ASTM D3448-85(2005)

(Test Method)Standard Test Method for Specific Aqueous Conductance of Trichlorotrifluoroethane

Standard Test Method for Specific Aqueous Conductance of Trichlorotrifluoroethane

SIGNIFICANCE AND USE

This test method allows for the determination of ionizable contaminants (expressed in terms of ppb of HCl) in trichlorotrifluoroethane via measurement of specific aqueous conductance.

This test method can be used for establishing manufacturing and purchasing specifications.

SCOPE

1.1 This test method covers the determination of aqueous conductivity due to ionizable contaminants extracted from trichlorotrifluoroethane. The value of 1.9 S/cm as maximum specific aqueous conductance corresponds to 0.1 ppm of chloride ion (100 ppb). It was calculated by putting the solvent specification of 0.1 ppm chloride into the equation of the subject method to find C2 C1 equals 19.08. The specific conductance due to contaminants from the solvent was then calculated as follows:

(C2- C1)C 3 = (19) (0.1) = 1.9 μS/cm

1.2 The above is exclusive of the background specific conductance of the water used in the analysis.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3448 – 85 (Reapproved 2005)

Standard Test Method for

Specific Aqueous Conductance of Trichlorotrifluoroethane

This standard is issued under the fixed designation D3448; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4.2 Conductivity Cell, dip-type. Cell constant of 0.1 recip-

rocal centimetre. Electrodes must be bright platinum.

1.1 This test method covers the determination of aqueous

4.3 Polyethylene Beaker, 250-mL.

conductivity due to ionizable contaminants extracted from

4.4 Polyethylene Bottles, wide mouth, 300-mLand 500-mL

trichlorotrifluoroethane. The value of 1.9 µS/cm as maximum

size.

specific aqueous conductance corresponds to 0.1 ppm of

4.4.1 Calibrate and mark the outside of the 300-mL poly-

chlorideion(100ppb).Itwascalculatedbyputtingthesolvent

ethylene bottles to indicate 20, 120, and 220 mL(graduate) of

specification of 0.1 ppm chloride into the equation of the

water volume, using deionized water to determine the liquid

subject method to find C − C equals 19.08. The specific

2 1

levels.

conductance due to contaminants from the solvent was then

4.5 Polyethylene Tubing, long enough to reach the bottom

calculated as follows:

of the 300-mL polyethylene bottle.

~C 2 C !C 5 ~19! ~0.1! 51.9µS/cm (1)

2 1 3

5. Reagents

1.2 The above is exclusive of the background specific

conductance of the water used in the analysis.

5.1 Purity of Reagents—Reagent grade chemicals shall be

1.3 This standard does not purport to address all of the

used in all tests. Unless otherwise indicated, it is intended that

safety concerns, if any, associated with its use. It is the

all reagents shall conform to the specifications of the Commit-

responsibility of the user of this standard to consult and

tee onAnalytical Reagents of theAmerican Chemical Society,

establish appropriate safety and health practices and deter-

where such specifications are available. Other grades may be

mine the applicability of regulatory limitations prior to use.

used, provided it is first ascertained that the reagent is of

Specific precautionary statements are given in Section 6.

sufficiently high purity to permit its use without lessening the

accuracy of the determination.

2. Summary of Test Method

5.2 Alcoholic Hydrochloric Acid (0.01 N)—Dilute 5.0 mL

2.1 Ionizable impurities in the solvent are extracted with

(pipet)ofconcentratedhydrochloricacidto6Lwithdenatured

water of known low conductivity. The increase in water

2B ethyl alcohol.

conductivity measures the amount of these impurities present.

5.3 Alumina Gel.

5.4 Deionized Trichloromonofluoromethane, in 50-lb cylin-

3. Significance and Use

der. This deionized solvent may be selected pure material or it

3.1 This test method allows for the determination of ioniz-

may be purified by multiple passes through an alumina gel

able contaminants (expressed in terms of ppb of HCl) in

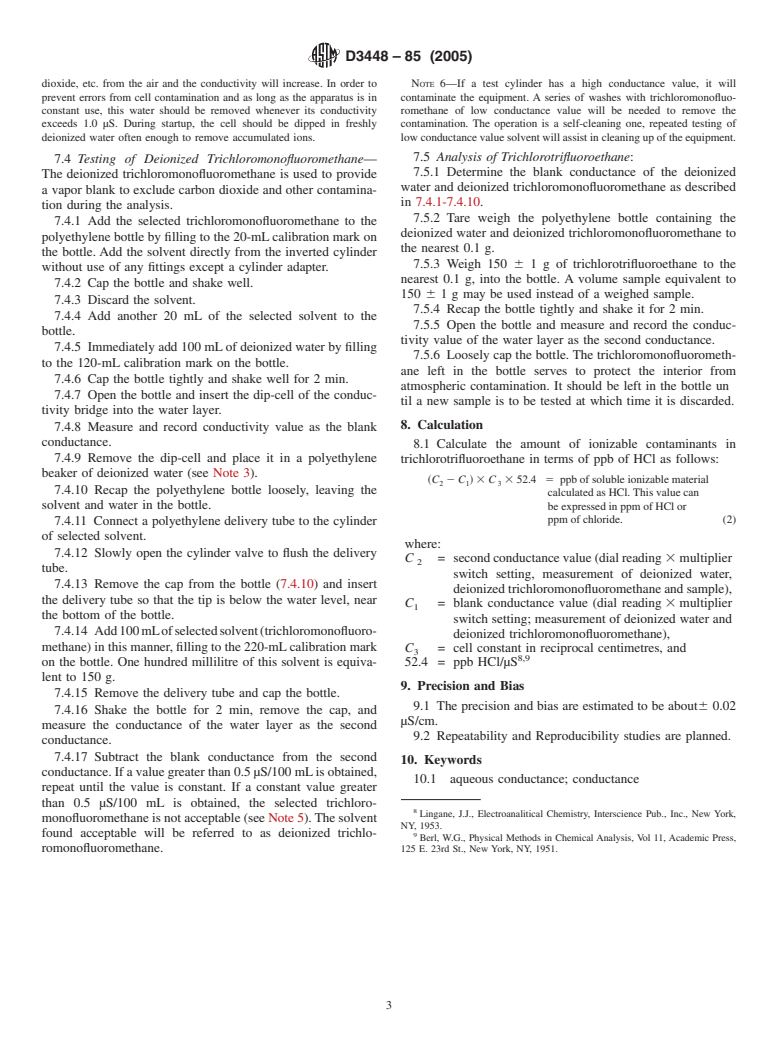

contactor(seeFig.1).Checktheacceptabilityofthisdeionized

trichlorotrifluoroethane via measurement of specific aqueous

solvent as described in 7.4.

conductance.

NOTE 1—The use of deionized trichloromonofluoromethane will serve

3.2 This test method can be used for establishing manufac-

as a check on the cleanliness. The deionized standard should be used as

turing and purchasing specifications.

4. Apparatus

ModelCel-A01hasbeenfoundsatisfactoryandcanbeobtainedfromIndustrial

4.1 Conductivity Bridge.

Instrument Inc., Cedar Grove, NJ. An equivalent may be used.

Catalog No. H-4040, Harshaw Scientific Co., Cleveland, OH, has been found

satisfactory. An equivalent may be used.

1 5

This test method is under the jurisdiction of ASTM Committee D26 on Reagent Chemicals, American Chemical Society Specifications, American

Halogenated Organic Solvents and Fire Extinguishing Agents and is the direct Chemical Society, Washington, DC. For suggestions on the testing of reagents not

responsibility of Subcommittee D26.04 on Test Methods. listed by the American Chemical Society, see Analar Standards for Laboratory

Current edition approved June 1, 2005. Published June 2005. Originally Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

approved in 1975. Last previous edition approved in 2000 as D3448–85(00). DOI: and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

10.1520/D3448-85R05. MD.

2 6

Serfass Model RCM-15B1 has been found satisfactory and can be obtained GradeF-3hasbeenfoundsatisfactoryandcanbeobtainedfromtheAluminum

from Industrial Instrument Inc., Cedar Grove, NJ. An equivalent may be used. Company of America.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3448 – 85 (2005)

6.3 Hydrochloric Acid—Take all precautions necessary to

avoid contact with the body internally and externally.The acid

is corrosive.

7. Procedure

7.1 The basis of this test method is the determination by

conductance of ions present in the test solution. Therefore,

cleanallequipmentcarefullytoremovealladsorbedionsinthe

measuring apparatus, otherwise, erroneously high values will

be obtained. Do the initial cleaning and the cleaning of

equipment in accordance with 7.2. All equipment must be

rinsed with deionized trichloromonofluoromethane before us-

ing in a test.

7.2 Deionizing of Equipment:

7.2.1 Polyethylene Bottles and Stainless Steel Cylinders:

7.2.1.1 Add about 30 g of ion exchange resin from an

exchange cylinder to the item to be cleaned. Use an exchange

cylinder as a source of resin for cleaning.

7.2.1.2 Adddeionizedwatertothecontaineruntilitisabout

two-thirds full.

7.2.1.3 Closethecontainerandrollforatleast24honaball

mill roller or its equivalent.

7.2.1.4 Discardtheion-exchangeresinandwater,rinsewith

deionized water and then with deionized trichloromono-

fluoromethane.

7.2.2 Polyethylene Delivery Tubes:

NOTE 3—Use of highly plasticized polyethylene tubing and bottles is

not recommended.

FIG. 1 Alumina Gel Contractor

7.2.2.1 Place the polyethylene delivery tubes in a 500-mL

polyethylene bottle.

required on a periodic basis when samples are being evaluated. Standards

7.2.2.2 Clean by following 7.2.1.1-7.2.1.4.

should be checked whenever high values are obtained or there is doubt of

7.2.3 Polyethylene Beakers, Dip-Cell, and Other Equip-

the results.

ment:

5.5 Deionized Water—Distilled water passed through two 7.2.3.1 Add about 30 g of ion-exchange resin to the beaker.

mixed resin ion exchangers connected in series and having a 7.2.3.2 Fill the beaker with deionized water.

conductance of no greater than 0.5 µS. Check the acceptability 7.2.3.3 Stir, shake, or transfer the mixture from one con-

tainer to another for at least 2 min.

of the deionized water in accordance with 7.3.

5.6 Ethyl Alcohol. 7.2.3.4 Discard the ion-exchange resin and deionized water

mixture.

NOTE 2—Specially denatured ethyl alcohol conforming to Formula

7.2.3.5 Rinse the equipment with deionized water and then

SD-2B of the U.S. Bureau of Internal Revenue may be substituted for

with deionized trichloromonofluoromethane before using in a

ethyl alcohol (95%).

test.

5.7 Hydrochloric Acid, concentrated.

7.3 Preparation of Deionized Water:

5.8 Ion-Exchange Cylinders.

7.3.1 Slowly pass distilled water through two mixed resin

ion exchangers, in series, immediately before use, into a clean

6. Safety Precautions

250-mL polyethylene beaker. (Note 4). Do not deionize water

6.1 Both trichlorotrifluoroethane and trichloromonofluoro-

and store, since it will adsorb carbon dioxide.

methane are not flammable and have threshold limit value’s of

NOTE 4—If the conductance of the water is greater than 0.5 µS, repeat

1000 ppm by volume in air. The respective boiling points of

the treatment and testing of the water until 0.5 µS or less is obtained,

thesesolventsareabout118and75°F(47.8and2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.