ASTM D5397-99e1

(Test Method)Standard Test Method for Evaluation of Stress Crack Resistance of Polyolefin Geomembranes Using Notched Constant Tensile Load Test

Standard Test Method for Evaluation of Stress Crack Resistance of Polyolefin Geomembranes Using Notched Constant Tensile Load Test

SCOPE

1.1 This test method is used to develop test data from which the susceptibility of polyolefin geomembrane sheet material to stress cracking under a constant tensile load condition and an accelerated environmental condition can be evaluated.

1.2 This test method measures the failure time associated with a given test specimen at a specified tensile load level. Results from a series of such tests utilizing a range of load levels can be used to construct a stress-time plot on a log-log axis.

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are provided for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

e1

Designation: D 5397 – 99

Standard Test Method for

Evaluation of Stress Crack Resistance of Polyolefin

1

Geomembranes Using Notched Constant Tensile Load Test

This standard is issued under the fixed designation D 5397; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—12.1 and Table 1 were added editorially in August 2002.

1. Scope man-made project, structure, or system (see Test Method

D 4833).

1.1 This test method is used to develop test data from which

3.1.2 stress crack, n—an external or internal crack in a

the susceptibility of polyolefin geomembrane sheet material to

plastic caused by tensile stresses less than its short-time

stress cracking under a constant tensile load condition and an

mechanical strength (see Definitions D 883).

accelerated environmental condition can be evaluated.

3.1.2.1 Discussion—The development of such cracks is

1.2 This test method measures the failure time associated

frequently accelerated by the environment to which the plastic

with a given test specimen at a specified tensile load level.

is exposed. The stresses that cause cracking may be present

Results from a series of such tests utilizing a range of load

internally or externally or may be combinations of these

levels can be used to construct a stress-time plot on a log-log

stresses.

axis.

1.3 The values stated in SI units are to be regarded as the

4. Summary of Test Method

standard. The inch-pound units given in parentheses are

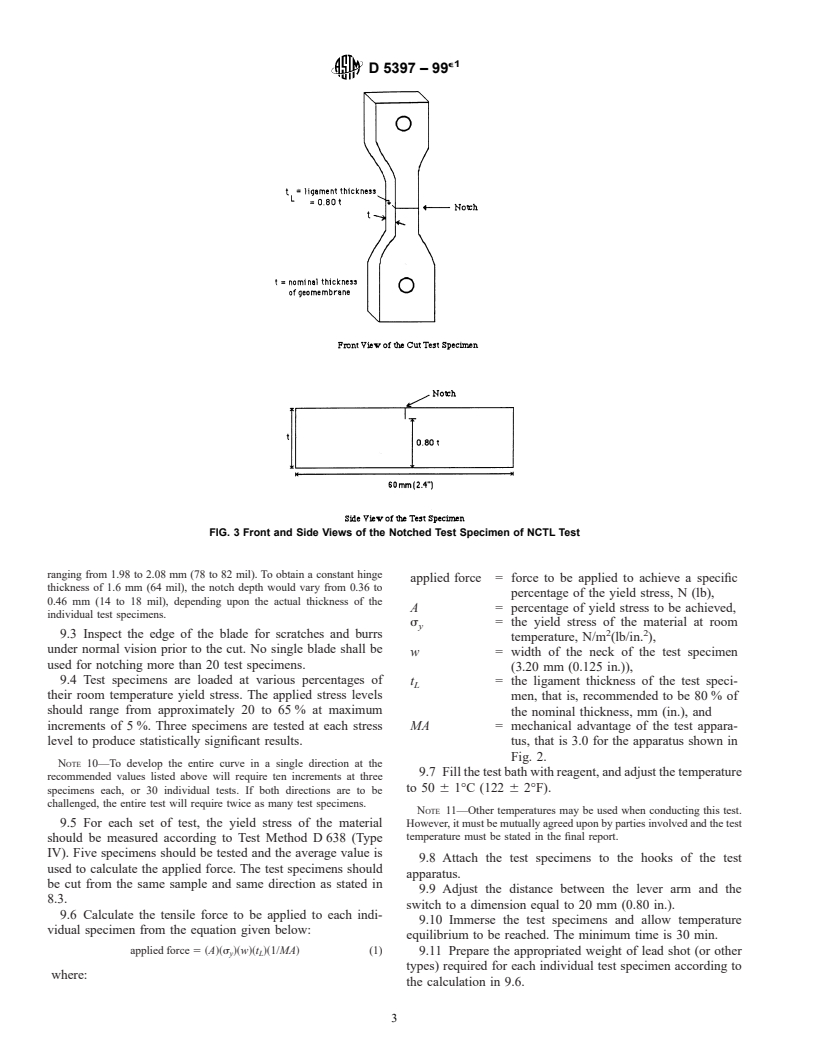

4.1 This test method consists of subjecting a dumbbell

provided for information only.

shaped notched test specimen from a polyolefin sheet to a

1.4 This standard does not purport to address all of the

constant tensile load in the presence of a surface-active agent

safety concerns, if any, associated with its use. It is the

and at an elevated temperature. The time to failure of the test

responsibility of the user of this standard to establish appro-

specimen is recorded. The results of a series of such tests

priate safety and health practices and determine the applica-

conducted at different stress levels are presented by plotting

bility of regulatory limitations prior to use.

stress level against failure time for each stress level on a

2. Referenced Documents log-log axis.

2.1 ASTM Standards:

5. Significance and Use

2

D 638 Test Method for Tensile Properties of Plastics

2 5.1 This test method does not purport to interpret the

D 883 Terminology Relating to Plastics

3 resulting response curve. Such interpretation is left to the

D 4354 Practice for Sampling of Geosynthetics for Testing

parties involved in the commissioning and reporting of the test

D 4491 Test Methods for Water Permeability of Geotextiles

3 results.

by Permittivity

5.2 This test method is intended as an index test and may be

D 4833 Test Method for Index Puncture Resistance of

3 used for grading polyolefin geomembrane sheets in regard to

Geotextiles, Geomembranes, and Related Products

their stress cracking sensitivity.

3. Terminology 5.2.1 Conditions that can affect stress cracking include:

level of loading, test temperature and environment, microstruc-

3.1 Definitions:

ture, polymer additive package, processing history, and thermal

3.1.1 geomembrane, n—very low permeability synthetic

history.

membrane liners or barriers used with any geotechnical engi-

neering related material so as to control fluid migration in a

6. Apparatus

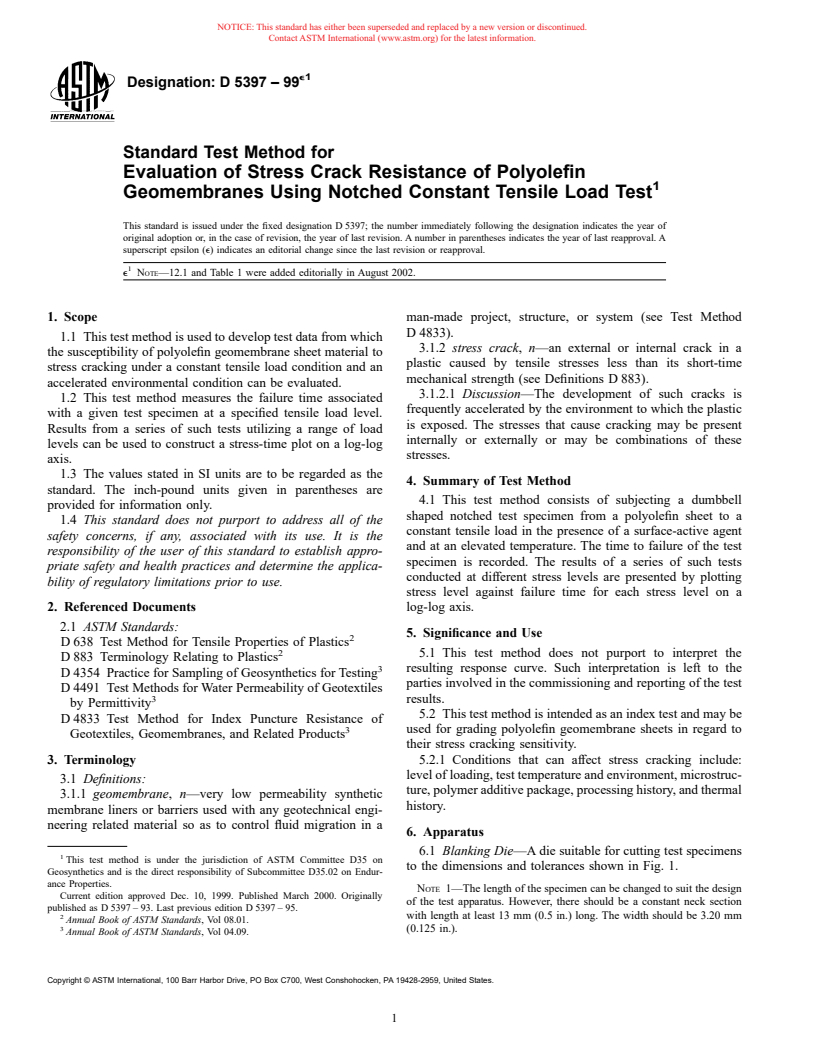

6.1 Blanking Die—A die suitable for cutting test specimens

1

This test method is under the jurisdiction of ASTM Committee D35 on

to the dimensions and tolerances shown in Fig. 1.

Geosynthetics and is the direct responsibility of Subcommittee D35.02 on Endur-

ance Properties.

NOTE 1—The length of the specimen can be changed to suit the design

Current edition approved Dec. 10, 1999. Published March 2000. Originally

of the test apparatus. However, there should be a constant neck section

published as D 5397 – 93. Last previous edition D 5397 – 95.

2 with length at least 13 mm (0.5 in.) long. The width should be 3.20 mm

Annual Book of ASTM Standards, Vol 08.01.

3

(0.125 in.).

Annual Book of ASTM Standards, Vol 04.09.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

D5397–99

desired loading on each specimen. The surface-active agent in which the

specimens are immersed is contained in an open stainless steel tank. A

submersion heater and controller are used to maintain the test temperature.

A pump keeps the liquid in a constant state of agitation. A timing clock for

each test specimen is also provided to record automatically the failure time

of the test specimens to the nearest 0.1 h.

NOTE 4—If “on/off” switches are used to control the ti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.