ASTM D1998-13

(Specification)Standard Specification for Polyethylene Upright Storage Tanks

Standard Specification for Polyethylene Upright Storage Tanks

ABSTRACT

This specification covers flat-bottom, upright, cylindrical tanks molded in one-piece seamless construction by rotational molding. The tanks are molded from polyethylene for above ground, vertical installation and are capable of containing aggressive chemicals at atmospheric pressure. This specification does not cover the design of vessels intended for use at pressures other than atmospheric pressure. Furthermore, this specification does not cover the design of portable tanks and is not for vessels intended for use with liquids heated above their flash points in continuous service. Special design considerations not covered in this specification shall be given to vessels subject to superimposed mechanical forces, such as seismic forces, wind load or agitation; to vessels subject to service above specified temperature; and vessels subject to specified superimposed pressure of water. Low-temperature impact test shall be performed on rotational-molded polyethylene tanks. The test method is used on tanks molded from both the crosslinked and non-crosslinked polyethylenes. Dart drop impact test shall be performed to determine the quality of the tank. O-xylene-insoluble fraction or gel test shall be performed on crosslinked polyethylene. Visual inspection and water test shall also be performed on the samples.

SCOPE

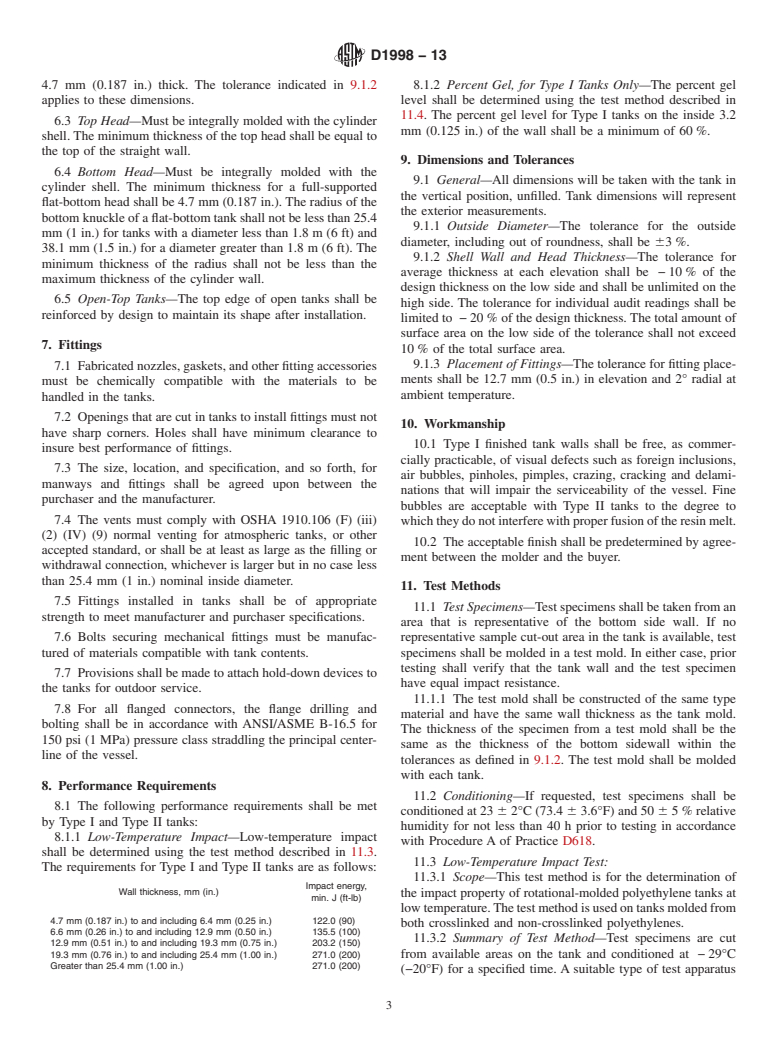

1.1 This specification covers flat-bottom, upright, cylindrical tanks molded in one-piece seamless construction by rotational molding. The tanks are molded from polyethylene for above ground, vertical installation and are capable of containing aggressive chemicals at atmospheric pressure. Included are requirements for materials, properties, design, construction, dimensions, tolerances, workmanship and appearance. Tank capacities are from 1900 L (500 gal) up.

1.2 This specification does not cover the design of vessels intended for use at pressures other than atmospheric pressure. Furthermore, this specification does not cover the design of portable tanks. It is also not for vessels intended for use with liquids heated above their flash points, or temperatures above 66°C (150°F) for Type I tanks and 60°C (140°F) for Type II tanks for continuous service. NFPA Standards 30 and 31 shall be consulted for installations that are subject to the requirements of these standards.

1.3 Special design considerations not covered in this specification shall be given to vessels subject to superimposed mechanical forces, such as seismic forces, wind load or agitation; to vessels subject to service temperature in excess of 23°C (73.4°F); and vessels subject to superimposed pressure exceeding 25.4 cm (10 in.) of water or 2.5 × 10−3 MPa (0.36 psi).

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. Note 1—ISO 13341:2005+A1:2011 and ISO 13575:2012 are similar, but not equivalent to this standard.

1.5 The following precautionary caveat pertains only to the test methods portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1998 −13

StandardSpecification for

1

Polyethylene Upright Storage Tanks

This standard is issued under the fixed designation D1998; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

1.1 This specification covers flat-bottom, upright, cylindri-

tions prior to use.

cal tanks molded in one-piece seamless construction by rota-

tional molding. The tanks are molded from polyethylene for

2. Referenced Documents

above ground, vertical installation and are capable of contain-

2

2.1 ASTM Standards:

ingaggressivechemicalsatatmosphericpressure.Includedare

D618Practice for Conditioning Plastics for Testing

requirements for materials, properties, design, construction,

D883Terminology Relating to Plastics

dimensions, tolerances, workmanship and appearance. Tank

D1693Test Method for Environmental Stress-Cracking of

capacities are from 1900 L (500 gal) up.

Ethylene Plastics

1.2 This specification does not cover the design of vessels D2837Test Method for Obtaining Hydrostatic Design Basis

intended for use at pressures other than atmospheric pressure.

forThermoplasticPipeMaterialsorPressureDesignBasis

Furthermore, this specification does not cover the design of for Thermoplastic Pipe Products

portable tanks. It is also not for vessels intended for use with

D3892Practice for Packaging/Packing of Plastics

liquids heated above their flash points, or temperatures above D4703Practice for Compression Molding Thermoplastic

66°C (150°F) for Type I tanks and 60°C (140°F) for Type II Materials into Test Specimens, Plaques, or Sheets

tanks for continuous service. NFPA Standards 30 and 31 shall E691Practice for Conducting an Interlaboratory Study to

be consulted for installations that are subject to the require- Determine the Precision of a Test Method

ments of these standards. F412Terminology Relating to Plastic Piping Systems

2.2 OSHA Standard:

1.3 Special design considerations not covered in this speci-

29 CFR 1910.106 Occupational Safety and Health

fication shall be given to vessels subject to superimposed

3

Administration, Flammable and Combustible Liquids

mechanical forces, such as seismic forces, wind load or

2.3 ANSI Standard:

agitation; to vessels subject to service temperature in excess of

4

B-16.5Pipe Flanges and Flanged Fittings

23°C (73.4°F); and vessels subject to superimposed pressure

−3

2.4 NFPA Standards:

exceeding 25.4 cm (10 in.) of water or 2.5×10 MPa (0.36

5

30Flammable and Combustible Liquid Code

psi).

5

31Installation of Oil Burning Equipment

1.4 The values stated in SI units are to be regarded as the

6

2.5 ISO Standards:

standard. The values given in parentheses are for information

ISO 13341:2005+A1:2011Static Thermoplastic Tanks for

only.

theAboveGroundStorageofChemicals–BlowMoulded

NOTE 1—ISO 13341:2005+A1:2011 and ISO 13575:2012 are similar, or Rotationally Moulded Polyethylene Tanks – Require-

but not equivalent to this standard.

ments and Test Methods

1.5 The following precautionary caveat pertains only to the

test methods portion, Section 11, of this specification: This

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

standard does not purport to address all of the safety concerns,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

if any, associated with its use. It is the responsibility of the user

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3

Available from Occupational Safety and Health Administration (OSHA), 200

Constitution Ave., NW, Washington, DC 20210.

1 4

This specification is under the jurisdiction of ASTM Committee D20 on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Plastics and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, 4th Floor, New York, NY 10036.

5

and Molded Products (Section D20.15.01). Available from National Fire Protection Association (NFPA), 1 Batterymarch

Current edition approved Oct. 1, 2013. Published October 2013. Originally Park, Quincy, MA 02269-9101.

6

approved in 1991. Last previous edition approved in 2006 as D1998-06. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/D1998-13. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1998 − 06 D1998 − 13

Standard Specification for

1

Polyethylene Upright Storage Tanks

This standard is issued under the fixed designation D1998; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

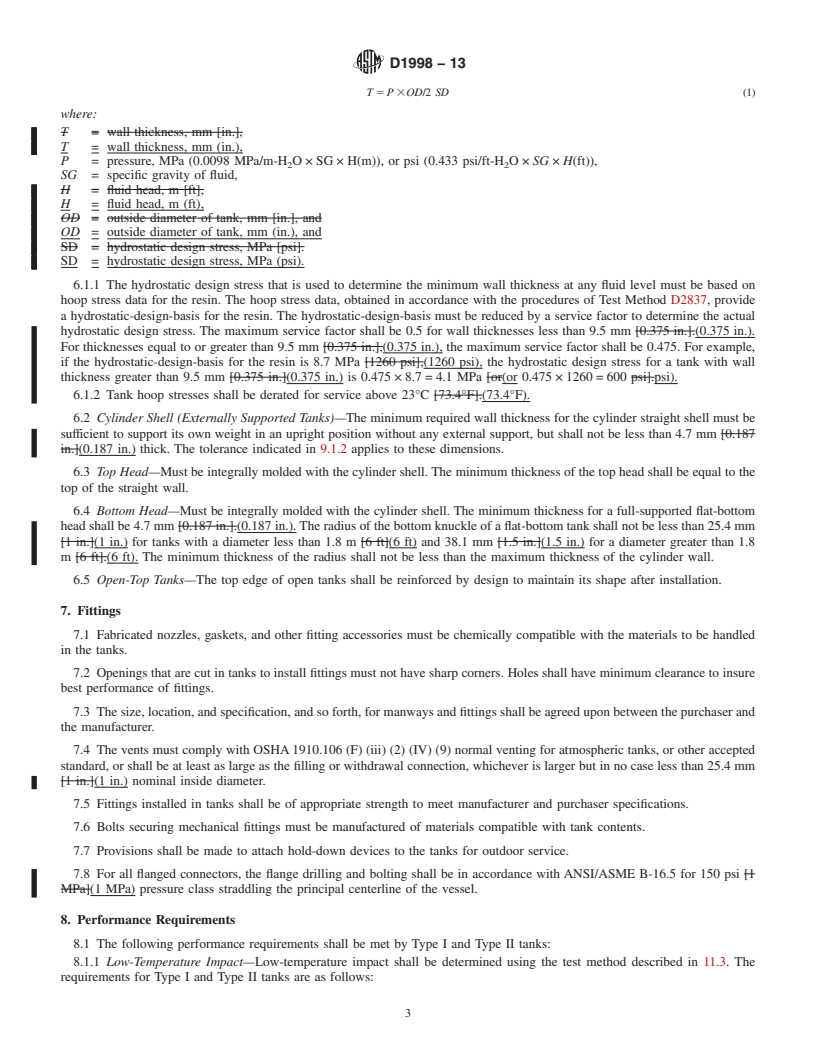

1. Scope*

1.1 This specification covers flat-bottom, upright, cylindrical tanks molded in one-piece seamless construction by rotational

molding. The tanks are molded from polyethylene for above ground, vertical installation and are capable of containing aggressive

chemicals at atmospheric pressure. Included are requirements for materials, properties, design, construction, dimensions,

tolerances, workmanship and appearance. Tank capacities are from 1900 L [500 gal](500 gal) up.

1.2 This specification does not cover the design of vessels intended for use at pressures other than atmospheric pressure.

Furthermore, this specification does not cover the design of portable tanks. It is also not for vessels intended for use with liquids

heated above their flash points, or temperatures above 66°C [150°F](150°F) for Type I tanks and 60°C [140°F](140°F) for Type

II tanks for continuous service. NFPA Standards 30 and 31 shall be consulted for installations that are subject to the requirements

of these standards.

1.3 Special design considerations not covered in this specification shall be given to vessels subject to superimposed mechanical

forces, such as seismic forces, wind load or agitation; to vessels subject to service temperature in excess of 23°C [73.4°F];(73.4°F);

−3

and vessels subject to superimposed pressure exceeding 25.4 cm [10 in.](10 in.) of water or 2.5 × 10 MPa [0.36 psi].(0.36 psi).

1.4 The values stated in SI units are to be regarded as the standard. The values given in bracketsparentheses are for information

only.

NOTE 1—There is no similar or equivalent ISO ISO 13341:2005+A1:2011 and ISO 13575:2012 are similar, but not equivalent to this standard.

1.5 The following precautionary caveat pertains only to the test methods portion, Section 11, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D883 Terminology Relating to Plastics

D1693 Test Method for Environmental Stress-Cracking of Ethylene Plastics

D2837 Test Method for Obtaining Hydrostatic Design Basis for Thermoplastic Pipe Materials or Pressure Design Basis for

Thermoplastic Pipe Products

D3892 Practice for Packaging/Packing of Plastics

D4703 Practice for Compression Molding Thermoplastic Materials into Test Specimens, Plaques, or Sheets

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

F412 Terminology Relating to Plastic Piping Systems

2.2 OSHA Standard:

3

29 CFR 1910.106 Occupational Safety and Health Administration, Flammable and Combustible Liquids

2.3 ANSI Standard:

4

B-16.5 Pipe Flanges and Flanged Fittings

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materials

(Section D20.15.01).

Current edition approved Sept. 1, 2006Oct. 1, 2013. Published October 2006October 2013. Originally approved in 1991. Last previous edition approved in 20042006 as

D1998 - 04.D1998 - 06. DOI: 10.1520/D1998-06.10.1520/D1998-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Occupational Safety and Health Administration (OSHA), 200 Constitution Ave., NW, Washington, DC 20210.

4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1998 − 13

2.4 NFPA Standards:

5

30 Flammable and Combust

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.