ASTM F1755M-96(2002)

(Specification)Standard Specification for Solid State Bargraph Meters for Shipboard Use (Metric)

Standard Specification for Solid State Bargraph Meters for Shipboard Use (Metric)

SCOPE

1.1 This specification provides the requirements for design, construction, performance, and testing of solid state bargraph-type indicating meters.

1.2 The solid state bargraph meters covered by this specification are intended for use in shipboard applications of electrical measurement. This specification covers the requirements and quality assurance provisions for solid state, panel-type (edgewise), and rectangular switchboard-type instruments, which use light-emitting diodes (LEDs) for bargraph indication and optional digital displays.

1.3 This specification's requirements may be invoked for specialized measurement applications where another quantity, for example, position, weight, concentration of a trace element in an atmosphere sample, and so forth, is converted to electrical energy for display and measurement. Special dial markings shall be specified for such cases.

1.4 The values stated in metric units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

An American National Standard

Designation: F 1755M – 96 (Reapproved 2002)

Standard Specification for

Solid State Bargraph Meters for Shipboard Use [Metric]

This standard is issued under the fixed designation F 1755M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 center-zero meter, n—meter with display mode char-

acterized by a sequentially illuminated string of LEDs starting

1.1 This specification provides the requirements for design,

at the center scale zero position and extending in either

construction, performance, and testing of solid state bargraph-

direction from zero, proportional to the polarity and magnitude

type indicating meters.

of the input signal.

1.2 The solid state bargraph meters covered by this speci-

3.1.3 dual bargraph display, n—two completely indepen-

fication are intended for use in shipboard applications of

dent bargraph displays included in a single enclosure.

electrical measurement. This specification covers the require-

3.1.4 end-scale value, n—the value of the actuating electri-

ments and quality assurance provisions for solid state, panel-

cal quantity that corresponds to end scale indication. When

type (edgewise), and rectangular switchboard-type instru-

zero is not at the end or at the electrical center of the scale, the

ments, which use light-emitting diodes (LEDs) for bargraph

higher value is used. See Table 1.

indication and optional digital displays.

3.1.5 end-zero meter, n—meter with display mode charac-

1.3 This specification’s requirements may be invoked for

terized by a sequentially illuminated string of LEDs starting

specialized measurement applications where another quantity,

from a zero point, normally at the left for switchboard-style

for example, position, weight, concentration of a trace element

meters or horizontally installed edgewise meters, or the bottom

in an atmosphere sample, and so forth, is converted to electrical

of vertically installed edgewise meters, that extends in the

energy for display and measurement. Special dial markings

direction of full-scale value.

shall be specified for such cases.

3.1.6 full-scale value, n—full-scale value is the largest

1.4 The values stated in metric units are to be regarded as

value of the actuating electrical quantity, which can be indi-

the standard. The values given in parentheses are for informa-

cated on the scale. For instruments with zero between the ends

tion only.

of the scale, the full-scale value is the arithmetic sum of the

2. Referenced Documents

values of the actuating electrical quantity corresponding to the

two ends of the scale.

2.1 ASTM Standards:

3.1.7 response time, n—the response time is the time

B 117 Practice for Operating Salt Spray (Fog) Apparatus

required for the indicating means to display a new value after

D 3951 Practice for Commercial Packaging

a step change has occurred in the measured quantity to a new

F 1166 Practice for Human Engineering Design for Marine

constant value.

Systems, Equipment and Facilities

3.1.8 scale division, n—a scale division is the increment

2.2 Federal Specifications:

between the centers of two consecutive scale marks. The

TT–E–529 Enamel, Alkyd, Semigloss, Low VOC Content

number of scale marks is one more than the number of scale

2.3 Federal Standards:

divisions. For example, 10 scale divisions require 11 scale

H28 Screw Thread Standards for Federal Services

marks.

3. Terminology

3.1.8.1 linear scale divisions, n—linear scale divisions are

scale divisions that are spaced an equal distance apart and of

3.1 Definitions of Terms Specific to This Standard:

the same value, for example, scale divisions spaced 5 A apart

3.1.1 accuracy, n—the accuracy is a number that defines the

on a 100–A meter.

limit of errors expressed as a percentage of full-scale value.

3.1.8.2 nonlinear scale divisions, n—nonlinear scale divi-

sions are scale divisions of the same value spaced an unequal

This specification is under the jurisdiction of ASTM Committee F25 on Ships

distance apart.

and Marine Technology and is the direct responsibility of Subcommittee F25.10 on

Electrical. 3.1.9 scale length, n—the scale length is the length of the

Current edition approved Nov. 10, 1996. Published December 1997.

path described by the pattern of the LEDs in moving from one

Annual Book of ASTM Standards, Vol 03.02.

end of the scale to the other. For multiple scale meters, the

Annual Book of ASTM Standards, Vol 15.09.

longest scale shall be used to determine the scale length.

Annual Book of ASTM Standards, Vol 01.07.

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

3.1.10 scale visibility, n—scale visibility is the maximum

Robbins Ave., Philadelphia, PA 19111–5098, ATTN: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1755M

TABLE 1 End-Scale Values

5.1.11.2 Splashproof or spraytight window (see 7.5.2).

End-Scale Values

5.1.11.3 Internal illumination (see 7.6).

Range End-Scale Values

(for Ratings)

5.1.11.4 External accessories (see 7.8).

0-150 0, 150 150

5.1.11.5 Alarm set points (see 8.1.4).

50-0-150 50, 150 150

5.1.11.6 Digital display:

150-0-150 150, 150 150

90-140 90, 140 140

5.1.11.7 Nonstandard range values (see 8.2.4).

5.1.11.8 Dot matrix display types (see 8.2.4).

5.1.11.9 Intensity control (see 8.2.5).

horizontal or vertical viewing angle measured from a line

5.1.12 Certification requirements (See 10).

normal to the scale from which all scale marks and arcs, but not

5.1.13 Packaging requirements.

necessarily all markings, may be seen.

5.1.14 Testing requirements (include only if tests other than

4. Classification the production tests required by this specification are to be

performed).

4.1 Classification—Bargraph meters covered in this speci-

fication shall be classified by type and style as specified in

6. Materials and Manufacture

4.2-4.3.

4.2 Type—The type designation defines the physical con- 6.1 Materials—All materials used in the construction of

figuration of the meter and the scale.

these bargraph meters shall be of a quality suitable for the

4.2.1 Rectangular/switchboard-type meters present angular purpose intended and shall conform to the requirements of this

displays from 90 to 270° scale for the measured parameter(s).

specification.

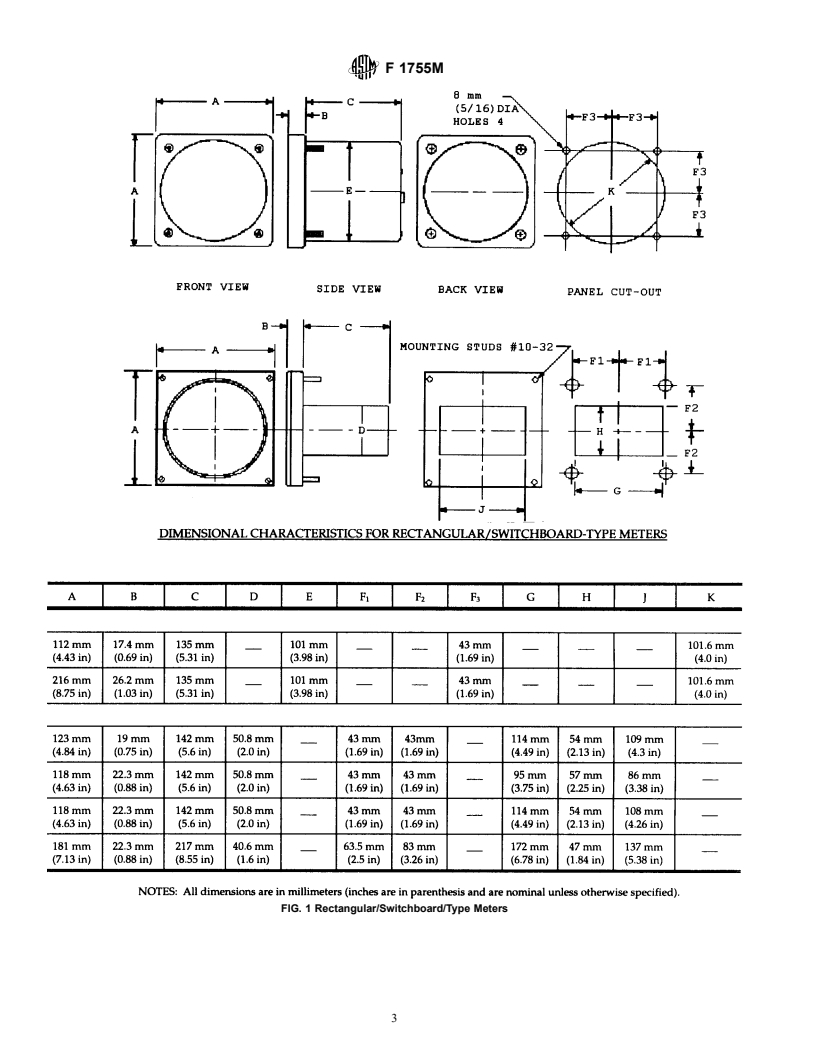

Fig. 1 provides typical dimensional and mounting data for

6.1.1 Metals—Metals and the treatment of metals shall be

rectangular/switchboard-type meters.

corrosion-resistant.

4.2.2 Edgewise/panel-type meters present linear displays

6.1.2 Plastics—Plastic, when used, shall be suitable ther-

for measured parameters. Fig. 2 provides typical dimensional

moplastic or thermosetting material so molded as to produce a

and mounting data for edgewise type meters.

dense solid structure, uniform in texture, finish, and mechani-

4.2.2.1 Orientation of Meter—For edgewise/panel-type

cal properties.

meters, the scale marking shall be specified either for a vertical

6.1.3 Glass—Glass used for the meter window shall be the

or horizontal mounting condition.

shatterproof type.

4.3 Style—The style designation defines the meters display

6.1.4 Gaskets—Material used in gaskets shall not cause

attributes as follows:

corrosion of metal parts with which they come in contact.

4.3.1 Bargraph Display—The bargraph display shall consist

6.2 Manufacture:

of light-emitting diode (LED) elements that illuminate to

6.2.1 Finishes:

produce a bar image proportional to the input signal. The

6.2.1.1 External Finishes—The portion of the meter case

display designation defines whether the meter has single or

exposed to view from the front of the panel or switchboard

dual bargraph displays.

shall have a black semigloss finish. No nickel or bright

4.3.2 Digital Display—The digital display designation de-

trimmings shall be used. The external finish may be epoxy-

fines the number of digits in the digital display as follows:

coated, electro-coated, or painted in accordance with

4.3.2.1 3-digit display.

TT–E–529. Metal cases shall be rendered resistant to corrosion

4.3.2.2 3 ⁄2-digit display.

prior to the application of the final finish.

4.3.2.3 4-digit display.

6.2.1.2 Internal Finishes—Internal finishes shall be of a

4.3.2.4 4 ⁄2-digit display

material that shall not melt, crack, chip, blister, or scale as a

4.3.2.5 No digital display.

result of the tests specified herein.

5. Ordering Information

6.3 Threaded Parts—Threaded parts shall be in accordance

with FED-STD-H28. Where practical, threads shall be in

5.1 Purchase orders or inquiries for bargraph meters of this

conformity with the coarse-thread series. The fine-thread series

specification shall specify the following:

shall be used only for applications that might show a definite

5.1.1 Title, date, and year of this specification.

advantage through their use. Where a special diameter pitch

5.1.2 Quantity.

combination is required, the thread shall be of American

5.1.3 Type and for edgewise meter, the orientation (see 4.2).

National Form and of any pitch between 16 and 36 which is

5.1.4 Style of display (single or dual, digital display) (see

used in the fine-thread series.

4.3).

6.3.1 Locking of Screw-Thread Assemblies—Screw-thread

5.1.5 Window type (plastic or shatterproof glass) (see 7.5).

assemblies shall not loosen as a result of the tests specified

5.1.6 Dial colors (see 7.9.1.1).

herein. When practicable, split-type lockwashers or equivalent

5.1.7 Range(s) (see 7.9.2).

means shall be provided under all nuts.

5.1.8 Power supply voltage (see 8.1.1).

5.1.9 Signal input (analog or digital) (see 8.1.2). 6.4 Sealing—The meter case shall be sealed by means of

5.1.10 Color(s) of bargraph display (see 8.2.2). gaskets, by fusing or soldering metal-to-metal or metal-to-

5.1.11 Optional features available: glass, or other means which will enable the meter to withstand

5.1.11.1 Anti-glare windows (see 7.5.1). the tests specified herein.

F 1755M

FIG. 1 Rectangular/Switchboard/Type Meters

F 1755M

FIG. 2 Dimensional Characteristics of Edgewise Meters

F 1755M

7. Design and Construction sharply defined and visible from the front of the case but not

distract attention from the scale markings. Unless otherwise

7.1 Dimensional Data—Typical physical dimensions for

specified, the following information shall be marked on the dial

switchboard and edgewise meters are shown in Fig. 1 and Fig.

or on an attached nameplate.

2.

(a) Manufacturer’s name.

7.2 Mounting—Bargraph meter shall be front panel

(b) Units of measurement.

mounted to simplify mechanical installation or removal for

(c) The quantity producing end-scale deflection. For end-

service, or both. Electrical connections locations shall be

zero meters, the dial markings shall be FS, indicating full scale,

designed to facilitate meter removal. Typical mounting dimen-

followed by the full-scale value and units of measurement, for

sions are indicated in Fig. 1 and Fig. 2.

example, FS-50 mV). For meters that are not end-zero meters,

7.2.1 Mounting Hardware—The necessary mounting hard-

the dial markings shall be marked ES indicating end scale

ware, such as mounting clips, nuts, washers, bolts, shall be

followed by the end-scale value and units of measurement, for

supplied with each meter. The machine screws shall have the

example, ES-50 mV).

same finish as the external finish (see 6.2.1.1).

7.9.2 Ranges—For end-zero meters, the full-scale ranges

7.3 Maintainability—The meter shall be constructed so that

shall be as specified. For meters that are not end-zero meters,

no special tools are required for insertion or removal of the

the center and end-scale ranges shall be specified appropriately.

meter.

7.9.3 Scale Divisions—Unless otherwise specified, the

7.4 Cases—Cases shall be corrosion resistant. Cases shall

value of each scale division shall be one, two, or five of the

be designed and constructed with close-fitting joints to mini-

units measured or any decimal multiple or submultiple of these

mize the entrance of dust and moisture (see 6.4).

numbers.

7.5 Windows—The meter display shall be provided with a

7.9.3.1 Linear Scales—The total number of scale divisions

window of methyl methacrylate (MMA), polycarbonate (PC),

shall be determined by dividing the total range by the smallest

or shatterproof glass. If the window is made MMA or PC, the

increment. For example; a 150-V scale with the smallest

external surface shall be treated to resist scratching. The

increment of 5 V is listed as having 30 scale divisions.

window shall be free from detrimental defects that would

7.9.3.2 Nonlinear Scales—The total number of scale divi-

prevent the display from being easily read or from meeting the

sions shall be determined by dividing the total range by the

luminous distribution and color requirement. such defects

smallest increment, although to avoid crowding scale marks, a

include electrostatic effects, scratches, chips, cracks, or craze.

portion of the scale shall not be marked. For example, a 100-A

7.5.1 Anti-Glare Coatings—When anti-glare is specified,

scale with the smallest increment of 2 A, but with no marks

windows shall be coated with an anti-glare coating. The

between 0 and 10 A, is listed as having 50 scale divisions.

coating shall be uniform in quality and condition, clean,

7.9.4 Scale Visibility—The scale and characters shall be

smooth, and free from foreign materials. The coating shall

show no evidence of flaking, peeling, or blistering. The coating uniform visually in character brightness, legibility, and clean-

liness of display with all elements of the meter illuminated. The

shall not contain blemishes such as discolorations, stains,

smears, and streaks. The coating shall show no evidence of a entire meter scale shall be clearly visible from a distance of 1

m (3 ft) and from a viewing angle of 45° from normal; both

cloudy or hazy appearance.

vertically and horizontally. The scale visibility shall not dete-

7.5.1.1 Specular Reflectance—The coating reflectance shall

riorate during the tests specified herein.

be not greater than 0.6 % for energy incident on the surface at

7.9.5 Scale Markings—Numerals, letters, and symbols shall

an angle of 0 to 15° inclusive. The reflectance shall be not

greater than 1.0 % at an angle of 30°. be in accordance with Practice F 1166. Scale markings shall be

as specified herein.

7.5.1.2 Light Loss—The coating light loss shall be not

greater than 2.0 %. 7.9.5.1 The orientation of numerals shall be tangential or

7.5.2 Splashproof/Spraytight Windows—When specified, erect for 90° scales, erect for 180 and 270° scaleplates, and

e

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.