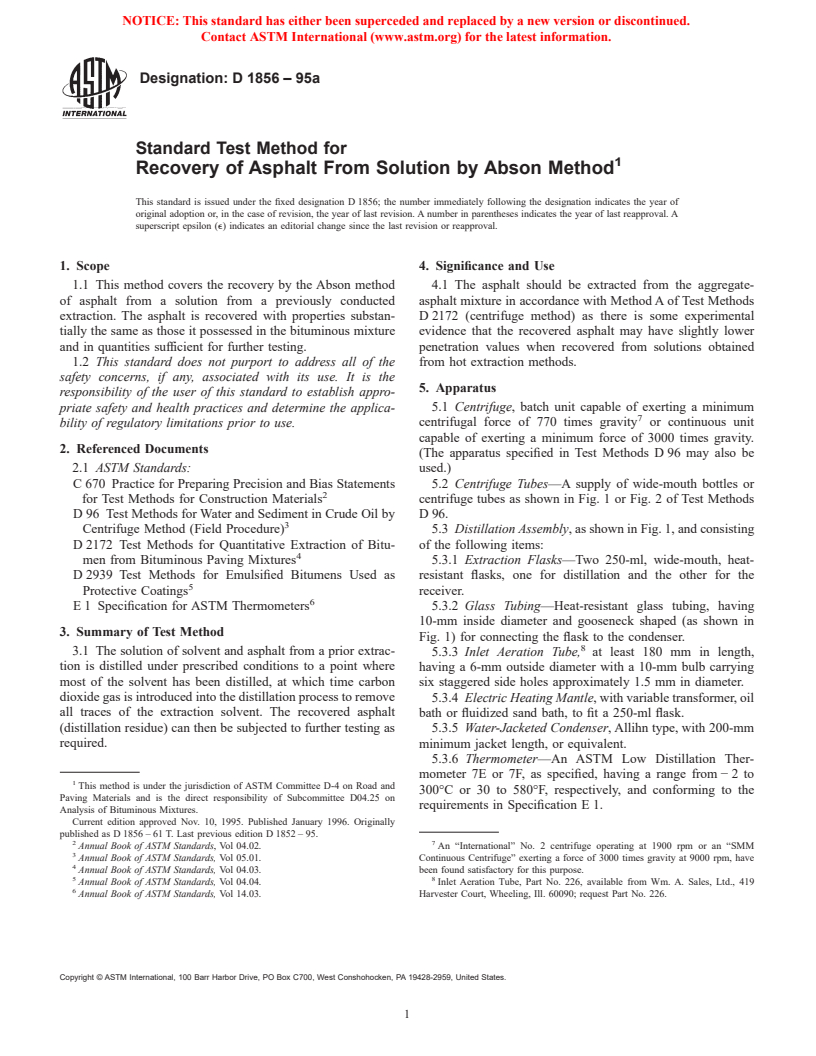

Centrifuge Method (Field Procedure) 5.3 Distillation Assembly, as shown in Fig. 1, and consisting

D 2172 Test Methods for Quantitative Extraction of Bitu- of the following items:

men from Bituminous Paving Mixtures 5.3.1 Extraction Flasks—Two 250-ml, wide-mouth, heat-

D 2939 Test Methods for Emulsified Bitumens Used as resistant flasks, one for distillation and the other for the

Protective Coatings receiver.

E 1 Specification for ASTM Thermometers 5.3.2 Glass Tubing—Heat-resistant glass tubing, having

10-mm inside diameter and gooseneck shaped (as shown in

3. Summary of Test Method

Fig. 1) for connecting the flask to the condenser.

3.1 The solution of solvent and asphalt from a prior extrac- 5.3.3 Inlet Aeration Tube, at least 180 mm in length,

tion is distilled under prescribed conditions to a point where

having a 6-mm outside diameter with a 10-mm bulb carrying

most of the solvent has been distilled, at which time carbon six staggered side holes approximately 1.5 mm in diameter.

dioxide gas is introduced into the distillation process to remove

5.3.4 Electric Heating Mantle, with variable transformer, oil

all traces of the extraction solvent. The recovered asphalt bath or fluidized sand bath, to fit a 250-ml flask.

(distillation residue) can then be subjected to further testing as

5.3.5 Water-Jacketed Condenser, Allihn type, with 200-mm

required. minimum jacket length, or equivalent.

5.3.6 Thermometer—An ASTM Low Distillation Ther-

mometer 7E or 7F, as specified, having a range from − 2 to

This method is under the jurisdiction of ASTM Committee D-4 on Road and

300°C or 30 to 580°F, respectively, and conforming to the

Paving Materials and is the direct responsibility of Subcommittee D04.25 on

requirements in Specification E 1.

Analysis of Bituminous Mixtures.

Current edition approved Nov. 10, 1995. Published January 1996. Originally

published as D 1856 – 61 T. Last previous edition D 1852 – 95.

2 7

Annual Book of ASTM Standards, Vol 04.02. An “International” No. 2 centrifuge operating at 1900 rpm or an “SMM

Annual Book of ASTM Standards, Vol 05.01. Continuous Centrifuge” exerting a force of 3000 times gravity at 9000 rpm, have

Annual Book of ASTM Standards, Vol 04.03. been found satisfactory for this purpose.

5 8

Annual Book of ASTM Standards, Vol 04.04. Inlet Aeration Tube, Part No. 226, available from Wm. A. Sales, Ltd., 419

Annual Book of ASTM Standards, Vol 14.03. Harvester Court, Wheeling, Ill. 60090; request Part No. 226.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 1856

FIG. 1 Distillation Assembly for Bitumen Recovery

Cincinnati, OH 45211-4438. 1990/1991 values. The TLV is a time weighted

5.3.7 Gas Flowmeter, as shown in Fig. 1, or any type

average for an exposure period of 8 h per day, 5 days per week.

capable of indicating a gas flow of up to 1000 ml/min.

B

Short term exposure limit (STEL) as established by ACGIH. 1990/1991 values.

5.3.8 Corks, No. 20, drilled as shown in Fig. 1.

5.3.9 Flexible Elastomeric Tubing, resistant to chlorinated

8. Sample

solvents having sufficient length and size to connect the

8.1 The sample shall consist of the solution from a previous

aeration tube to flowmeter, and equipped with a pinch clamp or

extraction by Method A of Test Methods D 2172 of asphalt-

stopcock to close aeration tube prior to introducing carbon

aggregate mixture of sufficient quantity to result in 75 to 100 g

dioxide.

of recovered bitumen. More or less quantities of bitumen may

5.3.10 Separatory Funnel, (Alternative Procedure, see

9.3.1) 125-ml capacity. be recovered; however, the properties of the recovered bitumen

may not be in agreement with those recovered of the afore-

6. Reagents and Materials

mentioned quantities, and in case of a disagreement, 75 to 100

g should be recovered.

6.1 Carbon Dioxide Gas—A pressurized tank, with

pressure-reducing valve or other convenient source.

8.2 During the extraction process, it is important that all of

6.2 The solvent for extracting the asphalt from mixtures the asphalt in the mixture be extracted as there could be some

should be reagent grade trichloroethylene.

selective solvency of the asphalt and the harder, more viscous

components of the asphalt might be left in the mixture if

7. Precautions

extraction is not carried to completion.

7.1 Caution—The solvent listed in 6.2 should be used only

8.3 Since heavy petroleum distillates such as mineral spirits

under a hood or with an effective surface exhaust system in a

or kerosine will affect the properties of the recovered asphalt,

well-ventilated area, since it is toxic to some degree as

it is important to avoid the use of such solvents in cleaning the

indicated below:

extraction and recovery apparatus and use only trichloroethyl-

A B

Solvent TLV, ppm STEL, ppm ene for cleaning. Residues of heavy petroleum solvents on the

Trichloroethylene 50 200

equipment may contaminate the recovered asphalt and affect its

_________

test properties. It is also necessary to use new filter rings, clean

A

Threshold limit value (TLV) as established by the American Conference of

felt pads, or other uncontaminated filtering media in the

Governmental Industrial Hygienists (ACGIH), Bldg. D-7, 6500 Glenway Ave.,

extraction process to avoid contamination from a previous

extraction.

9 8.4 Generally, the bitumen in mixtures will progressively

The Monostat Corp. “Flowmeter” No. 9144 has been found satisfactory for this

harden when exposed to air, particularly if the mixtures are in

purpose.

Kimball separatory funnel No. 29028 has been found satisfactory for this

a loose condition. Therefore, it is important to protect bitumi-

purpose.

nous mixtures from exposure to air and preferably to store

Trichloroethylene, Technical Grade, Type I, Federal Specification O-T-634,

them in airtight containers at a temperature below 0°C (32°F)

latest revision may be used, but it is recommended that for each new supply of the

solvent a blank should be run on an asphalt of known properties. until they can be tested. When samples of bituminous mixture

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 1856

are warmed for preparing representative proportions for extrac- contact with the bottom of the flask and introduce carbon

tion tests in accordance with Method A of Test Methods dioxide gas a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.