ASTM D3850-19

(Test Method)Standard Test Method for Rapid Thermal Degradation of Solid Electrical Insulating Materials By Thermogravimetric Method (TGA)

Standard Test Method for Rapid Thermal Degradation of Solid Electrical Insulating Materials By Thermogravimetric Method (TGA)

SIGNIFICANCE AND USE

5.1 Thermogravimetry is useful in determining the dynamic functional effect of temperature on the amount of volatile materials leaving a specimen as the latter is heated progressively to higher temperatures. TGA can be useful for process control, process development, material evaluation, and for identification and quality control in specifications.

5.2 The thermal stability of a material can be associated with the degree and time rate of mass loss as a function of temperature. TGA curves can, therefore, be used as a preliminary screen method in the evaluation of relative behavior of insulating materials of the same generic family.

5.3 The functional temperature-life relationship of an insulating material in any given application depends on a number of service and environmental factors. Therefore, the information obtained from TGA curves is not adequate by itself to describe the thermal capability of an insulating material.

5.4 Refer to the Appendix for further discussion of the interpretation of TGA data.

SCOPE

1.1 This test method outlines a procedure for obtaining thermogravimetric (TGA) data on solid polymeric materials intended for use as electrical insulating materials.

1.2 Do not use this standard to quantify an estimate of the long-term thermal capability for any electrical insulating material. If a relationship exists between TGA and the long-term thermal capabilities of a material, then that fact must be established and made public, preferably by comparing data between a candidate and another material known to display similar failure modes.

1.3 The values stated in SI units are the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3850 − 19

Standard Test Method for

Rapid Thermal Degradation of Solid Electrical Insulating

1

Materials By Thermogravimetric Method (TGA)

This standard is issued under the fixed designation D3850; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* D2307 Test Method for Thermal Endurance of Film-

Insulated Round Magnet Wire

1.1 This test method outlines a procedure for obtaining

E220Test Method for Calibration of Thermocouples By

thermogravimetric (TGA) data on solid polymeric materials

Comparison Techniques

intended for use as electrical insulating materials.

E473Terminology Relating to Thermal Analysis and Rhe-

1.2 Do not use this standard to quantify an estimate of the

ology

long-term thermal capability for any electrical insulating ma-

E1582Test Method forTemperature Calibration ofThermo-

terial. If a relationship exists between TGA and the long-term

gravimetric Analyzers

thermal capabilities of a material, then that fact must be

established and made public, preferably by comparing data

3. Terminology

between a candidate and another material known to display

3.1 Definitions—Definitions are in accordance with Termi-

similar failure modes.

nology D883, Terminology D1711, and Terminology E473.

1.3 The values stated in SI units are the standard.

3.2 Abbreviations—Abbreviations are in accordance with

1.4 This standard does not purport to address all of the

Terminology D1600, unless otherwise indicated.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety, health, and environmental practices and deter-

4.1 This thermogravimetric technique uses the record of the

mine the applicability of regulatory limitations prior to use.

mass loss versus the temperature of the specimen during the

1.5 This international standard was developed in accor-

time of exposure to a specified prescribed environment using a

dance with internationally recognized principles on standard-

controlled time rate of heating.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

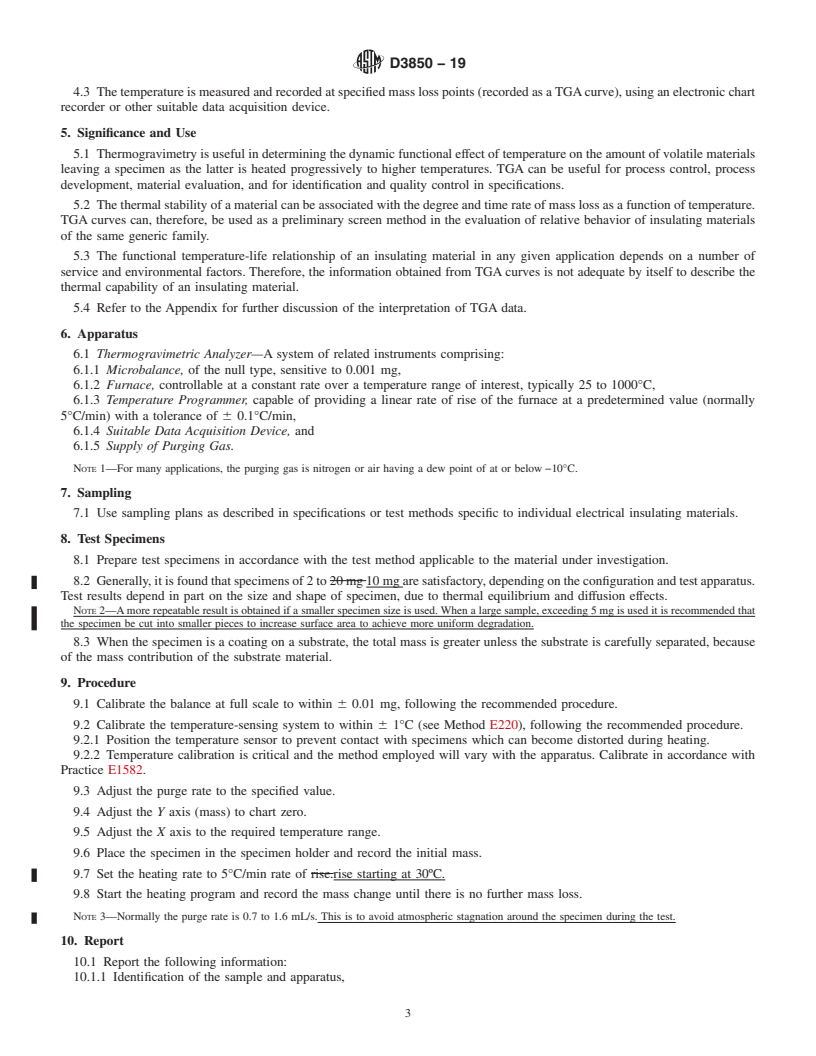

4.2 The record is a TGAcurve, with percent of initial mass

mendations issued by the World Trade Organization Technical

astheordinateandtemperatureastheabscissa(seeFigs.1and

Barriers to Trade (TBT) Committee.

2).

4.3 The temperature is measured and recorded at specified

2. Referenced Documents

masslosspoints(recordedasaTGAcurve),usinganelectronic

2

2.1 ASTM Standards:

chart recorder or other suitable data acquisition device.

D883Terminology Relating to Plastics

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

5. Significance and Use

tics

5.1 Thermogravimetry is useful in determining the dynamic

D1711Terminology Relating to Electrical Insulation

functional effect of temperature on the amount of volatile

materials leaving a specimen as the latter is heated progres-

sively to higher temperatures. TGA can be useful for process

1

This test method is under the jurisdiction of ASTM Committee D09 on

control, process development, material evaluation, and for

Electrical and Electronic Insulating Materials and is the direct responsibility of

Subcommittee D09.17 on Fire and Thermal Properties.

identification and quality control in specifications.

Current edition approved March 1, 2019. Published March 2019. Originally

5.2 The thermal stability of a material can be associated

approved in 1979. Last previous edition approved in 2012 as D3850–12. DOI:

10.1520/D3850-19.

with the degree and time rate of mass loss as a function of

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

temperature. TGAcurves can, therefore, be used as a prelimi-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

nary screen method in the evaluation of relative behavior of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. insulating materials of the same generic family.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3850 − 19

Sample 8.54 mg Heating Rate 5°C/min Purging Gas Flow 0.8 mL/s

FIG. 1 Cu

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3850 − 12 D3850 − 19

Standard Test Method for

Rapid Thermal Degradation of Solid Electrical Insulating

1

Materials By Thermogravimetric Method (TGA)

This standard is issued under the fixed designation D3850; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Scope*

1.1 This test method outlines a procedure for obtaining thermogravimetric (TGA) data on solid polymeric materials intended

for use as electrical insulating materials.

1.2 Do not use this standard to quantify an estimate of the long-term thermal capability for any electrical insulating material.

If a relationship exists between TGA and the long-term thermal capabilities of a material, then that fact must be established and

made public, preferably by comparing data between a candidate and another material known to display similar failure modes.

1.3 The values stated in SI units are the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics

D1711 Terminology Relating to Electrical Insulation

D2307 Test Method for Thermal Endurance of Film-Insulated Round Magnet Wire

E220 Test Method for Calibration of Thermocouples By Comparison Techniques

E473 Terminology Relating to Thermal Analysis and Rheology

E1582 Test Method for Temperature Calibration of Thermogravimetric Analyzers

3. Terminology

3.1 Definitions—Definitions are in accordance with Terminology D883, Terminology D1711, and Terminology E473.

3.2 Abbreviations—Abbreviations are in accordance with Terminology D1600, unless otherwise indicated.

4. Summary of Test Method

4.1 This thermogravimetric technique uses the record of the mass loss versus the temperature of the specimen during the time

of exposure to a specified prescribed environment using a controlled time rate of heating.

4.2 The record is a TGA curve, with percent of initial mass as the ordinate and temperature as the abscissa (see Figs. 1 and 2).

1

This test method is under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and is the direct responsibility of Subcommittee

D09.17 on Fire and Thermal CharacteristicsProperties.

Current edition approved Jan. 1, 2012March 1, 2019. Published February 2012March 2019. Originally approved in 1979. Last previous edition approved in 20062012 as

D3850 – 94D3850 – 12.(2006). DOI: 10.1520/D3850-12.10.1520/D3850-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3850 − 19

Sample 8.54 mg Heating Rate 5°C/min Purging Gas Flow 0.8 mL/s

FIG. 1 Curve No. 1, Typical TGA for Polyester Film

Sample 5.93 mg Heating Rate 5°C/min Purging Gas Flow 0.8 mL/s

FIG. 2 Curve No. 2, Typical TGA for Polyimide Film

2

---------------------- Page: 2 ----------------------

D3850 − 19

4.3 The temperature is measured and recorded at specified mass loss points (recorded as a TGA curve), using an electronic chart

recorder or other suitable data acquisition device.

5. Significance and Use

5.1 Thermogravimetry is useful in determining the dynamic functional effect of temperature on the amount of volatile materials

leaving a specimen as the latter is h

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.