ASTM D6522-00

(Test Method)Standard Test Method for Determination of Nitrogen Oxides, Carbon Monoxide, and Oxygen Concentrations in Emissions from Natural Gas-Fired Reciprocating Engines, Combustion Turbines, Boilers, and Process Heaters Using Portable Analyzers

Standard Test Method for Determination of Nitrogen Oxides, Carbon Monoxide, and Oxygen Concentrations in Emissions from Natural Gas-Fired Reciprocating Engines, Combustion Turbines, Boilers, and Process Heaters Using Portable Analyzers

SCOPE

1.1 This test method covers the determination of nitrogen oxides (NO and NO2), carbon monoxide (CO), and oxygen (O2) concentrations in controlled and uncontrolled emissions from natural gas-fired reciprocating engines, combustion turbines, boilers, and process heaters. Due to the inherent cross sensitivities of the electrochemical cells, this test method should not be applied to other pollutants or emission sources without a complete investigation of possible analytical interferences and a comparative evaluation with EPA test methods.

1.1.1 The procedures and specifications of this method were developed during laboratory and field tests funded by the Gas Research Institute (GRI). Comparative emission tests were conducted only on natural gas-fired combustion sources.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6522–00

Standard Test Method for

Determination of Nitrogen Oxides, Carbon Monoxide, and

Oxygen Concentrations in Emissions from Natural Gas-

Fired Reciprocating Engines, Combustion Turbines, Boilers,

and Process Heaters Using Portable Analyzers

This standard is issued under the fixed designation D6522; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Concentrations in Emissions from Stationary Sources

(Instrumental Analyzer Procedure)

1.1 This test method covers the determination of nitrogen

Method 7E - Determination of Nitrogen Oxides Emissions

oxides (NO and NO ), carbon monoxide (CO), and oxygen

from Stationary Sources (Instrumental Analyzer Proce-

(O ) concentrations in controlled and uncontrolled emissions

dure)

from natural gas-fired reciprocating engines, combustion tur-

Method10 -DeterminationofCarbonMonoxideEmissions

bines, boilers, and process heaters. Due to the inherent cross

from Stationary Source

sensitivities of the electrochemical cells, this test method

Method 20 - Determination of Nitrogen Oxides, Sulfur

should not be applied to other pollutants or emission sources

Dioxide, and Diluent Emissions from Stationary Gas

without a complete investigation of possible analytical inter-

Turbines

ferences and a comparative evaluation with EPAtest methods.

2.3 EPA Methods from 40 CFR Part 63, Appendix A

1.1.1 Theproceduresandspecificationsofthismethodwere

Method 301 - Field Validation of Pollutant Measurement

developed during laboratory and field tests funded by the Gas

Methods from Various Waste Media

Research Institute (GRI). Comparative emission tests were

2.4 EPA Methods from 40 CFR Part 75, Appendix H

conducted only on natural gas-fired combustion sources.

Revised Traceability Protocol No. 1: Protocol G1 and G2

1.2 The values stated in SI units are to be regarded as the

Procedures

standard. The values given in parentheses are for information

only.

3. Terminology

1.3 This standard does not purport to address all of the

3.1 For terminology relevant to this test method, seeTermi-

safety concerns, if any, associated with its use. It is the

nology D1356.

responsibility of the user of this standard to establish appro-

3.2 Definitions of Terms Specific to This Standard:

priate safety and health practices and to determine the

3.2.1 measurement system, n—total equipment required for

applicability of regulatory limitations prior to use.

the determination of gas concentration. The measurement

2. Referenced Documents system consists of the following major subsystems:

3.2.1.1 datarecorder,n—astripchartrecorder,computer,or

2.1 ASTM Standards:

digital recorder for recording measurement data.

D1356 Terminology Relating to Sampling andAnalysis of

3.2.1.2 electrochemical cell, n—that portion of the system

Atmospheres

4 that senses the gas to be measured and generates an output

2.2 EPA Methods from 40 CFR Part 60, Appendix A

proportional to its concentration, or any cell that uses

Method3A -DeterminationofOxygenandCarbonDioxide

diffusion-limited oxidation and reduction reactions to produce

an electrical potential between a sensing electrode and a

counter electrode.

This test method is under the jurisdiction of ASTM Committee D22 on Air

3.2.1.3 external interference gas scrubber, n—tube filled

Quality and is the direct responsibility of Subcommittee D22.03 on Ambient

with scrubbing agent used to remove interfering compounds

Atmospheres and Source Emissions.

upstream of some electrochemical cells.

Current edition approved February 10, 2000. Published April 2000.

Gas Research Institute Topical Report, “Development of an Electrochemical

3.2.1.4 sample interface, n—that portion of a system used

Cell Emission Analyzer Test Method,” GRI-96/0008, July 1997.

for one or more of the following: sample acquisition, sample

Annual Book of ASTM Standards, Vol 11.03.

transport, sample conditioning, or protection of the electro-

Available from Superintendent of Documents, U. G. Government Printing

Office, Washington, DC 20402. chemicalcellsfromparticulatematterandcondensedmoisture.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6522–00

3.2.2 interference check, n—method of quantifying analyti- measurements. The interference effects for the CO and NO

cal interferences from components in the stack gas other than emission measurements are quantified in 9.2 and shall not

the analyte. exceed 5% of the measurement.

3.2.3 initial NO cell temperature, n—temperatureoftheNO

7. Apparatus

cell that is recorded during the most recent pretest calibration

7.1 The minimum detectable limit depends on the nominal

error check.

range of the electrochemical cell, calibration drift, and signal-

3.2.3.1 Discussion—Since the NO cell can experience sig-

to-noise ratio of the measurement system. For a well designed

nificantzerodriftwithtemperaturechangesinsomesituations,

system, the minimum detectable limit should be less than 2%

the temperature must be monitored if the analyzer does not

of the nominal range.

display negative concentration results.

7.2 Any measurement system that meets the performance

3.2.4 linearity check, n—method of demonstrating the abil-

and design specifications in Sections 9 and 10.4.11 of this test

ityofagasanalyzertorespondconsistentlyoverarangeofgas

method may be used. The sampling system shall maintain the

concentrations.

gas sample at a temperature above the dew point up to the

3.2.5 nominal range, n—range of concentrations over

moisture removal system. The sample conditioning system

whicheachcellisoperated(25%to125%ofspangasvalue).

shall be designed so that there are no entrained water droplets

3.2.5.1 Discussion—Several nominal ranges may be used

in the gas sample when it contacts the electrochemical cells.A

for any given cell as long as the linearity and stability check

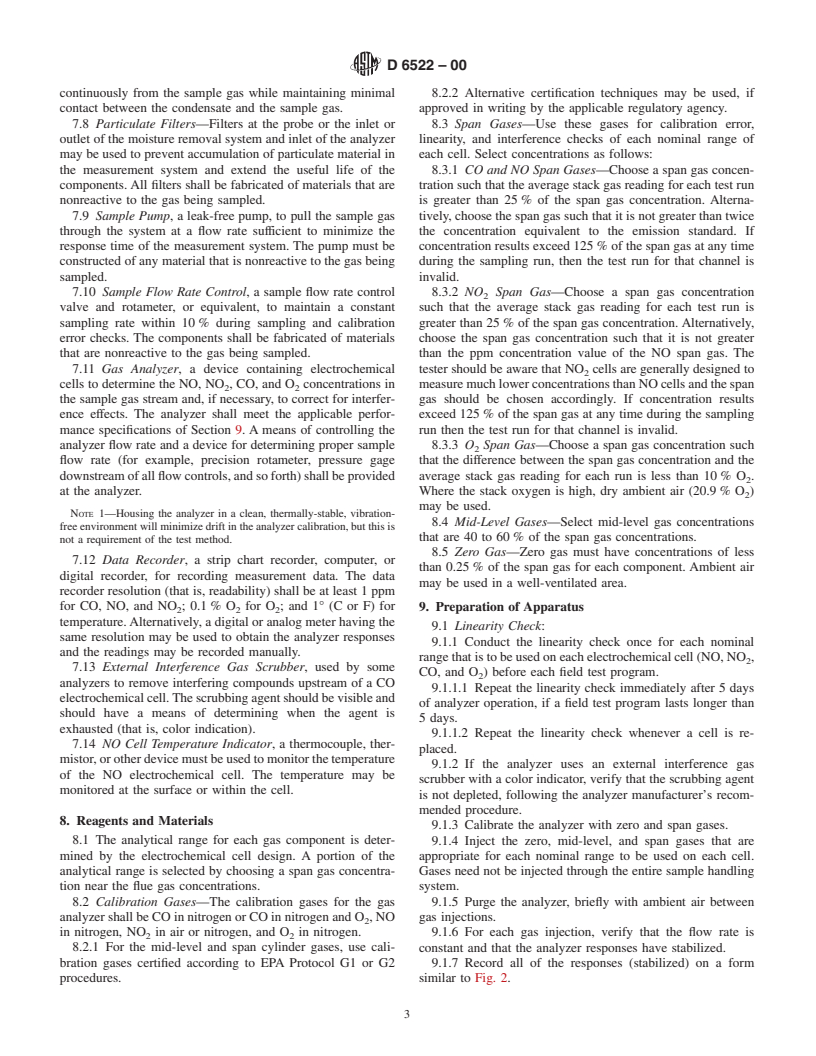

schematic of an acceptable measurement system is shown in

results remain within specification.

Fig. 1. The essential components of the measurement system

3.2.6 response time, n—amount of time required for the

are described below:

measurement system to display 95% of a step change in gas

7.3 Sample Probe,glass,stainlesssteel,orothernonreactive

concentration on the data recorder.

material,ofsufficientlengthtotraversethesamplepoints,and,

3.2.7 span gas, n—known concentration of a gas in an

if necessary, heated to prevent condensation.

appropriate diluent gas.

7.4 Heated Sample Line, heated (sufficient to prevent con-

3.2.8 span calibration error, n—difference between the gas

densation), nonreactive tubing, to transport the sample gas to

concentration exhibited by the gas analyzer and the known

the moisture removal system.

concentration of the span gas.

7.5 Sample Transport Lines, nonreactive tubing to transport

3.2.9 stability check, n—method of demonstrating that an

the sample from the moisture removal system to the sample

electrochemical cell operated over a given nominal range

pump, sample flow rate control, and electrochemical cells.

provides a stable response and is not significantly affected by

7.6 Calibration Assembly,atee-fittingtoattachtotheprobe

prolonged exposure to the analyte.

tipforintroducingcalibrationgasesatambientpressureduring

3.2.10 stability time, n—elapsed time from the start of the

the calibration error checks. The vented end of the tee should

gasinjectiontothestartofthe30-minstabilitycheckperiod,as

have a flow indicator to ensure sufficient calibration gas flow.

determined during the stability check.

Anyothermethodthatintroducescalibrationgasesattheprobe

3.2.11 zero calibration error, n—gas concentration exhib-

at atmospheric pressure may be used.

ited by the gas analyzer in response to zero-level calibration

7.7 MoistureRemovalSystem,achilledcondenserorsimilar

gas.

device (for example, permeation dryer), to remove condensate

4. Summary of Test Method

4.1 Agassampleiscontinuouslyextractedfromastackand

conveyedtoaportableanalyzerfordeterminationofNO,NO ,

CO, and O gas concentrations using electrochemical cells.

Analyzer design specifications, performance specifications,

and test procedures are provided to ensure reliable data.

Additionstoormodificationsofvendor-suppliedanalyzers(for

example,heatedsampleline,flowmeters,andsoforth)maybe

required to meet the design specifications of this test method.

5. Significance and Use

5.1 Theresultsofthistestmethodmaybeusedtodetermine

nitrogen oxides and carbon monoxide emissions from natural

gas combustion.

5.2 Thistestmethodmayalsobeusedtomonitoremissions

to optimize process operation for nitrogen oxides and carbon

monoxide control.

6. Interferences

6.1 NO and NO can interfere with CO concentration

measurements, and NO can interfere with NO concentration FIG. 1 Calibration System Schematic

D6522–00

continuously from the sample gas while maintaining minimal 8.2.2 Alternative certification techniques may be used, if

contact between the condensate and the sample gas. approved in writing by the applicable regulatory agency.

7.8 Particulate Filters—Filters at the probe or the inlet or 8.3 Span Gases—Use these gases for calibration error,

outlet of the moisture removal system and inlet of the analyzer linearity, and interference checks of each nominal range of

may be used to prevent accumulation of particulate material in each cell. Select concentrations as follows:

the measurement system and extend the useful life of the 8.3.1 CO and NO Span Gases—Choose a span gas concen-

components.All filters shall be fabricated of materials that are trationsuchthattheaveragestackgasreadingforeachtestrun

nonreactive to the gas being sampled. is greater than 25% of the span gas concentration. Alterna-

7.9 Sample Pump, a leak-free pump, to pull the sample gas tively,choosethespangassuchthatitisnotgreaterthantwice

through the system at a flow rate sufficient to minimize the the concentration equivalent to the emission standard. If

response time of the measurement system. The pump must be concentration results exceed 125% of the span gas at any time

constructed of any material that is nonreactive to the gas being during the sampling run, then the test run for that channel is

sampled. invalid.

7.10 Sample Flow Rate Control, a sample flow rate control 8.3.2 NO Span Gas—Choose a span gas concentration

valve and rotameter, or equivalent, to maintain a constant such that the average stack gas reading for each test run is

sampling rate within 10% during sampling and calibration greater than 25% of the span gas concentration.Alternatively,

error checks. The components shall be fabricated of materials choose the span gas concentration such that it is not greater

that are nonreactive to the gas being sampled. than the ppm concentration value of the NO span gas. The

7.11 Gas Analyzer, a device containing electrochemical tester should be aware that NO cells are generally designed to

cells to determine the NO, NO , CO, and O concentrations in measuremuchlowerconcentrationsthanNOcellsandthespan

2 2

the sample gas stream and, if necessary, to correct for interfer- gas should be chosen accordingly. If concentration results

ence effects. The analyzer shall meet the applicable perfor- exceed 125% of the span gas at any time during the sampling

mance specifications of Section 9. A means of controlling the run then the test run for that channel is invalid.

analyzer flow rate and a device for determining proper sample 8.3.3 O Span Gas—Choose a span gas concentration such

flow rate (for example, precision rotameter, pressure gage that the difference between the span gas concentration and the

downstreamofallflowcontrols,andsoforth)shallbeprovided average stack gas reading for each run is less than 10% O .

at the analyzer. Where the stack oxygen is high, dry ambient air (20.9% O )

may be used.

NOTE 1—Housing the analyzer in a clean, thermally-stable, vibration-

8.4 Mid-Level Gases—Select mid-level gas concentrations

freeenvironmentwillminimizedriftintheanalyzercalibration,butthisis

that are 40 to 60% of the span gas concentrations.

not a requirement of the test method.

8.5 Zero Gas—Zero gas must have concentrations of less

7.12 Data Recorder, a strip chart recorder, computer, or

than 0.25% of the span gas for each component. Ambient air

digital recorder, for recording measurement data. The data

may be used in a well-ventilated area.

recorder resolution (that is, readability) shall be at least 1 ppm

for CO, NO, and NO ; 0.1% O for O ; and 1° (C or F) for

9. Preparation of Apparatus

2 2 2

temperature.Alternatively,adigitaloranalogmeterhavingthe

9.1 Linearity Check:

same resolution may be used to obtain the analyzer responses

9.1.1 Conduct the linearity check once for each nominal

and the readings may be recorded manually.

rangethatistobeusedoneachelectrochemicalcell(NO,NO ,

7.13 External Interference Gas Scrubber, used by some

CO, and O ) before each field test program.

analyzers to remove interfering compounds upstream of a CO

9.1.1.1 Repeat the linearity check immediately after 5 days

electrochemicalcell.Thescrubbingagentshouldbevisibleand

of analyzer operation, if a field test program lasts longer than

should have a means of determining when the agent is

5 days.

exhausted (that is, color indication).

9.1.1.2 Repeat the linearity check whenever a cell is re-

7.14 NO Cell Temperature Indicator, a thermocouple, ther-

placed.

mistor,orotherdevicemustbeusedtomonitorthetemperature

9.1.2 If the analyzer uses an external interference gas

of the NO electrochemical cell. The temperature may be

scrubber with a color indicator, verify that the scrubbing agent

monitored at the surface or within the cell.

is not depleted, following the analyzer manufacturer’s recom-

mended procedure.

8. Reagents and Materials

9.1.3 Calibrate the analyzer with zero and span gases.

8.1 The analytical range for each gas component is deter- 9.1.4 Inject the zero, mid-level, and span gases that are

mined by the electrochemical cell design. A portion of the appropriate for each nominal range to be used on each cell.

analytical range is selected by choosing a span gas concentra- Gases need not be injected through the entire sample handling

tion near the flue gas concentrations. system.

8.2 Calibration Gases—The calibration gases for the gas 9.1.5 Purge the analyzer, briefly with ambient air between

analyzershallbeCOinnitrogenorCOinnitrogenandO,NO gas injections.

in nitrogen, NO in air or nitrogen, and O in nitrogen. 9.1.6 For each gas injection, verify that the fl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.