ASTM D2238-22

(Test Method)Standard Test Methods for Absorbance of Polyethylene Due to Methyl Groups at 1378 cm−1

Standard Test Methods for Absorbance of Polyethylene Due to Methyl Groups at 1378 cm<sup>−1</sup>

SIGNIFICANCE AND USE

4.1 When interpreted with the aid of appropriate calibration data, either test method is acceptable for use to compare the total methyl contents of polyethylenes made by similar processes. Data on infrared absorption at certain other wavelengths is potentially useful for information on certain other wavelengths (7).

Note 4: The bias of determination of the concentration of total alkyl groups depends on knowing the concentrations of methyl and ethyl branches present, since these branches have anomalously high absorptivities per group at 1378 cm−1 (7.25 μm).

4.2 Knowledge of total methyl groups in polyethylene, when combined with data on molecular weight and on reactive end groups such as vinyl, is potentially useful so as to lead to assignment of end-group structures and to shed light upon polymerization mechanisms.

4.3 Qualitative correlations are possible between data on total methyl groups in polyethylene with certain polymer properties such as melting point, density, stiffness, and other mechanical properties that are closely dependent on the degree of crystallinity of the polymer.

4.4 These test methods are especially suitable for research. They have not been tested for use in manufacturing control.

SCOPE

1.1 These test methods cover measurement by infrared absorption spectrophotometry of the 1378 cm−1 (7.25 μm) band in polyethylene due to methyl groups. (1, 2, 3-6)2 Two test methods are covered:

1.1.1 Test Method A uses compensation with a standard sample film of known methyl content.

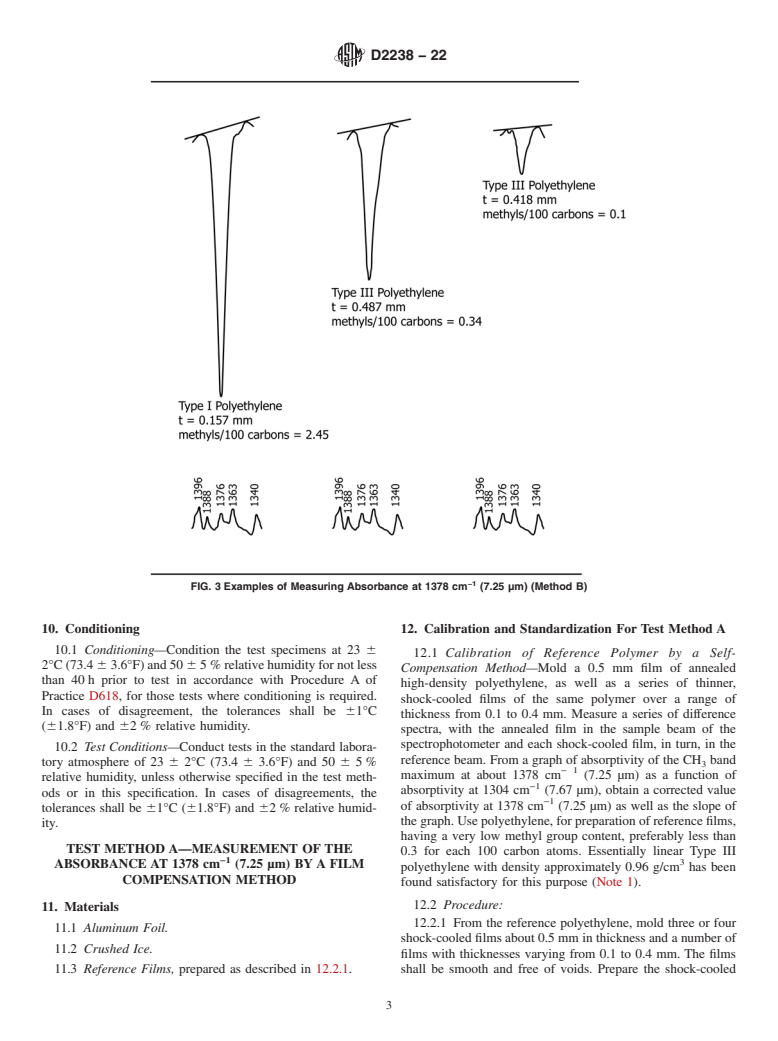

1.1.2 Test Method B uses compensation with a wedge of polymethylene or a polyethylene of known low methyl content.

1.2 These test methods are applicable to polyethylenes of Types I (density 0.910 to 0.925 g/cm3), II (density 0.926 to 0.940 g/cm3), and III (density 0.941 to 0.965 g/cm3).

Note 1: For determination of density, see Specifications D1505.

Note 2: In cases of Type III polyethylene with densities greater than 0.950 g/cm3, different results are obtained with the two test methods.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific hazards statements are given in Section 7.

Note 3: There is no known ISO equivalent to this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2238 − 22

Standard Test Methods for

1

Absorbance of Polyethylene Due to Methyl Groups at 1378

−1

cm

This standard is issued under the fixed designation D2238; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

3

2.1 ASTM Standards:

1.1 These test methods cover measurement by infrared

−1

absorptionspectrophotometryofthe1378cm (7.25µm)band D618Practice for Conditioning Plastics for Testing

2

D883Terminology Relating to Plastics

in polyethylene due to methyl groups. (1, 2, 3-6) Two test

methods are covered: D1505Test Method for Density of Plastics by the Density-

Gradient Technique

1.1.1 Test Method A uses compensation with a standard

E131Terminology Relating to Molecular Spectroscopy

sample film of known methyl content.

E168Practices for General Techniques of Infrared Quanti-

1.1.2 Test Method B uses compensation with a wedge of

tative Analysis

polymethyleneorapolyethyleneofknownlowmethylcontent.

E177Practice for Use of the Terms Precision and Bias in

1.2 These test methods are applicable to polyethylenes of

ASTM Test Methods

3

Types I (density 0.910 to 0.925 g/cm ), II (density 0.926 to

IEEE/ASTM SI-10Standard for Use of the International

3 3

0.940 g/cm ), and III (density 0.941 to 0.965 g/cm ).

System of Units (SI): The Modern Metric System

NOTE 1—For determination of density, see Specifications D1505.

NOTE 2—In cases of Type III polyethylene with densities greater than

3. Terminology

3

0.950 g/cm , different results are obtained with the two test methods.

3.1 For definitions of terms used in these test methods and

1.3 The values stated in SI units are to be regarded as the

associated with plastics issues refer to the terminology con-

standard. The values given in parentheses are for information

tained in Terminology D883.

only.

3.2 Units, symbols, and abbreviations used in this test

1.4 This standard does not purport to address all of the

method appear in Terminology E131 or Practice IEEE/ASTM

safety concerns, if any, associated with its use. It is the

SI-10.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

4. Significance and Use

mine the applicability of regulatory limitations prior to use.

4.1 When interpreted with the aid of appropriate calibration

Specific hazards statements are given in Section 7.

data, either test method is acceptable for use to compare the

NOTE 3—There is no known ISO equivalent to this standard.

total methyl contents of polyethylenes made by similar pro-

1.5 This international standard was developed in accor- cesses. Data on infrared absorption at certain other wave-

dance with internationally recognized principles on standard- lengths is potentially useful for information on certain other

ization established in the Decision on Principles for the wavelengths (7).

Development of International Standards, Guides and Recom-

NOTE 4—The bias of determination of the concentration of total alkyl

mendations issued by the World Trade Organization Technical

groups depends on knowing the concentrations of methyl and ethyl

Barriers to Trade (TBT) Committee.

branches present, since these branches have anomalously high absorptivi-

−1

ties per group at 1378 cm (7.25 µm).

4.2 Knowledge of total methyl groups in polyethylene,

1 whencombinedwithdataonmolecularweightandonreactive

These test methods are under the jurisdiction of ASTM Committee D20 on

Plastics and are the direct responsibility of Subcommittee D20.70 on Analytical end groups such as vinyl, is potentially useful so as to lead to

Methods (Section D20.70.08).

Current edition approved Sept. 1, 2022. Published September 2022. Originally

ɛ1

approved in 1964. Last previous edition approved in 2012 as D2238-92 (2012) ,

3

which was withdrawn January 2021 and reinstated in September 2022. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/D2238-22. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof Standards volume information, refer to the standard’s Document Summary page on

these test methods. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2238 − 22

assignment of end-group structures and to shed ligh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.