ASTM F18-64(2000)

(Test Method)Standard Specification and Test Method for Evaluation of Glass-to-Metal Headers Used in Electron Devices

Standard Specification and Test Method for Evaluation of Glass-to-Metal Headers Used in Electron Devices

SCOPE

1.1 This specification and test method cover acceptance requirements for headers used in electron devices and describes procedures for determining conformance to these requirements.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following safety hazard caveat pertains only to the test method (Sections 6 - 12) described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 18 – 64 (Reapproved 2000)

Standard Specification and Test Method for

Evaluation of Glass-to-Metal Headers Used in Electron

Devices

ThisstandardisissuedunderthefixeddesignationF18;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1.3 Metallic parts shall be as free of draw lines or

grooves longer (by visual estimate) than one half of the seal

1.1 This specification and test method cover acceptance

length as best commercial practice will permit.

requirementsforheadersusedinelectrondevicesanddescribes

3.1.1.4 In the case of clear glass seals, reference is made to

procedures for determining conformance to these require-

the seal area only.

ments.

3.1.1.5 In the case of opaque glass seals, reference is made

1.2 The values stated in inch-pound units are to be regarded

to any portion of the exposed metal parts.

as the standard. The values given in parentheses are for

3.1.2 Leak:

information only.

3.1.2.1 Withtheheadersealedtothemassspectrometerleak

1.3 The following safety hazard caveat pertains only to the

detector,thenumberofdetectableleaksinasamplelotshallbe

testmethod(Sections6-12)describedinthisspecification. This

less than the limit agreed upon between the purchaser and the

standard does not purport to address all of the safety concerns,

seller.

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

TEST METHODS

practices and determine the applicability of regulatory limita-

tions prior to use.

4. Apparatus

4.1 Microscope, of 10 power magnification, unless other-

2. Terminology

wise specified, in combination with suitable incandescent

2.1 Definitions of Terms Specific to This Standard:

white light source.

2.1.1 The header may be described as an external metal

4.2 Mass Spectrometer Leak Detector, adjusted to respond

memberofcylindrical,oval,orothershapeintowhichissealed

toatracergassuchasheliumandcapableofdetectingleaksof

one or more wire leads or metal tubulations through a glass

−9

10 mL/s at standard temperature and pressure.

medium. The metal parts may be plated or unplated and the

4.3 Hood, having a volume of approximately 250 cm ,to

glass may be clear or opaque.

cover the test specimen completely with the tracer gas. (The

hood should be flushed with the tracer gas for at least 10 s).

3. Acceptance Requirements

4.4 Fixture, suitable for making a seal between the header

3.1 The headers shall conform to the requirements as

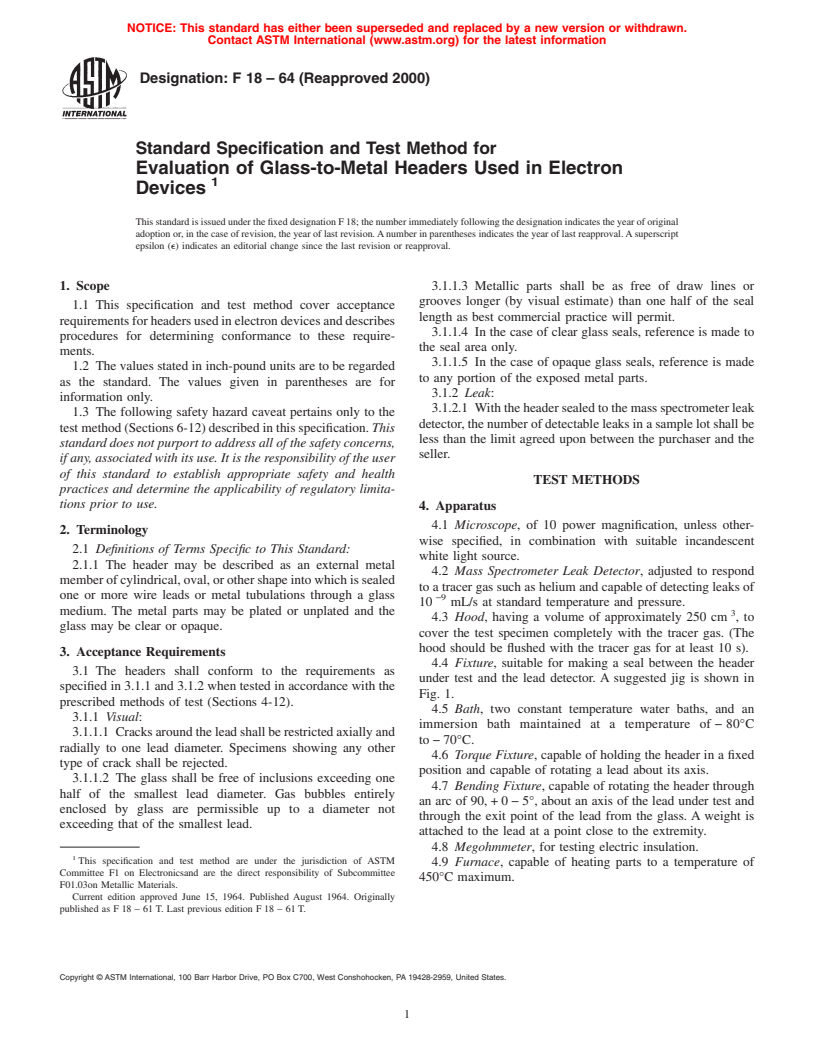

under test and the lead detector. A suggested jig is shown in

specified in 3.1.1 and 3.1.2 when tested in accordance with the

Fig. 1.

prescribed methods of test (Sections 4-12).

4.5 Bath, two constant temperature water baths, and an

3.1.1 Visual:

immersion bath maintained at a temperature of − 80°C

3.1.1.1 Cracksaroundtheleadshallberestrictedaxiallyand

to−70°C.

radially to one lead diameter. Specimens showing any other

4.6 Torque Fixture, capable of holding the header in a fixed

type of crack shall be rejected.

position and capable of rotating a lead about its axis.

3.1.1.2 The glass shall be free of inclusions exceeding one

4.7 Bending Fixture, capable of rotating the header through

half of the smallest lead diameter. Gas bubbles entirely

anarcof90,+0−5°, about an axis of the lead under test and

enclosed by glass are permissible up to a diameter not

through the exit point of the lead from the glass. A weight is

exceeding that of the smallest lead.

attached to the lead at a point close to the extremity.

4.8 Megohmmeter, for testing electric insulation.

This specification and test method are under the jurisdiction of ASTM

4.9 Furnace, capable of heating parts to a temperature of

Committee F1 on Electronicsand are the direct responsibility of Subcommittee

450°C maximum.

F01.03on Metallic Materials.

Current edition approved June 15, 1964. Published August 1964. Originally

published as F18 – 61T. Last previous edition F18 – 61T.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F18

FIG. 1 Fixture for Making a Seal Between the Header Under Test and the Leak Detector

4.10 Lead Pull Tester, capable of holding the header in a 1080 6 30° (3 complete revolutions) about its own axis at a

fixed position while applying a load along the axis of the lead

uniformrateof10to20r/min.Aftercompletionofthetest,the

in a direction perpendicular to the plane containing the rim of

header shall conform to the requirements specified in 3.1.

the header. The displacement of one constraining member of

7.2 Leads or Terminals Greater than 0.021 in. (0.53 mm) in

the tester shall increase at a constant rate with respect to the

Diameter—To the outer portion of the terminal at a point

second constraining member of the tester.

between 2 and 4 terminal diameters away from the glass,

slowly apply a torque of at least 0.445 kgf·cm/(mm of lead

5. Conditions of Test

diameter) or 250 lbf·in./(in. of lead diameter) as shown in

5.1 Tests

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.