ASTM F2026-07e1

(Specification)Standard Specification for Polyetheretherketone (PEEK) Polymers for Surgical Implant Applications

Standard Specification for Polyetheretherketone (PEEK) Polymers for Surgical Implant Applications

SCOPE

1.1 This specification covers polyetheretherketone (PEEK) polymer in virgin forms as supplied by a vendor (pellets, powder, and so forth). It provides requirements and associated test methods for these thermoplastics when they are to be used in the manufacture of intracorporeal devices such as surgical implants or components of surgical or dental devices.

1.2 As with any material, some characteristics may be altered by the processing techniques (molding, extrusion, machining, assembly, sterilization, and so forth) required for the production of a specific part or device. Therefore, properties of fabricated forms of these polymers should be evaluated using test methods which are appropriate to ensure safety and efficacy as agreed upon by the vendor, purchaser, and regulating bodies.

1.3 The properties included in this specification are those applicable for PEEK polymers only. Indicated properties are for injection molded forms. Fabricated forms, material or forms containing colorants, fillers, processing aids, or other additives, as well as polymer blends which contain PEEK, or reclaimed materials, are not covered by this specification.

1.4 This specification is designed to recommend physical, chemical, and biological test methods to establish a reasonable level of confidence concerning the performance of virgin PEEK polymers for use in medical implant devices. The properties listed should be considered in selecting material(s) in accordance with the specific end-use requirements.

1.5 When evaluating material in accordance with this specification, hazardous materials, operations, and equipment may be involved. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: F 2026 – 07

Standard Specification for

Polyetheretherketone (PEEK) Polymers for Surgical Implant

1

Applications

This standard is issued under the fixed designation F 2026; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

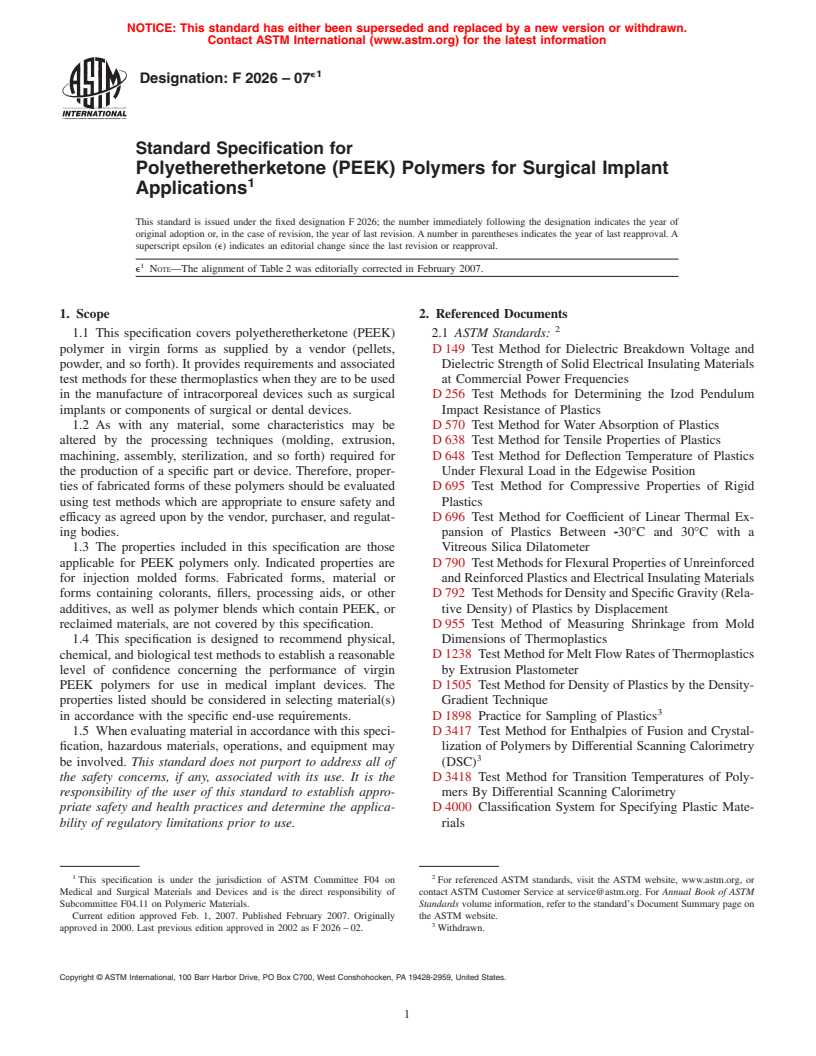

e NOTE—The alignment of Table 2 was editorially corrected in February 2007.

1. Scope 2. Referenced Documents

2

1.1 This specification covers polyetheretherketone (PEEK) 2.1 ASTM Standards:

polymer in virgin forms as supplied by a vendor (pellets, D 149 Test Method for Dielectric Breakdown Voltage and

powder, and so forth). It provides requirements and associated Dielectric Strength of Solid Electrical Insulating Materials

test methods for these thermoplastics when they are to be used at Commercial Power Frequencies

in the manufacture of intracorporeal devices such as surgical D 256 Test Methods for Determining the Izod Pendulum

implants or components of surgical or dental devices. Impact Resistance of Plastics

1.2 As with any material, some characteristics may be D 570 Test Method for Water Absorption of Plastics

altered by the processing techniques (molding, extrusion, D 638 Test Method for Tensile Properties of Plastics

machining, assembly, sterilization, and so forth) required for D 648 Test Method for Deflection Temperature of Plastics

the production of a specific part or device. Therefore, proper- Under Flexural Load in the Edgewise Position

ties of fabricated forms of these polymers should be evaluated D 695 Test Method for Compressive Properties of Rigid

using test methods which are appropriate to ensure safety and Plastics

efficacy as agreed upon by the vendor, purchaser, and regulat- D 696 Test Method for Coefficient of Linear Thermal Ex-

ing bodies. pansion of Plastics Between Ø30°C and 30°C with a

1.3 The properties included in this specification are those Vitreous Silica Dilatometer

applicable for PEEK polymers only. Indicated properties are D 790 TestMethodsforFlexuralPropertiesofUnreinforced

for injection molded forms. Fabricated forms, material or and Reinforced Plastics and Electrical Insulating Materials

forms containing colorants, fillers, processing aids, or other D 792 TestMethodsforDensityandSpecificGravity(Rela-

additives, as well as polymer blends which contain PEEK, or tive Density) of Plastics by Displacement

reclaimed materials, are not covered by this specification. D 955 Test Method of Measuring Shrinkage from Mold

1.4 This specification is designed to recommend physical, Dimensions of Thermoplastics

chemical, and biological test methods to establish a reasonable D 1238 TestMethodforMeltFlowRatesofThermoplastics

level of confidence concerning the performance of virgin by Extrusion Plastometer

PEEK polymers for use in medical implant devices. The D 1505 Test Method for Density of Plastics by the Density-

properties listed should be considered in selecting material(s) Gradient Technique

3

in accordance with the specific end-use requirements. D 1898 Practice for Sampling of Plastics

1.5 When evaluating material in accordance with this speci- D 3417 Test Method for Enthalpies of Fusion and Crystal-

fication, hazardous materials, operations, and equipment may lization of Polymers by Differential Scanning Calorimetry

3

be involved. This standard does not purport to address all of (DSC)

the safety concerns, if any, associated with its use. It is the D 3418 Test Method for Transition Temperatures of Poly-

responsibility of the user of this standard to establish appro- mers By Differential Scanning Calorimetry

priate safety and health practices and determine the applica- D 4000 Classification System for Specifying Plastic Mate-

bility of regulatory limitations prior to use. rials

1 2

This specification is under the jurisdiction of ASTM Committee F04 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Medical and Surgical Materials and Devices and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee F04.11 on Polymeric Materials. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Feb. 1, 2007. Published February 2007. Originally the ASTM website.

3

approved in 2000. Last previous edition approved in 2002 as F 2026 – 02. Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

F2026–07

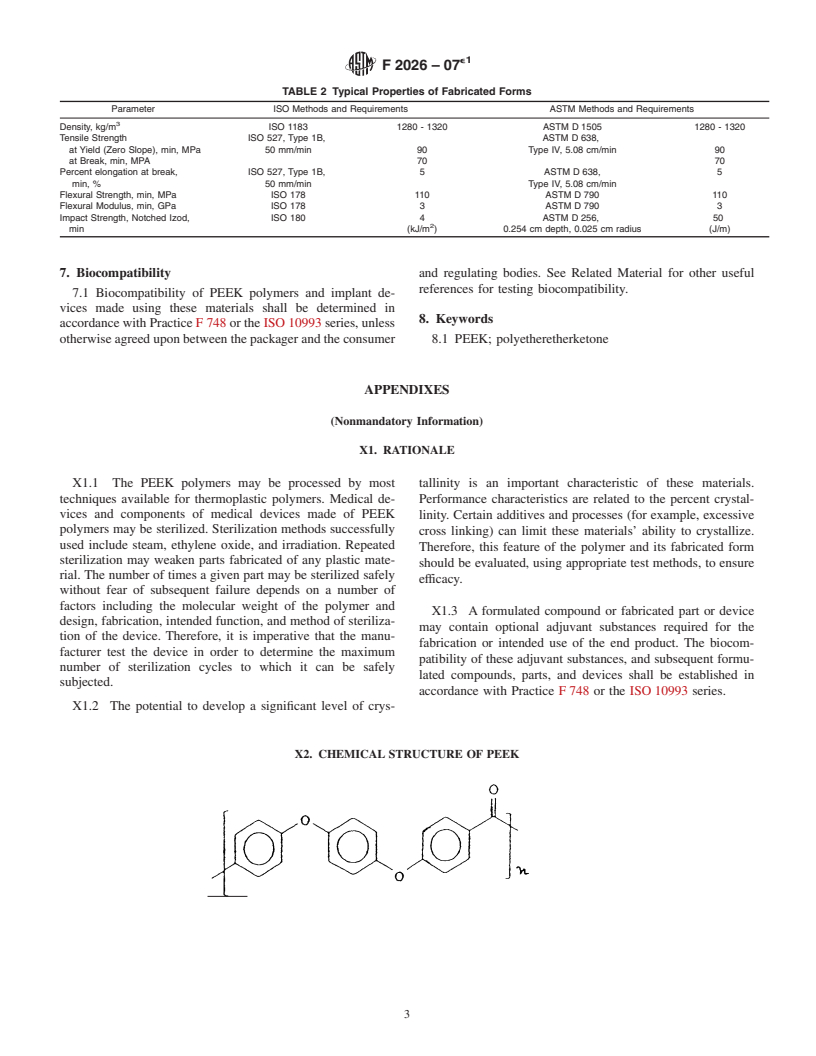

F 748 Practice for Selecting Generic Biological Test Meth- rings connected by ether (E) and carbonyl (or k

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.