ASTM E1520-23

(Test Method)Standard Test Method for Particle Counts Per Pound of Granular Carriers and Dry-Applied Granular Formulations

Standard Test Method for Particle Counts Per Pound of Granular Carriers and Dry-Applied Granular Formulations

SIGNIFICANCE AND USE

4.1 This test method was designed principally for clay granular carriers and clay-based granular formulations, but need not be limited to these materials.

4.2 This procedure is applicable to granules in the range from 6 to 80 mesh (3.36 to 0.17 mm).

4.3 The sieve sizes used to calculate total particle count will be called the desired range and should be specified as part of the test results.

SCOPE

1.1 This test method is used to determine the number of particles per pound of granular carriers and granular pesticide formulations.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 6.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1520 − 23

Standard Test Method for

Particle Counts Per Pound of Granular Carriers and Dry-

1

Applied Granular Formulations

This standard is issued under the fixed designation E1520; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Test Method

3.1 A known weight of the granular carrier or granular

1.1 This test method is used to determine the number of

pesticide formulation is placed on the top sieve of a stacked set

particles per pound of granular carriers and granular pesticide

of U.S. standard stainless steel screens. The sieves are shaken

formulations.

for a specified period of time. The weight percent of the

1.2 The values stated in SI units are to be regarded as

granules retained on each sieve is determined. The number of

standard. No other units of measurement are included in this

particles per pound of granular material is then calculated.

standard.

4. Significance and Use

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4.1 This test method was designed principally for clay

responsibility of the user of this standard to establish appro-

granular carriers and clay-based granular formulations, but

priate safety, health, and environmental practices and deter-

need not be limited to these materials.

mine the applicability of regulatory limitations prior to use.

4.2 This procedure is applicable to granules in the range

For specific precautionary statements, see Section 6.

from 6 to 80 mesh (3.36 to 0.17 mm).

1.4 This international standard was developed in accor-

4.3 The sieve sizes used to calculate total particle count will

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the be called the desired range and should be specified as part of

the test results.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

5. Apparatus

Barriers to Trade (TBT) Committee.

5.1 Mechanical Sieve Shaker, a Tyler RoTap sieve shaker or

2. Referenced Documents equivalent.

2

5.2 Sieves, U.S. standard stainless steel 8-in. diameter sieves

2.1 ASTM Standards:

conforming to Specification E11.

E11 Specification for Woven Wire Test Sieve Cloth and Test

Sieves

5.3 Bottom Receiver Pan and Top Sieve Cover.

E725 Test Method for Sampling Granular Carriers and

5.4 Interval Timer, adjustable, with an accuracy of +10 s.

Granular Pesticides

E726 Test Method for Particle Size Distribution of Granular 5.5 Balance, sensitivity of 0.01 g.

Carriers and Granular Pesticides

6. Safety Precautions

E727/E727M Test Methods for Determining Bulk Density of

Granular Carriers and Granular Pesticides

6.1 Before testing read the precautionary statements on the

product label or the Material Safety Data Sheet (MSDS), or

both. Take proper precautions to prevent skin contact and

inhalation of the fines or vapors, or both. Take care to prevent

1

This test method is under the jurisdiction of ASTM Committee E35 on

contamination of the surrounding area. Always wear the

Pesticides, Antimicrobials, and Alternative Control Agents and is the direct

responsibility of Subcommittee E35.22 on Pesticide Formulations and Delivery

appropriate safety equipment and, where indicated, wear respi-

Systems.

ratory devices approved by (NIOSH) for the product being

Current edition approved April 1, 2023. Published May 2023. Originally

tested.

approved in 1993. Last previous edition approved in 2015 as E1520 – 99 (2015).

DOI: 10.1520/E1520-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 7. Procedure

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.1 Record tare weights of each sieve and bottom pan to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 60.01 g.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1520 − 23

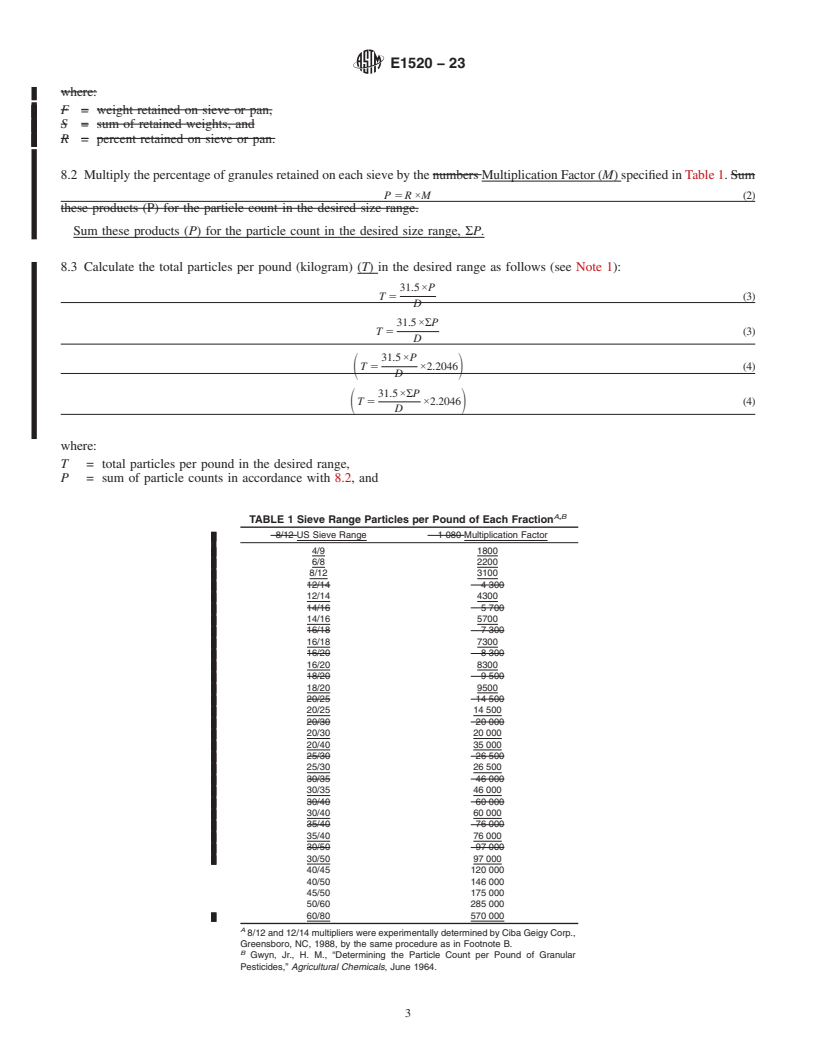

A,B

TABLE 1 Sieve Range Particles per Pound of Each Fraction

7.2 Order stack of screens by size with the finest sieve next

US Sieve Range Multiplication Factor

to the pan.

4/9 1800

7.3 Use a representative sample of 100 6 5 g obtained in

6/8 2200

accordance with Test Method E725. 8/12 3100

12/14 4300

7.4 Weigh the sample to 60.01 g.

14/16 5700

16/18 7300

7.5

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1520 − 99 (Reapproved 2015) E1520 − 23

Standard Test Method for

Particle Counts Per Pound of Granular Carriers and Dry-

1

Applied Granular Formulations

This standard is issued under the fixed designation E1520; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method is used to determine the number of particles per pound of granular carriers and granular pesticide

formulations.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and determine

the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 6.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

E725 Test Method for Sampling Granular Carriers and Granular Pesticides

E726 Test Method for Particle Size Distribution of Granular Carriers and Granular Pesticides

E727/E727M Test Methods for Determining Bulk Density of Granular Carriers and Granular Pesticides

3. Summary of Test Method

3.1 A known weight of the granular carrier or granular pesticide formulation is placed on the top sieve of a stacked set of U.S.

standard stainless steel screens. The sieves are shaken for a specified period of time. The weight percent of the granules retained

on each sieve is determined. The number of particles per pound of granular material is then calculated.

4. Significance and Use

4.1 This test method was designed principally for clay granular carriers and clay-based granular formulations, but need not be

limited to these materials.

1

This test method is under the jurisdiction of ASTM Committee E35 on Pesticides, Antimicrobials, and Alternative Control Agents and is the direct responsibility of

Subcommittee E35.22 on Pesticide Formulations and Delivery Systems.

Current edition approved Oct. 1, 2015April 1, 2023. Published November 2015May 2023. Originally approved in 1993. Last previous edition approved in 20092015 as

E1520 - 99E1520 – 99 (2015).(2009). DOI: 10.1520/E1520-99R15.10.1520/E1520-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1520 − 23

4.2 This procedure is applicable to granules in the range from 8 to 60 mesh (2.36 to 0.256 to 80 mesh (3.36 to 0.17 mm).

4.3 The sieve sizes used to calculate total particle count will be called the desired range and should be specified as part of the test

results.

5. Apparatus

5.1 Mechanical Sieve Shaker, a Tyler RoTap sieve shaker or equivalent.

5.2 Sieves, U.S. standard stainless steel 8-in. diameter sieves conforming to Specification E11.

5.3 Bottom Receiver Pan and Top Sieve Cover.

5.4 Interval Timer, adjustable, with an accuracy of +10 s.

5.5 Balance, sensitivity of 0.01 g.

6. Safety Precautions

6.1 Before testing read the precautionary statements on the product label or the Material Safety Data Sheet (MSDS), or both. Take

proper precautions to prevent skin contact and inhalation of the fines or vapors, or both. Take care to prevent contamination of the

surrounding area. Always wear the appropriate safety equipment and, where indicated, wear respiratory devices approved by

(NIOSH) for the product being tested.

7. Procedure

7.1 Record tare weights of each sieve and bottom pan to 60.01 g.

7.2 Order stack of screens by size with the finest sieve next to the pan.

7.3 Use a representative sample of 100

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.