ASTM D5617-99e1

(Test Method)Standard Test Method for Multi-Axial Tension Test for Geosynthetics

Standard Test Method for Multi-Axial Tension Test for Geosynthetics

SCOPE

1.1 This test method covers the measurement of the out-of-plane response of geosynthetics to a force that is applied perpendicular to the initial plane of the sample.

1.2 When the geosynthetic deforms to a prescribed geometric shape (segmented sphere or elliptic) formulations are provided to convert the test data to biaxial tensile stress-strain values. These formulations cannot be used for other geometric shapes. With other geometric shapes, comparative data on deformation versus pressure is obtained.

1.3 This test method is more commonly used to test geomembranes. Permeable materials may also be tested in conjunction with an impermeable material.

1.4 This test method requires a large diameter pressure vessel (greater than 450 mm). Information obtained from this test method may be more appropriate for design purposes than many small scale index tests such as Test Method D638 or Test Method D751 (Bursting Strength).

1.5 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

e1

Designation: D 5617 – 99

Standard Test Method for

1

Multi-Axial Tension Test for Geosynthetics

This standard is issued under the fixed designation D 5617; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—This test method was corrected editorially in April 2000.

1. Scope 3. Terminology

1.1 This test method covers the measurement of the out-of- 3.1 Definitions:

plane response of geosynthetics to a force that is applied 3.1.1 geosynthetic, n—a planar product manufactured from

perpendicular to the initial plane of the sample. polymeric material used with soil, rock, earth, or other geo-

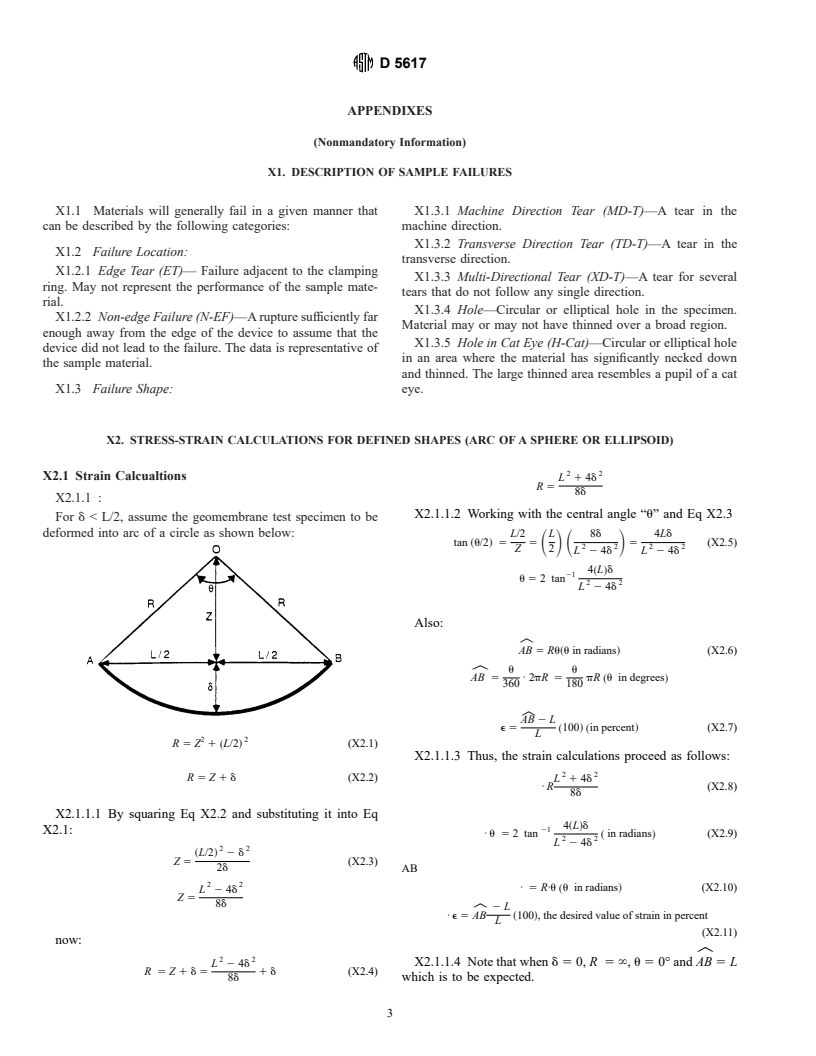

1.2 When the geosynthetic deforms to a prescribed geomet- technical engineering related material as an integral part of a

ric shape (arc of a sphere or ellipsoid) formulations are man-made project, structure, or system.

provided to convert the test data to biaxial tensile stress-strain 3.1.2 multi-axial tension, n—stress in more than one direc-

values. These formulations cannot be used for other geometric tion.

shapes. With other geometric shapes, comparative data on 3.1.3 For definitions of other terms used in this test method,

deformation versus pressure is obtained. refer to Terminology D 4439.

1.3 This test method is more commonly used to test

4. Summary of Test Method

geomembranes. Permeable materials may also be tested in

4.1 A pre-cut geosynthetic sample is secured at the edges of

conjunction with an impermeable material.

1.4 This test method requires a large diameter pressure a large diameter (600 mm) pressure vessel. Pressure is applied

to the sample to cause out-of-plane deformation and failure.

vessel (600 mm). Information obtained from this test method

may be more appropriate for design purposes than many small This deformation with pressure information can then be

analyzed to evaluate various materials.

scale index tests such as Test Method D 638 or Test Method

D 751 (Bursting Strength).

5. Significance and Use

1.5 The values stated in SI units are to be regarded as the

5.1 Installed geosynthetics are subjected to forces from

standard. The inch-pound units given in parentheses are for

more than one direction including forces perpendicular to the

information only.

surfaces of the geosynthetic. Out of plane deformation of a

1.6 This standard does not purport to address all of the

geosynthetic may be useful in evaluating materials for caps

safety concerns, if any, associated with its use. It is the

where subsidence of the subsoil may be problematic.

responsibility of the user of this standard to establish appro-

5.2 Failure mechanisms on this test may be different com-

priate safety and health practices and determine the applica-

pared to other relatively small scale index tests and may be

bility of regulatory limitations prior to use.

beneficial for design purposes.

2. Referenced Documents

5.3 In applications where local subsidence is expected, this

test can be considered a performance test.

2.1 ASTM Standards:

2

D 638 Test Method for Tensile Properties of Plastics

NOTE 1—Although, this test specifies a vessel size of 600 mm, larger

3

D 751 Test Methods for Coated Fabrics

diameter vessels will better approximate field performance. However, the

4

D 4439 Terminology for Geotextiles

user is cautioned that different size vessels may yield different results and

hence may not be comparable.

5.4 For applications where geosynthetics cannot be de-

formed in the fashion this test method prescribes, this test

method should be considered an index test.

1

This test method is under the jurisdiction of ASTM Committee D-35 on

5.5 Due to the time involved to perform this test method, it

Geosynthetics and is the direct responsibility of Subcommittee D35.10 on Geomem-

branes.

is not considered practical as a quality control test.

Current edition approved Jan. 10, 1999. Published May 1999. Originally

published as D5617–94. Last previous edition D5617–94.

6. Apparatus

2

Annual Book of ASTM Standards, Vol 08.01.

3

6.1 Fig. 1 shows an example of the test apparatus that can be

Annual Book of ASTM Standards, Vol 09.02.

4

Annual Book of ASTM Standards, Vol 04.09.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 5617

7.3.2 Test results on permeable materials will be affected by

the impermeable material used in the test.

7.4 Test three replicate specimens on each sample unless

otherwise noted.

8. Procedure

8.1 Cut the test specimen to the requirements of the test

vessel to ensure a good seal. Place specimen across the opening

of the vessel. Be sure the specimen is not sagging.

8.2 Be sure the specimen remains flat while the edge of the

specimen is being securely clamped into place.

8.3 Eith

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.