ASTM D83-84(2002)

(Specification)Standard Specification for Red Lead Pigment

Standard Specification for Red Lead Pigment

SCOPE

1.1 This specification covers four grades of red pigment commercially known as red lead. The pigment may be purchased in the dry form or as a paste in oil.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 83 – 84 (Reapproved 2002)

Standard Specification for

Red Lead Pigment

ThisstandardisissuedunderthefixeddesignationD 83;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

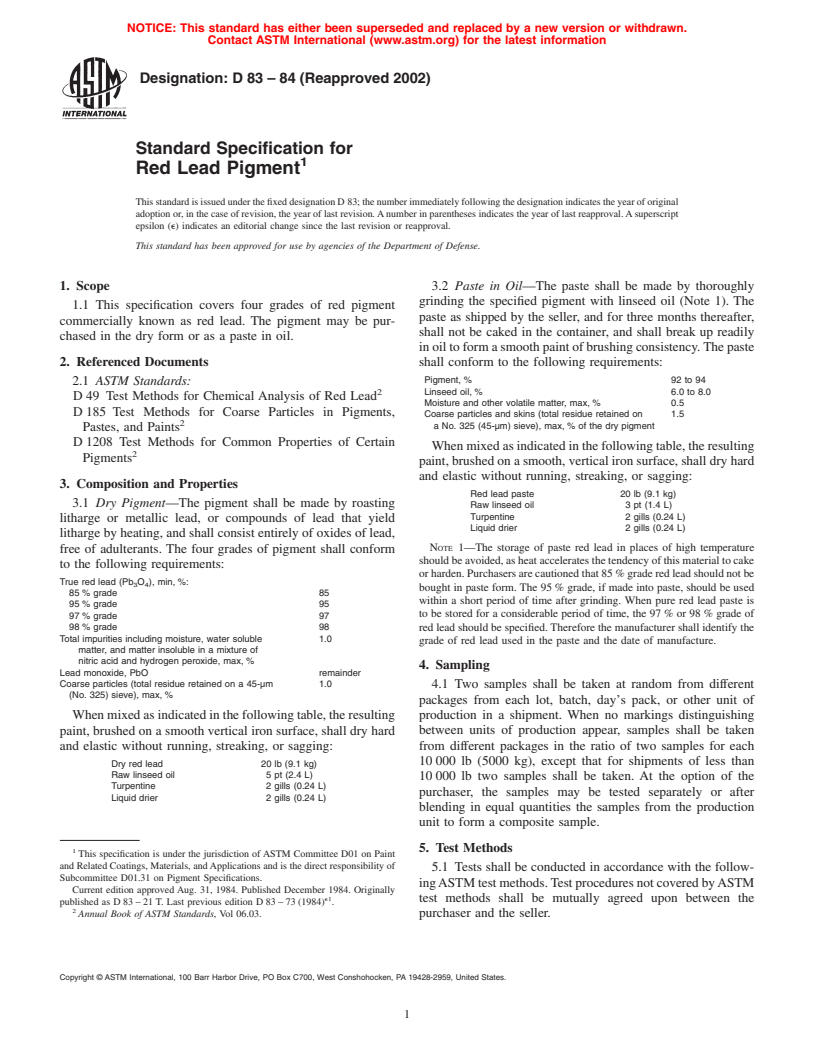

1. Scope 3.2 Paste in Oil—The paste shall be made by thoroughly

grinding the specified pigment with linseed oil (Note 1). The

1.1 This specification covers four grades of red pigment

paste as shipped by the seller, and for three months thereafter,

commercially known as red lead. The pigment may be pur-

shall not be caked in the container, and shall break up readily

chased in the dry form or as a paste in oil.

inoiltoformasmoothpaintofbrushingconsistency.Thepaste

2. Referenced Documents shall conform to the following requirements:

Pigment, % 92 to 94

2.1 ASTM Standards:

Linseed oil, % 6.0 to 8.0

D 49 Test Methods for Chemical Analysis of Red Lead

Moisture and other volatile matter, max, % 0.5

D 185 Test Methods for Coarse Particles in Pigments,

Coarse particles and skins (total residue retained on 1.5

a No. 325 (45-µm) sieve), max, % of the dry pigment

Pastes, and Paints

D 1208 Test Methods for Common Properties of Certain

Whenmixedasindicatedinthefollowingtable,theresulting

Pigments

paint, brushed on a smooth, vertical iron surface, shall dry hard

and elastic without running, streaking, or sagging:

3. Composition and Properties

Red lead paste 20 lb (9.1 kg)

3.1 Dry Pigment—The pigment shall be made by roasting

Raw linseed oil 3 pt (1.4 L)

Turpentine 2 gills (0.24 L)

litharge or metallic lead, or compounds of lead that yield

Liquid drier 2 gills (0.24 L)

litharge by heating, and shall consist entirely of oxides of lead,

NOTE 1—The storage of paste red lead in places of high temperature

free of adulterants. The four grades of pigment shall conform

shouldbeavoided,asheatacceleratesthetendencyofthismaterialtocake

to the following requirements:

or harden. Purchasers are cautioned that 85 % grade red lead should not be

True red lead (Pb O ), min, %:

3 4

bought in paste form. The 95 % grade, if made into paste, should be used

85 % grade 85

within a short period of time after grinding. When pure red lead paste is

95 % grade 95

to be stored for a considerable period of time, the 97 % or 98 % grade of

97 % grade 97

98 % grade 98 red lead should be specified. Therefore the manufacturer shall identify the

Total impurities including moisture, water soluble 1.0

grade of red lead used in the paste and the date of manufacture.

matter, and matter insoluble in a mixture of

nitric acid and hydrogen peroxide, max, %

4. Sampling

Lead monoxide, PbO remainder

Coarse particles (total residue retained on a 45-µm 1.0

4.1 Two samples shall be taken at random from different

(No. 325) sieve), max, %

pac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.