ASTM D7854-15

(Test Method)Standard Test Method for Carbon Black-Void Volume at Mean Pressure

Standard Test Method for Carbon Black-Void Volume at Mean Pressure

SIGNIFICANCE AND USE

5.1 The void volume of a carbon black expressed as a function of geometric mean pressure, VVGM, is a carbon black structure property. Structure is a generic term that is a function of the shape irregularity and deviation from sphericity of carbon black aggregates. The greater a carbon black resists compression by having substantial aggregate irregularity and non-sphericity, the greater the compressed volume and void volume. Also, the more that a carbon black resists compression, the greater the energy required to compress the sample per unit void volume.

5.2 Structure is a property that strongly influences the physical properties developed in carbon black-elastomer compounds for use in tires, mechanical rubber goods, and other manufactured rubber products. Structure measurements by OAN (Test Method D2414) and COAN (Test Method D3493), are based on oil absorption.

SCOPE

1.1 This test method covers a procedure to measure a carbon black structure property known as Void Volume at mean pressure. Compressed void volumes are obtained by measuring the compressed volume of a weighed sample in a cylindrical chamber as a function of pressure exerted by a movable piston. A profile of void volume as a function of pressure provides a means to assess carbon black structure at varying levels of density and aggregate reduction.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7854 − 15

StandardTest Method for

1

Carbon Black-Void Volume at Mean Pressure

This standard is issued under the fixed designation D7854; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D6086 Test Method for Carbon Black—Void Volume (VV)

3

(Withdrawn 2015)

1.1 Thistestmethodcoversaproceduretomeasureacarbon

black structure property known as Void Volume at mean

3. Terminology

pressure. Compressed void volumes are obtained by measuring

3.1 Refer to Sections 4 and 9 for a more complete under-

the compressed volume of a weighed sample in a cylindrical

standing of the use of these terms in this test method.

chamber as a function of pressure exerted by a movable piston.

A profile of void volume as a function of pressure provides a

3.2 Definitions of Terms Specific to This Standard:

means to assess carbon black structure at varying levels of

3.2.1 applied pressure, n—the pressure exerted on a sample

density and aggregate reduction.

mass by a movable piston in a cylindrical chamber, where the

load cell or force measuring system is in contact with the

1.2 The values stated in SI units are to be regarded as

movable piston.

standard. No other units of measurement are included in this

standard. 3.2.2 compressed volume (carbon black), n—the apparent

volume that a specified mass of carbon black occupies when it

1.3 This standard does not purport to address all of the

is contained in a specified cylindrical chamber and subjected to

safety concerns, if any, associated with its use. It is the

a single uniaxial compression at a specified pressure by means

responsibility of the user of this standard to establish appro-

of a movable piston.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 3.2.3 geometric mean pressure, n—the geometric mean of

the applied and transmitted pressures at a specific void volume;

2. Referenced Documents

the geometric mean pressure is defined in Eq 1:

2

0.5

2.1 ASTM Standards:

Geometric Mean P 5 ~P 3 P ! (1)

GM a t

D1799 Practice for Carbon Black—Sampling Packaged

3.2.4 theoretical volume (carbon black), n—the volume that

Shipments

a specific mass of carbon black would occupy if there were no

D1900 Practice for Carbon Black—Sampling Bulk Ship-

void space within the carbon black, and is given by the ratio of

ments

mass to skeletal density, where the skeletal density is deter-

D2414 Test Method for Carbon Black—Oil Absorption

mined by an accepted test method.

Number (OAN)

3.2.5 transmitted pressure, n—the resulting pressure trans-

D3493 Test Method for Carbon Black—Oil Absorption

mitted through a sample in a cylindrical chamber, where the

Number of Compressed Sample (COAN)

load cell or force measuring system is in contact with the

D4483 Practice for Evaluating Precision for Test Method

sample opposite the movable piston, typically via a stationary

Standards in the Rubber and Carbon Black Manufacturing

second piston.

Industries

3.2.6 void volume (carbon black), n—a measure of the

D4821 Guide for Carbon Black—Validation of Test Method

intra-aggregate void space or occluded volume within the

Precision and Bias

primary structure of carbon black, characterized by the irregu-

larity and non-sphericity of carbon black aggregate particles,

1 and expressed as the difference (compressed volume minus

This test method is under the jurisdiction ofASTM Committee D24 on Carbon

Black and is the direct responsibility of Subcommittee D24.11 on Carbon Black theoretical volume) as a function of specified uniaxial com-

Structure.

pression pressure, and normalized to 100 g mass.

Current edition approved June 1, 2015. Published September 2015. Originally

3.2.6.1 Discussion—Carbon blacks resist packing,

approved in 2013. Last previous edition approved in 2013 as D7854 – 13. DOI:

compression, and fracture due to aggregate irregularities and

10.1520/D7854-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

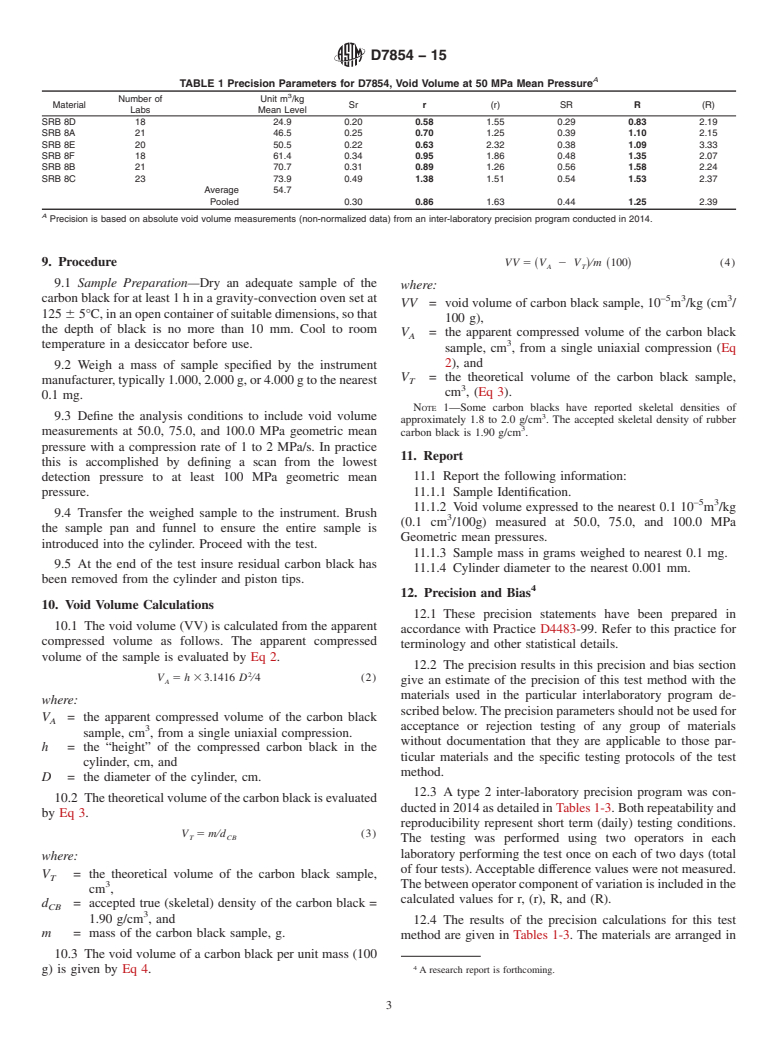

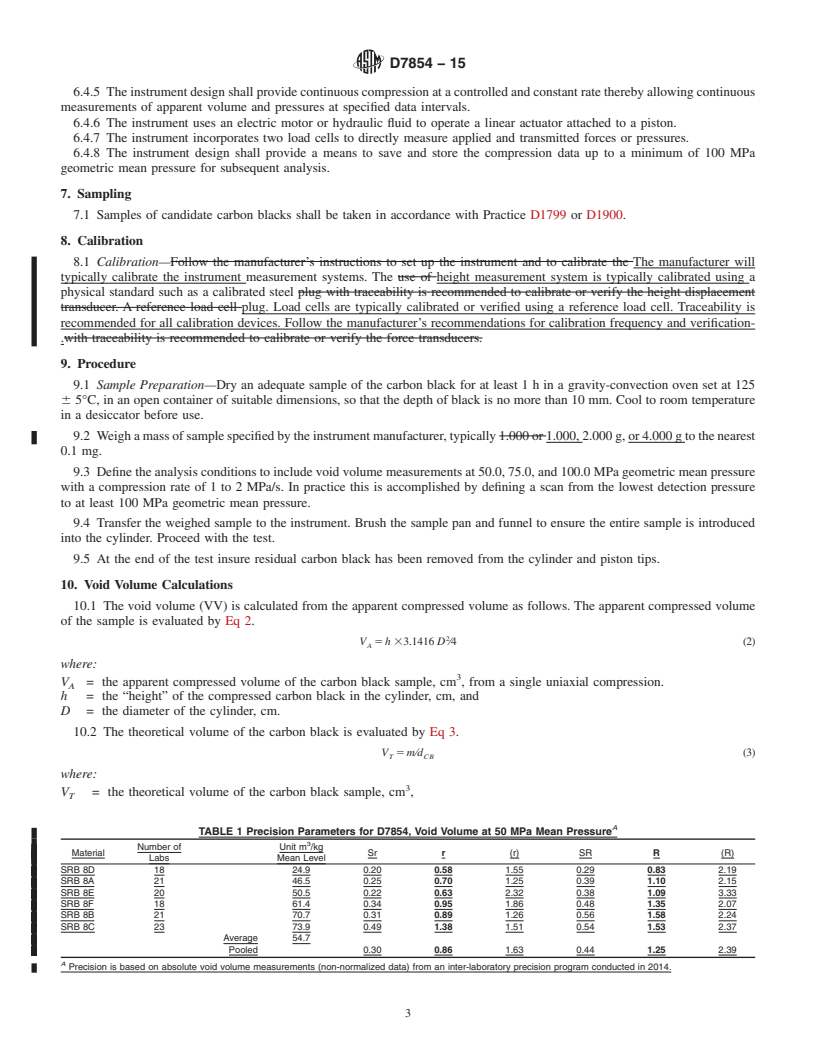

D7854 − 15

entanglements, size distribution, and aggregate strength result- 6. Apparatus

ing from particle to-particle necks within aggregate branches.

6.1 Analytical Balance,orequivalent,capable

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7854 − 13 D7854 − 15

Standard Test Method for

1

Carbon Black-Void Volume at Mean Pressure

This standard is issued under the fixed designation D7854; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a procedure to measure a carbon black structure property known as Void Volume at mean pressure.

Compressed void volumes are obtained by measuring the compressed volume of a weighed sample in a cylindrical chamber as a

function of pressure exerted by a movable piston. A profile of void volume as a function of pressure provides a means to assess

carbon black structure at varying levels of density and aggregate reduction.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1799 Practice for Carbon Black—Sampling Packaged Shipments

D1900 Practice for Carbon Black—Sampling Bulk Shipments

D2414 Test Method for Carbon Black—Oil Absorption Number (OAN)

D3493 Test Method for Carbon Black—Oil Absorption Number of Compressed Sample (COAN)

D4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries

D4821 Guide for Carbon Black—Validation of Test Method Precision and Bias

3

D6086 Test Method for Carbon Black—Void Volume (VV) (Withdrawn 2015)

3. Terminology

3.1 Refer to Sections 4 and 9 for a more complete understanding of the use of these terms in this test method.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 applied pressure, n—the pressure exerted on a sample mass by a movable piston in a cylindrical chamber, where the load

cell or force measuring system is in contact with the movable piston.

3.2.2 compressed volume (carbon black), n—the apparent volume that a specified mass of carbon black occupies when it is

contained in a specified cylindrical chamber and subjected to a single uniaxial compression at a specified pressure by means of

a movable piston.

3.2.3 geometric mean pressure, n—the geometric mean of the applied and transmitted pressures at a specific void volume; the

geometric mean pressure is defined in Eq 1:

0.5

Geometric Mean P 5 P 3 P (1)

~ !

GM a t

3.2.4 theoretical volume (carbon black), n—the volume that a specific mass of carbon black would occupy if there were no void

space within the carbon black, and is given by the ratio of mass to skeletal density, where the skeletal density is determined by

an accepted test method.

3.2.5 transmitted pressure, n—the resulting pressure transmitted through a sample in a cylindrical chamber, where the load cell

or force measuring system is in contact with the sample opposite the movable piston, typically via a stationary second piston.

1

This test method is under the jurisdiction of ASTM Committee D24 on Carbon Black and is the direct responsibility of Subcommittee D24.11 on Carbon Black Structure.

Current edition approved Nov. 1, 2013June 1, 2015. Published December 2013September 2015. Originally approved in 2013. Last previous edition approved in 2013 as

D7854 – 13. DOI: 10.1520/D7854-13.10.1520/D7854-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7854 − 15

3.2.6 void volume (carbon black), n—a measure of the intra-aggregate void space or occluded volume within the primary

structure of carbon black, characterized by the irregularity and non-sphericity of carbon black aggregate particles, and expressed

as the difference (compressed volume minus theoretical volume) as a function of specified uniaxial compression pressur

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.