ASTM B265-05e1

(Specification)Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate

Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate

SCOPE

1.1 This specification covers annealed titanium and titanium alloy strip, sheet, and plate as follows:

1.1.1 Grade 1Unalloyed titanium,

1.1.2 Grade 2Unalloyed titanium,

1.1.3 Grade 3Unalloyed titanium,

1.1.4 Grade 4Unalloyed titanium,

1.1.5 Grade 5Titanium alloy (6 % aluminum, 4 % vanadium),

1.1.6 Grade 6Titanium alloy (5 % aluminum, 2.5 % tin),

1.1.7 Grade 7Unalloyed titanium plus 0.12 to 0.25 % palladium,

1.1.8 Grade 9Titanium alloy (3.0 % aluminum, 2.5 % vanadium),

1.1.9 Grade 11Unalloyed titanium plus 0.12 to 0.25 % palladium,

1.1.10 Grade 12Titanium alloy (0.3 % molybdenum, 0.8 % nickel),

1.1.11 Grade 13Titanium alloy (0.5 % nickel, 0.05 % ruthenium),

1.1.12 Grade 14Titanium alloy (0.5 % nickel, 0.05 % ruthenium),

1.1.13 Grade 15Titanium alloy (0.5 % nickel, 0.05 % ruthenium),

1.1.14 Grade 16Unalloyed titanium plus 0.04 to 0.08 % palladium,

1.1.15 Grade 17Unalloyed titanium plus 0.04 to 0.08 % palladium,

1.1.16 Grade 18Titanium alloy (3 % aluminum, 2.5 % vanadium) plus 0.04 to 0.08 % palladium.

1.1.17 Grade 19Titanium alloy (3 % aluminum, 8 % vanadium, 6 % chromium, 4 % zirconium, 4 % molybdenum),

1.1.18 Grade 20Titanium alloy (3 % aluminum, 8 % vanadium, 6 % chromium, 4 % zirconium, 4 % molybdenum) plus 0.04 % to 0.08 % palladium,

1.1.19 Grade 21Titanium alloy (15 % molybdenum, 3 % aluminum, 2.7 % niobium, 0.25 % silicon),

1.1.20 Grade 23Titanium alloy (6 % aluminum, 4 % vanadium with extra low interstitial elements, ELI),

1.1.21 Grade 24Titanium alloy (6 % aluminum, 4 % vanadium) plus 0.04 % to 0.08 % palladium,

1.1.22 Grade 25Titanium alloy (6 % aluminum, 4 % vanadium) plus 0.3 % to 0.8 % nickel and 0.04 % to 0.08 % palladium,

1.1.23 Grade 26Unalloyed titanium plus 0.08 to 0.14 % ruthenium,

1.1.24 Grade 27Unalloyed titanium plus 0.08 to 0.14 % ruthenium,

1.1.25 Grade 28Titanium alloy (3 % aluminum, 2.5 % vanadium) plus 0.08 to 0.14 % ruthenium,

1.1.26 Grade 29Titanium alloy (6 % aluminum, 4 % vanadium with extra low interstitial elements, ELI) plus 0.08 to 0.14 % ruthenium,

1.1.27 Grade 30Titanium alloy (0.3 % cobalt, 0.05 % palladium),

1.1.28 Grade 31Titanium alloy (0.3 % cobalt, 0.05 % palladium),

1.1.29 Grade 32Titanium alloy (5 % aluminum, 1 % tin, 1 % zirconium, 1 % vanadium, 0.8 % molybdenum),

1.1.30 Grade 33Titanium alloy (0.4 % nickel, 0.015 % palladium, 0.02 5 % ruthenium, 0.15 % chromium),

1.1.31 Grade 34Titanium alloy (0.4 % nickel, 0.015 % palladium, 0.025 % ruthenium, 0.15 % chromium),

1.1.32 Grade 35Titanium alloy (4.5 % aluminum, 2 % molybdenum, 1.6 % vanadium, 0.5 % iron, 0.3 % silicon),

1.1.33 Grade 36Titanium alloy (45 % niobium), and

1.1.34 Grade 37Titanium alloy (1.5 % aluminum).

1.2 &inch-pound-units;

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

ε1

Designation: B 265 – 05

Standard Specification for

1

Titanium and Titanium Alloy Strip, Sheet, and Plate

This standard is issued under the fixed designation B 265; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ε) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

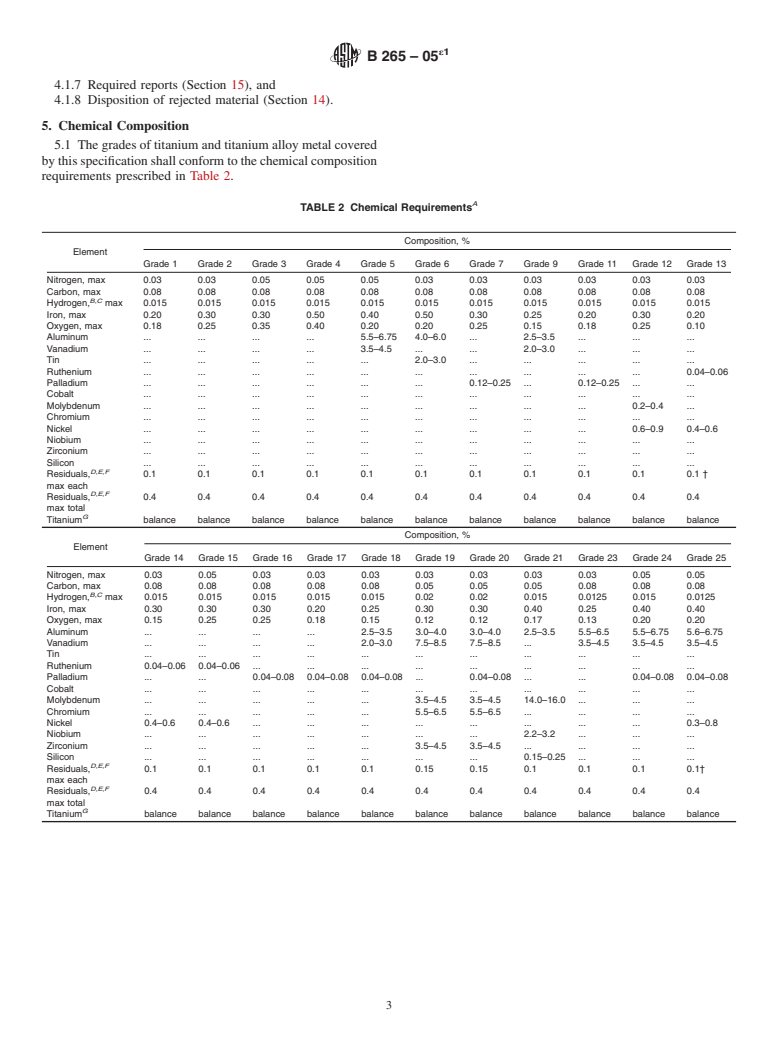

ε NOTE—Silicon residual max in Grade 25 in Table 2 was corrected editorially in January 2006.

1. Scope 1.1.18 Grade 20—Titanium alloy (3 % aluminum, 8 %

2 vanadium, 6 % chromium, 4 % zirconium, 4 % molybdenum)

1.1 This specification covers annealed titanium and tita-

plus 0.04 % to 0.08 % palladium,

nium alloy strip, sheet, and plate as follows:

1.1.19 Grade 21—Titanium alloy (15 % molybdenum, 3 %

1.1.1 Grade 1—Unalloyed titanium,

aluminum, 2.7 % niobium, 0.25 % silicon),

1.1.2 Grade 2—Unalloyed titanium,

1.1.20 Grade 23—Titanium alloy (6 % aluminum, 4 %

1.1.3 Grade 3—Unalloyed titanium,

vanadium with extra low interstitial elements, ELI),

1.1.4 Grade 4—Unalloyed titanium,

1.1.21 Grade 24—Titanium alloy (6 % aluminum, 4 %

1.1.5 Grade 5—Titanium alloy (6 % aluminum, 4 % vana-

vanadium) plus 0.04 % to 0.08 % palladium,

dium),

1.1.22 Grade 25—Titanium alloy (6 % aluminum, 4 %

1.1.6 Grade 6—Titanium alloy (5 % aluminum, 2.5 % tin),

vanadium) plus 0.3 % to 0.8 % nickel and 0.04 % to 0.08 %

1.1.7 Grade 7—Unalloyed titanium plus 0.12 to 0.25 %

palladium,

palladium,

1.1.23 Grade 26—Unalloyed titanium plus 0.08 to 0.14 %

1.1.8 Grade 9—Titanium alloy (3.0 % aluminum, 2.5 %

ruthenium,

vanadium),

1.1.24 Grade 27—Unalloyed titanium plus 0.08 to 0.14 %

1.1.9 Grade 11—Unalloyed titanium plus 0.12 to 0.25 %

ruthenium,

palladium,

1.1.25 Grade 28—Titanium alloy (3 % aluminum, 2.5 %

1.1.10 Grade 12—Titanium alloy (0.3 % molybdenum,

vanadium) plus 0.08 to 0.14 % ruthenium,

0.8 % nickel),

1.1.26 Grade 29—Titanium alloy (6 % aluminum, 4 %

1.1.11 Grade 13—Titanium alloy (0.5 % nickel, 0.05 %

vanadiumwithextralowinterstitialelements,ELI)plus0.08to

ruthenium),

0.14 % ruthenium,

1.1.12 Grade 14—Titanium alloy (0.5 % nickel, 0.05 %

1.1.27 Grade 30—Titanium alloy (0.3 % cobalt, 0.05 %

ruthenium),

palladium),

1.1.13 Grade 15—Titanium alloy (0.5 % nickel, 0.05 %

1.1.28 Grade 31—Titanium alloy (0.3 % cobalt, 0.05 %

ruthenium),

palladium),

1.1.14 Grade 16—Unalloyed titanium plus 0.04 to 0.08 %

1.1.29 Grade 32—Titanium alloy (5 % aluminum, 1 % tin,

palladium,

1 % zirconium, 1 % vanadium, 0.8 % molybdenum),

1.1.15 Grade 17—Unalloyed titanium plus 0.04 to 0.08 %

1.1.30 Grade 33—Titanium alloy (0.4 % nickel, 0.015 %

palladium,

palladium, 0.02 5 % ruthenium, 0.15 % chromium),

1.1.16 Grade 18—Titanium alloy (3 % aluminum, 2.5 %

1.1.31 Grade 34—Titanium alloy (0.4 % nickel, 0.015 %

vanadium) plus 0.04 to 0.08 % palladium.

palladium, 0.025 % ruthenium, 0.15 % chromium),

1.1.17 Grade 19—Titanium alloy (3 % aluminum, 8 %

1.1.32 Grade 35—Titanium alloy (4.5 % aluminum, 2 %

vanadium, 6 % chromium, 4 % zirconium, 4 % molybdenum),

molybdenum, 1.6 % vanadium, 0.5 % iron, 0.3 % silicon),

1.1.33 Grade 36—Titanium alloy (45 % niobium), and

1

This specification is under the jurisdiction of ASTM Committee B10 on

1.1.34 Grade 37—Titanium alloy (1.5 % aluminum).

Reactive and Refractory Metals and Alloys and is the direct responsibility of

1.2 The values stated in inch-pound units are to be regarded

Subcommittee B10.01 on Titanium.

Current edition approved Jan. 1, 2005. Published February 2005. Originally

as standard. The values given in parentheses are mathematical

approved in 1952. Last previous edition approved in 2003 as B 265 – 03.

conversions to SI units that are provided for information only

2

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

and are not considered standard.

cations SB-265 in Section II of that Code.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

ε1

B265–05

A

TABLE 1 Tensile Requirements

B

Tensile Strength, min Yield Strength, 0.2 % Offset Bend Test

Elongation in

min max Under 0.070 in. 0.070 to 0.187 in.

Grade 2 in. or 50 mm,

ksi MPa (1.8 mm) in (1.8–4.75 mm) in

min, %

ksi MPa ksi MPa

Thickness Thickness

1 35 240 20 138 45 310 24 3T 4T

2 50 345 40 275 65 450 20 4T 5T

3 65 450 55 380 80 550 18 4T 5T

4 80 550 70 483 95 655 15 5T 6T

C

5 130 895 120 828 . . 10 9T 10T

C

6 120 828 115 793 . . 10 8T 9T

7 50 345 40 275 65 450 20 4T 5T

D

9 90 620 70 483 . . 15 5T 6T

11 35 240 20 138 45 310 24 3T 4T

12 70 483 50 345 . . 18 4T 5T

13 40 275 25 170 . . 24 3T 4T

14 60 410 40 275 .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.