ASTM C1063-14d

(Specification)Standard Specification for Installation of Lathing and Furring to Receive Interior and Exterior Portland Cement-Based Plaster

Standard Specification for Installation of Lathing and Furring to Receive Interior and Exterior Portland Cement-Based Plaster

ABSTRACT

This specification covers the installation of lathing and furring to receive interior and exterior Portland cement-based plaster. The following materials shall be used: metal plaster bases—expanded metal lath and wire laths; accessories—steel, PVC plastic, zinc alloy, and cornerite; channels—external corner reinforcement and foundation weep screed; wire; rod and strap hangers; clips; fasteners—nails and screws. Hangers and cold-rolled channel main runner shall conform to the allowable spacing and spans, respectively. The following methods are discussed: installation of hangers for suspended ceilings under wood constructions, attachment of hangers to main runners, installation of main runners, installation of cross furring, metal furring for walls, lapping of metal plaster bases, spacing of attachments for metal plaster bases, application of metal plaster bases, and application of accessories.

SCOPE

1.1 This specification covers the minimum requirements for lathing and furring for the application of exterior and interior portland cement-based plaster, as in Specifications C841 or C926.

1.2 Where a fire resistance rating is required for plastered assemblies and constructions, details of construction shall be in accordance with reports of fire tests of assemblies that have met the requirements of the fire rating imposed.

1.3 Where a specific degree of sound control is required for plastered assemblies and constructions, details of construction shall be in accordance with official reports of tests conducted in recognized testing laboratories in accordance with the applicable requirements of Test Method E90.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1063 −14d

StandardSpecification for

Installation of Lathing and Furring to Receive Interior and

Exterior Portland Cement-Based Plaster

This standard is issued under the fixed designation C1063; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* C11 Terminology Relating to Gypsum and Related Building

Materials and Systems

1.1 This specification covers the minimum requirements for

C841 Specification for Installation of Interior Lathing and

lathing and furring for the application of exterior and interior

Furring

portland cement-based plaster, as in Specifications C841 or

C847 Specification for Metal Lath

C926.

C926 Specification for Application of Portland Cement-

1.2 Where a fire resistance rating is required for plastered

Based Plaster

assembliesandconstructions,detailsofconstructionshallbein

C933 Specification for Welded Wire Lath

accordance with reports of fire tests of assemblies that have

C954 SpecificationforSteelDrillScrewsfortheApplication

met the requirements of the fire rating imposed.

of Gypsum Panel Products or Metal Plaster Bases to Steel

1.3 Where a specific degree of sound control is required for Studs from 0.033 in. (0.84 mm) to 0.112 in. (2.84 mm) in

Thickness

plastered assemblies and constructions, details of construction

shallbeinaccordancewithofficialreportsoftestsconductedin C1002 Specification for Steel Self-Piercing Tapping Screws

for Application of Gypsum Panel Products or Metal

recognized testing laboratories in accordance with the appli-

cable requirements of Test Method E90. Plaster Bases to Wood Studs or Steel Studs

C1032 Specification for Woven Wire Plaster Base

1.4 The values stated in inch-pound units are to be regarded

D1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

as standard. The values given in parentheses are mathematical

Compounds and Chlorinated Poly(Vinyl Chloride)

conversions to SI units that are provided for information only

(CPVC) Compounds

and are not considered standard.

D4216 Specification for Rigid Poly(Vinyl Chloride) (PVC)

and Related PVC and Chlorinated Poly(Vinyl Chloride)

2. Referenced Documents

(CPVC) Building Products Compounds

2.1 ASTM Standards:

E90 Test Method for Laboratory Measurement of Airborne

A641/A641M Specification for Zinc–Coated (Galvanized)

Sound Transmission Loss of Building Partitions and

Carbon Steel Wire

Elements

A653/A653M Specification for Steel Sheet, Zinc-Coated

(Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed)

3. Terminology

by the Hot-Dip Process

3.1 Definitions—For definitions relating to ceilings and

B69 Specification for Rolled Zinc

walls, see Terminology C11.

B221 Specification forAluminum andAluminum-Alloy Ex-

truded Bars, Rods, Wire, Profiles, and Tubes 3.2 Definitions of Terms Specific to This Standard:

3.2.1 barrier wall, n—typeofwallsystemthatisintendedto

block or interrupt the movement of water to the interior.

This specification is under the jurisdiction of ASTM Committee C11 on

3.2.2 building enclosure, n—system of building assemblies

Gypsum and Related Building Materials and Systems and is the direct responsibility

and materials designed and installed in such a manner as to

ofSubcommitteeC11.03onSpecificationsfortheApplicationofGypsumandOther

provide a barrier between different environments.

Products in Assemblies.

Current edition approved Aug. 15, 2014. Published November 2014. Originally

3.2.3 control joint, n—a joint that accommodates movement

approved in 1986. Last previous edition approved in 2014 as C1063 – 14c. DOI:

of plaster shrinkage and curing along predetermined, usually

10.1520/C1063-14D.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

straight, lines.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.4 drainage plane, n—surface between the back of the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. cladding and the front of the water barrier which resists liquid

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1063−14d

moisture infiltration and provides for gravitational flow to a

collection or exhaust location.

3.2.5 drainage space, n—volumetric area that allows the

gravitational flow of liquid moisture to a collection or exhaust

location.

3.2.6 drainage wall, n—a wall system in which the cladding

providesasubstantialbarriertowaterintrusion,andwhichalso

incorporates a concealed water resistive barrier over which

drainage will occur.

3.2.7 expansion joint, n—a joint that accommodates move-

ment beyond plaster shrinkage and curing.

NOTE 1—For design consideration of control and expansion joints, see

FIG. 2Saddle Tie

Annex A2.3.1.2 of Specification C926.

3.2.8 framing member, n—studs, joist, runners (track),

bridging, bracing, and related accessories manufactured or

5. Storage of Materials

supplied in wood or light gauge steel.

5.1 All materials shall be kept dry. Materials shall be

3.2.9 hangers, n—wires or steel rods or straps used to

stacked off the ground, supported on a level platform, and

support main runners for suspended ceilings beneath floor or

protected from the weather and surface contamination.

roof constructions.

5.2 Materials shall be neatly stacked with care taken to

3.2.10 inserts, n—devices embedded in concrete structural

avoid damage to edges, ends, or surfaces.

members to provide a loop or opening for attachment of

hangers. 5.3 Paper backed metal plaster bases shall be handled

carefully in delivery, storage, and erection to prevent punctur-

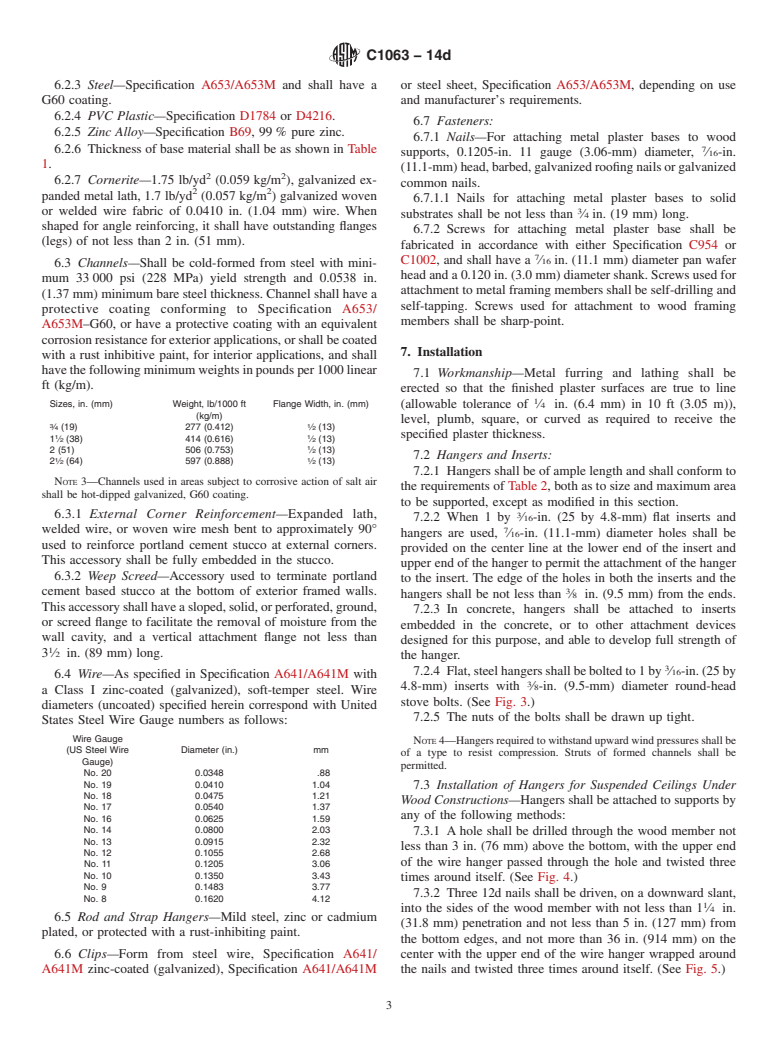

3.2.11 saddle tie, n—see Figs. 1 and 2.

ing or removal of paper.

3.2.12 self-furring, adj—a metal plaster base manufactured

with evenly-spaced indentations that hold the body of the lath

6. Materials

approximately ⁄4 in. (6.4 mm) away from solid surfaces to

6.1 Metal Plaster Bases:

which it is applied.

6.1.1 Expanded Metal Lath—Specification C847, galva-

3.2.13 water resistive barrier, n—a material that resists the

nized.

infiltration of liquid moisture through the building enclosure

6.1.2 Wire Laths:

system.

6.1.2.1 Welded Wire Lath—Specification C933.

3.2.14 water barrier system, n—a combination of water 6.1.2.2 Woven Wire Lath—Specification C1032.

barrier assemblies that prevent the infiltration of liquid mois-

6.1.2.3 Paper Backed Plaster Bases—Specification C847.

ture through the building enclosure system, and facilitates its

6.2 Accessories:

gravitational flow to a collection or exhaust location.

6.2.1 General—All accessories shall have perforated or

expanded flanges or clips shaped to permit complete embed-

4. Delivery of Materials

ment in the plaster, to provide means for accurate alignment,

4.1 All materials shall be delivered in the original packages,

and to secure attachment of the accessory to the underlying

containers, or bundles bearing the brand-name and manufac-

surface.Accessories shall be designed to receive application of

turer’s (or supplier’s) identification.

the specified plaster thickness.

6.2.2 Accessories shall be fabricated from ZincAlloy (99 %

pure zinc), galvanized (zinc-coated) steel, rigid PVC or CPVC

plastic, or anodized aluminum alloy (see Specification B221).

(See Table 1 for minimum allowable thicknesses.)

NOTE 2—The selection of an appropriate type of material for accesso-

ries shall be determined by applicable surrounding climatic and environ-

mental conditions specific to the project location, such as salt air,

industrial pollution, high moisture, or humidity.

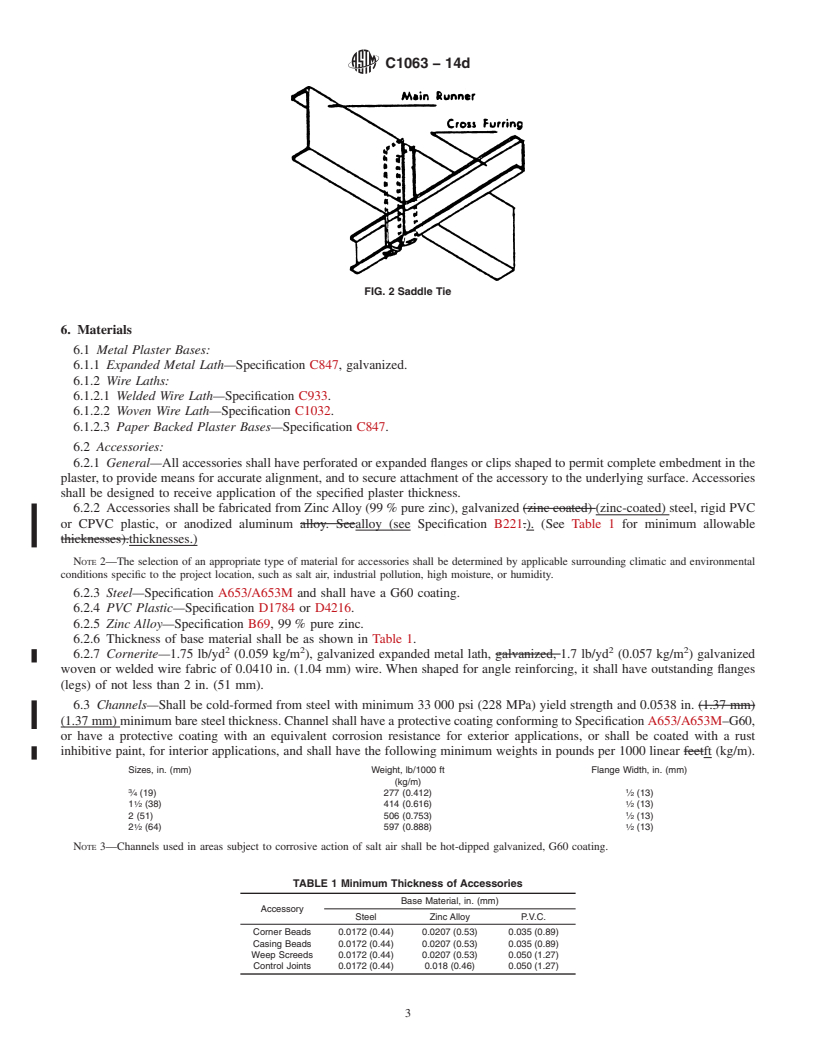

TABLE 1 Minimum Thickness of Accessories

Base Material, in. (mm)

Accessory

Steel Zinc Alloy P.V.C.

Corner Beads 0.0172 (0.44) 0.0207 (0.53) 0.035 (0.89)

Casing Beads 0.0172 (0.44) 0.0207 (0.53) 0.035 (0.89)

Weep Screeds 0.0172 (0.44) 0.0207 (0.53) 0.050 (1.27)

Control Joints 0.0172 (0.44) 0.018 (0.46) 0.050 (1.27)

FIG. 1Saddle Tie

C1063−14d

6.2.3 Steel—Specification A653/A653M and shall have a or steel sheet, Specification A653/A653M, depending on use

G60 coating. and manufacturer’s requirements.

6.2.4 PVC Plastic—Specification D1784 or D4216.

6.7 Fasteners:

6.2.5 Zinc Alloy—Specification B69, 99 % pure zinc.

6.7.1 Nails—For attaching metal plaster bases to wood

6.2.6 Thickness of base material shall be as shown in Table 7

supports, 0.1205-in. 11 gauge (3.06-mm) diameter, ⁄16-in.

1.

(11.1-mm)head,barbed,galvanizedroofingnailsorgalvanized

2 2

6.2.7 Cornerite—1.75 lb/yd (0.059 kg/m ), galvanized ex-

common nails.

2 2

panded metal lath, 1.7 lb/yd (0.057 kg/m ) galvanized woven

6.7.1.1 Nails for attaching metal plaster bases to solid

or welded wire fabric of 0.0410 in. (1.04 mm) wire. When

substrates shall be not less than ⁄4 in. (19 mm) long.

shaped for angle reinforcing, it shall have outstanding flanges

6.7.2 Screws for attaching metal plaster base shall be

(legs) of not less than 2 in. (51 mm).

fabricated in accordance with either Specification C954 or

C1002, and shall have a ⁄16 in. (11.1 mm) diameter pan wafer

6.3 Channels—Shall be cold-formed from steel with mini-

head and a 0.120 in. (3.0 mm) diameter shank. Screws used for

mum 33 000 psi (228 MPa) yield strength and 0.0538 in.

attachment to metal framing members shall be self-drilling and

(1.37 mm) minimum bare steel thickness. Channel shall have a

self-tapping. Screws used for attachment to wood framing

protective coating conforming to Specification A653/

members shall be sharp-point.

A653M–G60, or have a protective coating with an equivalent

corrosionresistanceforexteriorapplications,orshallbecoated

7. Installation

with a rust inhibitive paint, for interior applications, and shall

havethefollowingminimumweightsinpoundsper1000linear

7.1 Workmanship—Metal furring and lathing shall be

ft (kg/m).

erected so that the finished plaster surfaces are true to line

Sizes, in. (mm) Weight, lb/1000 ft Flange Width, in. (mm)

(allowable tolerance of ⁄4 in. (6.4 mm) in 10 ft (3.05 m)),

(kg/m)

level, plumb, square, or curved as required to receive the

3 1

⁄4 (19) 277 (0.412) ⁄2 (13)

1 1 specified plaster thickness.

1 ⁄2 (38) 414 (0.616) ⁄2 (13)

2 (51) 506 (0.753) ⁄2 (13)

7.2 Hangers and Inserts:

1 1

2 ⁄2 (64) 597 (0.888) ⁄2 (13)

7.2.1 Hangers shall be of ample length and shall conform to

NOTE 3—Channels used in areas subject to corrosive action of salt air

the requirements of Table 2, both as to size and maximum area

shall be hot-dipped galvanized, G60 coating.

to be supported, except as modified in this section.

6.3.1 External Corner Reinforcement—Expanded lath, 3

7.2.2 When 1 by ⁄16-in. (25 by 4.8-mm) flat inserts and

welded wire, or woven wire mesh bent to approximately 90° 7

hangers are used, ⁄16-in. (11.1-mm) diameter holes shall be

used to reinforce portland cement stucco at external corners.

provided on the center line at the lower end of the insert and

This accessory shall be fully embedded in the stucco.

upper end of the hanger to permit the attachment of the hanger

6.3.2 Weep Screed—Accessory used to terminate portland

to the insert. The edge of the holes in both the inserts and the

cement based stucco at the bottom of exterior framed walls.

hangers shall be not less than ⁄8 in. (9.5 mm) from the ends.

Thisaccessoryshallhaveasloped,solid,orperforated,ground,

7.2.3 In concrete, hangers shall be attached to inserts

or screed flange to facilitate the removal of moisture from the

embedded in the concrete, or to other attachment devices

wall cavity, and a vertical attachment flange not less than

designed for this purpose, and able to develop full strength of

3 ⁄2 in. (89 mm) long.

the hanger.

7.2.4 Flat,steelhangersshallbeboltedto1by ⁄16-in.(25by

6.4 Wire—As specified in Specification A641/A641M with

4.8-mm) inserts with ⁄8-in. (9.5-mm) diameter round-head

a Class I zinc-coated (galvanized), soft-temper steel. Wire

stove bolts. (See Fig. 3.)

diameters (uncoated) specified herein correspond with United

7.2.5 The nuts of the bolts shall be drawn up tight.

States Steel Wire Gauge numbers as follows:

Wire Gauge

NOTE4—Hangersrequiredtowithstandupwardwindpressuresshallbe

(US Steel Wire Diameter (in.) mm

of a type to resist compression. Struts of formed channels shall be

Gauge)

permitted.

No. 20 0.0348 .88

No. 19 0.0410 1.04

7.3 Installation of Hangers for Suspended Ceilings Under

No. 18 0.0475 1.21

Wood Constructions—Hangers shall be attached to supports by

No. 17 0.0540 1.37

any of the following methods:

No. 16 0.0625 1.59

No. 14 0.0800 2.03

7.3.1 A hole shall be drilled through the wood member not

No. 13 0.0915 2.32

less than 3 in. (76 mm) above the bottom, with the upper end

No. 12 0.1055 2.68

of the wire hanger passed through the hole and twisted three

No. 11 0.1205 3.06

No. 10 0.1350 3.43

times around itself. (See Fig. 4.)

No. 9 0.1483 3.77

7.3.2 Three 12d nails shall be driven, on a downward slant,

No. 8 0.1620 4.12

into the sides of the wood member with not less than 1 ⁄4 in.

6.5 Rod and Strap Hangers—Mild steel, zinc or cadmium

(31.8 mm) penetration and not less than 5 in. (127 mm) from

plated, or protected with a rust-inhibiting paint.

the bottom edges, and not more than 36 in. (914 mm) on the

6.6 Clips—Form from steel wire, Specification A641/ center with the upper end of the wire hanger wrapped around

A641M zinc-coated (galvanized), Specification A641/A641M the nails and twisted three times around itself. (See Fig. 5.)

C1063−14d

1–10

TABLE 2 Allowable Support or Hanger Wire Spacing ft-in. (mm) and Cold-Rolled Channel Main Runner Spans, ft-in. (mm)

2 2

NOTE 1—1 in. = 25.4 mm; 1 ft = 0.093 m

Uniform Load = 12 psf (0.479 kPa)

Member Spacing, in. (mm)

Member Size, in. Member Weight,

9,10

Span Condition

(mm) lb/1000 ft (kg/m)

24 (610) 36 (914) 48 (1220) 60 (1520) 72 (1830)

Allowable Hanger Wire or Support Spacing, ft-in. (mm)

1 ⁄2 414 Single 3-6 (1070) 3-1 (940) 2-9 (840) 2-9 (790) 2-5 (740)

(38.1) (0.615) 2 or More 4-11 (1500) 4-2 (1270) 3-7 (1090) 3-2 (970) 2-11 (890)

2 506 Single 3-9 (1140) 3-3 (990) 3-0 (910) 2-9 (840) 2-8 (810)

(50.8) (0.753) 2 or More 5-2 (1570) 4-6 (1370) 4-1 (1240) 3-10 (1170) 3-7 (1090)

2 ⁄2 597 Single 3-11 (1190) 3-5 (1040) 3-2 (970) 2-11 (890) 2-9 (840)

(63.5) (0.888) 2 or More 5-5 (1650) 4-9 (1450) 4-4 (1320) 4.0 (1220) 3-10 (1170)

Uniform Load = 15 psf (0.287 kPa)

Member Size, in. Member Weight,

9,10

Span Condition Member Spacing, in. (mm)

(mm) lb/1000 ft (kg/m)

24 (610) 36 (914) 48 (1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1063 − 14c C1063 − 14d

Standard Specification for

Installation of Lathing and Furring to Receive Interior and

Exterior Portland Cement-Based Plaster

This standard is issued under the fixed designation C1063; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers the minimum requirements for lathing and furring for the application of exterior and interior

portland cement-based plaster, as in SpecificationSpecifications C926C841 or Specification C841C926.

1.2 Where a fire resistance rating is required for plastered assemblies and constructions, details of construction shall be in

accordance with reports of fire tests of assemblies that have met the requirements of the fire rating imposed.

1.3 Where a specific degree of sound control is required for plastered assemblies and constructions, details of construction shall

be in accordance with official reports of tests conducted in recognized testing laboratories in accordance with the applicable

requirements of Test Method E90.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2.1 ASTM Standards:

A641/A641M Specification for Zinc–Coated (Galvanized) Carbon Steel Wire

A653/A653M Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the

Hot-Dip Process

B69 Specification for Rolled Zinc

B221 Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

C11 Terminology Relating to Gypsum and Related Building Materials and Systems

C841 Specification for Installation of Interior Lathing and Furring

C847 Specification for Metal Lath

C926 Specification for Application of Portland Cement-Based Plaster

C933 Specification for Welded Wire Lath

C954 Specification for Steel Drill Screws for the Application of Gypsum Panel Products or Metal Plaster Bases to Steel Studs

from 0.033 in. (0.84 mm) to 0.112 in. (2.84 mm) in Thickness

C1002 Specification for Steel Self-Piercing Tapping Screws for Application of Gypsum Panel Products or Metal Plaster Bases

to Wood Studs or Steel Studs

C1032 Specification for Woven Wire Plaster Base

D1784 Specification for Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated Poly(Vinyl Chloride) (CPVC)

Compounds

D4216 Specification for Rigid Poly(Vinyl Chloride) (PVC) and Related PVC and Chlorinated Poly(Vinyl Chloride) (CPVC)

Building Products Compounds

E90 Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions and Elements

This specification is under the jurisdiction of ASTM Committee C11 on Gypsum and Related Building Materials and Systems and is the direct responsibility of

Subcommittee C11.03 on Specifications for the Application of Gypsum and Other Products in Assemblies.

Current edition approved June 1, 2014Aug. 15, 2014. Published July 2014November 2014. Originally approved in 1986. Last previous edition approved in 2014 as

C1063 – 14b.C1063 – 14c. DOI: 10.1520/C1063-14C.10.1520/C1063-14D.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1063 − 14d

3. Terminology

3.1 Definitions—For definitions relating to Ceilingsceilings and Walls,walls, see Terminology C11.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 barrier wall, n—type of wall system that is intended to block or interrupt the movement of water to the interior.

3.2.2 building enclosure, n—system of building assemblies and materials designed and installed in such a manner as to provide

a barrier between different environments.

3.2.3 control joint, n—a joint that accommodates movement of plaster shrinkage and curing along predetermined, usually

straight, lines.

3.2.4 drainage plane, n—surface between the back of the cladding and the front of the water barrier which resists liquid

moisture infiltration and provides for gravitational flow to a collection or exhaust location.

3.2.5 drainage space, n—volumetric area that allows the gravitational flow of liquid moisture to a collection or exhaust location.

3.2.6 drainage wall, n—a wall system in which the cladding provides a substantial barrier to water intrusion, and which also

incorporates a concealed water resistive barrier over which drainage will occur.

3.2.7 expansion joint, n—a joint that accommodates movement beyond plaster shrinkage and curing.

NOTE 1—For design consideration of control and expansion joints, see Annex A2.3.1.2 of Specification C926.

3.2.8 framing member, n—studs, joist, runners (track), bridging, bracing, and related accessories manufactured or supplied in

wood or light gauge steel.

3.2.9 hangers, n—wires or steel rods or straps used to support main runners for suspended ceilings beneath floor or roof

constructions.

3.2.10 inserts, n—devices embedded in concrete structural members to provide a loop or opening for attachment of hangers.

3.2.11 saddle tie, n—see Figs. 1 and 2.

3.2.12 self-furring, adj—a metal plaster base manufactured with evenly-spaced indentations that hold the body of the lath

approximately ⁄4 in. (6.4 mm) away from solid surfaces to which it is applied.

3.2.13 water resistive barrier, n—a material that resists the infiltration of liquid moisture through the building enclosure system.

3.2.14 water barrier system, n—a combination of water barrier assemblies that prevent the infiltration of liquid moisture through

the building enclosure system, and facilitates its gravitational flow to a collection or exhaust location.

4. Delivery of Materials

4.1 All materials shall be delivered in the original packages, containers, or bundles bearing the brand-name and manufacturer’s

(or supplier’s) identification.

5. Storage of Materials

5.1 All materials shall be kept dry. Materials shall be stacked off the ground, supported on a level platform, and protected from

the weather and surface contamination.

5.2 Materials shall be neatly stacked with care taken to avoid damage to edges, ends, or surfaces.

5.3 Paper backed metal plaster bases shall be handled carefully in delivery, storage, and erection to prevent puncturing or

removal of paper.

FIG. 1 Saddle Tie

C1063 − 14d

FIG. 2 Saddle Tie

6. Materials

6.1 Metal Plaster Bases:

6.1.1 Expanded Metal Lath—Specification C847, galvanized.

6.1.2 Wire Laths:

6.1.2.1 Welded Wire Lath—Specification C933.

6.1.2.2 Woven Wire Lath—Specification C1032.

6.1.2.3 Paper Backed Plaster Bases—Specification C847.

6.2 Accessories:

6.2.1 General—All accessories shall have perforated or expanded flanges or clips shaped to permit complete embedment in the

plaster, to provide means for accurate alignment, and to secure attachment of the accessory to the underlying surface. Accessories

shall be designed to receive application of the specified plaster thickness.

6.2.2 Accessories shall be fabricated from Zinc Alloy (99 % pure zinc), galvanized (zinc coated) (zinc-coated) steel, rigid PVC

or CPVC plastic, or anodized aluminum alloy. Seealloy (see Specification B221.). (See Table 1 for minimum allowable

thicknesses).thicknesses.)

NOTE 2—The selection of an appropriate type of material for accessories shall be determined by applicable surrounding climatic and environmental

conditions specific to the project location, such as salt air, industrial pollution, high moisture, or humidity.

6.2.3 Steel—Specification A653/A653M and shall have a G60 coating.

6.2.4 PVC Plastic—Specification D1784 or D4216.

6.2.5 Zinc Alloy—Specification B69, 99 % pure zinc.

6.2.6 Thickness of base material shall be as shown in Table 1.

2 2 2 2

6.2.7 Cornerite—1.75 lb/yd (0.059 kg/m ), galvanized expanded metal lath, galvanized, 1.7 lb/yd (0.057 kg/m ) galvanized

woven or welded wire fabric of 0.0410 in. (1.04 mm) wire. When shaped for angle reinforcing, it shall have outstanding flanges

(legs) of not less than 2 in. (51 mm).

6.3 Channels—Shall be cold-formed from steel with minimum 33 000 psi (228 MPa) yield strength and 0.0538 in. (1.37 mm)

(1.37 mm) minimum bare steel thickness. Channel shall have a protective coating conforming to Specification A653/A653M–G60,

or have a protective coating with an equivalent corrosion resistance for exterior applications, or shall be coated with a rust

inhibitive paint, for interior applications, and shall have the following minimum weights in pounds per 1000 linear feetft (kg/m).

Sizes, in. (mm) Weight, lb/1000 ft Flange Width, in. (mm)

(kg/m)

3 1

⁄4 (19) 277 (0.412) ⁄2 (13)

1 1

1 ⁄2 (38) 414 (0.616) ⁄2 (13)

2 (51) 506 (0.753) ⁄2 (13)

1 1

2 ⁄2 (64) 597 (0.888) ⁄2 (13)

NOTE 3—Channels used in areas subject to corrosive action of salt air shall be hot-dipped galvanized, G60 coating.

TABLE 1 Minimum Thickness of Accessories

Base Material, in. (mm)

Accessory

Steel Zinc Alloy P.V.C.

Corner Beads 0.0172 (0.44) 0.0207 (0.53) 0.035 (0.89)

Casing Beads 0.0172 (0.44) 0.0207 (0.53) 0.035 (0.89)

Weep Screeds 0.0172 (0.44) 0.0207 (0.53) 0.050 (1.27)

Control Joints 0.0172 (0.44) 0.018 (0.46) 0.050 (1.27)

C1063 − 14d

6.3.1 External Corner Reinforcement—Expanded lath, welded wire, or woven wire mesh bent to approximately 90° used to

reinforce portland cement stucco at external corners. This accessory shall be fully embedded in the stucco.

6.3.2 Weep Screed—Accessory used to terminate portland cement based stucco at the bottom of exterior framed walls. This

accessory shall have a sloped, solid, or perforated, ground, or screed flange to facilitate the removal of moisture from the wall

cavity, and a vertical attachment flange not less than 3 ⁄2 in. in. (89 mm) long.

6.4 Wire—As specified in Specification A641/A641M with a Class I zinc coated (galvanized), soft temper zinc-coated

(galvanized), soft-temper steel. Wire diameters (uncoated) specified herein correspond with United States Steel Wire Gauge

numbers as follows:

Wire Gauge Diameter (in.)

(US Steel Wire

Gauge) mm

Wire Gauge

(US Steel Wire Diameter (in.) mm

Gauge)

No. 20 0.0348 .88

No. 19 0.0410 1.04

No. 18 0.0475 1.21

No. 17 0.0540 1.37

No. 16 0.0625 1.59

No. 14 0.0800 2.03

No. 13 0.0915 2.32

No. 12 0.1055 2.68

No. 11 0.1205 3.06

No. 10 0.1350 3.43

No. 9 0.1483 3.77

No. 8 0.1620 4.12

6.5 Rod and Strap Hangers—Mild steel, zinc or cadmium plated, or protected with a rust-inhibiting paint.

6.6 Clips—Form from steel wire, Specification A641/A641M zinc-coated (galvanized), Specification A641/A641M or steel

sheet, Specification A653/A653M, depending on use and manufacturer’s requirements.

6.7 Fasteners:

6.7.1 Nails—For attaching metal plaster bases to wood supports, 0.1205-in. 11 gauge (3.06-mm) diameter, ⁄16-in. (11.1-mm)

head, barbed, galvanized roofing nails or galvanized common nails.

6.7.1.1 Nails for attaching metal plaster bases to solid substrates shall be not less than ⁄4 in. (19 mm) long.

6.7.2 Screws for attaching metal plaster base shall be fabricated in accordance with either Specification C954 or C1002, and

shall have a ⁄16 in. (11.1 mm) diameter pan wafer head and a 0.120 in. (3.0 mm) diameter shank. Screws used for attachment to

metal framing members shall be self-drilling and self-tapping. Screws used for attachment to wood framing members shall be

sharp-point.

7. Installation

7.1 Workmanship—Metal furring and lathing shall be erected so that the finished plaster surfaces are true to line (allowable

tolerance of ⁄4 in. (6.4 mm) in 10 ft (3.05 m)), level, plumb, square, or curved as required to receive the specified plaster thickness.

7.2 Hangers and Inserts:

7.2.1 Hangers shall be of ample length and shall conform to the requirements of Table 2, both as to size and maximum area

to be supported, except as modified in this section.

3 7

7.2.2 When 1 by ⁄16-in. (25 by 4.8-mm) flat inserts and hangers are used, ⁄16-in. (11.1-mm) diameter holes shall be provided

on the center line at the lower end of the insert and upper end of the hanger to permit the attachment of the hanger to the insert.

The edge of the holes in both the inserts and the hangers shall be not less than ⁄8 in. (9.5 mm) from the ends.

7.2.3 In concrete, hangers shall be attached to inserts embedded in the concrete, or to other attachment devices designed for this

purpose, and able to develop full strength of the hanger.

3 3

7.2.4 Flat, steel hangers shall be bolted to 1 by ⁄16-in. (25 by 4.8-mm) inserts with ⁄8-in. (9.5-mm) diameter round-head stove

bolts. (See Fig. 3.)

7.2.5 The nuts of the bolts shall be drawn up tight.

NOTE 4—Hangers required to withstand upward wind pressures shall be of a type to resist compression. Struts of formed channels shall be permitted.

NOTE 4—Hangers required to withstand upward wind pressures shall be of a type to resist compression. Struts of formed channels shall be permitted.

7.3 Installation of Hangers for Suspended Ceilings Under Wood Constructions—Hangers shall be attached to supports by any

of the following methods:

7.3.1 A hole shall be drilled through the wood member not less than 3 in. (76 mm) above the bottom, with the upper end of

the wire hanger passed through the hole and twisted three times around itself. See(See Fig. 4.)

7.3.2 Three 12d nails shall be driven, on a downward slant, into the sides of the wood member with not less than 1 ⁄4 in. (31.8

mm) penetration and not less than 5 in. (127 mm) from the bottom edges, and not more than 36 in. (914 mm) on the center with

the upper end of the wire hanger wrapped around the nails and twisted three times around itself. See(See Fig. 5.)

C1063 − 14d

1–10

TABLE 2 Allowable Support or Hanger Wire Spacing ft-in. (mm) and Cold-Rolled Channel Main Runner Spans, ft-in. (mm)

2 2

NOTE 1—1 in. =

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.