ASTM B787/B787M-01

(Specification)Standard Specification for 19 Wire Combination Unilay-Stranded Copper Conductors for Subsequent Insulation

Standard Specification for 19 Wire Combination Unilay-Stranded Copper Conductors for Subsequent Insulation

SCOPE

1.1 This specification covers bare combination unilay-stranded conductors made from round copper wires, either uncoated or coated with tin or lead alloy for insulated conductors for electrical purposes. These conductors shall be constructed with a central core wire surrounded by two layers of helically laid wires, resulting in an outer diameter equal to the compressed-stranded equivalent conductor. (See Explanatory Note 1 and Note 2).

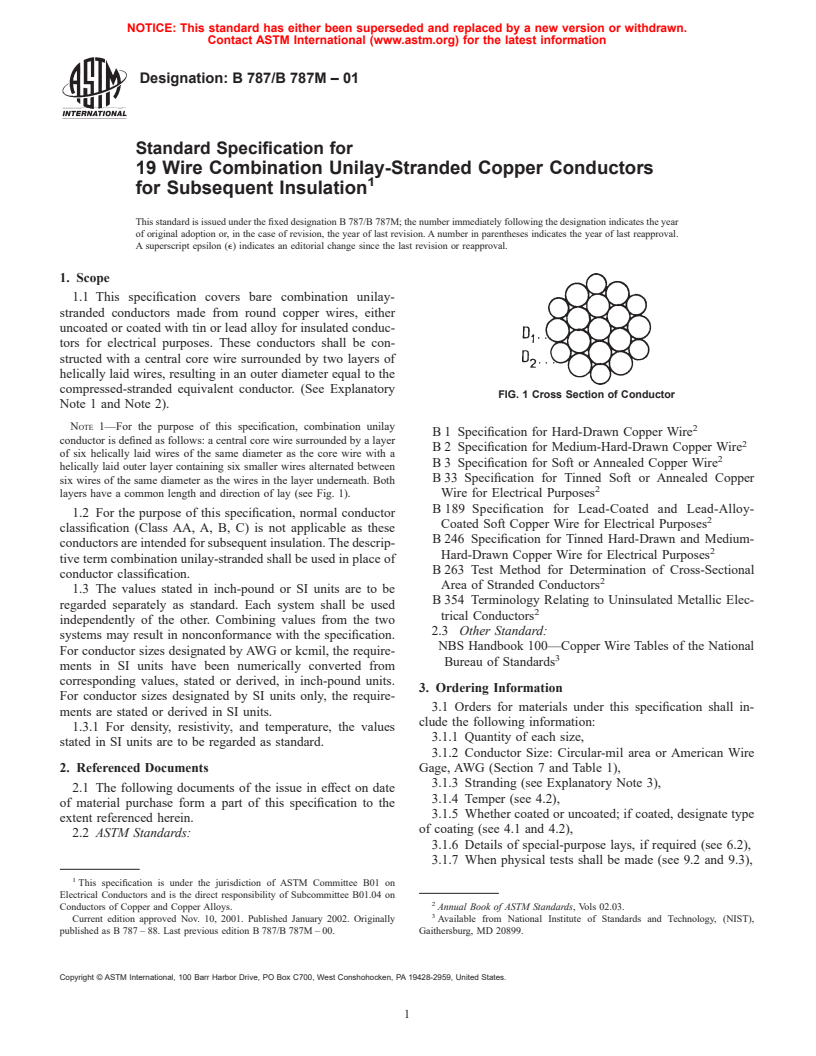

Note 1—For the purpose of this specification, combination unilay conductor is defined as follows: a central core wire surrounded by a layer of six helically laid wires of the same diameter as the core wire with a helically laid outer layer containing six smaller wires alternated between six wires of the same diameter as the wires in the layer underneath. Both layers have a common length and direction of lay (see Fig 1).

1.2 For the purpose of this specification, normal conductor classification (Class AA, A, B, C) is not applicable as these conductors are intended for subsequent insulation. The descriptive term combination unilay-stranded shall be used in place of conductor classification.

1.3 The values stated in inch-pound or SI units are to be regarded separately as standard. Each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. For conductor sizes designated by AWG or kcmil, the requirements in SI units have been numerically converted from corresponding values, stated or derived, in inch-pound units. For conductor sizes designated by SI units only, the requirements are stated or derived in SI units.

1.3.1 For density, resistivity, and temperature, the values stated in SI units are to be regarded as standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 787/B 787M – 01

Standard Specification for

19 Wire Combination Unilay-Stranded Copper Conductors

1

for Subsequent Insulation

This standard is issued under the fixed designation B 787/B 787M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers bare combination unilay-

stranded conductors made from round copper wires, either

uncoated or coated with tin or lead alloy for insulated conduc-

tors for electrical purposes. These conductors shall be con-

structed with a central core wire surrounded by two layers of

helically laid wires, resulting in an outer diameter equal to the

compressed-stranded equivalent conductor. (See Explanatory

FIG. 1 Cross Section of Conductor

Note 1 and Note 2).

NOTE 1—For the purpose of this specification, combination unilay

2

B 1 Specification for Hard-Drawn Copper Wire

conductor is defined as follows: a central core wire surrounded by a layer

2

B 2 Specification for Medium-Hard-Drawn Copper Wire

of six helically laid wires of the same diameter as the core wire with a

2

B 3 Specification for Soft or Annealed Copper Wire

helically laid outer layer containing six smaller wires alternated between

B 33 Specification for Tinned Soft or Annealed Copper

six wires of the same diameter as the wires in the layer underneath. Both

2

layers have a common length and direction of lay (see Fig. 1).

Wire for Electrical Purposes

B 189 Specification for Lead-Coated and Lead-Alloy-

1.2 For the purpose of this specification, normal conductor

2

Coated Soft Copper Wire for Electrical Purposes

classification (Class AA, A, B, C) is not applicable as these

B 246 Specification for Tinned Hard-Drawn and Medium-

conductors are intended for subsequent insulation. The descrip-

2

Hard-Drawn Copper Wire for Electrical Purposes

tive term combination unilay-stranded shall be used in place of

B 263 Test Method for Determination of Cross-Sectional

conductor classification.

2

Area of Stranded Conductors

1.3 The values stated in inch-pound or SI units are to be

B 354 Terminology Relating to Uninsulated Metallic Elec-

regarded separately as standard. Each system shall be used

2

trical Conductors

independently of the other. Combining values from the two

2.3 Other Standard:

systems may result in nonconformance with the specification.

NBS Handbook 100—Copper Wire Tables of the National

For conductor sizes designated by AWG or kcmil, the require-

3

Bureau of Standards

ments in SI units have been numerically converted from

corresponding values, stated or derived, in inch-pound units.

3. Ordering Information

For conductor sizes designated by SI units only, the require-

3.1 Orders for materials under this specification shall in-

ments are stated or derived in SI units.

clude the following information:

1.3.1 For density, resistivity, and temperature, the values

3.1.1 Quantity of each size,

stated in SI units are to be regarded as standard.

3.1.2 Conductor Size: Circular-mil area or American Wire

2. Referenced Documents Gage, AWG (Section 7 and Table 1),

3.1.3 Stranding (see Explanatory Note 3),

2.1 The following documents of the issue in effect on date

3.1.4 Temper (see 4.2),

of material purchase form a part of this specification to the

3.1.5 Whether coated or uncoated; if coated, designate type

extent referenced herein.

of coating (see 4.1 and 4.2),

2.2 ASTM Standards:

3.1.6 Details of special-purpose lays, if required (see 6.2),

3.1.7 When physical tests shall be made (see 9.2 and 9.3),

1

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on

2

Conductors of Copper and Copper Alloys. Annual Book of ASTM Standards, Vols 02.03.

3

Current edition approved Nov. 10, 2001. Published January 2002. Originally Available from National Institute of Standards and Technology, (NIST),

published as B 787 – 88. Last previous edition B 787/B 787M – 00. Gaithersburg, MD 20899.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 787/B 787M

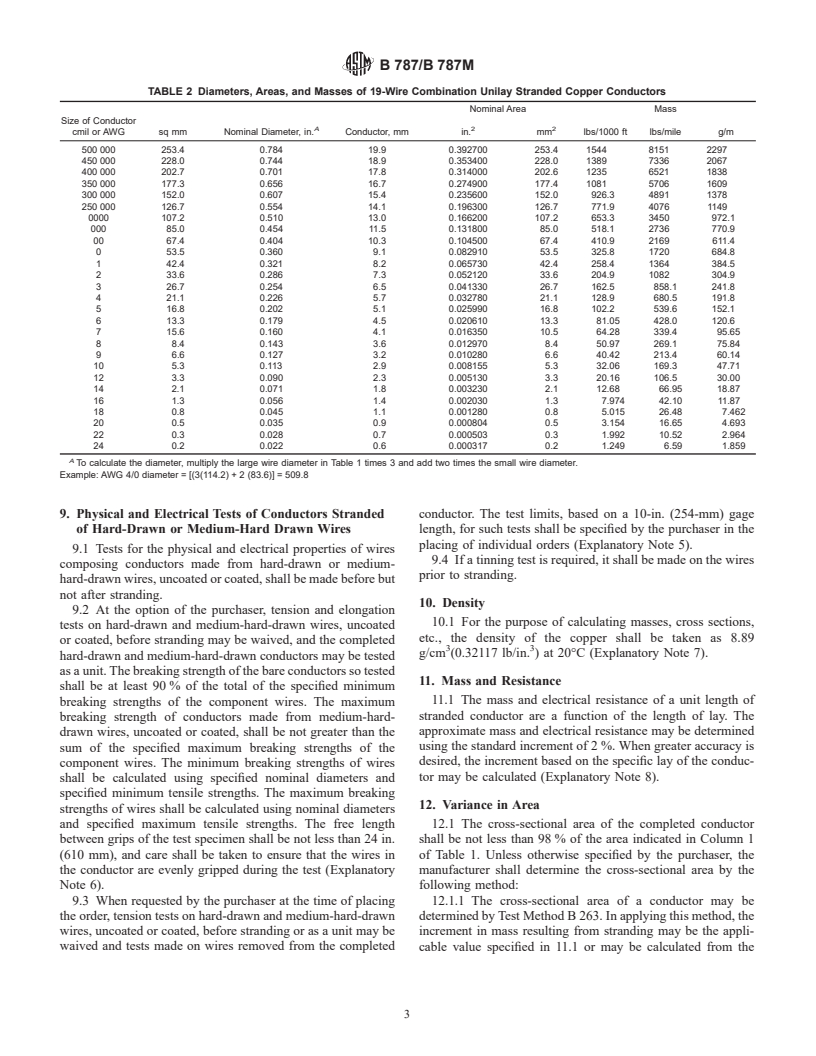

TABLE 1 Construction Requirements for 19-Wire Combination

6. Lay

Unilay Stranded Copper Conductors

6.1 For combination unilay conductors the lay of a layer of

Size, American (or

A B

wires shall be not less than 8 nor more than 16 times the

Brown and Wire D Wire D

1 2

Cross-Sectional Area Sharpe) Diameter, Diameter,

outside diameter of the outer layer.

cmil sq mm Wire Gage mils mm mils mm

6.2 Other lays for special purposes shall be furnished by

500 000 2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.