ASTM C266-08

(Test Method)Standard Test Method for Time of Setting of Hydraulic-Cement Paste by Gillmore Needles

Standard Test Method for Time of Setting of Hydraulic-Cement Paste by Gillmore Needles

SIGNIFICANCE AND USE

The purpose of this test method is to establish whether a cement complies with a specification limit on Gillmore time of setting.

SCOPE

1.1 This test method covers the determination of the time of setting of hydraulic-cement paste by means of the Gillmore needles.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Warning: Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure. The use of gloves, protective clothing, and eye protection is recommended. Wash contact area with copious amounts of water after contact. Wash eyes for a minimum of 15 min. Avoid exposure of the body to clothing saturated with the liquid phase of the unhardened material. Remove contaminated clothing immediately after exposure.

1.4 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C266–08

Standard Test Method for

Time of Setting of Hydraulic-Cement Paste by Gillmore

1

Needles

This standard is issued under the fixed designation C266; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* C219 Terminology Relating to Hydraulic Cement

C305 Practice for Mechanical Mixing of Hydraulic Cement

1.1 This test method covers the determination of the time of

Pastes and Mortars of Plastic Consistency

setting of hydraulic-cement paste by means of the Gillmore

C511 Specification for Mixing Rooms, Moist Cabinets,

needles.

Moist Rooms, and Water Storage Tanks Used in the

1.2 The values stated in inch-pound units are to be regarded

Testing of Hydraulic Cements and Concretes

as standard. The values given in parentheses are mathematical

C670 Practice for Preparing Precision and Bias Statements

conversions to SI units that are provided for information only

for Test Methods for Construction Materials

and are not considered standard.

C1005 Specification for Reference Masses and Devices for

1.3 This standard does not purport to address all of the

Determining Mass and Volume for Use in the Physical

safety concerns, if any, associated with its use. It is the

Testing of Hydraulic Cements

responsibility of the user of this standard to establish appro-

D1193 Specification for Reagent Water

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3. Terminology

Warning: Fresh hydraulic cementitious mixtures are caustic

3.1 Refer to Terminology C219 for definitions of terms.

and may cause chemical burns to skin and tissue upon

prolonged exposure. The use of gloves, protective clothing,

4. Summary of Test Method

and eye protection is recommended. Wash contact area with

4.1 Sufficient water is added to the cement that is being

copious amounts of water after contact. Wash eyes for a

tested to produce a paste of normal consistency.Aspecimen is

minimum of 15 min. Avoid exposure of the body to clothing

molded from this paste and is tested for time of setting by

saturated with the liquid phase of the unhardened material.

means of the Gillmore initial and final needles.The initial time

Remove contaminated clothing immediately after exposure.

of setting is the time elapsed between initial contact of cement

1.4 The text of this standard references notes and footnotes

and water and the time when the Gillmore Initial needle does

which provide explanatory material. These notes and footnotes

not leave a complete circular impression in the paste surface.

(excluding those in tables and figures) shall not be considered

The final time of setting is the time elapsed between initial

as requirements of the standard.

contact of cement and water and the time when the Gillmore

Final needle does not leave a complete circular impression in

2. Referenced Documents

2 the paste surface.

2.1 ASTM Standards:

C151 Test Method for Autoclave Expansion of Hydraulic

5. Significance and Use

Cement

5.1 The purpose of this test method is to establish whether

C183 Practice for Sampling and the Amount of Testing of

a cement complies with a specification limit on Gillmore time

Hydraulic Cement

of setting.

C187 Test Method for Normal Consistency of Hydraulic

Cement

6. Apparatus

6.1 Flat Trowel, having a sharpened straight-edged steel

1

This test method is under the jurisdiction ofASTM Committee C01 on Cement

blade 100 to 150 mm in length. The edges when placed on a

and is the direct responsibility of Subcommittee C01.30 on Time of Set

plane surface shall not depart from straightness by more than 1

CurrenteditionapprovedJune1,2008.PublishedJuly2008.Originallyapproved

mm.

in 1951. Last previous edition approved in 2007 as C266 – 07. DOI: 10.1520/

C0266-08.

6.2 Mixer, Bowl, Paddle, and Scraper, conforming to the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

requirements of Practice C305.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.3 Glass Graduates, 200 or 250 mL capacity, conforming

Standards volume information, refer to the standard’s Document Summary page on

to the requirements of Specification C1005.

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C266–08

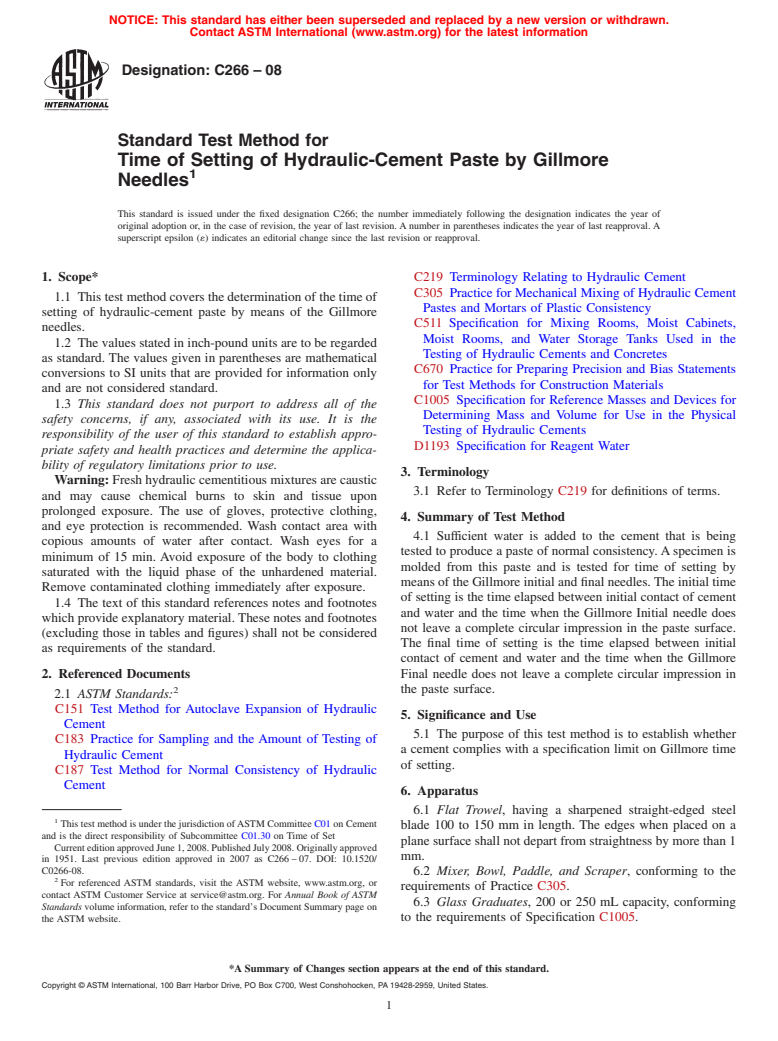

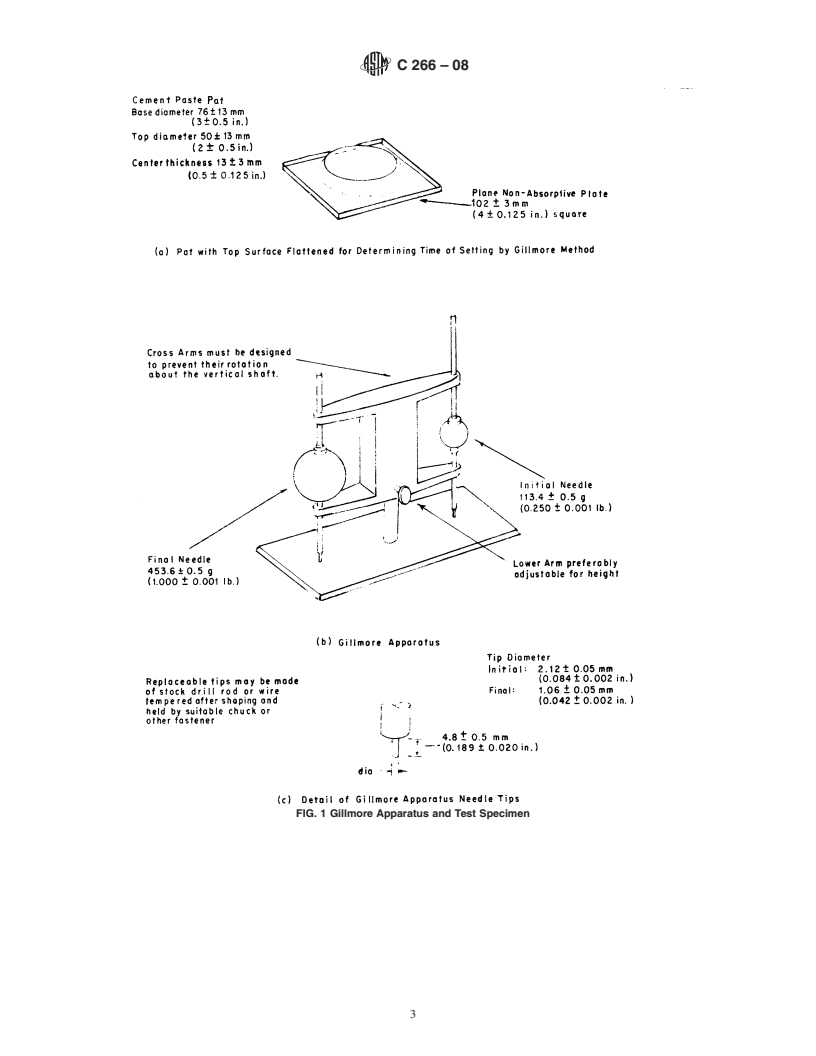

6.4 Mass Determining Devices, conforming to the require- sides tapering to a thin edge on a plane non-absorptive plate,

ments of Specification C1005. The devices for det

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C266–07 Designation:C266–08

Standard Test Method for

Time of Setting of Hydraulic-Cement Paste by Gillmore

1

Needles

This standard is issued under the fixed designation C 266; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 Thistestmethodcoversthedeterminationofthetimeofsettingofhydraulic-cementpastebymeansoftheGillmoreneedles.

1.2The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

Warning: Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged

exposure. The use of gloves, protective clothing, and eye protection is recommended. Wash contact area with copious amounts of

water after contact. Wash eyes for a minimum of 15 min. Avoid exposure of the body to clothing saturated with the liquid phase

of the unhardened material. Remove contaminated clothing immediately after exposure.

1.4 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of the standard.

2. Referenced Documents

2

2.1 ASTM Standards:

C 151 Test Method for Autoclave Expansion of Hydraulic Cement

C 183 Practice for Sampling and the Amount of Testing of Hydraulic Cement

C 187 Test Method for Normal Consistency of Hydraulic Cement

C 219 Terminology Relating to Hydraulic Cement

C 305 Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency

C 511 Specification for Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in the Testing of

Hydraulic Cements and Concretes

C 670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

C 1005 Specification for Reference Masses and Devices for Determining Mass and Volume for Use in the Physical Testing of

Hydraulic Cements

D 1193 Specification for Reagent Water

3. Terminology

3.1 Refer to Terminology C 219 for definitions of terms.

4. Summary of Test Method

4.1Sufficient water is added to the cement that is being tested to produce a paste of normal consistency. A specimen is molded

from this paste and is tested for time of setting by means of the Gillmore initial and final needles. The initial time of setting is the

time required for the test specimen to bear the initial Gillmore needle without appreciable indentation, while the time required for

the test specimen to bear the final Gillmore needle without appreciable indentation is the final time of setting.

4.1 Sufficient water is added to the cement that is being tested to produce a paste of normal consistency.Aspecimen is molded

from this paste and is tested for time of setting by means of the Gillmore initial and final needles. The initial time of setting is the

1

This test method is under the jurisdiction of ASTM Committee C01 on Cement and is the direct responsibility of Subcommittee C01.30 on Time of Set

Current edition approved July 15, 2007. Published August 2007. Originally approved in 1951. Last previous edition approved in 2004 as C266–04.

Current edition approved June 1, 2008. Published July 2008. Originally approved in 1951. Last previous edition approved in 2007 as C 266 – 07.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For AnnualBookofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C266–08

time elapsed between initial c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.