ASTM E10-01

(Test Method)Standard Test Method for Brinell Hardness of Metallic Materials

Standard Test Method for Brinell Hardness of Metallic Materials

SCOPE

1.1 This test method (Test Method A) covers the determination of the Brinell hardness of metallic materials, including methods for the verification of Brinell hardness testing machines (Test Method B) and the calibration of standardized hardness test blocks (Test Method C).

1.2 The values stated in SI units are to be regarded as the standard.

Note 1--In common terminology, the equivalent force in kgf is substituted for N.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

American Association State Highway

Designation:E10–01 and Transportation Officials Standard

AASHTO No.: T70–86

Standard Test Method for

1

Brinell Hardness of Metallic Materials

ThisstandardisissuedunderthefixeddesignationE10;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (ε) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* curved surface area of the indentation which is assumed to be

spherical and of the diameter of the ball.

1.1 This test method (Test Method A) covers the determi-

nation of the Brinell hardness of metallic materials, including 2F

HBW 50.102 3 ~SeeTable1! (1)

2 2

methods for the verification of Brinell hardness testing ma-

p D~D 2 =D 2 d !

chines (Test Method B) and the calibration of standardized

where:

hardness test blocks (Test Method C).

D = diameter of the ball, mm,

1.2 The values stated in SI units are to be regarded as the

F = test force, N, and

standard.

d = mean diameter of the indentation, mm.

NOTE 1—In common terminology, the equivalent force in kgf is

The Brinell hardness is denoted by the symbol: HBW.

substituted for N.

3.1.1.1 Discussion—In former standards, a steel ball was

1.3 This standard does not purport to address all of the

allowed for hardness values below 450. In cases when a steel

safety concerns, if any, associated with its use. It is the

ballwasused,theBrinellhardnesswasdenotedbyHBorHBS.

responsibility of the user of this standard to establish appro-

3.1.1.2 Discussion—The symbol HBW is preceded by the

priate safety and health practices and determine the applica-

hardness value. When conditions other than those specified in

bility of regulatory limitations prior to use.

11.1.2 are used, the hardness value is supplemented by an

index indicating the test conditions in the order:

2. Referenced Documents

(1) Diameter of the ball, in mm,

2.1 ASTM Standards:

2 (2) A value representing the test force in kg/f (see Table 3), and,

E4 Practices for Force Verification of Testing Machines

(3) Duration of loading, in s.

E29 Practice for Using Significant Digits in Test Data to

Examples:

3

Determine Conformance with Specifications

350 HBW 5/750 = Brinell hardness of 350 determined with a ball of 5-mm diam-

E74 Practice of Calibration of Force-Measuring Instru-

eter and with a test force of 7.355 kN (750 kgf) applied for 10 to 15 s.

600 HBW 1/30/20 = Brinell hardness of 600 determined with a ball of 1-mm di-

ments for Verifying the Force Indication of Testing Ma-

ameter and with a test force of 294.2 N (30 kgf) applied for 20 s.

2

chines

3.1.1.3 Discussion—Brinellhardnessnumbersvarywiththe

E140 HardnessConversionTablesforMetalsRelationship

test force used; however, test results will generally be in

Among Brinell Hardness, Vickers Hardness, Rockwell

agreement when the ratio of the test force to the square of the

Hardness, Rockwell Superficial Hardness, Knoop Hard-

2 ball diameter is held constant (see Table 3).

ness, and Scleroscope Hardness

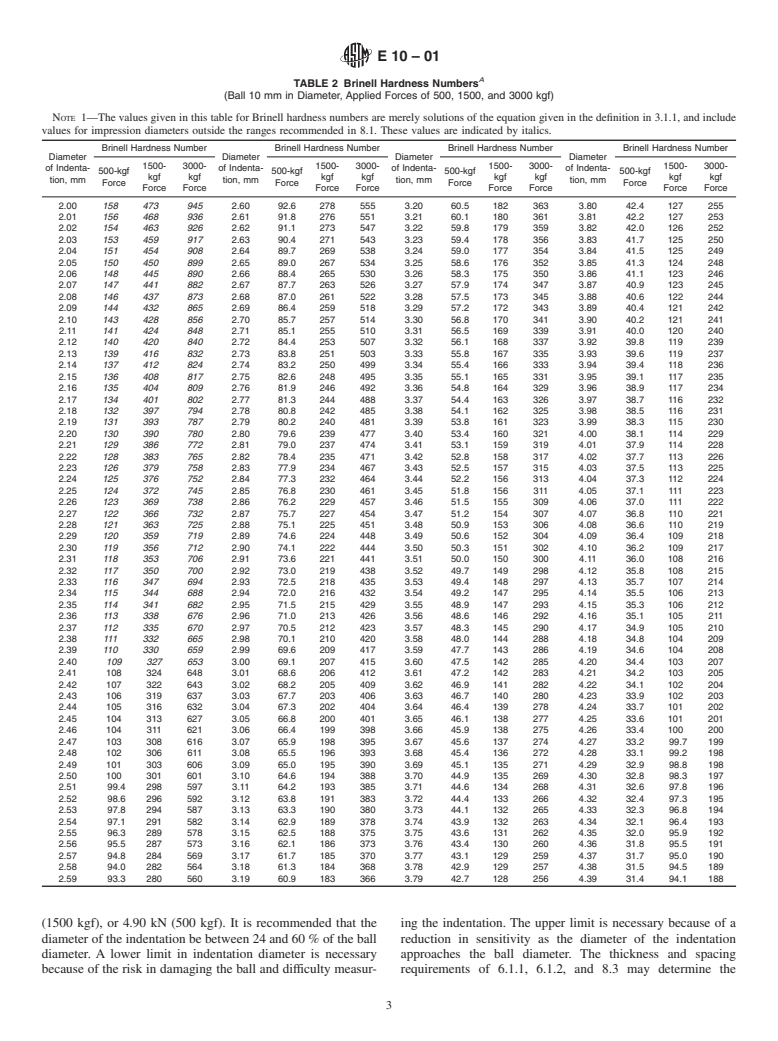

3.1.1.4 Discussion—Table 2 lists the Brinell hardness num-

3. Terminology

bers corresponding to various diameters of indentations for

29.4kN(3000kgf),14.7kN(1500kgf),and4.90kN(500kgf)

3.1 Definitions of Terms Specific to This Standard:

test forces making it unnecessary to calculate for each test the

3.1.1 Brinell hardness number—a number, which is propor-

value of the Brinell hardness number by the above equation in

tional to the quotient obtained by dividing the test force by the

Table1whentheseforcesareusedwitha10-mmdiameterball.

3.1.2 Brinell hardness test—an indenter (tungsten carbide

1 ball with diameter D) is forced into the surface of a test piece

This test method is under the jurisdiction of ASTM Committee E28 on

and the diameter of the indentation d left in the surface after

Mechanical Testing and is the direct responsibility of Subcommittee E28.06 on

Indentation Hardness Testing.

removalofthetestforce,F,ismeasured.(seeTable1andFigs.

Current edition approved February 10, 2001. Published April 2001. Originally

1 and 2.)

published as E10–24T. Last previous edition E10–00a.

2

3.1.2.1 Discussion—The tungsten carbide ball may be used

Annual Book of ASTM Standards, Vol 03.01.

3

Annual Book of ASTM Standards, Vol 14.02. for materials with a Brinell hardness not exceeding 650.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E10–01

TABLE 1 Symbols and Designations

5.2.2 The tungsten carbide ball indenter shall have a mini-

mum hardness of 1500

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.