ASTM A229/A229M-99(2005)

(Specification)Standard Specification for Steel Wire, Oil-Tempered for Mechanical Springs

Standard Specification for Steel Wire, Oil-Tempered for Mechanical Springs

ABSTRACT

This specification covers two classes of oil-tempered steel spring wire intended especially for the manufacture of mechanical springs and wire forms. The steel may be made by any commercially accepted steel-making process and shall either be ingot cast or strand cast. The finished wire shall be free of detrimental pipe and undue segregation. The wire shall be oil quenched and tempered to produce the desired mechanical properties such as tensile strength. Cast, heat, and product analysis shall conform to the chemical composition requirements prescribed for carbon, manganese, phosphorus, sulfur, and silicon. Tension, wrap, and surface tests shall be performed. The surface of the wire as-received shall be free of rust, excessive scale die marks, pits, and scratches detrimental to the end application. Other metallurgical requirements such as microstructure and decarburization are detailed.

SCOPE

1.1 This specification covers two classes of oil-tempered steel spring wire intended especially for the manufacture of mechanical springs and wire forms.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A229/A229M – 99 (Reapproved 2005)

Standard Specification for

Steel Wire, Oil-Tempered for Mechanical Springs

This standard is issued under the fixed designationA229/A229M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.3 Military Standard:

MIL-STD-163 Steel Mill Products, Preparation for Ship-

1.1 This specification covers two classes of oil-tempered

ment and Storage

steel spring wire intended especially for the manufacture of

2.4 Federal Standard:

mechanical springs and wire forms.

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

1.2 The values stated in either SI units or inch-pound units

2.5 AIAG Standard:

are to be regarded separately as standard. The values stated in

AIAGB-5 02.00 Primary Metals Identification TagApplica-

each system may not be exact equivalents; therefore, each

tion Standard

system shall be used independently of the other. Combining

values from the two systems may result in non-conformance

3. Terminology

with the standard.

3.1 Definitions of Terms Specific to This Standard:

2. Referenced Documents 3.1.1 For definition of terms used in this specification, refer

2 to Terminology A941.

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing

4. Ordering Information

of Steel Products

4.1 It shall be the responsibility of the purchaser to specify

A510 Specification for General Requirements for Wire

all requirements that are necessary for material under this

Rods and Coarse Round Wire, Carbon Steel

specification. Such requirements may include, but are not

A510M Specification for General Requirements for Wire

limited to, the following:

Rods and Coarse Round Wire, Carbon Steel (Metric)

4.1.1 Quantity (mass or weight),

A700 PracticesforPackaging,Marking,andLoadingMeth-

4.1.2 Name of material (oil-tempered steel mechanical

ods for Steel Products for Shipment

spring wire) and class (Table 1 or Table 2),

A751 Test Methods, Practices, andTerminology for Chemi-

4.1.3 Dimensions (Section 10),

cal Analysis of Steel Products

4.1.4 Chemical composition (Table 3), if required,

A941 Terminology Relating to Steel, Stainless Steel, Re-

4.1.5 Packaging (Section 16),

lated Alloys, and Ferroalloys

4.1.6 Cast or heat analysis report, if desired (see 7.2),

E29 Practice for Using Significant Digits in Test Data to

4.1.7 Certification or test report, or both, if specified (Sec-

Determine Conformance with Specifications

tion 15), and

E1077 Test Methods for Estimating the Depth of Decarbur-

4.1.8 ASTM designation and date of issue.

ization of Steel Specimens

2.2 American National Standard:

NOTE 1—Atypicalmetricorderingdescriptionisasfollows:10 000kg

B 32.4M Preferred Metric Sizes for Round, Square, Rect- oil-tempered steel mechanical spring wire, Class I, 8.00 mm diameter, in

250-kg coils to ASTM A229 M – xx, or for inch-pound units, 20 000 lb

angle, and Hexagon Metal Products

oil-tempered steel mechanical Spring Wire, Class I 0.315 in. diameter, in

500-lb coils to ASTM A 229 – xx.

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

5. General Requirements

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

A01.03 on Steel Rod and Wire.

5.1 Material furnished to this specification shall conform to

Current edition approved May 1, 2005. Published May 2005. Originally

the applicable requirements of either Specification A510Mor

approved in 1939. Last previous edition approved in 1999A229/A229M – 99. DOI:

Specification A510.

10.1520/A0229_A0229M-99R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

3 5

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., Available from the Automotive Industry Action Group, 26200 Lahser, Suite

4th Floor, New York, NY 10036. 200, Southfield, MI 48034.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A229/A229M – 99 (2005)

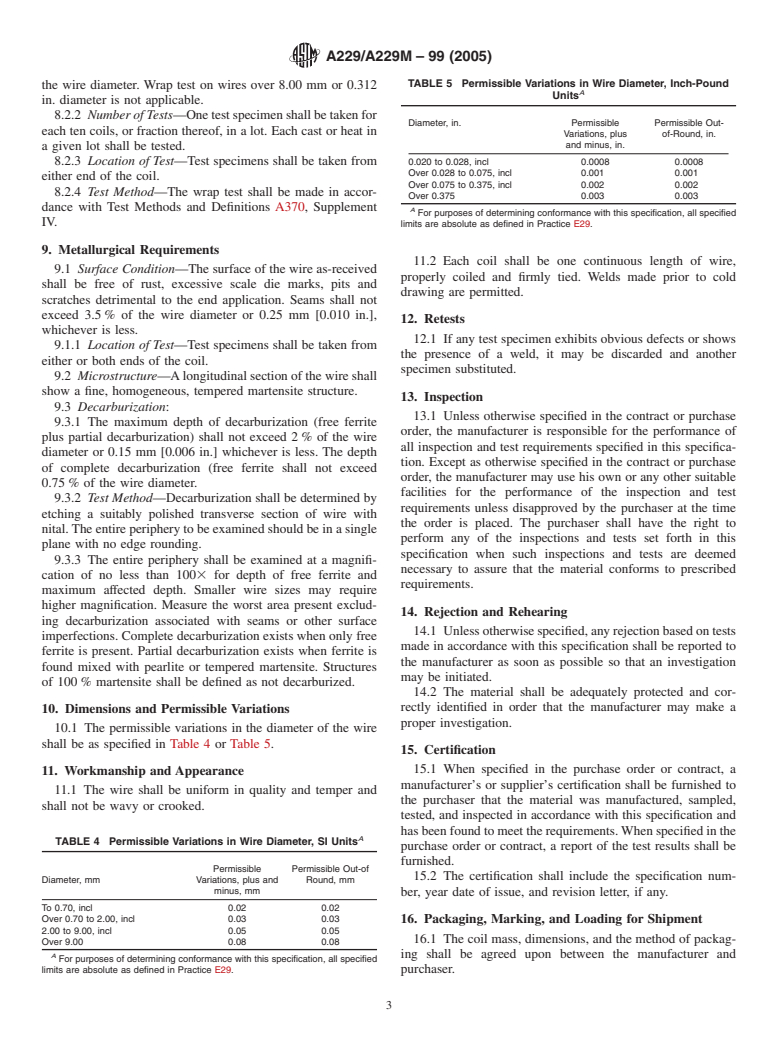

A

TABLE 1 Tensile Requirements, SI Units TABLE 2 Tensile Requirements, Inch-Pound Units

Class I Class II Class I Class II

B A

Diameter, mm Tensile Strength, MPa Tensile Strength, MPa Diameter, in. Tensile Strength, ksi† Tensile Strength, ksi

min max min max min max min max

0.50 2050 2250 2230 2450 0.020 293 323 324 354

0.55 2020 2220 2220 2440 0.023 289 319 320 350

0.60 2000 2200 2210 2430 0.026 286 316 317 347

0.65 1950 2150 2190 2410 0.029 283 313 314 344

0.70 1950 2150 2170 2190 0.032 280 310 311 341

0.80 1900 2100 2140 2360 0.035 274 304 305 335

0.90 1850 2050 2100 2320 0.041 266 296 297 327

1.00 1800 2000 2060 2280 0.048 259 289 290 320

1.10 1780 1980 2030 2240 0.054 253 283 284 314

1.20 1750 1950 2000 2210 0.062 247 277 278 308

1.40 1700 1900 1950 2150 0.072 241 271 272 302

1.60 1650 1850 1900 2100 0.080 235 265 266 296

1.80 1620 1820 1860 2060 0.092 230 260 261 291

2.00 1600 1800 1820 2020 0.106 225 255 256 286

2.20 1580 1780 1790 1990 0.120 220 250 251 281

2.50 1550 1750 1750 1950 0.135 215 240 241 266

2.80 1520 1720 1710 1900 0.148 210 235 236 261

3.00 1500 1700 1690 1880 0.162 205 230 231 256

3.50 1450 1620 1640 1830 0.177 200 225 226 251

4.00 1400 1580 1600 1780 0.192 195 220 221 246

4.50 1380 1550 1560 1740 0.207 190 215 216 241

5.00 1350 1520 1520 1700 0.225 188 213 214 239

5.50 1320 1500 1500 1680 0.244 187 212 213 238

6.00 1300 1480 1480 1660 0.250 185 210 211 236

7.00 1280 1450 1450 1630 0.312 183 208 209 234

8.00 1250 1430 1430 1610 0.375 180 205 206 231

9.00 1220 1400 1410 1590 0.438 175 200 201 226

10.00 1200 1380 1400 1580 0.500 170 195 196 221

11.00 1180 1350 1380 1560 0.562 165 190 191 216

12.00 1150 1320 1360 1540 0.625 165 190 191 216

14.00 1120 1300 1340 1520

A

Tensile strength values for intermediate diameters shall be interpolated.

16.00 1120 1300 1320 1500

A

Tensile strength values for intermediate diameters shall be interpolated.

B TABLE 3 Chemical Requirements

Preferred sizes. For a complete list, refer to ANSI B 32.4M , Preferred Metric

Sizes for Round, Square, Rectangle, and Hexagon Metal Products.

Element Composition, %

Carbon 0.55–0.85

6. Materials and Manufacture

A

Manganese 0.30–1.20

6.1 The steel may be made by any commercially accepted

Phosphorus, max 0.040

Sulfur, max 0.050

steel-making process. The steel may be either ingot cast or

Silicon 0.15–0.35

strand cast.

A

Generally 0.80/1.20 % manganese for diameter 5.00 mm or 0.192 in. and

6.2 The finished wire shall be free of detrimental pipe and

larger; 0.30/0.90 % for diameters less than 5.00 mm or 0.192 in. The choice of

undue segregation.

composition shall be optional with the manufacturer unless the purchaser definitely

specifies otherwise.

6.3 The wire shall be oil quenched and tempered to produce

the desired mechanical properties.

7. Chemical Composition 8. Mechanical Properties

7.1 Thesteelshallconformtotherequirementsforchemical 8.1 Tension Test:

8.1.1 Requirements—Thematerialasrepresentedbytension

composition prescribed in Table 3.

7.2 Cast or Heat Analysis—Each cast or heat of steel shall test specimens shall conform to the requirements prescribed in

beanalyzedbythemanufacturertodeterminethepercentageof Table 1 or Table 2.

elements prescribed in Table 3. This analysis shall be made 8.1.2 Number of Tests—Onetestspecimenshallbetakenfor

fromatestspecimenpreferablytakenduringthepouringofthe each ten coils or fraction thereof, in a lot. Each cast or heat in

cast or heat. When requested, this shall be reported to the a given lot shall be tested.

purchaser and shall conform to the requirements of Table 3. 8.1.3 Location of Tests—Test specime

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.