ASTM D5470-17

(Test Method)Standard Test Method for Thermal Transmission Properties of Thermally Conductive Electrical Insulation Materials

Standard Test Method for Thermal Transmission Properties of Thermally Conductive Electrical Insulation Materials

SIGNIFICANCE AND USE

5.1 This standard measures the steady state thermal impedance of electrical insulating materials used to enhance heat transfer in electrical and electronic applications. This standard is especially useful for measuring thermal transmission properties of specimens that are either too thin or have insufficient mechanical stability to allow placement of temperature sensors in the specimen as in Test Method E1225.

5.2 This standard imposes an idealized heat flow pattern and specifies an average specimen test temperature. The thermal impedances thus measured cannot be directly applied to most practical applications where these required uniform, parallel heat conduction conditions do not exist.

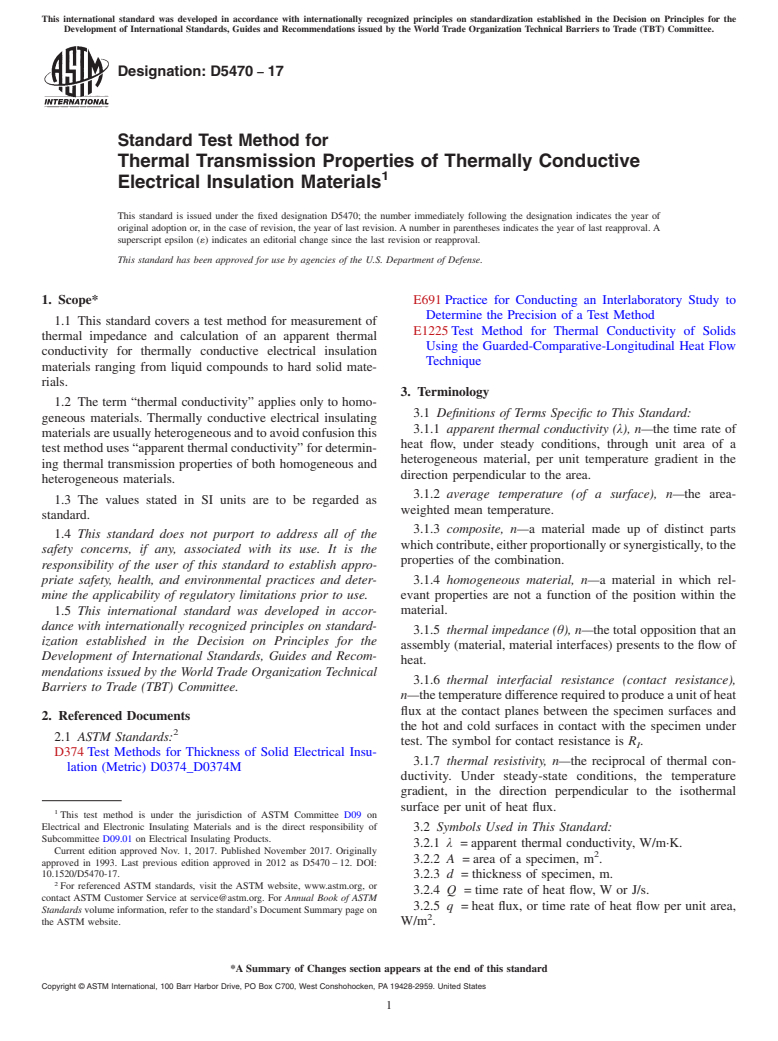

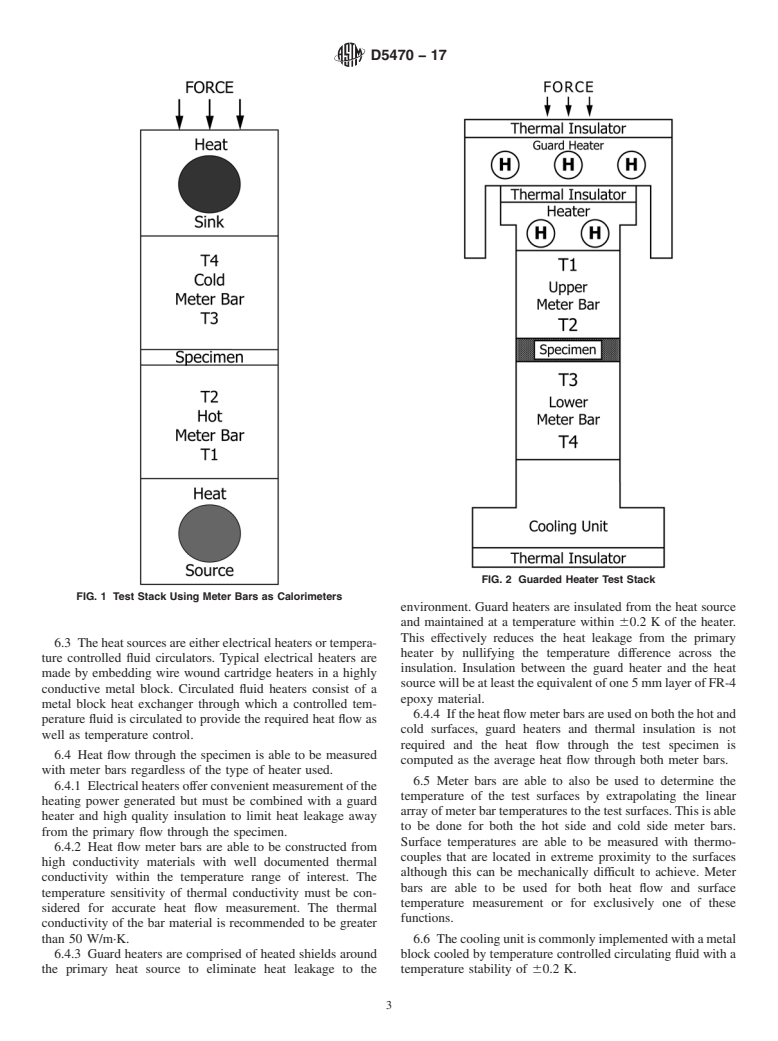

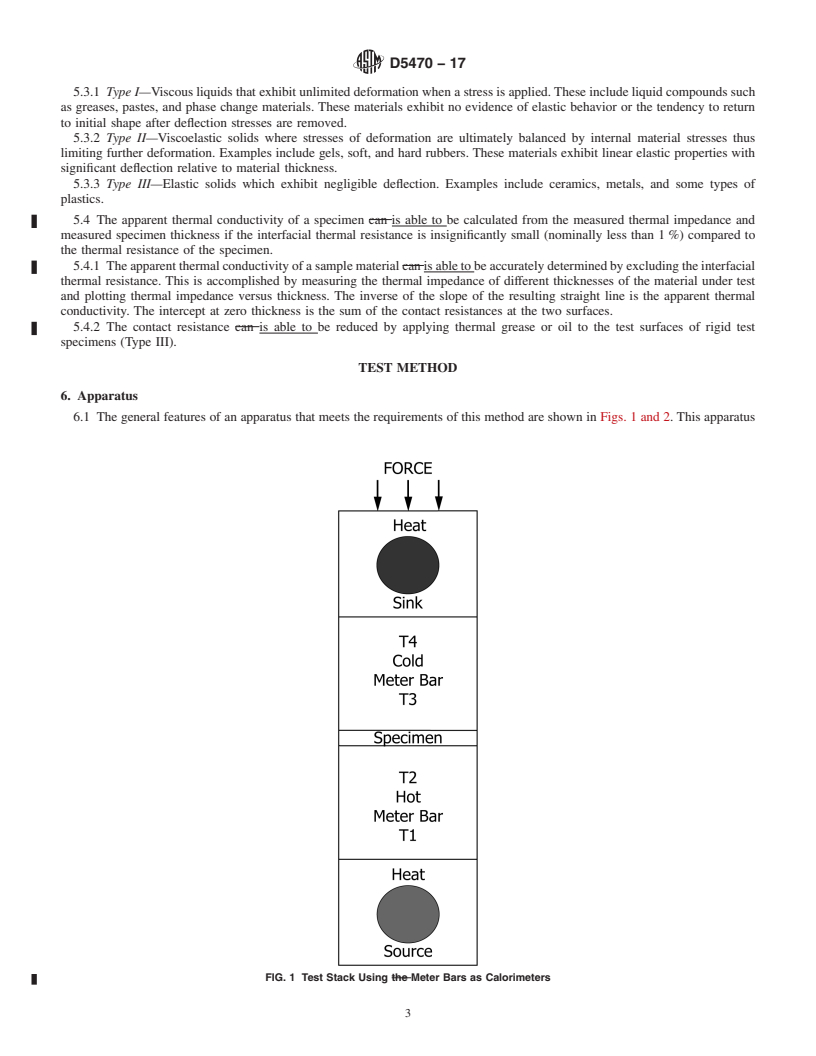

5.3 This standard is useful for measuring the thermal impedance of the following material types.

5.3.1 Type I—Viscous liquids that exhibit unlimited deformation when a stress is applied. These include liquid compounds such as greases, pastes, and phase change materials. These materials exhibit no evidence of elastic behavior or the tendency to return to initial shape after deflection stresses are removed.

5.3.2 Type II—Viscoelastic solids where stresses of deformation are ultimately balanced by internal material stresses thus limiting further deformation. Examples include gels, soft, and hard rubbers. These materials exhibit linear elastic properties with significant deflection relative to material thickness.

5.3.3 Type III—Elastic solids which exhibit negligible deflection. Examples include ceramics, metals, and some types of plastics.

5.4 The apparent thermal conductivity of a specimen is able to be calculated from the measured thermal impedance and measured specimen thickness if the interfacial thermal resistance is insignificantly small (nominally less than 1 %) compared to the thermal resistance of the specimen.

5.4.1 The apparent thermal conductivity of a sample material is able to be accurately determined by excluding the interfacial thermal resistance. ...

SCOPE

1.1 This standard covers a test method for measurement of thermal impedance and calculation of an apparent thermal conductivity for thermally conductive electrical insulation materials ranging from liquid compounds to hard solid materials.

1.2 The term “thermal conductivity” applies only to homogeneous materials. Thermally conductive electrical insulating materials are usually heterogeneous and to avoid confusion this test method uses “apparent thermal conductivity” for determining thermal transmission properties of both homogeneous and heterogeneous materials.

1.3 The values stated in SI units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5470 − 17

Standard Test Method for

Thermal Transmission Properties of Thermally Conductive

1

Electrical Insulation Materials

This standard is issued under the fixed designation D5470; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This standard covers a test method for measurement of

E1225 Test Method for Thermal Conductivity of Solids

thermal impedance and calculation of an apparent thermal

Using the Guarded-Comparative-Longitudinal Heat Flow

conductivity for thermally conductive electrical insulation

Technique

materials ranging from liquid compounds to hard solid mate-

rials.

3. Terminology

1.2 The term “thermal conductivity” applies only to homo-

3.1 Definitions of Terms Specific to This Standard:

geneous materials. Thermally conductive electrical insulating

3.1.1 apparent thermal conductivity (λ), n—the time rate of

materialsareusuallyheterogeneousandtoavoidconfusionthis

heat flow, under steady conditions, through unit area of a

testmethoduses“apparentthermalconductivity”fordetermin-

heterogeneous material, per unit temperature gradient in the

ing thermal transmission properties of both homogeneous and

direction perpendicular to the area.

heterogeneous materials.

3.1.2 average temperature (of a surface), n—the area-

1.3 The values stated in SI units are to be regarded as

weighted mean temperature.

standard.

3.1.3 composite, n—a material made up of distinct parts

1.4 This standard does not purport to address all of the

whichcontribute,eitherproportionallyorsynergistically,tothe

safety concerns, if any, associated with its use. It is the

properties of the combination.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- 3.1.4 homogeneous material, n—a material in which rel-

mine the applicability of regulatory limitations prior to use. evant properties are not a function of the position within the

1.5 This international standard was developed in accor- material.

dance with internationally recognized principles on standard-

3.1.5 thermal impedance (θ), n—the total opposition that an

ization established in the Decision on Principles for the

assembly (material, material interfaces) presents to the flow of

Development of International Standards, Guides and Recom-

heat.

mendations issued by the World Trade Organization Technical

3.1.6 thermal interfacial resistance (contact resistance),

Barriers to Trade (TBT) Committee.

n—thetemperaturedifferencerequiredtoproduceaunitofheat

flux at the contact planes between the specimen surfaces and

2. Referenced Documents

the hot and cold surfaces in contact with the specimen under

2

2.1 ASTM Standards:

test. The symbol for contact resistance is R .

I

D374 Test Methods for Thickness of Solid Electrical Insu-

3.1.7 thermal resistivity, n—the reciprocal of thermal con-

lation (Metric) D0374_D0374M

ductivity. Under steady-state conditions, the temperature

gradient, in the direction perpendicular to the isothermal

surface per unit of heat flux.

1

This test method is under the jurisdiction of ASTM Committee D09 on

Electrical and Electronic Insulating Materials and is the direct responsibility of

3.2 Symbols Used in This Standard:

Subcommittee D09.01 on Electrical Insulating Products.

3.2.1 λ = apparent thermal conductivity, W/m·K.

Current edition approved Nov. 1, 2017. Published November 2017. Originally

2

3.2.2 A = area of a specimen, m .

approved in 1993. Last previous edition approved in 2012 as D5470 – 12. DOI:

10.1520/D5470-17.

3.2.3 d = thickness of specimen, m.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.2.4 Q = time rate of heat flow, W or J/s.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.5 q = heat flux, or time rate of heat flow per unit area,

Standards volume information, refer to the standard’s Document Summary page on

2

the ASTM website. W/m .

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5470 − 17

3.2.6 θ = thermal impedance, temperature difference per 5. Significance and

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5470 − 12 D5470 − 17

Standard Test Method for

Thermal Transmission Properties of Thermally Conductive

1

Electrical Insulation Materials

This standard is issued under the fixed designation D5470; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This standard covers a test method for measurement of thermal impedance and calculation of an apparent thermal

conductivity for thermally conductive electrical insulation materials ranging from liquid compounds to hard solid materials.

1.2 The term “thermal conductivity” applies only to homogeneous materials. Thermally conductive electrical insulating

materials are usually heterogeneous and to avoid confusion this test method uses “apparent thermal conductivity” for determining

thermal transmission properties of both homogeneous and heterogeneous materials.

1.3 The values stated in SI units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D374 Test Methods for Thickness of Solid Electrical Insulation (Metric) D0374_D0374M

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E1225 Test Method for Thermal Conductivity of Solids Using the Guarded-Comparative-Longitudinal Heat Flow Technique

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 apparent thermal conductivity (λ), n—the time rate of heat flow, under steady conditions, through unit area of a

heterogeneous material, per unit temperature gradient in the direction perpendicular to the area.

3.1.2 average temperature (of a surface), n—the area-weighted mean temperature.

3.1.3 composite, n—a material made up of distinct parts which contribute, either proportionally or synergistically, to the

properties of the combination.

3.1.4 homogeneous material, n—a material in which relevant properties are not a function of the position within the material.

3.1.5 thermal impedance (θ), n—the total opposition that an assembly (material, material interfaces) presents to the flow of heat.

3.1.6 thermal interfacial resistance (contact resistance), n—the temperature difference required to produce a unit of heat flux

at the contact planes between the specimen surfaces and the hot and cold surfaces in contact with the specimen under test. The

symbol for contact resistance is R .

I

1

This test method is under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and is the direct responsibility of Subcommittee

D09.01 on Electrical Insulating Products.

Current edition approved Jan. 1, 2012Nov. 1, 2017. Published February 2012November 2017. Originally approved in 1993. Last previous edition approved in 20112012

as D5470 – 11.D5470 – 12. DOI: 10.1520/D5470-12.10.1520/D5470-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5470 − 17

3.1.7 thermal resistivity, n—the reciprocal of thermal conductivity. Under steady-state conditions, the temperature gradient, in

the direction perpendicular to the isothermal surface per unit of heat flux.

3.2 Symbols Used in This Standard:

3.2.1 λ = apparent thermal conductivity, W/m·K.

2

3.2.2 A = area of a specimen, m .

3.2.3 d = t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.