ASTM E2871-21

(Test Method)Standard Test Method for Determining Disinfectant Efficacy Against Biofilm Grown in the CDC Biofilm Reactor Using the Single Tube Method

Standard Test Method for Determining Disinfectant Efficacy Against Biofilm Grown in the CDC Biofilm Reactor Using the Single Tube Method

SIGNIFICANCE AND USE

5.1 The Single Tube Method is designed to evaluate the efficacy of disinfectants against biofilm grown in the CDC biofilm reactor following the procedures outlined in Practice E3161. Biofilm grown in the CDC reactor is representative of biofilm that forms under high fluid shear on surfaces conducive to biofilm formation.

5.1.1 Vegetative biofilm bacteria are phenotypically different from suspended planktonic cells of the same genotype. Biofilm growth reactors are engineered to produce biofilm with specific characteristics (2). Altering either the engineered system or operating conditions will modify those characteristics as well as the physicochemical environment. The goal in biofilm research and testing is to choose the growth reactor and operating conditions that generate the most relevant biofilm for the particular study.

5.2 The test method was designed to determine the log10 reduction in bacteria after exposure to a disinfectant in a closed system.

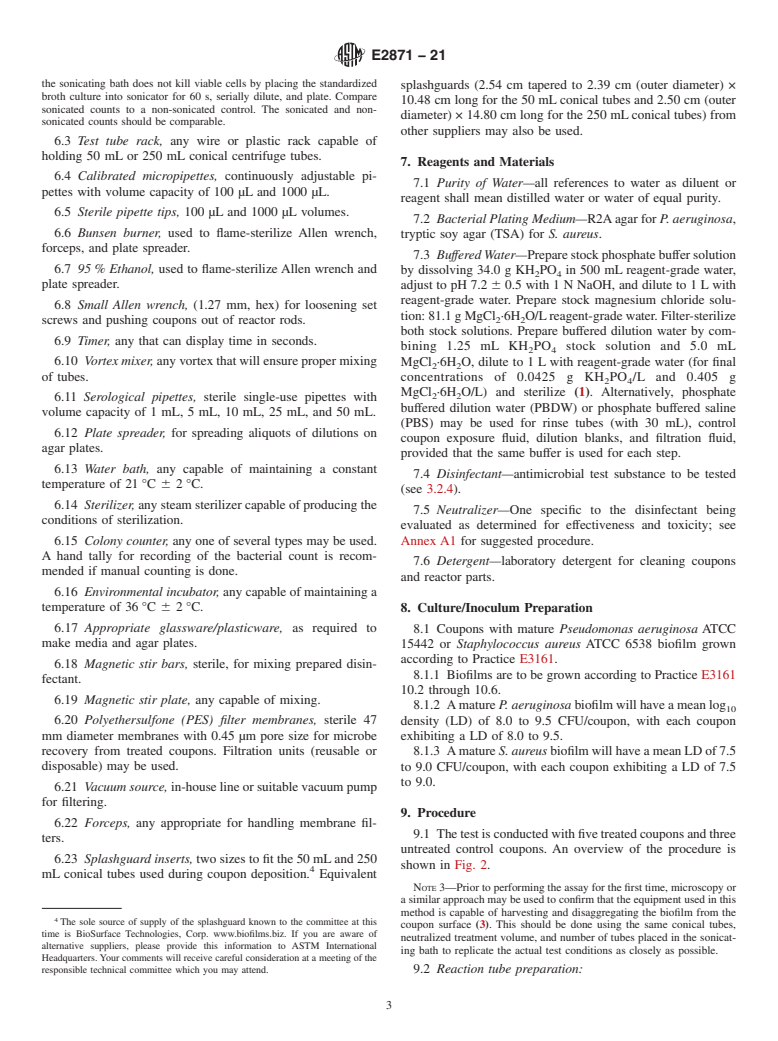

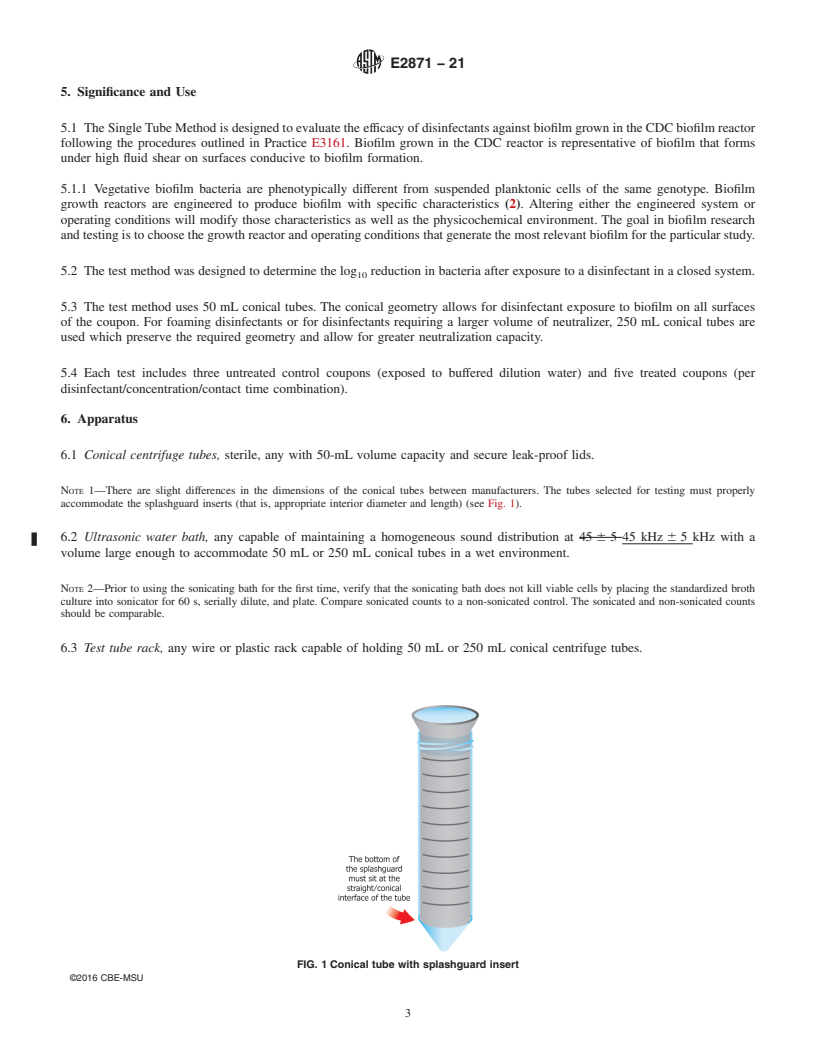

5.3 The test method uses 50 mL conical tubes. The conical geometry allows for disinfectant exposure to biofilm on all surfaces of the coupon. For foaming disinfectants or for disinfectants requiring a larger volume of neutralizer, 250 mL conical tubes are used which preserve the required geometry and allow for greater neutralization capacity.

5.4 Each test includes three untreated control coupons (exposed to buffered dilution water) and five treated coupons (per disinfectant/concentration/contact time combination).

SCOPE

1.1 This test method specifies the operational parameters required to perform a quantitative liquid disinfectant efficacy test against bacterial biofilm.

1.2 The test method was optimized and validated for a Pseudomonas aeruginosa or Staphylococcus aureus biofilm grown in the CDC Biofilm Reactor (E3161). The method is suitable for evaluating additional bacteria grown using the procedures outlined in methods with comparable coupon dimensions such as Practice E3161, Test Method E2562, or Test Method E2196.

1.3 Disinfectant preparation and contact time are used in the assessment according to the manufacturer’s instructions for use.

1.4 The test method uses a closed system to treat biofilm. A coupon is placed in a single tube for the treatment, neutralization, and harvesting steps to prevent the loss of cells.

1.5 This test method describes a harvesting and analysis procedure which includes vortexing and sonicating treated and untreated control biofilm, and recovery of culturable cells using filtration to lower the limit of detection. Biofilm population density is recorded as log10 colony-forming units per coupon. Efficacy is reported as a log10 reduction of culturable cells.

1.6 Basic microbiology training is required to perform this assay.

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:E2871 −21

Standard Test Method for

Determining Disinfectant Efficacy Against Biofilm Grown in

1

the CDC Biofilm Reactor Using the Single Tube Method

This standard is issued under the fixed designation E2871; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.9 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This test method specifies the operational parameters

ization established in the Decision on Principles for the

required to perform a quantitative liquid disinfectant efficacy

Development of International Standards, Guides and Recom-

test against bacterial biofilm.

mendations issued by the World Trade Organization Technical

1.2 The test method was optimized and validated for a

Barriers to Trade (TBT) Committee.

Pseudomonas aeruginosa or Staphylococcus aureus biofilm

grown in the CDC Biofilm Reactor (E3161). The method is 2. Referenced Documents

suitable for evaluating additional bacteria grown using the 2

2.1 ASTM Standards:

procedures outlined in methods with comparable coupon

E2196Test Method for Quantification of Pseudomonas

dimensions such as Practice E3161, Test Method E2562,or

aeruginosa Biofilm Grown with Medium Shear and

Test Method E2196.

Continuous Flow Using Rotating Disk Reactor

1.3 Disinfectantpreparationandcontacttimeareusedinthe

E2562Test Method for Quantification of Pseudomonas

assessment according to the manufacturer’s instructions for aeruginosaBiofilmGrownwithHighShearandContinu-

use.

ous Flow using CDC Biofilm Reactor

E2756Terminology Relating toAntimicrobial andAntiviral

1.4 The test method uses a closed system to treat biofilm.A

Agents

coupon is placed in a single tube for the treatment,

E3161PracticeforPreparinga Pseudomonas aeruginosaor

neutralization, and harvesting steps to prevent the loss of cells.

Staphylococcus aureus Biofilm using the CDC Biofilm

1.5 This test method describes a harvesting and analysis

Reactor

procedure which includes vortexing and sonicating treated and

2.2 Other Standards:

untreated control biofilm, and recovery of culturable cells

Method 9050 C.1.a Buffered Dilution Water Preparation

using filtration to lower the limit of detection. Biofilm popu-

3

according to Eaton et al (1)

lation density is recorded as log colony-forming units per

10

coupon. Efficacy is reported as a log reduction of culturable

3. Terminology

10

cells.

3.1 For definitions of terms used in this test method refer to

1.6 Basic microbiology training is required to perform this

Terminology E2756.

assay.

3.2 Definitions:

1.7 The values stated in SI units are to be regarded as

3.2.1 biofilm, n—microorganisms living in a self-organized

standard. No other units of measurement are included in this

community attached to surfaces, interfaces, or each other,

standard.

embedded in a matrix of extracellular polymeric substances of

microbial origin, while exhibiting altered phenotypes with

1.8 This standard does not purport to address all of the

respect to growth rate and gene transcription.

safety concerns, if any, associated with its use. It is the

3.2.1.1 Discussion—Biofilm may be comprised of bacteria,

responsibility of the user of this standard to establish appro-

fungi, algae, protozoa, viruses, or infinite combinations of

priate safety, health, and environmental practices and deter-

these microorganisms. The qualitative characteristics of a

mine the applicability of regulatory limitations prior to use.

1 2

This test method is under the jurisdiction of ASTM Committee E35 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Pesticides, Antimicrobials, and Alternative Control Agents and is the direct contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

responsibility of Subcommittee E35.15 on Antimicrobial Agents. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Nov. 1, 2021. Published January 2022. Originally the ASTM website.

3

approved in 2012. Last previous edition approved in 2019 as E2871–19. DOI: The boldface numbers in parentheses refer to a list of references at the end of

10.1520/E2871–21. this standard.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2871−21

biofilm inc

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2871 − 19 E2871 − 21

Standard Test Method for

Determining Disinfectant Efficacy Against Biofilm Grown in

1

the CDC Biofilm Reactor Using the Single Tube Method

This standard is issued under the fixed designation E2871; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method specifies the operational parameters required to perform a quantitative liquid disinfectant efficacy test against

bacterial biofilm.

1.2 The test method was optimized and validated for a Pseudomonas aeruginosa or Staphylococcus aureus biofilm grown in the

CDC Biofilm Reactor (E3161). The method is suitable for evaluating additional bacteria grown using the procedures outlined in

methods with comparable coupon dimensions such as Practice E3161, Test Method E2562, or Test Method E2196.

1.3 Disinfectant preparation and contact time are used in the assessment according to the manufacturer’s instructions for use.

1.4 The test method uses a closed system to treat biofilm. A coupon is placed in a single tube for the treatment, neutralization,

and harvesting steps to prevent the loss of cells.

1.5 This test method describes a harvesting and analysis procedure which includes vortexing and sonicating treated and untreated

control biofilm, and recovery of culturable cells using filtration to lower the limit of detection. Biofilm population density is

recorded as log colony-forming units per coupon. Efficacy is reported as a log reduction of culturable cells.

10 10

1.6 Basic microbiology training is required to perform this assay.

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This test method is under the jurisdiction of ASTM Committee E35 on Pesticides, Antimicrobials, and Alternative Control Agents and is the direct responsibility of

Subcommittee E35.15 on Antimicrobial Agents.

Current edition approved Jan. 1, 2019Nov. 1, 2021. Published February 2019January 2022. Originally approved in 2012. Last previous edition approved in 20132019 as

E2871–13.–19. DOI: 10.1520/E2871–19.10.1520/E2871–21.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2871 − 21

2. Referenced Documents

2

2.1 ASTM Standards:

E1054 Practices for Evaluation of Inactivators of Antimicrobial Agents

E2196 Test Method for Quantification of Pseudomonas aeruginosa Biofilm Grown with Medium Shear and Continuous Flow

Using Rotating Disk Reactor

E2562 Test Method for Quantification of Pseudomonas aeruginosa Biofilm Grown with High Shear and Continuous Flow using

CDC Biofilm Reactor

E2756 Terminology Relating to Antimicrobial and Antiviral Agents

E3161 Practice for Preparing a Pseudomonas aeruginosa or Staphylococcus aureus Biofilm using the CDC Biofilm Reactor

2.2 Other Standards:

3

Method 9050 C.1.a Buffered Dilution Water Preparation according to Eaton et al (1)

3. Terminology

3.1 For definitions of terms used in this test method refer to Terminology E2756.

3.2 Definitions:

3.2.1 biofilm, n—microorganisms living in a self-organized community attached to surfaces, interfaces, or each other, embedded

in a matrix of extracellular polymeric substances of microbial origin, while exhibiting altered phenotypes with respect to growth

rate and gene transcription.

3.2.1.1 Discussion—

Biofilm may be comprised of bacteria, fungi, algae, protozoa, viruses, or infinite combinations of these microorganisms. The

qualitative characteristics of a biofilm including, but not limited to, population density, taxonomic dive

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.