ASTM D1335-03

(Test Method)Standard Test Method for Tuft Bind of Pile Yarn Floor Coverings

Standard Test Method for Tuft Bind of Pile Yarn Floor Coverings

SCOPE

1.1 This test method covers the measurement of the force required to pull a tuft completely out of a pile yarn floor covering sample.

1.2 This test method is applicable to both cut and loop pile yarn floor covering.

1.3 The values stated in SI units are to be regarded as standard; the values inch-pound units are provided as information only and are not exact equivalents. In case of referee decisions the SI units shall prevail.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1335–03

Standard Test Method for

1

Tuft Bind of Pile Yarn Floor Coverings

This standard is issued under the fixed designation D 1335; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.2 loop pile yarn floor covering, n—a pile yarn floor

covering in which the pile is composed only of uncut loops.

1.1 This test method covers the measurement of the force

3.1.3 tuft bind, n—in pile fabrics, the force required to pull

required to pull a tuft completely out of a pile yarn floor

a tuft element from the pile yarn floor covering.

covering sample.

3.1.4 For definitions of pile yarn floor covering related

1.2 This test method is applicable to both cut and loop pile

terms, refer to Terminology D 5684. For definitions of other

yarn floor covering.

textile terms used in this test method refer to Terminology

1.3 The values stated in SI units are to be regarded as

D 123.

standard; the values inch-pound units are provided as informa-

tion only and are not exact equivalents. In case of referee

4. Summary of Method

decisions the SI units shall prevail.

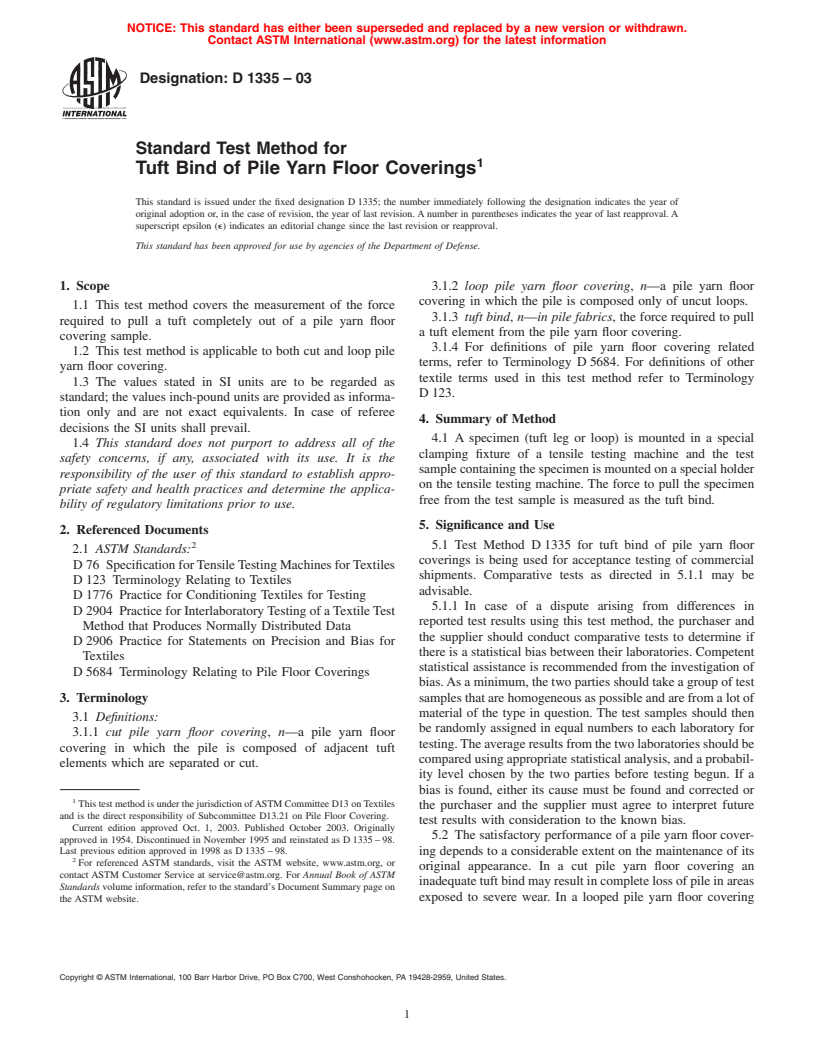

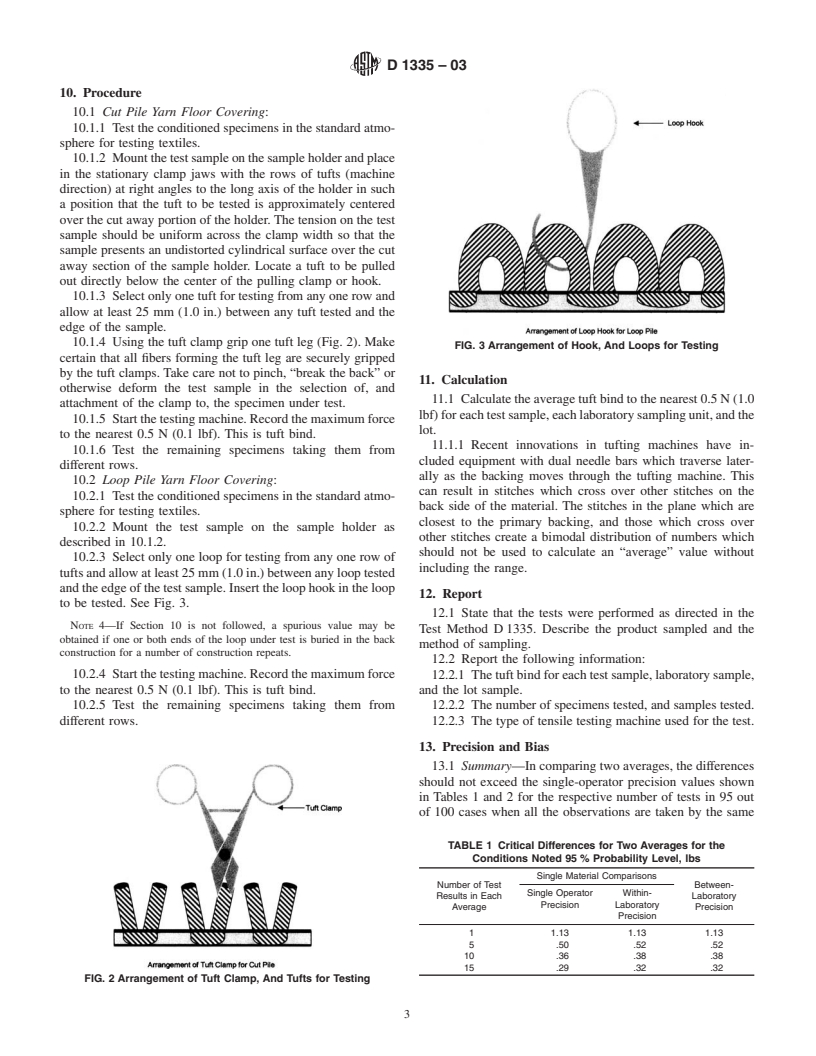

4.1 A specimen (tuft leg or loop) is mounted in a special

1.4 This standard does not purport to address all of the

clamping fixture of a tensile testing machine and the test

safety concerns, if any, associated with its use. It is the

sample containing the specimen is mounted on a special holder

responsibility of the user of this standard to establish appro-

on the tensile testing machine. The force to pull the specimen

priate safety and health practices and determine the applica-

free from the test sample is measured as the tuft bind.

bility of regulatory limitations prior to use.

5. Significance and Use

2. Referenced Documents

2 5.1 Test Method D 1335 for tuft bind of pile yarn floor

2.1 ASTM Standards:

coverings is being used for acceptance testing of commercial

D 76 SpecificationforTensileTestingMachinesforTextiles

shipments. Comparative tests as directed in 5.1.1 may be

D 123 Terminology Relating to Textiles

advisable.

D 1776 Practice for Conditioning Textiles for Testing

5.1.1 In case of a dispute arising from differences in

D 2904 Practice for Interlaboratory Testing of a Textile Test

reported test results using this test method, the purchaser and

Method that Produces Normally Distributed Data

the supplier should conduct comparative tests to determine if

D 2906 Practice for Statements on Precision and Bias for

there is a statistical bias between their laboratories. Competent

Textiles

statistical assistance is recommended from the investigation of

D 5684 Terminology Relating to Pile Floor Coverings

bias.As a minimum, the two parties should take a group of test

3. Terminology samples that are homogeneous as possible and are from a lot of

material of the type in question. The test samples should then

3.1 Definitions:

be randomly assigned in equal numbers to each laboratory for

3.1.1 cut pile yarn floor covering, n—a pile yarn floor

testing.Theaverageresultsfromthetwolaboratoriesshouldbe

covering in which the pile is composed of adjacent tuft

compared using appropriate statistical analysis, and a probabil-

elements which are separated or cut.

ity level chosen by the two parties before testing begun. If a

bias is found, either its cause must be found and corrected or

1

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

the purchaser and the supplier must agree to interpret future

and is the direct responsibility of Subcommittee D13.21 on Pile Floor Covering.

test results with consideration to the known bias.

Current edition approved Oct. 1, 2003. Published October 2003. Originally

5.2 The satisfactory performance of a pile yarn floor cover-

approved in 1954. Discontinued in November 1995 and reinstated as D 1335 – 98.

Last previous edition approved in 1998 as D 1335 – 98.

ing depends to a considerable extent on the maintenance of its

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

original appearance. In a cut pile yarn floor covering an

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

inadequate tuft bind may result in complete loss of pile in areas

Standards volume information, refer to the standard’s Document Summary page on

exposed to severe wear. In a looped pile yarn floor covering

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1335–03

with inadequate tuf

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.