ASTM F3139-15

(Test Method)Standard Test Method for Analysis of Tin-Based Solder Alloys for Minor and Trace Elements Using Inductively Coupled Plasma Atomic Emission Spectrometry

Standard Test Method for Analysis of Tin-Based Solder Alloys for Minor and Trace Elements Using Inductively Coupled Plasma Atomic Emission Spectrometry

SIGNIFICANCE AND USE

4.1 Tin-based solder alloys are commonly used to manufacture electrical and electronic goods. The elements lead, cadmium, mercury, antimony and bismuth are often declarable substances in solder materials. This test method provides a means of determining the listed declarable substances, as well as other minor and trace constituents, in tin-based solder alloys.

4.2 Two methods of dissolving tin-based solder alloys are given in this standard. The first method uses open-vessel hydrofluoric and nitric acid room temperature digestions; the second method employs closed-vessel nitric and hydrofluoric acid microwave digestions, both for use only with ICP-AES instruments equipped with a hydrofluoric acid resistant sample introduction system.

4.3 The method of preparing calibration solutions uses 1000 mg/kg single element reference material solutions, and uses matching concentrated acids for both the calibration solutions and the sample solutions.

4.4 This test method is intended for use by laboratories experienced with the set-up, calibration and analysis of samples using ICP-AES.

SCOPE

1.1 This test method covers procedures for the analysis of tin-based solder alloys for minor and trace elements using inductively-coupled plasma atomic emission spectrometry (ICP-AES) instrumentation.

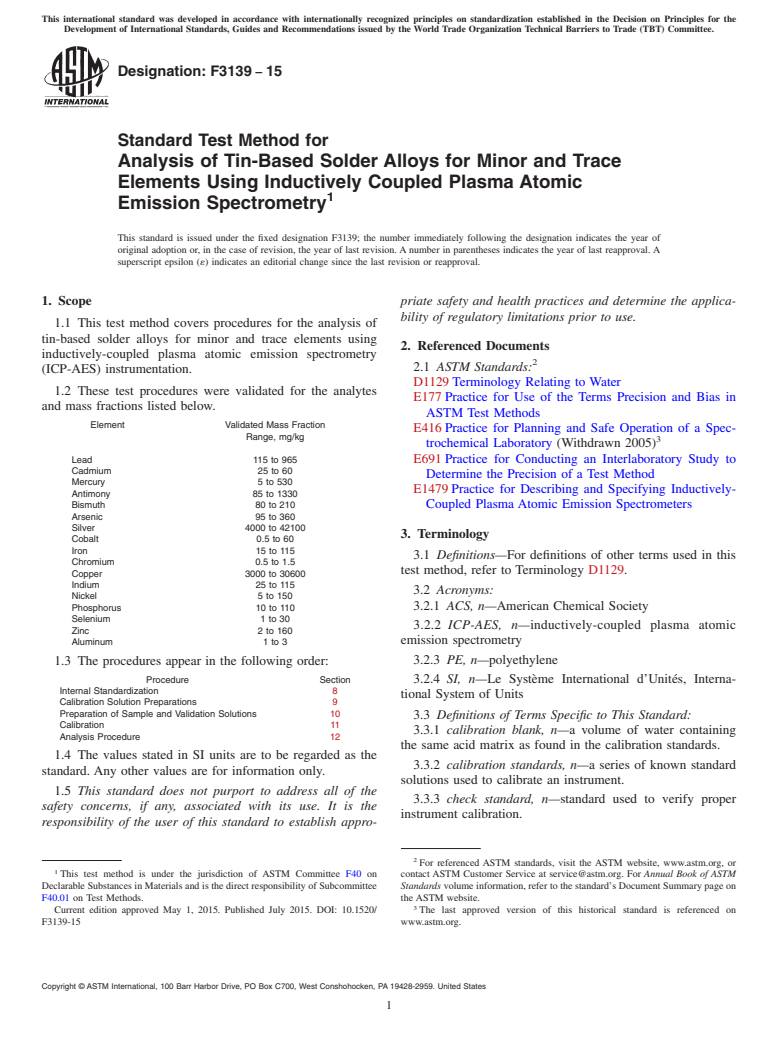

1.2 These test procedures were validated for the analytes and mass fractions listed below.

Element

Validated Mass Fraction

Range, mg/kg

Lead

115 to 965

Cadmium

25 to 60

Mercury

5 to 530

Antimony

85 to 1330

Bismuth

80 to 210

Arsenic

95 to 360

Silver

4000 to 42100

Cobalt

0.5 to 60

Iron

15 to 115

Chromium

0.5 to 1.5

Copper

3000 to 30600

Indium

25 to 115

Nickel

5 to 150

Phosphorus

10 to 110

Selenium

1 to 30

Zinc

2 to 160

Aluminum

1 to 3

1.3 The procedures appear in the following order:

Procedure

Section

Internal Standardization

8

Calibration Solution Preparations

9

Preparation of Sample and Validation Solutions

10

Calibration

11

Analysis Procedure

12

1.4 The values stated in SI units are to be regarded as the standard. Any other values are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3139 − 15

Standard Test Method for

Analysis of Tin-Based Solder Alloys for Minor and Trace

Elements Using Inductively Coupled Plasma Atomic

1

Emission Spectrometry

This standard is issued under the fixed designation F3139; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This test method covers procedures for the analysis of

tin-based solder alloys for minor and trace elements using

2. Referenced Documents

inductively-coupled plasma atomic emission spectrometry

2

2.1 ASTM Standards:

(ICP-AES) instrumentation.

D1129Terminology Relating to Water

1.2 These test procedures were validated for the analytes

E177Practice for Use of the Terms Precision and Bias in

and mass fractions listed below.

ASTM Test Methods

Element Validated Mass Fraction

E416Practice for Planning and Safe Operation of a Spec-

Range, mg/kg

3

trochemical Laboratory (Withdrawn 2005)

Lead 115 to 965 E691Practice for Conducting an Interlaboratory Study to

Cadmium 25 to 60

Determine the Precision of a Test Method

Mercury 5 to 530

E1479Practice for Describing and Specifying Inductively-

Antimony 85 to 1330

Bismuth 80 to 210 Coupled Plasma Atomic Emission Spectrometers

Arsenic 95 to 360

Silver 4000 to 42100

3. Terminology

Cobalt 0.5 to 60

Iron 15to115

3.1 Definitions—For definitions of other terms used in this

Chromium 0.5 to 1.5

test method, refer to Terminology D1129.

Copper 3000 to 30600

Indium 25 to 115

3.2 Acronyms:

Nickel 5 to 150

3.2.1 ACS, n—American Chemical Society

Phosphorus 10 to 110

Selenium 1 to 30

3.2.2 ICP-AES, n—inductively-coupled plasma atomic

Zinc 2 to 160

emission spectrometry

Aluminum 1 to 3

3.2.3 PE, n—polyethylene

1.3 The procedures appear in the following order:

Procedure Section 3.2.4 SI, n—Le Système International d’Unités, Interna-

Internal Standardization 8

tional System of Units

Calibration Solution Preparations 9

Preparation of Sample and Validation Solutions 10

3.3 Definitions of Terms Specific to This Standard:

Calibration 11

3.3.1 calibration blank, n—a volume of water containing

Analysis Procedure 12

the same acid matrix as found in the calibration standards.

1.4 The values stated in SI units are to be regarded as the

3.3.2 calibration standards, n—a series of known standard

standard. Any other values are for information only.

solutions used to calibrate an instrument.

1.5 This standard does not purport to address all of the

3.3.3 check standard, n—standard used to verify proper

safety concerns, if any, associated with its use. It is the

instrument calibration.

responsibility of the user of this standard to establish appro-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This test method is under the jurisdiction of ASTM Committee F40 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Declarable Substances in Materials and is the direct responsibility of Subcommittee Standards volume information, refer to the standard’s Document Summary page on

F40.01 on Test Methods. the ASTM website.

3

Current edition approved May 1, 2015. Published July 2015. DOI: 10.1520/ The last approved version of this historical standard is referenced on

F3139-15 www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3139 − 15

3.3.4 instrument linear range, n—range where instrument 5.3 Concentrated Acids—When acids are specified by name

response and accuracy remain within typically 5 to 10 % of or chemical formula only, it should be understood that concen-

known values.

trated reagents of the following mass fractions are intended:

Nominal Mass

3.3.5 internal standard, n—pureelement(s)addedinknown

Concentrated Acid

Fraction

amount(s) to a solution to be used to improve instrument

accuracy.

Hydrofluoric acid, HF 48 %

Nitric acid, HNO 69 %

3

3.3.6 reference material solution, n—solution standard with

knowncertifiedmassfraction(s),typicallycommerciallyavail-

5.4 Single Element Reference Material Solutions—All

able.

single element solutions used in this method must have

assigned mass fraction values in mg/kg units as opposed to

3.3.7 sample introduction system, n—plasma torch, mixing

mg/L units. It is possible to derive mg/kg values from mg/L

chamber and nebulizer used to

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F3139 − 15

Standard Test Method for

Analysis of Tin-Based Solder Alloys for Minor and Trace

Elements Using Inductively Coupled Plasma Atomic

1

Emission Spectrometry

This standard is issued under the fixed designation F3139; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This test method covers procedures for the analysis of

tin-based solder alloys for minor and trace elements using

2. Referenced Documents

inductively-coupled plasma atomic emission spectrometry

2

2.1 ASTM Standards:

(ICP-AES) instrumentation.

D1129 Terminology Relating to Water

1.2 These test procedures were validated for the analytes

E177 Practice for Use of the Terms Precision and Bias in

and mass fractions listed below.

ASTM Test Methods

Element Validated Mass Fraction

E416 Practice for Planning and Safe Operation of a Spec-

Range, mg/kg

3

trochemical Laboratory (Withdrawn 2005)

Lead 115 to 965 E691 Practice for Conducting an Interlaboratory Study to

Cadmium 25 to 60

Determine the Precision of a Test Method

Mercury 5 to 530

E1479 Practice for Describing and Specifying Inductively-

Antimony 85 to 1330

Bismuth 80 to 210 Coupled Plasma Atomic Emission Spectrometers

Arsenic 95 to 360

Silver 4000 to 42100

3. Terminology

Cobalt 0.5 to 60

Iron 15 to 115

3.1 Definitions—For definitions of other terms used in this

Chromium 0.5 to 1.5

test method, refer to Terminology D1129.

Copper 3000 to 30600

Indium 25 to 115

3.2 Acronyms:

Nickel 5 to 150

3.2.1 ACS, n—American Chemical Society

Phosphorus 10 to 110

Selenium 1 to 30

3.2.2 ICP-AES, n—inductively-coupled plasma atomic

Zinc 2 to 160

Aluminum 1 to 3 emission spectrometry

3.2.3 PE, n—polyethylene

1.3 The procedures appear in the following order:

Procedure Section 3.2.4 SI, n—Le Système International d’Unités, Interna-

Internal Standardization 8

tional System of Units

Calibration Solution Preparations 9

Preparation of Sample and Validation Solutions 10

3.3 Definitions of Terms Specific to This Standard:

Calibration 11

3.3.1 calibration blank, n—a volume of water containing

Analysis Procedure 12

the same acid matrix as found in the calibration standards.

1.4 The values stated in SI units are to be regarded as the

3.3.2 calibration standards, n—a series of known standard

standard. Any other values are for information only.

solutions used to calibrate an instrument.

1.5 This standard does not purport to address all of the

3.3.3 check standard, n—standard used to verify proper

safety concerns, if any, associated with its use. It is the

instrument calibration.

responsibility of the user of this standard to establish appro-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This test method is under the jurisdiction of ASTM Committee F40 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Declarable Substances in Materials and is the direct responsibility of Subcommittee Standards volume information, refer to the standard’s Document Summary page on

F40.01 on Test Methods. the ASTM website.

3

Current edition approved May 1, 2015. Published July 2015. DOI: 10.1520/ The last approved version of this historical standard is referenced on

F3139-15 www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3139 − 15

3.3.4 instrument linear range, n—range where instrument 5.3 Concentrated Acids—When acids are specified by name

response and accuracy remain within typically 5 to 10 % of

or chemical formula only, it should be understood that concen-

known values. trated reagents of the following mass fractions are intended:

3.3.5 internal standard, n—pure element(s) added in known Nominal Mass

Concentrated Acid

Fraction

amount(s) to a solution to be used to improve instrument

accuracy.

Hydrofluoric acid, HF 48 %

Nitric acid, HNO 69 %

3

3.3.6 reference material solution, n—solution standard with

known certified mass fraction(s), typically commercially avail-

5.4 Single Element Reference Material Solutions—All

able.

single element solutions used in this method must have

assigned mass fraction values in mg/kg units as opposed to

3.3.7 sample introduction system, n—plasma torch, mixing

mg/L units. It is possible to derive mg/kg values from mg/L

chamber and nebulizer used to deliver solutions to the plasma

assigned values through determination of standard solution

for analysis.

density and subsequent c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.