ASTM F1047-95(2001)

(Specification)Standard Specification for Frying and Braising Pans, Tilting Type

Standard Specification for Frying and Braising Pans, Tilting Type

SCOPE

1.1 This specification covers tilting frying and braising pans (also known as tilting skillets; hereinafter called braising pans) suitable for the preparation of foods by several methods, such as frying, braising, and boiling.

1.2 Braising pans shall be self-contained units with all required operating and safety controls ready for connection to utilities.

1.3 The values as stated in inch-pound units are to be regarded as the standard. The values in parentheses are given for information only.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 9, of this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 1047 – 95 (Reapproved 2001)

Standard Specification for

Frying and Braising Pans, Tilting Type

This standard is issued under the fixed designation F 1047; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope mum Percent), Hot-Rolled Sheet and Strip Commercial

Quality

1.1 This specification covers tilting frying and braising pans

D 3951 Practice for Commercial Packaging

(also known as tilting skillets; hereinafter called braising pans)

F 760 Specification for Food Service Equipment Manuals

suitable for the preparation of foods by several methods, such

2.2 ANSI Standard:

as frying, braising, and boiling.

ANSI Z83.11 Gas Food Service Equipment’s Counter Ap-

1.2 Braising pans shall be self-contained units with all

pliances

required operating and safety controls ready for connection to

2.3 Underwriters Laboratories Standard:

utilities.

UL Standard No. 197 Commercial Electric Cooking Appli-

1.3 The values as stated in inch-pound units are to be

ances

regarded as the standard. The values in parentheses are given

2.4 National Sanitation Foundation Standard:

for information only.

NSF Standard No. 4 Commercial Cooking and Hot Food

1.4 The following safety hazards caveat pertains only to the

Storage Equipment

test methods portion, Section 9, of this specification:This

standard does not purport to address all of the safety concerns,

3. Classification

if any, associated with its use. It is the responsibility of the user

3.1 Braising pans of the following types are covered by this

of this standard to establish appropriate safety and health

specification:

practices and determine the applicability of regulatory limita-

3.1.1 Type I—Electrically-Heated, and

tions prior to use.

3.1.2 Type II—Gas-Fired.

2. Referenced Documents 3.2 Braising pans of the following styles are covered by this

specification:

2.1 ASTM Standards:

2 3.2.1 Style 1—Counter-Mounted Pans:

A 36/A 36M Specification for Carbon Structural Steel

3.2.1.1 Style 1a—Rectangular.

A 167 Specification for Stainless and Heat-Resisting

3 3.2.1.2 Style 1b—Circular.

Chromium-Nickel Steel Plate, Sheet, and Strip

3.2.2 Style 2—Wall-Mounted Pans.

A 240/A 240M Specification for Heat-Resisting Chromium

3.2.3 Style 3—Floor-Mounted Pans with Open Stand.

and Chromium-Nickel Stainless Steel Plate, Sheet, and

3.2.4 Style 4—Floor-Mounted Pans with Cabinet Base.

Strip for Pressure Vessels

A 269 Specification for Seamless and Welded Austenitic

4. Ordering Information

Stainless Steel Tubing for General Service

3 4.1 Orders for braising pans under this specification shall

A 276 Specification for Stainless Steel Bars and Shapes

include the following information:

A 366/A 366M Specification for Steel, Sheet, Carbon,

4.1.1 ASTM specification number and date of issue.

Cold-Rolled, Commercial Quality

4.1.2 Quantity of pans to be furnished.

A 569/A 569M Specification for Steel, Carbon (0.15 Maxi-

4.1.3 Type pan:

1 5

This specification is under the jurisdiction of ASTM Commitee F26 on Food Annual Book of ASTM Standards, Vol 15.09.

Service Equipment and is the direct responsibility of Subcommittee F26.02 on Annual Book of ASTM Standards, Vol 15.07.

Cooking and Warming Equipment. Available from the American National Standards Institute, 11 West 42nd Street,

Current edition approved Sept. 10, 1995. Published November 1995. Originally 13th Floor, New York, NY 10036.

published as F 1047 – 87. Last previous edition F 1047 – 91. Available from the Underwriters Laboratories, Inc., 333 Pfingsten Rd., North-

Annual Book of ASTM Standards, Vol 01.04.

brook, IL 60062.

Annual Book of ASTM Standards, Vol 01.03. Available from the National Sanitation Foundation, NSF Building, Ann Arbor,

Annual Book of ASTM Standards, Vol 01.01. MI 48105.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1047

4.1.3.1 For Type I braising pans, specify operating voltage, 5. Physical Requirements

phase, and Hertz.

5.1 Design and Manufacture—The braising pan shall con-

4.1.3.2 For Type II braising pans, specify gas (natural,

sist of a flat bottom pan section, a tilting mechanism, a control

propane, butane, etc.).

system, a stand, a cover (except as noted in 5.1.5), and a

4.1.4 Braising pan style.

method of applying heat to the pan bottom (such as using

4.1.5 Braising pan size.

burners or electric heaters).

4.1.6 State test sampling size if quantity is greater than one.

5.1.1 Pan Section—The pan section shall have a flat bottom

4.1.7 When other than manufacturer’s standard, commer-

to which various depth side(s) are cast in, formed, or welded.

cial, domestic packaging is required, specify packaging re-

The top edge of the front wall of the pan section shall have a

quirements.

product-retaining lip to limit spillover. There shall also be a

4.1.8 Special requirements such as inspections, accessories,

pouring lip or spout on the front wall. The bottom, the side, rear

additional nameplate data, etc.

and front walls, and the pouring lip shall be of integral

construction.

5.1.2 Tilting Mechanism—The tilting mechanism for Styles

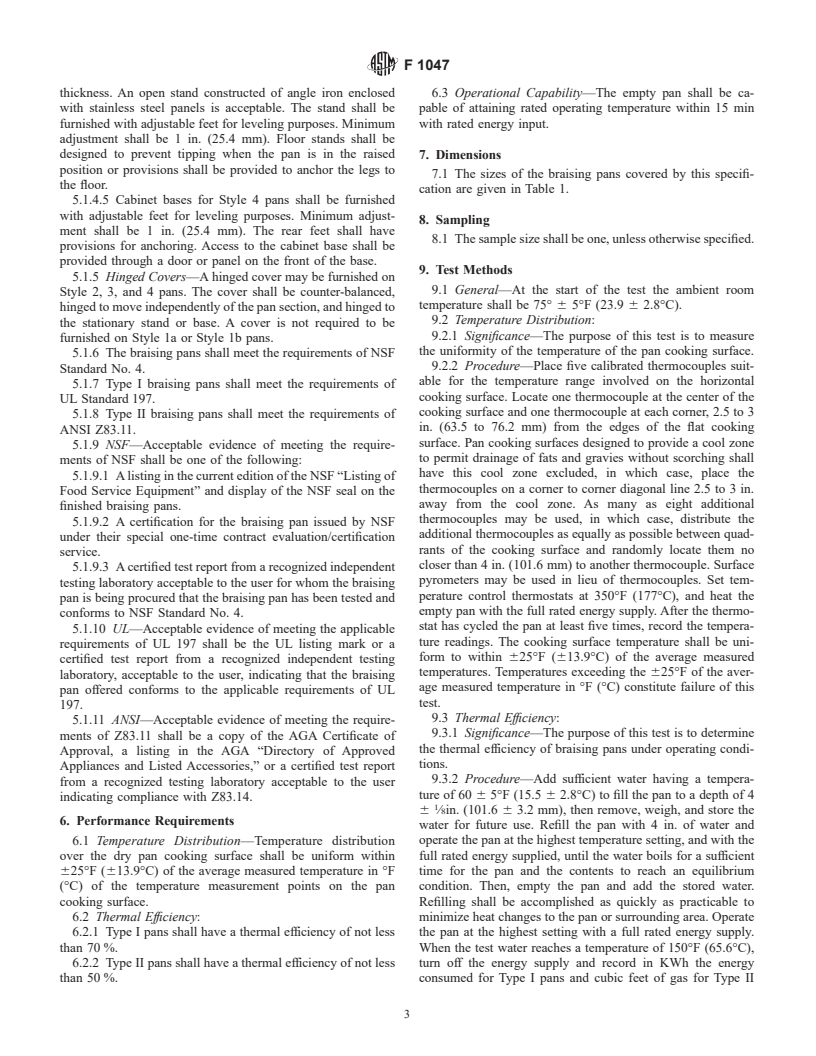

TABLE 1 Sizes of Braising Pans

2, 3, and 4 pans shall provide a means of tilting the fully-loaded

Approximate

pan section from the normal horizontal operating position to

Approximate

A

Size Style Cooking

the position in which the contents of the pan will drain. The

Capacity, gal

Surface, in.

tilting mechanism shall be self-locking with the loaded or

0 1a 410 12

empty pan section in any position between level and fully

1 1b 430 15

2 2, 3 576 17 tilted.

3 2, 3 576 22

5.1.3 Control System:

4 2, 3, 4 740 22

5.1.3.1 Type I pans shall be equipped with electric heaters.

5 2, 3, 4 740 29

6 4 860 26

The control system shall energize and de-energize the heaters

7 2, 3, 4 980 30

as required by the operation of the temperature control and

8 2, 3, 4 980 38

high limit and safety controls.

9 2, 3, 4 1060 40

A 5.1.3.2 Type II pans shall be equipped with gas burners and

Height from floor to pan rim on Styles 3 and 4 pans shall not exceed 41 in.

(1041 mm). have a means for automatic ignition of main burner gas. A

constant burning pilot, or an electrically ignited pilot or

TABLE 2 Unacceptable Defects pilotless ignition (direct spark ignition or glow coil), shall be

provided for each burner system. The control system shall shut

Examine Defect

off the gas to all burners, including pilot burners, in the event

Design Not in accordance with specified

requirements. the means of ignition becomes inoperative. The control system

shall turn the burners “on” and“ off” as required by the

Finish Not finished where required, or

operation of the temperature control and high limit and safety

Finish stained or not type-specified, or has

embedded foreign matter, or controls.

Has burrs or slivers on surface to be

5.1.3.3 When the pan is tilted more than 10° from the

handled during operation.

horizontal position, the power supply or gas to the main

Construction Workmanship not as specified, or

burners shall be turned off automatically.

Sheet metal surface dented or otherwise

5.1.3.4 Each pan shall be equipped with an adjustable

given a poor appearance, or

thermostat and the range shall include 200° to 400°F (93.3° to

Cover does not close properly or distorts

during operation, or

204.4°C). This thermostat shall automatically control the pan

Welding defects such as cracks,

cooking surface temperature and must contain an “off” position

incomplete fusion, undercuts, inclusions,

as an integral part of the thermostat.

scale or flux not removed, and burn-

through holes.

5.1.3.5 Each pan shall be equipped with a high temperature

limit protection set at a maximum of 460°F (237.77°C) in

Components and subassemblies Improper assembly, or

Damaged, defective, missing, incorrect addition to the adjustable thermostat.

type of size castings, miscast,

5.1.4 Stands:

incomplete, or containing blow holes, or

5.1.4.1 Stands, bases, and cabinet supports shall be con-

Parts inoperative or will not function as

intended; fasteners missing, loose,

structed to safely support a pan loaded to capacity (see Table 1)

broken, stripped.

during the loading, cooking, and emptying operations.

5.1.4.2 The base for Style 1a or Style 1b pans shall have

Wiring Not easily identified, cut, abraded, loose

at terminal, or

provisions for attaching the base to the countertop.

Inadequate slack for strain relief.

5.1.4.3 Style 2 pans shall have a rear support bracket for

Marking Missing, incomplete, illegible, not correct attachment of the pan to the in-wall carrier. Attachment means

data or data plate material.

it shall be readily accessible.

5.1.4.4 Open stands for Style 3 pans constructed of pipe or

Instruction manuals Missing, incomplete, illegible.

tubing shall be not less than 1.5 in. (38.1 mm) in outside

diameter and not less than 0.060 in. (1.5 2 mm) in thick wall

F 1047

thickness. An open stand constructed of angle iron enclosed 6.3 Operational Capability—The empty pan shall be ca-

with stainless steel panels is acceptable. The stand shall be pable of attaining rated operating temperature within 15 min

furnished with adjustable feet for leveling purposes. Minimum with rated energy input.

adjustment shall be 1 in. (25.4 mm). Floor stands shall be

designed to prevent tipping when the pan is in the raised 7. Dimensions

position or provisions shall be provided to anchor the legs to

7.1 The sizes of the braising pans covered by this specifi-

the floor.

cation are given in Table 1.

5.1.4.5 Cabinet bases for Style 4 pans shall be furnished

with adjustable feet for leveling purposes. Minimum adjust-

8. Sampling

ment shall be 1 in. (25.4 mm). The rear feet shall have

8.1 The sample size shall be one, unless otherwise specified.

provisions for anchoring. Access to the cabinet base shall be

provided through a door or panel on the front of the base.

9. Test Methods

5.1.5 Hinged Covers—A hinged cover may be furnished on

9.1 General—At the start of the test the ambient room

Style 2, 3, and 4 pans. The cover shall be counter-balanced,

temperature shall be 75° 6 5°F (23.9 6 2.8°C).

hinged to move independently of the pan section, and hinged to

9.2 Temperature Distribution:

the stationary stand or base. A cover is not required to be

9.2.1 Significance—The purpose of this test is to measure

furnished on Style 1a or Style 1b pans.

the uniformity of the temperature of the pan cooking surface.

5.1.6 The braising pans shall meet the requirements of NSF

9.2.2 Procedure—Place five calibrated thermocouples suit-

Standard No. 4.

able for the temperature range involved on the horizontal

5.1.7 Type I braising pans shall meet the requirements of

cooking surface. Locate one thermocouple at the center of the

UL Standard 197.

cooking surface and one thermocouple at each corner, 2.5 to 3

5.1.8 Type II braising pans shall meet the requirements of

in. (63.5 to 76.2 mm) from the edges of the flat cooking

ANSI Z83.11.

surface. Pan cooking surfaces designed to provide a cool zone

5.1.9 NSF—Acceptable evidence of meeting the require-

to permit drainage of fats and gravies without scorching shall

ments of NSF shall be one of the following:

have this cool zone excluded, in which case, place the

5.1.9.1 A listing in the current edition of the NSF “Listing of

thermocouples on a corner to corner diagonal line 2.5 to 3 in.

Food Service Equipment” and display of the NSF seal on the

away from the cool zone. As many as eight additional

finished braising pans.

thermocouples may be used, in which case, distribute the

5.1.9.2 A certification for the braising pan issued by NSF

additional thermocouples as equally as possible between quad-

under their special one-time contract evaluation/certification

rants of the cooking surface and randomly locate them no

service.

closer than 4 in. (101.6 mm) to another thermocouple. Surface

5.1.9.3 A certified test report from a recognized independent

pyrometers may be used in lieu of thermocouples. Set tem-

testing laboratory acceptable to the user for whom the braising

perature control thermostats at 350°F (177°C), and heat the

pan is being procured that the braising pan has been tested and

empty pan with the full rated energy supply. After the thermo-

conforms to NSF Standard No. 4.

stat has cycled the pan at least five times, record the tempera-

5.1.10 UL—Acceptable evidence of meeting the applicable

ture readings. The cooking surface temperature shall be uni-

requirements of UL 197 shall be the UL listing mark or a

form to within 625°F (613.9°C) of the average measured

certified test report from a recognized independent testing

temperatures. Temperatures exceeding the 625°F of the aver-

laboratory, acceptable to the user, indicating that the braising

age measured temperature in °F (°C) constitute failure of this

pan offered conforms to the applicable requirements of UL

test.

197.

9.3 Thermal Effıciency:

5.1.11 ANSI—Acceptable evidence of meeting the require-

9.3.1 Significance—The purpose of this test is to determine

ments of Z83.11 shall be a copy of the AGA Certificate of

the thermal efficiency of braising pans under operating condi-

Approval, a listing in the AGA “Directory of Approved

tions.

Appliances and Listed Accessories,” or a certified test report

9.3.2 Procedure—Add sufficient water having a tempera-

from a recognized testing laboratory acceptable to the user

ture of 60 6 5°F (15.5 6 2.8°C) to fill the pan to a depth of 4

indicating compliance with Z83.14.

6 ⁄8in. (101.6 6 3.2 mm), then remove, weigh, and store the

6. Performance Requirements

water for future use. Refill the pan with 4 in. of water and

6.1 Temperature Distribution—Temperature distribution operate the pan at the highest temperature setting, and with the

over the dry pan cooking surface shall be uniform within full rated energy supplied, until the water boils for a sufficient

625°F (613.9°C) of the average measured temperature in °F time for the pan and the contents to reach an equilibrium

(°C) of the temperature measurement points on the pan condition. Then, empty the pan and add the stored water.

cooking surface. Refilling shall be accomplished as quickly as practicable to

6.2 Thermal Effıciency: minimize heat changes to the pan or surrounding area. Operate

6.2.1 Type I pans shall have a thermal efficiency of not less the pan at the highest setting with a full rated energy supply.

than 70 %. When the test water

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.