ASTM D1913-00(2023)

(Test Method)Standard Test Method for Resistance to Wetting of Garment-Type Leathers (Spray Test)

Standard Test Method for Resistance to Wetting of Garment-Type Leathers<brk/> (Spray Test)

SIGNIFICANCE AND USE

3.1 The procedure is intended primarily to evaluate garment-type leathers. The test method is qualitative and measures the surface-water repellency or surface-water resistance only. It is not intended for use in determining resistance to water penetration. A visual means is given to evaluate the relative effects of materials showing water repellency, but no comparison is possible with conditions found in actual use.

SCOPE

1.1 This test method covers the qualitative evaluation of the surface repellency to water of garment-type leathers. This test method does not apply to wet blue.

1.2 The values stated in inch-pound units are to be regarded as standard. The values shown in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1913 − 00 (Reapproved 2023)

Standard Test Method for

Resistance to Wetting of Garment-Type Leathers

(Spray Test)

This standard is issued under the fixed designation D1913; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Apparatus

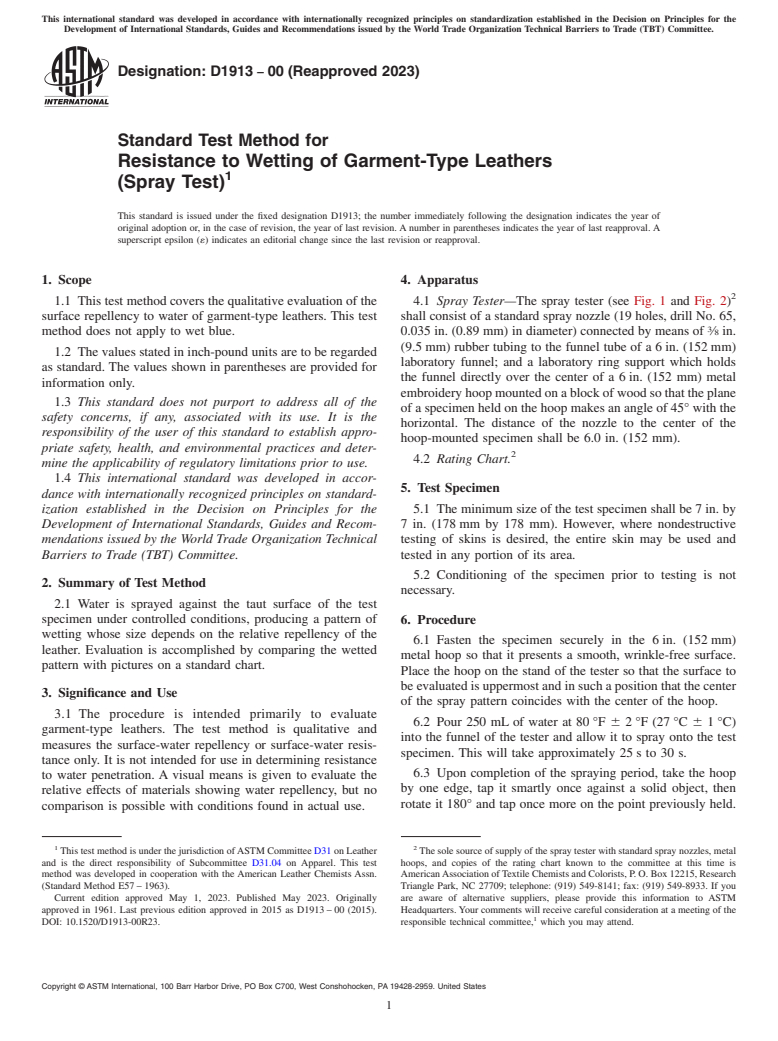

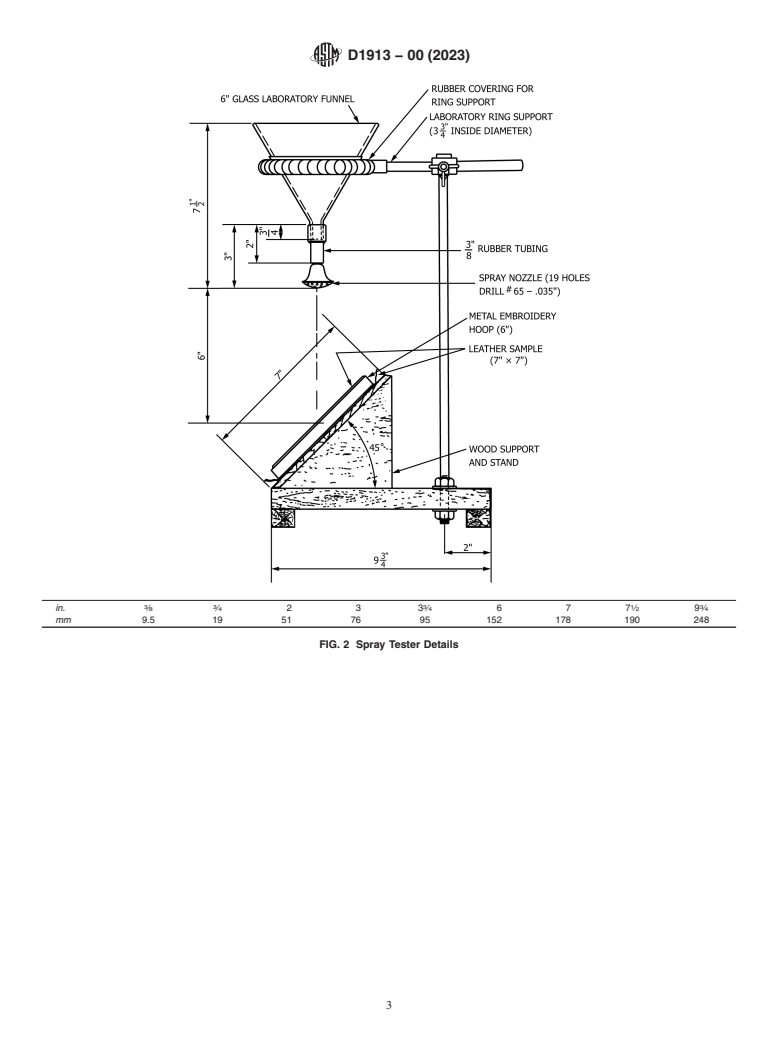

1.1 This test method covers the qualitative evaluation of the 4.1 Spray Tester—The spray tester (see Fig. 1 and Fig. 2)

surface repellency to water of garment-type leathers. This test shall consist of a standard spray nozzle (19 holes, drill No. 65,

method does not apply to wet blue. 0.035 in. (0.89 mm) in diameter) connected by means of ⁄8 in.

(9.5 mm) rubber tubing to the funnel tube of a 6 in. (152 mm)

1.2 The values stated in inch-pound units are to be regarded

laboratory funnel; and a laboratory ring support which holds

as standard. The values shown in parentheses are provided for

the funnel directly over the center of a 6 in. (152 mm) metal

information only.

embroidery hoop mounted on a block of wood so that the plane

1.3 This standard does not purport to address all of the

of a specimen held on the hoop makes an angle of 45° with the

safety concerns, if any, associated with its use. It is the

horizontal. The distance of the nozzle to the center of the

responsibility of the user of this standard to establish appro-

hoop-mounted specimen shall be 6.0 in. (152 mm).

priate safety, health, and environmental practices and deter-

4.2 Rating Chart.

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

5. Test Specimen

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 5.1 The minimum size of the test specimen shall be 7 in. by

Development of International Standards, Guides and Recom- 7 in. (178 mm by 178 mm). However, where nondestructive

testing of skins is desired, the entire skin may be used and

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. tested in any portion of its area.

5.2 Conditioning of the specimen prior to testing is not

2. Summary of Test Method

necessary.

2.1 Water is sprayed against the taut surface of the test

specimen under controlled conditions, producing a pattern of

6. Procedure

wetting whose size depends on the relative repellency of the

6.1 Fasten the specimen securely in the 6 in. (152 mm)

leather. Evaluation is accomplished by comparing the wetted

metal hoop so that it presents a smooth, wrinkle-free surface.

pattern with pictures on a standard chart.

Place the hoop on the stand of the tester so that the surface to

be evaluated is uppermost and in such a position that the center

3. Significance and Use

of the spray pattern coincides with the center of the hoop.

3.1 The procedure is intended primarily to evaluate

6.2 Pour 250 mL of water at 80 °F 6 2 °F (27 °C 6 1 °C)

garment-type leathers. The test method is qualitative and

into the funnel of the tester and allow it to spray onto the test

measures the surface-water repellency or surface-water resis-

specimen. This will take approximately 25 s to 30 s.

tance only. It is not intended for use in determining resistance

6.3 Upon completion of the spraying period, take the hoop

to water penetration. A visual means is given to evaluate the

by one edge, tap it smartly once a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.