ASTM D4685/D4685M-15(2020)

(Test Method)Standard Test Method for Pile Fabric Abrasion

Standard Test Method for Pile Fabric Abrasion

SIGNIFICANCE AND USE

5.1 This test method is considered satisfactory for quality control testing and commercial shipment acceptance.

5.1.1 In case of a dispute arising from differences in reported test results when using this test method, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take test specimens that are from the lot of material of the type in question. The test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using student's t-test for unpaired data and an acceptable probability level chosen by the two parties before the testing is begun. If a bias is found, either its cause must be found and corrected or the purchaser and the supplier must agree to interpret future test results in the light of the known bias.

5.2 Finishes and changes in fabric surfaces may exert a large effect on pile retention of corduroy. Therefore, it may be desirable to test before as well as after laundering or drycleaning, or both.

5.3 The separate testing of specimens on the face and back of the fabric is important in this test method since the pile pull-out may be due to abrasive action on either the face or back. With many pile fabrics, specifically corduroy constructions, pile retention properties are worse when abraded on the back.

SCOPE

1.1 This test method covers the determination of the abrasion of pile fabrics when the loss of pile tuffs occur, sometimes called pile retention or pile pull out. It includes two procedures:

1.1.1 Procedure A—The “Heavy Duty” procedure describes the test option for fabrics over 240 g/m2 (7 oz/yd2) or fabrics which should meet heavy duty end-use conditions of wear.

1.1.2 Procedure B—The “Light Duty” procedure describes the test option for fabrics under 240 g/m2 (7 oz/yd2) or fabrics which should meet light duty end-use conditions of wear.

1.2 The test method is intended for both regular, ribless woven corduroy or other woven pile fabric constructions.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4685/D4685M − 15 (Reapproved 2020)

Standard Test Method for

Pile Fabric Abrasion

This standard is issued under the fixed designation D4685/D4685M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1776 Practice for Conditioning and Testing Textiles

D2724 Test Method for Bond Strength of Bonded, Fused,

1.1 This test method covers the determination of the abra-

and Laminated Apparel Fabrics

sion of pile fabrics when the loss of pile tuffs occur, sometimes

D3884 Guide for Abrasion Resistance of Textile Fabrics

calledpileretentionorpilepullout.Itincludestwoprocedures:

(Rotary Platform, Double-Head Method)

1.1.1 ProcedureA—The “Heavy Duty” procedure describes

2 2 D4850 Terminology Relating to Fabrics and Fabric Test

the test option for fabrics over 240 g/m (7 oz/yd ) or fabrics

Methods

which should meet heavy duty end-use conditions of wear.

E177 Practice for Use of the Terms Precision and Bias in

1.1.2 Procedure B—The “Light Duty” procedure describes

2 2 ASTM Test Methods

the test option for fabrics under 240 g/m (7 oz/yd ) or fabrics

E691 Practice for Conducting an Interlaboratory Study to

which should meet light duty end-use conditions of wear.

Determine the Precision of a Test Method

1.2 The test method is intended for both regular, ribless 3

2.2 ASTM Adjunct:

woven corduroy or other woven pile fabric constructions.

Photographic Scale for Pile Retention

1.3 The values stated in either SI units or inch-pound units

2.3 AATCC Method:

are to be regarded separately as standard. The values stated in

TM 135 Dimensional Changes of Fabrics after Home Laun-

each system are not necessarily exact equivalents; therefore, to

dering

ensure conformance with the standard, each system shall be

used independently of the other, and values from the two 3. Terminology

systems shall not be combined.

3.1 For all terminology related to D13.59 on Fabric Test

1.4 This standard does not purport to address all of the

Methods, General, see Terminology D4850.

safety concerns, if any, associated with its use. It is the

3.2 The following terms are relevant to this standard:

responsibility of the user of this standard to establish appro-

abrasion, corduroy, pile fabric, pile retention, velveteen.

priate safety, health, and environmental practices and deter-

3.3 FordefinitionsofallothertextiletermsseeTerminology

mine the applicability of regulatory limitations prior to use.

D123.

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4. Summary of Test Method

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- 4.1 Test specimens are exposed to a specified number of

mendations issued by the World Trade Organization Technical abrasion cycles on face and back separately and then evaluated

Barriers to Trade (TBT) Committee. by viewing the specimen over a light box and comparing to

photographicstandards.Themethodmeasuresonlytheamount

2. Referenced Documents

of pile pulled out of the base fabric structure and not the

surface pile appearance attributes, such as crushed or flatten

2.1 ASTM Standards:

ribs.

D123 Terminology Relating to Textiles

5. Significance and Use

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

5.1 This test method is considered satisfactory for quality

and is the direct responsibility of Subcommittee D13.59 on Fabric Test Methods,

control testing and commercial shipment acceptance.

General.

Current edition approved July 1, 2020. Published July 2020. Originally approved

in 1987. Last previous edition approved in 2015 as D4685/D4685M – 15. DOI:

10.1520/D4685_D4685M-15R20. A set of six photographic standards for pile retention of corduroy fabrics is

For referenced ASTM standards, visit the ASTM website, www.astm.org, or available from ASTM International Headquarters. Order Adjunct No. ADJ4685.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Association of Textile Chemists and Colorists

Standards volume information, refer to the standard’s Document Summary page on (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709, http://

the ASTM website. www.aatcc.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4685/D4685M − 15 (2020)

5.1.1 In case of a dispute arising from differences in

reported test results when using this test method, the purchaser

and the supplier should conduct comparative tests to determine

if there is a statistical bias between their laboratories. Compe-

tent statistical assistance is recommended for the investigation

of bias. As a minimum, the two parties should take test

specimens that are from the lot of material of the type in

question.Thetestspecimensshouldthenberandomlyassigned

in equal numbers to each laboratory for testing. The average

results from the two laboratories should be compared using

student’s t-test for unpaired data and an acceptable probability

level chosen by the two parties before the testing is begun. If

a bias is found, either its cause must be found and corrected or

the purchaser and the supplier must agree to interpret future

test results in the light of the known bias.

5.2 Finishes and changes in fabric surfaces may exert a

large effect on pile retention of corduroy. Therefore, it may be

desirable to test before as well as after laundering or

drycleaning, or both.

5.3 The separate testing of specimens on the face and back

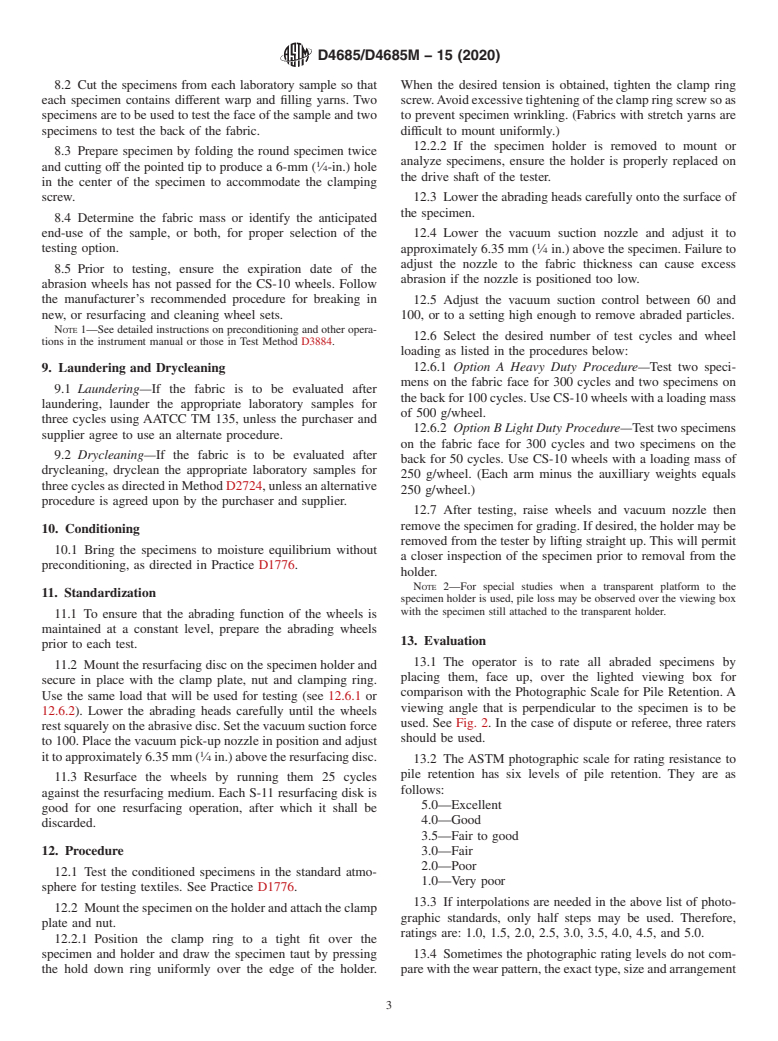

FIG. 1 Pile Retention Viewing Box

of the fabric is important in this test method since the pile

pull-out may be due to abrasive action on either the face or 3

6.6.1 The box is approximately 215 mm (8 ⁄8 in.) in height,

back. With many pile fabrics, specifically corduroy 7 7

150 mm (5 ⁄8 in.) wide, 150 mm (5 ⁄8 in.) in depth, with a 90

constructions,pileretentionpropertiesareworsewhenabraded 3

mm (3 ⁄4 in.) diameter opening in the top. The opening is

on the back.

covered with a clear glass plate which has a black 25 mm (1

in.) circular tape glued to the center of the opening to prevent

6. Apparatus

light from passing through the center hole of the specimen

6.1 Rotary Platform Abraser, as described in Test Method while grading.

6.6.2 The box contains a 75 W reflector flood light the top

D3884 and consisting of the following:

6.1.1 Specimen Holder, rubber pad, clamp plate, and clamp of which is 38 mm (1 ⁄2 in.) below the glass surface of the box

and the specimen. The lamp size and spacing is critical.

ring.

6.1.2 Auxillary Weight, to give a load of 500 g per wheel

7. Sampling

(exclusive of the mass of the wheel).

6.1.3 Vacuum Unit. 7.1 LotSample—Asalotsampleforacceptancetesting,take

at random the number of rolls of fabric directed in an

6.2 CS-10 Calibrase Abrading Wheels .

applicable material specification or other agreement between

6.2.1 Thewheelsshallbeacylindricalshapewhichincludes

thepurchaserandthesupplier.Considerrollsoffabrictobethe

an axial hole 16.0 6 0.1 mm (0.625 6 0.004 in.); sides of the

primary sampling units.

wheelshallbeparallel,andeachwheelshallbe12.7 60.3mm

(0.50 6 0.012 in.) thick and have an external diameter of less

7.2 Laboratory Sample—As a laboratory sample, take from

than 52 mm (2 in.) when new but in no case less than 44.4 mm each roll of fabric in the lot sample a full width swatch at least

(1.75 in.). 500 mm (20 in.) long after removing at least1m(1yd)of

fabric from the outside of the roll. If the fabric is also to be

6.3 Resurfacing Discs (S-11), used to resurface the CS-10

evaluated after laundering or drycleaning, take a second full

abrading wheels.

width swatch 500 mm (20 in.) long from each roll of fabric in

6.3.1 The resurfacing disc shall be 150 grit silicon carbide

the lot sample.

coated abrasive paper, approximately 102 mm (4 in.) diameter

witha7mm( ⁄4 in.) center hole. 7.3 Test Specimens—Cut four specimens from each swatch

in the laboratory sample as directed in 8.1.

6.4 Round Template, or die approximately 135 mm (5 ⁄4 in.)

in diameter for cutting out specimens.

8. Specimens and Preparation

6.5 Photographic Rating Standards.

8.1 Using the template or die specified in 6.4, cut four

6.6 Lighted Viewing Box, for evaluation (see Fig. 1). specimens approximately 135 mm (5 ⁄4 in.) in diameter from

each laboratory sample. If a sample is to be evaluated after

laundering or drycleaning, four additional specimens will be

The sole source of supply of the apparatus known to the committee at this time taken. (See Section 9).

is Taber Industries, North Tonawanda, NY. If you are aware of alternative suppliers,

please provide this information to ASTM International Headquarters. Your com-

ments will receive careful consideration at a meeting of the responsible technical A 75-watt reflector flood light manufactured by General Electric Co. (75R

committee, which you may attend. 30/FL) has been found suitable for this purpose.

D4685/D4685M − 15 (2020)

8.2 Cut the specimens from each laboratory sample so that When the desired tension is obtained, tighten the clamp ring

each specimen contains different warp and filling yarns. Two screw.Avoidexcessivetighteningoftheclampringscrewsoas

specimens are to be used to test the face of the sample and two to prevent specimen wrinkling. (Fabrics with stretch yarns are

specimens to test the back of the fabric. difficult to mount uniformly.)

12.2.2 If the specimen holder is removed to mount or

8.3 Prepare specimen by folding the round specimen twice

analyze specimens, ensure the holder is properly replaced on

and cutting off the pointed tip to produce a 6-mm ( ⁄4-in.) hole

the drive shaft of the tester.

in the center of the specimen to accommodate the clamping

screw. 12.3 Lower the abrading heads carefully onto the surface of

the specimen.

8.4 Determine the fabric mass or identify the anticipated

end-use of the sample, or both, for proper selection of the 12.4 Lower the vacuum suction nozzle and adjust it to

testing option. approximately 6.35 mm ( ⁄4 in.) above the specimen. Failure to

adjust the nozzle to the fabric thickness can cause excess

8.5 Prior to testing, ensure the expiration date of the

abrasion if the nozzle is positioned too low.

abrasion wheels has not passed for the CS-10 wheels. Follow

the manufacturer’s recommended procedure for breaking in

12.5 Adjust the vacuum suction control between 60 and

new, or resurfacing and cleaning wheel sets. 100, or to a setting high enough to remove abra

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.