ASTM C794-01

(Test Method)Standard Test Method for Adhesion-in-Peel of Elastomeric Joint Sealants

Standard Test Method for Adhesion-in-Peel of Elastomeric Joint Sealants

SCOPE

1.1 This test method covers a laboratory procedure for determining the strength and characteristics of the peel properties of a cured-in-place elastomeric joint sealant, single- or multicomponent, for use in building construction.

1.2 The values stated in metric (SI) units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation:C794–01

Standard Test Method for

1

Adhesion-in-Peel of Elastomeric Joint Sealants

This standard is issued under the fixed designation C 794; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

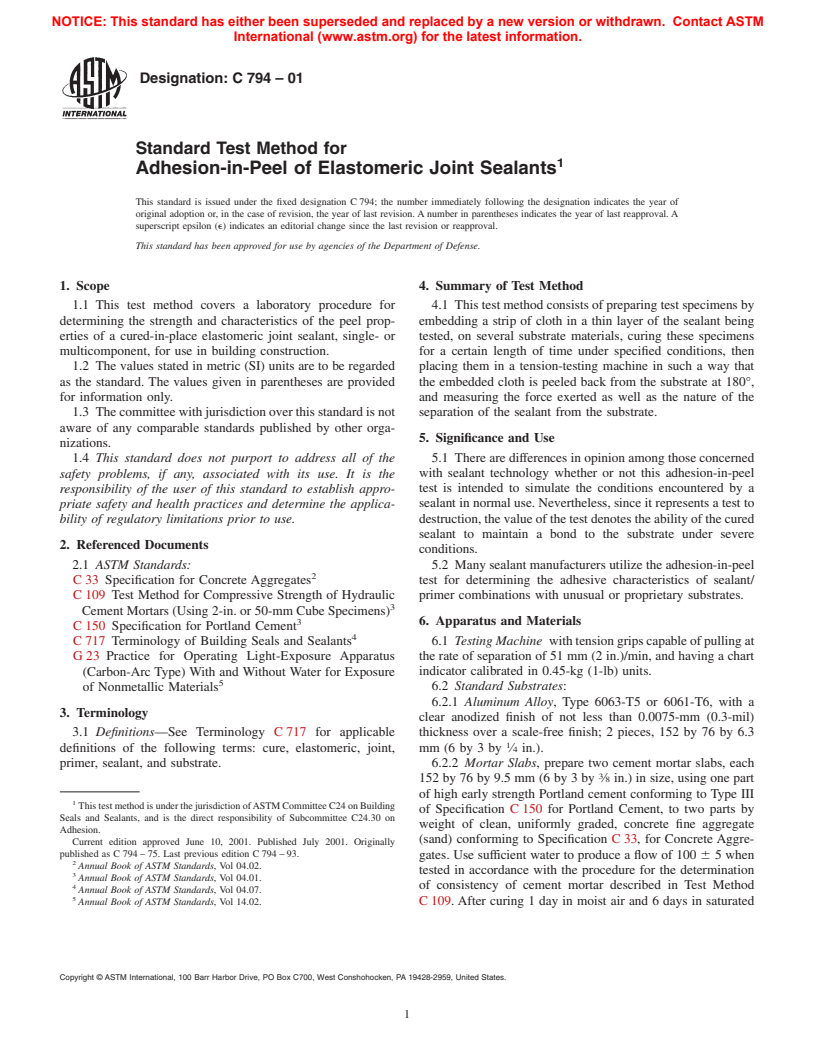

1. Scope 4. Summary of Test Method

1.1 This test method covers a laboratory procedure for 4.1 This test method consists of preparing test specimens by

determining the strength and characteristics of the peel prop- embedding a strip of cloth in a thin layer of the sealant being

erties of a cured-in-place elastomeric joint sealant, single- or tested, on several substrate materials, curing these specimens

multicomponent, for use in building construction. for a certain length of time under specified conditions, then

1.2 The values stated in metric (SI) units are to be regarded placing them in a tension-testing machine in such a way that

as the standard. The values given in parentheses are provided the embedded cloth is peeled back from the substrate at 180°,

for information only. and measuring the force exerted as well as the nature of the

1.3 Thecommitteewithjurisdictionoverthisstandardisnot separation of the sealant from the substrate.

aware of any comparable standards published by other orga-

5. Significance and Use

nizations.

1.4 This standard does not purport to address all of the 5.1 There are differences in opinion among those concerned

with sealant technology whether or not this adhesion-in-peel

safety problems, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- test is intended to simulate the conditions encountered by a

sealant in normal use. Nevertheless, since it represents a test to

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. destruction,thevalueofthetestdenotestheabilityofthecured

sealant to maintain a bond to the substrate under severe

2. Referenced Documents

conditions.

2.1 ASTM Standards: 5.2 Many sealant manufacturers utilize the adhesion-in-peel

2

C33 Specification for Concrete Aggregates test for determining the adhesive characteristics of sealant/

C 109 Test Method for Compressive Strength of Hydraulic primer combinations with unusual or proprietary substrates.

3

Cement Mortars (Using 2-in. or 50-mm Cube Specimens)

3 6. Apparatus and Materials

C 150 Specification for Portland Cement

4

C 717 Terminology of Building Seals and Sealants 6.1 Testing Machine withtensiongripscapableofpullingat

the rate of separation of 51 mm (2 in.)/min, and having a chart

G23 Practice for Operating Light-Exposure Apparatus

(Carbon-Arc Type) With and Without Water for Exposure indicator calibrated in 0.45-kg (1-lb) units.

5

6.2 Standard Substrates:

of Nonmetallic Materials

6.2.1 Aluminum Alloy, Type 6063-T5 or 6061-T6, with a

3. Terminology

clear anodized finish of not less than 0.0075-mm (0.3-mil)

3.1 Definitions—See Terminology C 717 for applicable thickness over a scale-free finish; 2 pieces, 152 by 76 by 6.3

1

definitions of the following terms: cure, elastomeric, joint, mm (6 by 3 by ⁄4 in.).

primer, sealant, and substrate. 6.2.2 Mortar Slabs, prepare two cement mortar slabs, each

3

152 by 76 by 9.5 mm (6 by 3 by ⁄8 in.) in size, using one part

of high early strength Portland cement conforming to Type III

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC24onBuilding

of Specification C 150 for Portland Cement, to two parts by

Seals and Sealants, and is the direct responsibility of Subcommittee C24.30 on

weight of clean, uniformly graded, concrete fine aggregate

Adhesion.

(sand) conforming to SpecificationC33, for Concrete Aggre-

Current edition approved June 10, 2001. Published July 2001. Originally

published as C 794 – 75. Last previous edition C 794 – 93.

gates. Use sufficient water to produce a flow of 100 6 5 when

2

Annual Book of ASTM Standards, Vol 04.02.

tested in accordance with the procedure for the determination

3

Annual Book of ASTM Standards, Vol 04.01.

4 of consistency of cement mortar described in Test Method

Annual Book of ASTM Standards, Vol 04.07.

5

Annual Book of ASTM Standards, Vol 14.02. C 109. After curing 1 day in moist air and 6 days in saturated

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

C794–0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.