ASTM B37-96(2001)

(Specification)Standard Specification for Aluminum for Use in Iron and Steel Manufacture

Standard Specification for Aluminum for Use in Iron and Steel Manufacture

SCOPE

1.1 This specification covers aluminum and aluminum alloys in the form of ingots, rods, or shot, designated as shown in Table 1, for use in the manufacture of iron and steel.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 37 – 96 (Reapproved 2001)

Standard Specification for

Aluminum for Use in Iron and Steel Manufacture

This standard is issued under the fixed designation B 37; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

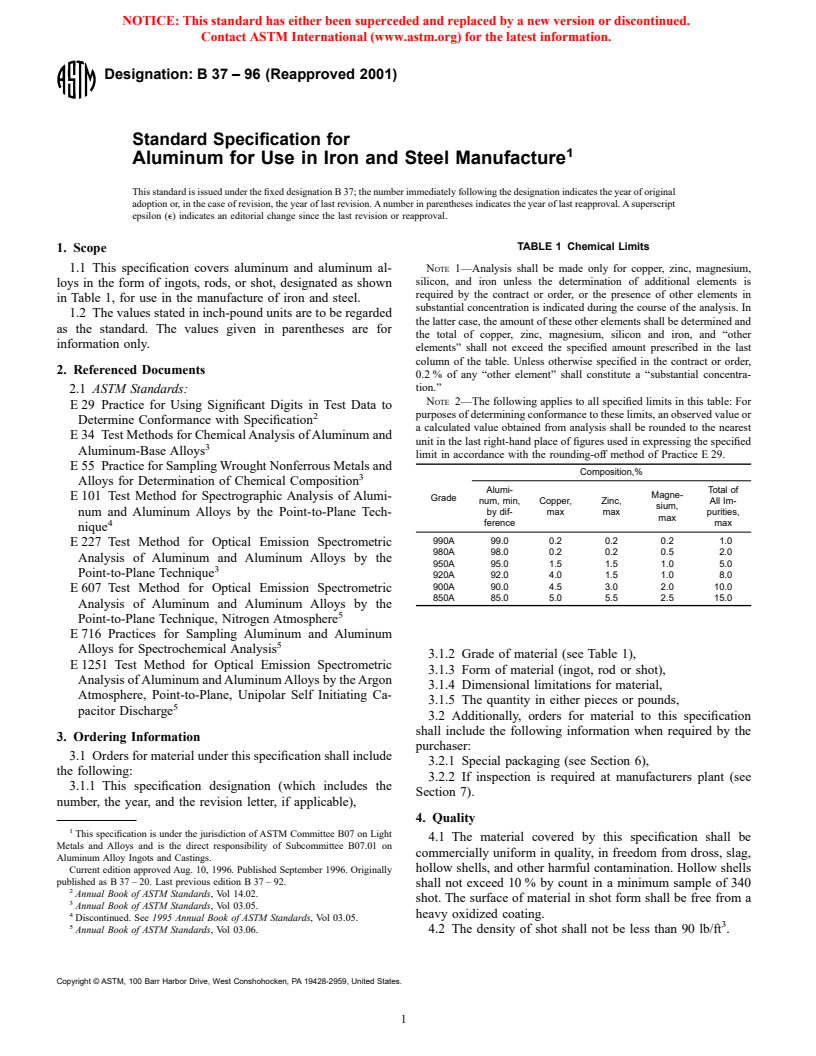

TABLE 1 Chemical Limits

1. Scope

1.1 This specification covers aluminum and aluminum al- NOTE 1—Analysis shall be made only for copper, zinc, magnesium,

silicon, and iron unless the determination of additional elements is

loys in the form of ingots, rods, or shot, designated as shown

required by the contract or order, or the presence of other elements in

in Table 1, for use in the manufacture of iron and steel.

substantial concentration is indicated during the course of the analysis. In

1.2 The values stated in inch-pound units are to be regarded

the latter case, the amount of these other elements shall be determined and

as the standard. The values given in parentheses are for

the total of copper, zinc, magnesium, silicon and iron, and “other

information only.

elements” shall not exceed the specified amount prescribed in the last

column of the table. Unless otherwise specified in the contract or order,

2. Referenced Documents

0.2 % of any “other element” shall constitute a “substantial concentra-

tion.”

2.1 ASTM Standards:

NOTE 2—The following applies to all specified limits in this table: For

E 29 Practice for Using Significant Digits in Test Data to

purposes of determining conformance to these limits, an observed value or

Determine Conformance with Specification

a calculated value obtained from analysis shall be rounded to the nearest

E 34 Test Methods for Chemical Analysis of Aluminum and

unit in the last right-hand place of figures used in expressing the specified

Aluminum-Base Alloys

limit in accordance with the rounding-off method of Practice E 29.

E 55 Practice for Sampling Wrought Nonferrous Metals and

Composition,%

Alloys for Determination of Chemical Composition

Alumi- Total of

Magne-

E 101 Test Method for Spectrographic Analysis of Alumi- Grade

num, min, Copper, Zinc, All Im-

sium,

num and Aluminum Alloys by the Point-to-Plane Tech- by dif- max max purities,

max

4 ference max

nique

990A 99.0 0.2 0.2 0.2 1.0

E 227 Test Method for Optical Emission Spectrometric

980A 98.0 0.2 0.2 0.5 2.0

Analysis of Aluminum and Aluminum Alloys by the

950A 95.0 1.5 1.5 1.0 5.0

Point-to-Plane Technique

920A 92.0 4.0 1.5 1.0 8.0

900A 90.0 4.5 3.0 2.0 10.0

E 607 Test Method for Optical Emission Spectrometric

850A 85.0 5.0 5.5 2.5 15.0

Analysis of Aluminum and Aluminum Alloys by the

Point-to-Plane Technique, Nitrogen Atmosphere

E 716 Practices for Sampling Aluminum and Aluminum

Alloys for Spectrochemical Analysis

3.1.2 Grade of material (see Table 1),

E 1251 Test Method for Optical Emission Spectrometric

3.1.3 Form of material (ingot, rod or shot),

Analysis of Aluminum and Aluminum Alloys by the Argon

3.1.4 Dimensional limitations for material,

Atmosphere, Point-to-Plane, Unipolar Self Initiating Ca-

3.1.5 The quantity in either pieces or pounds,

pacitor Discharge

3.2 Additionally, orders for material to this specification

shall include the following information when required by the

3. Ordering Information

purchaser:

3.1 Orders for material under this specification shall include

3.2.1 Special packaging (see Section 6),

the following:

3.2.2 If inspection is required at manufacturers plant (see

3.1.1 This specification designation (which includes the

Section 7).

number, the year, and the revision letter, if applicable),

4. Quality

This specification is under the jurisdiction of ASTM Committee B07 on Light

4.1 The material covered by this specification shall be

Metals and Alloys and is the direct responsibility of Subcommittee B07.01 on

commercially uniform in quality, in freedom from dross, slag,

Aluminum Alloy Ingots and Castings.

hollow shells, and other harmful contamination. Hollow shells

Current edition approved Aug. 10, 1996. Published September 1996. Originally

published as B 37 – 20. Last previous edition B 37 – 92.

shall not exceed 10 % by count in a minimum sample of 340

Annual Book of ASTM Standards, Vol 14.02.

shot. The surface of material in shot form shall be free from a

Annual Book of ASTM Standards, Vol 03.05.

heavy oxidized coating.

Discontinued. See 1995 Annual Book of ASTM Standards, Vol 03.05.

Annual Book of ASTM Standards, Vol 03.06. 4.2 The density of shot shall not be less than 90 lb/ft .

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B37

5. Chemical Composition 6. Packaging, Marking, and Shipping

5.1 Limits—The material shall conform to the chemical

6.1 The material shall be packaged in such a manner as to

composition limits specified in Table 1. Conformance shall be prevent damage in ordinary handling and transportation. The

determined by the producer by analyzing samples from e

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.