ASTM D5252-15

(Practice)Standard Practice for the Operation of the Hexapod Tumble Drum Tester

Standard Practice for the Operation of the Hexapod Tumble Drum Tester

SIGNIFICANCE AND USE

5.1 This equipment may be used to bring about the changes in appearance and texture on the surface of pile floor covering caused by mechanical action.

SCOPE

1.1 This practice describes the equipment and operation of the hexapod tumble drum tester for testing pile floor covering to produce changes in appearance and color due to changes in surface structure by mechanical action tester.

1.2 This practice is applicable for use in testing unused pile floor covering of all types. It is not applicable for use in testing used pile yarn floor coverings.

1.3 This practice may be used by mutual agreement between the purchaser and supplier to set purchasing specifications.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This practice does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this practice to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5252 − 15

Standard Practice for

1

the Operation of the Hexapod Tumble Drum Tester

This standard is issued under the fixed designation D5252; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 For all other terminology related to textiles see Termi-

nology D123.

1.1 This practice describes the equipment and operation of

the hexapod tumble drum tester for testing pile floor covering

4. Summary of Practice

to produce changes in appearance and color due to changes in

4.1 The specimen is secured to a backing sheet that is

surface structure by mechanical action tester.

mounted inside the rotatable drum with the pile surface

1.2 This practice is applicable for use in testing unused pile

exposed. A metal hexapod, with six polyurethane studs, rolls

floor covering of all types. It is not applicable for use in testing

randomly on the pile surface inside the rotating drum for a

used pile yarn floor coverings.

specified number of revolutions.

1.3 Thispracticemaybeusedbymutualagreementbetween

5. Significance and Use

the purchaser and supplier to set purchasing specifications.

5.1 This equipment may be used to bring about the changes

1.4 The values stated in inch-pound units are to be regarded

in appearance and texture on the surface of pile floor covering

as standard. The values given in parentheses are mathematical

caused by mechanical action.

conversions to SI units that are provided for information only

and are not considered standard.

6. Apparatus, Materials, and Reagent

1.5 This practice does not purport to address all of the

6.1 Hexapod Tumble Tester

safety concerns, if any, associated with its use. It is the

6.1.1 Drum—Constructed of Nylon or other like material

responsibility of the user of this practice to establish appro-

and capped by a lid that is secured by a latching device. The

priate safety and health practices and determine the applica-

drum base and lid have a locating groove to hold the specimen

bility of regulatory limitations prior to use.

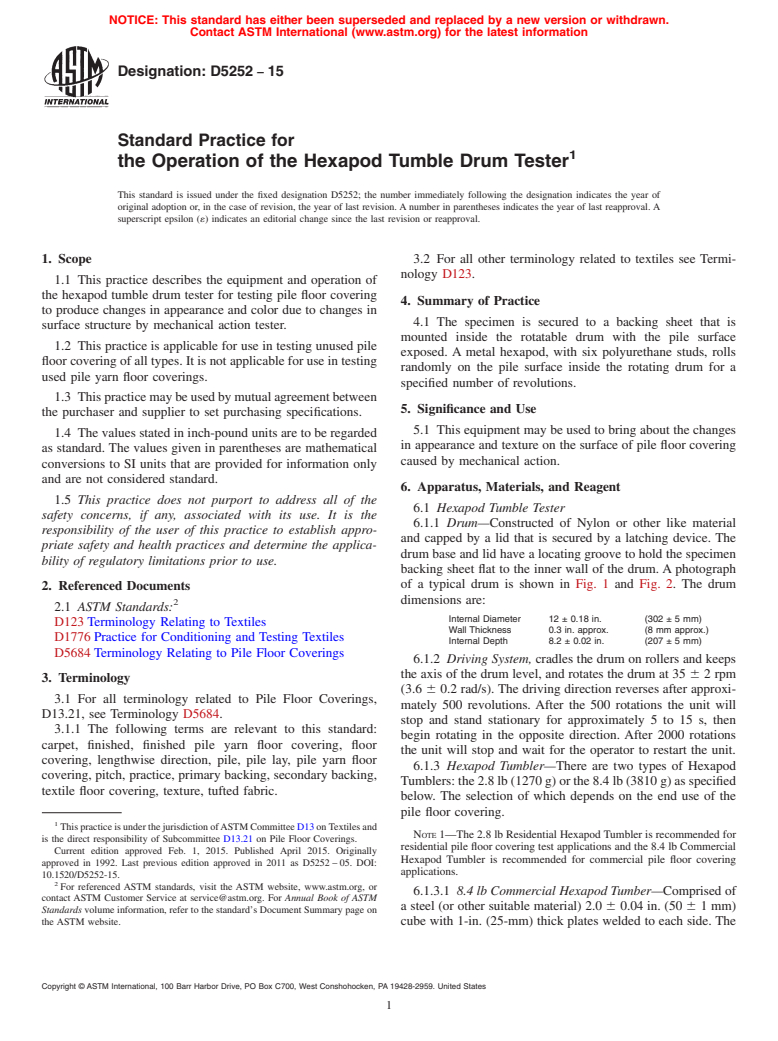

backing sheet flat to the inner wall of the drum. A photograph

of a typical drum is shown in Fig. 1 and Fig. 2. The drum

2. Referenced Documents

dimensions are:

2

2.1 ASTM Standards:

Internal Diameter 12 ± 0.18 in. (302±5mm)

D123 Terminology Relating to Textiles

Wall Thickness 0.3 in. approx. (8 mm approx.)

D1776 Practice for Conditioning and Testing Textiles

Internal Depth 8.2 ± 0.02 in. (207±5mm)

D5684 Terminology Relating to Pile Floor Coverings

6.1.2 Driving System, cradles the drum on rollers and keeps

the axis of the drum level, and rotates the drum at 35 6 2 rpm

3. Terminology

(3.6 6 0.2 rad/s). The driving direction reverses after approxi-

3.1 For all terminology related to Pile Floor Coverings,

mately 500 revolutions. After the 500 rotations the unit will

D13.21, see Terminology D5684.

stop and stand stationary for approximately 5 to 15 s, then

3.1.1 The following terms are relevant to this standard:

begin rotating in the opposite direction. After 2000 rotations

carpet, finished, finished pile yarn floor covering, floor

the unit will stop and wait for the operator to restart the unit.

covering, lengthwise direction, pile, pile lay, pile yarn floor

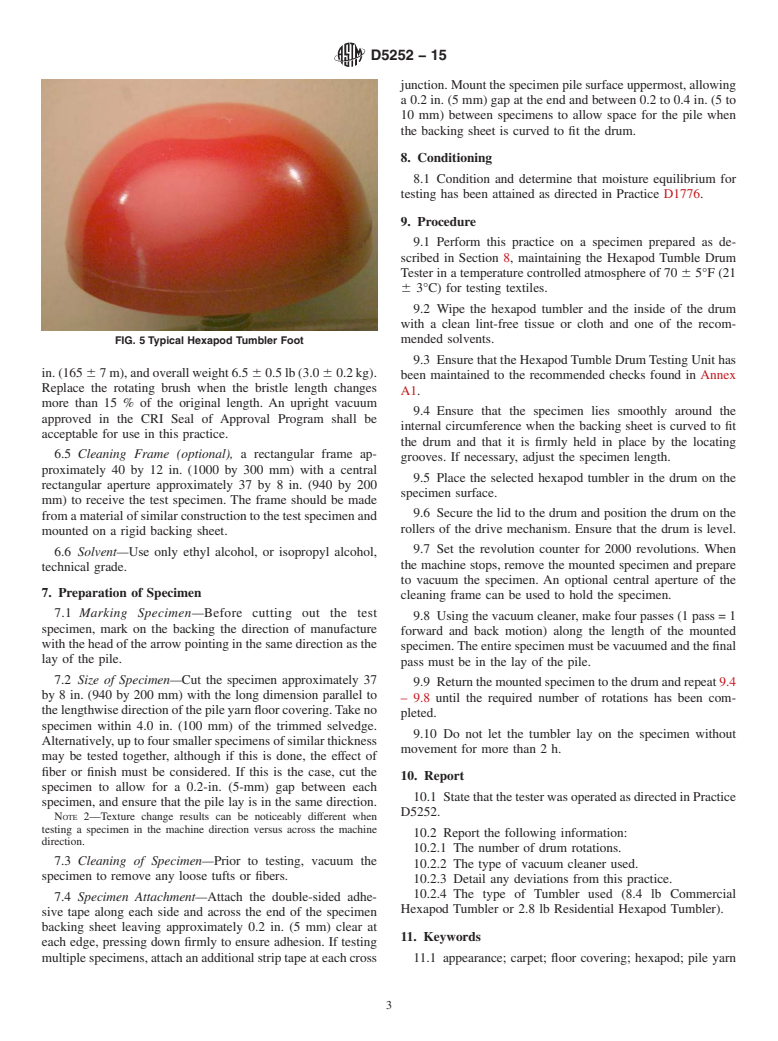

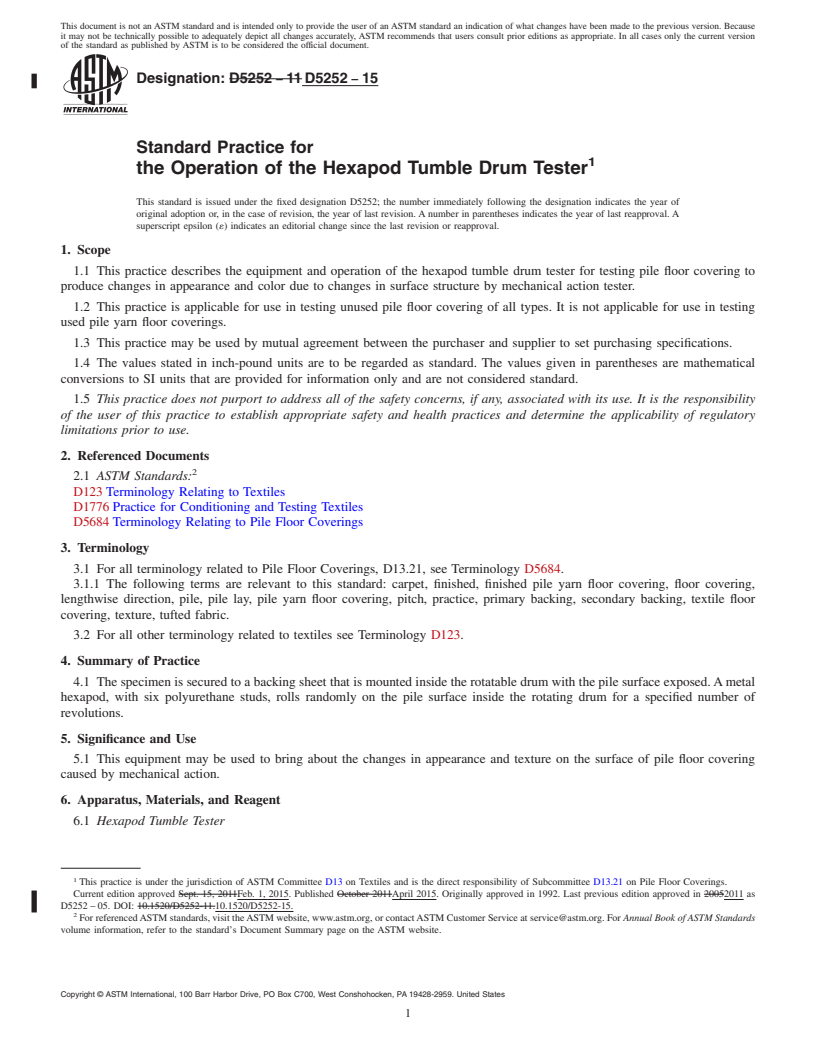

6.1.3 Hexapod Tumbler—There are two types of Hexapod

covering, pitch, practice, primary backing, secondary backing,

Tumblers:the2.8lb(1270g)orthe8.4lb(3810g)asspecified

textile floor covering, texture, tufted fabric.

below. The selection of which depends on the end use of the

pile floor covering.

1

ThispracticeisunderthejurisdictionofASTMCommitteeD13onTextilesand

NOTE 1—The 2.8 lb Residential Hexapod Tumbler is recommended for

is the direct responsibility of Subcommittee D13.21 on Pile Floor Coverings.

residential pile floor covering test applications and the 8.4 lb Commercial

Current edition approved Feb. 1, 2015. Published April 2015. Originally

Hexapod Tumbler is recommended for commercial pile floor covering

approved in 1992. Last previous edition approved in 2011 as D5252 – 05. DOI:

applications.

10.1520/D5252-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1.3.1 8.4 lb Commercial Hexapod Tumber—Comprised of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

a steel (or other suitable material) 2.0 6 0.04 in. (50 6 1 mm)

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. cube with 1-in. (25-mm) thick plates welded to each side. The

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5252 − 11 D5252 − 15

Standard Practice for

1

the Operation of the Hexapod Tumble Drum Tester

This standard is issued under the fixed designation D5252; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes the equipment and operation of the hexapod tumble drum tester for testing pile floor covering to

produce changes in appearance and color due to changes in surface structure by mechanical action tester.

1.2 This practice is applicable for use in testing unused pile floor covering of all types. It is not applicable for use in testing

used pile yarn floor coverings.

1.3 This practice may be used by mutual agreement between the purchaser and supplier to set purchasing specifications.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 This practice does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this practice to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D1776 Practice for Conditioning and Testing Textiles

D5684 Terminology Relating to Pile Floor Coverings

3. Terminology

3.1 For all terminology related to Pile Floor Coverings, D13.21, see Terminology D5684.

3.1.1 The following terms are relevant to this standard: carpet, finished, finished pile yarn floor covering, floor covering,

lengthwise direction, pile, pile lay, pile yarn floor covering, pitch, practice, primary backing, secondary backing, textile floor

covering, texture, tufted fabric.

3.2 For all other terminology related to textiles see Terminology D123.

4. Summary of Practice

4.1 The specimen is secured to a backing sheet that is mounted inside the rotatable drum with the pile surface exposed. A metal

hexapod, with six polyurethane studs, rolls randomly on the pile surface inside the rotating drum for a specified number of

revolutions.

5. Significance and Use

5.1 This equipment may be used to bring about the changes in appearance and texture on the surface of pile floor covering

caused by mechanical action.

6. Apparatus, Materials, and Reagent

6.1 Hexapod Tumble Tester

1

This practice is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.21 on Pile Floor Coverings.

Current edition approved Sept. 15, 2011Feb. 1, 2015. Published October 2011April 2015. Originally approved in 1992. Last previous edition approved in 20052011 as

D5252 – 05. DOI: 10.1520/D5252-11.10.1520/D5252-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5252 − 15

6.1.1 Drum—Constructed of Nylon or other like material and capped by a lid that is secured by a latching device. The drum

base and lid have a locating groove to hold the specimen backing sheet flat to the inner wall of the drum. A photograph of a typical

drum is shown in Fig. 1 and Fig. 2. The drum dimensions are:

Internal Diameter 12 ± 0.18 in. (302 ± 5 mm)

Wall Thickness 0.3 in. approx. (8 mm approx.)

Internal Depth 8.2 ± 0.02 in. (207 ± 5 mm)

Internal Diameter 12 ± 0.18 in. (302 ± 5 mm)

Wall Thickness 0.3 in. approx. (8 mm approx.)

Internal Depth 8.2 ± 0.02 in. (207 ± 5 mm)

6.1.2 Driving System, cradles the drum on rollers and keeps the axis of the drum level, and rotates the drum at 35 6 2 rpm (3.6

6 0.2 rad/s). The driving direction reverses after approximately 500 revolutions. After the 500 rotations the unit will stop and stand

stationary for approximately 5 to 15 s, then begin rotating in the opposite direction. After 2000 rotations the unit will stop and wait

for the operator to restart the unit.

6.1.3 Hexapod Tumbler—There are two types of Hexapod Tumblers: the 2.8 l

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.