ASTM D3641-97

(Practice)Standard Practice for Injection Molding Test Specimens of Thermoplastic Molding and Extrusion Materials

Standard Practice for Injection Molding Test Specimens of Thermoplastic Molding and Extrusion Materials

SCOPE

1.1 This practice covers the general principles to be followed when injection molding test specimens of thermoplastic molding and extrusion materials. This practice is to be used to obtain uniformity in methods of describing the various steps of the injection molding process and to set up uniform methods of reporting these conditions. The exact conditions required to prepare suitable specimens will vary for each plastic material. Those conditions should become a part of the specification for the material, or be agreed upon between the purchaser and the supplier. Any requirements or recommendations in the material specification which differ from this standard take precedence over those in this standard.

1.2 The methodology presented assumes the use of reciprocating screw injection molding machines.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—This practice is equivalent to the following parts of ISO 294: Plastics-Injection Moulding of Test Specimens of Thermoplastic Materials; 294-1: Part 1-General Principles and Multipurpose Test Specimens (ISO Type A Mould) and Bars (ISO Type B Mould); ISO 294-2: Part 2-Small Tensile Bars (ISO Type C Mould); ISO 294-3: Part 3-Plates (ISO Type D Moulds).

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3641 – 97

Standard Practice for

Injection Molding Test Specimens of Thermoplastic Molding

and Extrusion Materials

This standard is issued under the fixed designation D 3641; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * 2. Referenced Documents

1.1 This practice covers the general principles to be fol- 2.1 ASTM Standards:

lowed when injection molding test specimens of thermoplastic D 256 Test Methods for Impact Resistance of Plastics and

molding and extrusion materials. This practice is to be used to Electrical Insulating Materials

obtain uniformity in methods of describing the various steps of D 570 Test Method for Water Absorption of Plastics

the injection molding process and to set up uniform methods of D 638 Test Method for Tensile Properties of Plastics

reporting these conditions. The exact conditions required to D 648 Test Method for Deflection Temperature of Plastics

prepare adequate specimens will vary for each plastic material. Under Flexural Load

These conditions should become a part of the specification for D 788 Specification for Methacrylate Molding and Extru-

the material, or be agreed upon between the purchaser and the sion Compounds

supplier. D 790 Test Methods for Flexural Properties of Unreinforced

1.2 The methodology presented assumes the use of recipro- and Reinforced Plastics and Electrical Insulating Materi-

cating screw injection molding machines. Users of other types als

of machines will need to adapt this practice to their machines D 883 Terminology Relating to Plastics

with appropriate precautions. D 955 Test Method for Measuring Shrinkage from Mold

1.3 The values stated in SI units are to be regarded as the Dimensions of Molded Plastics

standard. The values given in parentheses are for information D 957 Practice for Determining Surface Temperature of

only. Molds for Plastics

1.4 This standard does not purport to address all of the D 3935 Specification for Polycarbonate (PC) Unfilled and

safety concerns, if any, associated with its use. It is the Reinforced Materials

responsibility of the user of this standard to establish appro- D 4066 Specification for Nylon Injection and Extrusion

priate safety and health practices and determine the applica- Materials

bility of regulatory limitations prior to use. D 4101 Specification for Propylene Plastic Injection and

Extrusion Materials

NOTE 1—This practice is equivalent to the following parts of ISO 294:

D 4181 Specification for Acetal (POM) Molding and Extru-

Plastics—Injection Moulding of Test Specimens of Thermoplastic Mate-

sion Materials

rials ; 294-1: Part 1—General Principles and Multipurpose Test Speci-

mens (ISO Type A Mould) and Bars (ISO Type B Mould) ; ISO 294-2: D 4507 Specification for Thermoplastic Polyester (TPES)

Part 2—Small Tensile Bars (ISO Type C Mould); ISO 294-3: Part

Materials

3—Plates (ISO Type D Moulds).

D 4549 Specification for Polystyrene Molding and Extru-

NOTE 2—Care should be taken in the design of the cavities for tensile

sion Materials (PS)

test specimens to assure that the flat, parallel test area between the radii

2.2 ISO Standards:

extending to the end tabs be of uniform dimensions and cross sectional

ISO 3167 Plastics—Preparation and Use of Multipurpose

area for the entire length. With some materials, lack of uniformity in

Test Specimens

dimensions or cross sectional area, or both, could lead to problems in

testing. In these cases, it may be advantageous to slightly thicken the tabs ISO 294-1: Plastics—Injection Moulding of Test Specimens

and fillet (radii area) of the specimen.

of Thermoplastic Materials—Part 1: General Principles

and Multipurpose Test Specimens (ISO Type A Mould)

and Bars (ISO Type B Mould)

ISO 294-2: Plastics—Injection Moulding of Test Specimens

This practice is under the jurisdiction of ASTM Committee D-20 on Plastics

of Thermoplastic Materials—Part 2: Small Tensile Bars

and is the direct responsibility of Subcommittee D20.09 on Specimen Preparation.

(ISO Type C Mould)

Current edition approved Dec. 10, 1997. Published May 1998. Originally

published as D 3641 – 91. Last previous edition D 3641 – 93.

Available from American National Standards Institute, 11 West 42nd St., 13th

Floor, New York, NY 10036.

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 08.03.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 3641

ISO 294-3: Plastics—Injection Moulding of Test Specimens sequence of operations the pressures, timing settings, and mode

of Thermoplastic Materials—Part 3: Plates (ISO Type D of control are established on the basis of their effects upon the

Moulds) molded part itself rather than upon any universal setpoints.

5. Significance and Use

3. Terminology

3.1 Definitions—Definitions of terms applying to this prac- 5.1 It is well known that plastic test specimens molded

under different conditions can have significantly different

tice appear in Terminology D 883.

3.2 Definitions of Terms Specific to This Standard: properties. This practice is designed to minimize those differ-

ences by establishing operating protocols without being unnec-

3.2.1 average injection velocity, n—the mean value of the

velocity of the molten plastic flow front within a cavity during essarily restrictive.

5.2 Always refer to the ASTM material specification or ISO

the injection time that is calculated from the shot volume and

injection time. (See Terminology D 883.) designation for the material for recommended molding condi-

tions. If not available, consult the material supplier.

3.2.1.1 Discussion—The average injection velocity is cal-

culated as follows: 5.3 This practice requires the use of adequate quantities of

plastic material to find desirable operating conditions and to

V

s

V 5

av make the desired test specimens.

T 3 A 3 n

i c

6. Apparatus

where:

V = average injection velocity, mm/s,

6.1 Injection Molding Machine—The machine selected for

av

V = shot volume, mm ,

use must be equipped with appropriate devices for the control

s

T = injection time, s,

and measurement of hydraulic pressure, all relevant tempera-

i

A = cross section of the cavity, mm , and

c

tures, and the timing of certain cycle elements. Additional

n = number of cavities.

devices to monitor cavity pressure and ram position and

velocity are very useful in the effective control of the injection

The calculation is valid for molds containing a single cavity or those

molding cycle. The capacity of the machine should be such that

containing identical multi-specimen cavities only and not for family

molds.

the total shot weight (specimens plus sprue and runners) is 20

to 80 % of rated capacity. The injection machine must be

3.2.2 cross section of the cavity, n—in a mold for test

capable of maintaining the proper injection velocity range if

specimens, the area of a planar section perpendicular to the

specified in the material standard.

flow pattern during filling of the mold that forms the critical

portion of the test specimen.

NOTE 3—Heat-sensitive materials may require using the high end of the

3.2.3 flash, n—thin fin of material formed at the parting line

30 to 80 % range in order to minimize residence time of the melt in the

of a part during molding, caused by unintentional opening of barrel.

the mold or by defective mating surfaces.

6.1.1 Control System—The various control systems should

3.2.4 switchover point, n—that point in the injection stage

be able to maintain the operating parameters of the injection

of the injection molding cycle when the control or level of the

molding process from cycle to cycle within the following

forwarding force on the screw is switched from that used

limits:

during injection to that used during pack/hold.

plastic melt, or stock temperature 63°C

3.2.5 velocity-pressure transfer point (VPT), n—that point

mold temperature 63°C, #80°C

65°C, >80°C

in the injection stage of the injection molding cycle as defined

injection pressure 62%

by pressure, position, or time when the rate of ram travel is

hold pressure 65%

switched from speed control to pressure control.

injection time 60.1 s

hold time 65%

shot weight 61%

4. Summary of Practice

4.1 Many factors in the injection molding process can have Suitable means of monitoring these parameters to ensure

an influence on the character of the moldings and the numerical

control within the above limits should be present.

values of test results. Among these are geometry, size, and

NOTE 4—The mold temperature may be measured using a calibrated

temperature conditions of the heating chamber, pressures and

surface pyrometer and the technique described in Practice D 957.

speeds used, size, shape, and length of runners and gates, mold

6.1.2 Screw—The design of the screw will be determined by

temperature and its uniformity, cavity surface finish, and

the material being molded. A key criterion of screw design is to

timing cycles used along with the method of sequencing from

provide a melt that is as uniform as possible with respect to

stage to stage in the process. It is sometimes necessary to

composition, temperature, and viscosity.

pretreat materials before molding. For materials that absorb

6.1.3 Clamp—The clamping force of the machine shall be

water this may mean drying under prescribed conditions. This

high enough to prevent flashing at all operating conditions.

practice attempts to control some of these variables, nullify

others, and report those that are necessary to the obtaining of

NOTE 5—The minimum clamp force required is the product of the

reproducible specimens. Definite stock and mold temperatures, highest possible cavity pressure and the projected surface area of the

cavities (and runners). A force greater than this minimum will be required

based on the relevant material specifications or the material

to prevent flashing.

supplier’s recommendations or past experience, and measured

by standard techniques, are used for the molding process. By a 6.2 Mold—The design of the mold is one of the more

D 3641

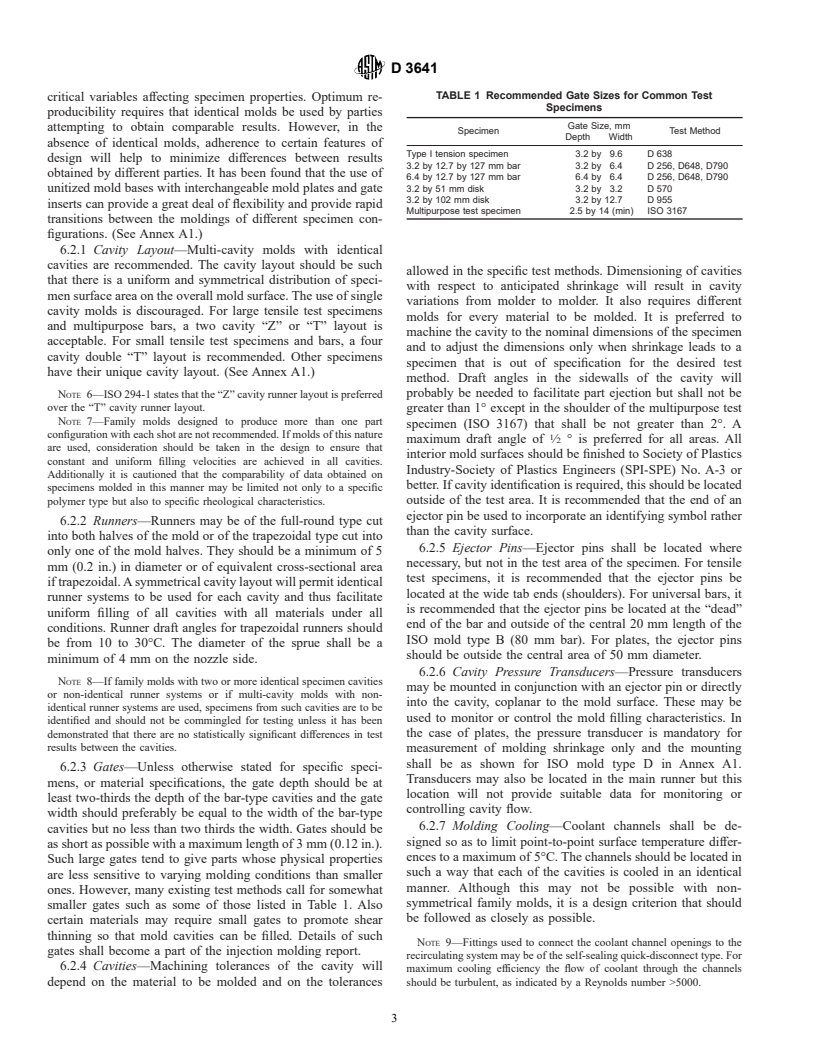

TABLE 1 Recommended Gate Sizes for Common Test

critical variables affecting specimen properties. Optimum re-

Specimens

producibility requires that identical molds be used by parties

Gate Size, mm

attempting to obtain comparable results. However, in the

Specimen Test Method

Depth Width

absence of identical molds, adherence to certain features of

Type I tension specimen 3.2 by 9.6 D 638

design will help to minimize differences between results

3.2 by 12.7 by 127 mm bar 3.2 by 6.4 D 256, D648, D790

obtained by different parties. It has been found that the use of

6.4 by 12.7 by 127 mm bar 6.4 by 6.4 D 256, D648, D790

3.2 by 51 mm disk 3.2 by 3.2 D 570

unitized mold bases with interchangeable mold plates and gate

3.2 by 102 mm disk 3.2 by 12.7 D 955

inserts can provide a great deal of flexibility and provide rapid

Multipurpose test specimen 2.5 by 14 (min) ISO 3167

transitions between the moldings of different specimen con-

figurations. (See Annex A1.)

6.2.1 Cavity Layout—Multi-cavity molds with identical

cavities are recommended. The cavity layout should be such

allowed in the specific test methods. Dimensioning of cavities

that there is a uniform and symmetrical distribution of speci-

with respect to anticipated shrinkage will result in cavity

men surface area on the overall mold surface. The use of single

variations from molder to molder. It also requires different

cavity molds is discouraged. For large tensile test specimens

molds for every material to be molded. It is preferred to

and multipurpose bars, a two cavity “Z” or “T” layout is

machine the cavity to the nominal dimensions of the specimen

acceptable. For small tensile test specimens and bars, a four

and to adjust the dimensions only when shrinkage leads to a

cavity double “T” layout is recommended. Other specimens

specimen that is out of specification for the desired test

have their unique cavity layout. (See Annex A1.)

method. Draft angles in the sidewalls of the cavity will

probably be needed to facilitate part ejection but shall not be

NOTE 6—ISO 294-1 states that the “Z” cavity runner layout is preferred

over the “T” cavity runner layout.

greater than 1° except in the shoulder of the multipurpose test

NOTE 7—Family molds designed to produce more than one part

specimen (ISO 3167) that shall be not greater than 2°. A

configuration with each shot are not recommended. If molds of this nature

maximum draft angle of ⁄2 ° is preferred for all areas. All

are used, consideration should be taken in the design to ensure that

interior mold surfaces should be finished to Society of Plastics

constant and uniform filling velocities are achieved in all cavities.

Industry-Society of Plastics Engineers (SPI-SPE) No. A-3 or

Additionally it is cautioned that the comparability of data obtained on

better. If cavity identification is required, this should be located

specimens molded in this manner may be limited not only to a specific

polymer type but also to specific rheological characteristics. outside of the test area. It is recommended that the end of an

ejector pin be used to incorporate an identifying symbol rather

6.2.2 Runners—Runners may be of the full-round type cut

than the cavity surface.

into both halves of the mold or of the trapezoidal type cut into

6.2.5 Ejector Pins—Ejector pins shall be located where

only one of the mold halves. They should be a minimum of 5

necessary, but not in the test area of the specimen. For tensile

mm (0.2 in.) in diameter or of equivalent cross-sectional area

test specimens, it is recommended that the ejector pins be

if trapezoidal. A symmetrical cavity layout will permit identical

located at the wide tab ends (shoulders). For universal bars, it

runner systems to be used for each cavity and thus facilitate

is recommended that the ejector pins be located at the “dead”

uniform filling of all cavities with all materials under all

end of the bar and outside of the central 20 mm length of the

conditions. Runner draft angles for trapezoidal runners should

ISO mold type B (80 mm bar). For plates, the ejector pins

be from 10 to 30°C. The diameter of the sprue shall be a

should be outside the central area of 50 mm diameter.

minimum of 4 mm on the nozzle side.

6.2.6 Cavity Pressure Transducers—Pressure transducers

NOTE 8—If family molds with two or more identical specimen cavities

may

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.