ASTM F2159-01

(Specification)Standard Specification for Plastic Insert Fittings Utilizing a Copper Crimp Ring for SDR9 Cross-linked Polyethylene (PEX) Tubing

Standard Specification for Plastic Insert Fittings Utilizing a Copper Crimp Ring for SDR9 Cross-linked Polyethylene (PEX) Tubing

SCOPE

1.1 This specification establishes requirements for sulfone plastic insert fittings and copper crimp rings for three sizes (3/8, 1/2, and 3/4) of cross-linked polyethylene (PEX) plastic tubing. These fittings are intended for use in 100 psi (690 kPa) cold- and hot-water distribution systems operating at temperatures up to and including 180°F (82°C). Included are the requirements for material, molded part properties, performance, workmanship, dimensions, and markings to be used on the fittings and rings.

1.2 Units—The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units, which are provided for information only and are not considered the standard.

1.3 The following is an index of the appendix in this specification:GO/NO-GO Crimp GaugesAppendix X1Torque (Break Off) TestAppendix X2

1.4 The following precautionary caveat pertains only to the test method portions, Sections 11 and 12, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

Designation: F 2159 – 01

Standard Specification for

Plastic Insert Fittings Utilizing a Copper Crimp Ring for

SDR9 Cross-linked Polyethylene (PEX) Tubing

This standard is issued under the fixed designation F 2159; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope moplastic Pipe and Fittings

D 6394 Specification for Sulfone Plastics (SP)

1.1 This specification establishes requirements for sulfone

3 F 412 Terminology Relating to Plastic Piping Systems

plastic insert fittings and copper crimp rings for three sizes ( ⁄8

F 876 Specification for Cross-linked Polyethylene (PEX)

1 3

, ⁄2,and ⁄4)ofcross-linkedpolyethylene(PEX)plastictubing.

Tubing

These fittings are intended for use in 100 psi (690 kPa) cold-

F 877 Specification for Cross-linked Polyethylene (PEX)

and hot-water distribution systems operating at temperatures

Plastic Hot- and Cold-Water Distribution Systems

up to and including 180°F (82°C). Included are the require-

F 1498 Specification for Taper Pipe Threads 60° for Ther-

mentsformaterial,moldedpartproperties,performance,work-

moplastic Pipe and Fittings

manship, dimensions, and markings to be used on the fittings

F 1807 Specification for Metal Insert Fitting Utilizing a

and rings.

Copper Crimp Ring for SDR9 Cross-linked Polyethylene

1.2 Units—The values stated in inch-pound units are to be

(PEX) Tubing

regarded as the standard. The values given in parentheses are

2.2 ASME Standard:

mathematical conversions to SI units, which are provided for

B 1.20.1 Pipe Threads General Purpose Inch

information only and are not considered the standard.

2.3 NSF International Standard:

1.3 The following is an index of the appendix in this

ANSI/NSF Standard No. 14 for Plastic Piping Components

specification:

and Related Materials

GO/NO-GO Crimp Gauges Appendix X1

ANSI/NSF Standard No. 61 for Drinking Water System

Torque (Break Off) Test Appendix X2

Components-Health Effects

1.4 The following precautionary caveat pertains only to the

test method portions, Sections 11 and 12, of this specification.

3. Terminology

This standard does not purport to address all of the safety

3.1 Definitions—Definitions are in accordance with Termi-

concerns, if any, associated with its use. It is the responsibility

nology F 412 and abbreviations are in accordance with Termi-

of the user of this standard to establish appropriate safety and

nology D 1600, unless otherwise indicated.

health practices and determine the applicability of regulatory

requirements prior to use.

4. Classification

4.1 This specification governs one class of fittings and

2. Referenced Documents

3 1

copper crimp rings suitable for use with nominal size ⁄8 , ⁄2 ,

2.1 ASTM Standards:

and ⁄4 size PEX tubing that meets the requirements of ASTM

D 618 Practice for Conditioning Plastics and Electrical

Specifications F 876 or F 877.

Insulating Materials for Testing

D 1598 Test Method for Time-To-Failure of Plastic Pipe

5. Materials and Manufacture

Under Constant Internal Pressure

5.1 Material—Fittings shall be molded from sulfone plastic

D 1599 Test Method for Short-Time, Hydraulic Failure

(SP) as specified in Specification D 6394.The material shall be

Pressure of Plastic Pipe, Tubing, and Fittings

unreinforced polysulfone (group 01, or 03; class 1, grade 1, 2

D 1600 Terminology for Abbreviated Terms Relating to

or 3 for group 03) or polyphenylsulfone (group 03, class 1,

Plastics

grade 1) 2, 3, 4, 5 or 6 for group 01. Material may also be a an

D 2122 Test Method for Determining Dimensions of Ther-

1 4

This specification is under the jurisdiction ofASTM Committee F17 on Plastic Annual Book of ASTM Standards, Vol 08.03.

Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings. Available from the American National Standards Institute, 11 West 42nd St.,

Current edition approved Dec. 10, 2001. Published April 2002. 13th Floor, New York, NY 10036.

2 6

Annual Book of ASTM Standards, Vol 08.01. Available from the National Sanitation Foundation (NSF International), P.O.

Annual Book of ASTM Standards, Vol 08.04. Box 130140, Ann Arbor, MI 48113.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2159–01

TABLE 1 Minimum Hydrostatic Burst Strength Requirements for

unreinforcedblendofthesetwoormoreofthespecifiedgroups

Fitting, Crimp Ring, and PEX Tubing Assemblies

materials with the polyphenylsulfone continuous phase com-

Nominal Minimum Burst Pressures at

prising 55 to 80 % of the blend. Fittings shall be made from

Tubing Size Different Temperatures

virgin plastic or reworked plastic in accordance with 5.1.2.

A A

psig at (kPa) at psig at (kPa) at

in.

73.4°F (23°C) 180°F (82.2°C)

5.1.1 Discussion—Since fittings specified by this standard

⁄8 620 (4275) 275 (1896)

will be used in hot-and-cold water plumbing systems, a

⁄2 480 (3309) 215 (1482)

material used to manufacture fittings in accordance with this 3

⁄4 475 (3275) 210 (1448)

specification must demonstrate qualities consistent with that A

The fiber stress to derive this test pressure is: at 73.4°F (23.0°C) 1900 psi

application in addition to the performance requirements of this (13.10 MPa) at 180°F (82.2°C) 850 psi (5.86 MPa).

specification. Those qualifying characteristics include, but are

notlimitedto,anestablishedhydrostaticdesignbasis(HDB)or TABLE 2 Minimum Hydrostatic Sustained Pressure

Requirements for Fitting, Crimp Ring and PEX Tubing

stress design basis (SDB) in accordance with PPI TR-3 or

A,B

Assemblies

similar rating, demonstration of resistance to the long-term

Nominal

effects of water contact and those chemicals normally found in

Pressure Required for Test, psig (kPa)

Tubing Size

potable water and at the maximum temperature stated in this

in. 180°F (82.2°C)

specification, or an applicable history of use in a similar ⁄8 250 (1724)

⁄2 195 (1344)

configuration and environment, or both. Sulfone plastic as

⁄4 190 (1310)

specified in Specification D 6394, meets these additional quali-

A

The fiber stress to derive this test pressure is: 770 psi (5.31 MPa) at 180° F

fications and should establish a baseline performance profile

(82.2°C).

B

for other materials that may be added to this specification at

Test duration is 1000 h.

some future time.

5.1.2 Rework Material—Clean rework material of the same

7.4 Thermocycling—Assemblies shall not leak or separate

commercial designation, generated from the manufacturer’s

when thermocycled 1000 cycles between the temperatures of

own production may be used by the same manufacturer

60°F (16°C) and 180°F (82°C) when tested in accordance with

provided the fittings meet all of the requirements of this

11.7.

specification. Reworked material shall not be introduced at a

7.5 Excessive Temperature-Pressure Capability:

ratio exceeding 25 %.

7.5.1 General—Assemblies shall have adequate strength to

5.2 Potable Water Requirements—Products intended for the

accommodate short-term conditions, 30 days (720 h) of 210° F

transport of potable water shall be evaluated, tested and

(99° C) and 150 psi (1034 kPa) when tested in accordance with

certified for conformance with ANSI/NSF Standard No. 61 or

11.8.

the health effects portion ofANSI/NSF Standard No. 14 by an

acceptable certifying organization when required by the regu-

8. Dimensions

latory authority having jurisdiction.

8.1 Dimensions and Tolerances—The dimensions and tol-

5.3 Crimp Rings—Crimp rings shall be manufactured and

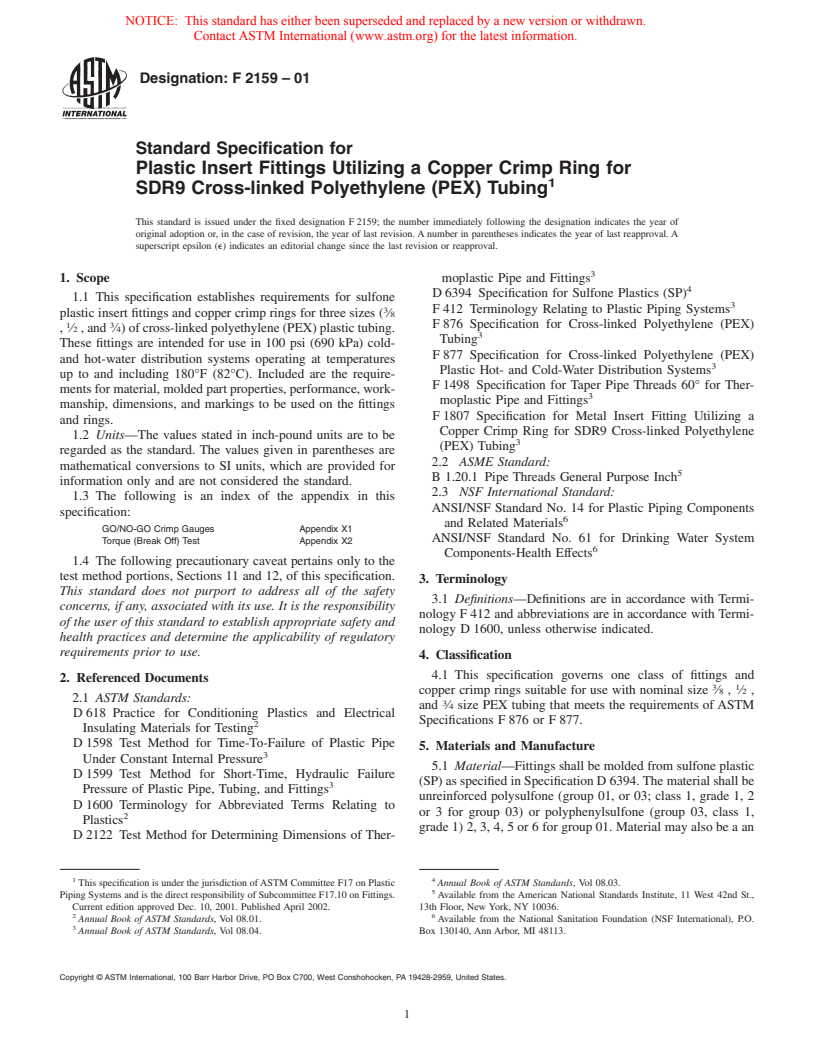

erances of fittings shall be as shown in Fig. 1, when measured

marked in accordance with the requirements of Specification

in accordance with 11.4.

F 1807.

8.1.1 Alignment—The maximum angular variation of any

opening shall not exceed 1° off the true centerline axis.

6. Molded Part Properties

8.1.2 Tapered Threads—Fitting threads shall be American

National Standard Taper Pipe Thread Form conforming to

6.1 Insert Crush—The fitting insert shall not crack, split, or

ASTM F 1498.

shatter when tested in accordance with 12.1.

8.1.3 Straight Threads—Straight pipe threads, intended for

6.2 Splay—The molded part shall be free of visible splay

the making of a gasketed seal with taper pipe threads, shall be

excepting some slight blushing at the gate location.

NPSM and conform to ASME B 1.20.1.

7. Performance Requirements

9. Workmanship, Finish and Appearance

7.1 General—All performance tests shall be performed on

9.1 The sealing surfaces of the insert shall be smooth and

assemblies of fittings, crimp rings, and PEX tubing. Fittings

free of foreign material. The fitting walls shall be free of

and crimp rings shall meet the material and dimensional

cracks, holes, blisters, voids, foreign inclusions, or other

requirements of this standard. PEX tubing shall meet the

defects that are visible to the unaided eye and that affect the

requirements of Specification F 876 or F 877.Assembly of test

wall integrity.

specimensshallbeinaccordancewithSection10.Useseparate

9.2 Except for the insert, the molded part shall be free of

sets of assemblies for each performance test requirement.

flash in excess of .005. Flash, mismatch, and witness mark

7.2 Hydrostatic Burst—Assemblies shall meet the mini-

requirements for the insert shall be in accordance with Fig. 1.

mum hydrostatic burst requirements shown in Table 1, when

10. Assembly

tested in accordance with 11.5.

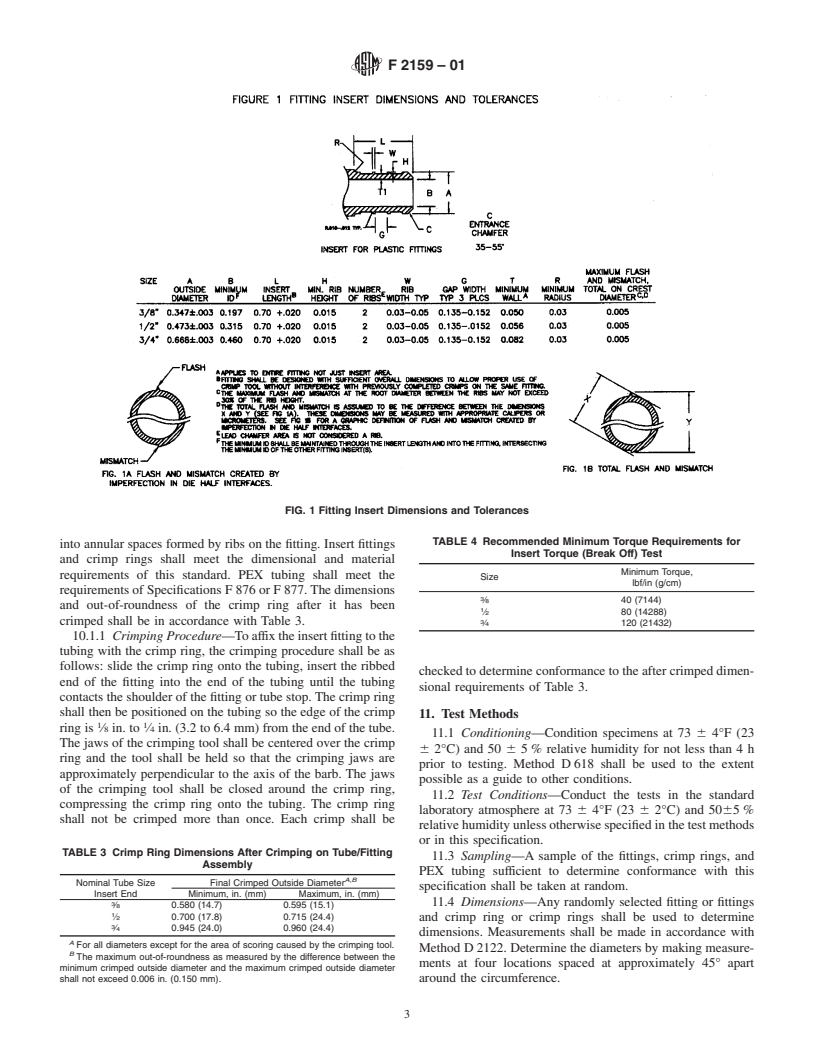

7.3 Hydrostatic Sustained Pressure Strength—Assemblies 10.1 Crimp Joints—Insert fittings shall be joined to PEX

shall meet the hydrostatic sustained pressure requirements tubing by the compression of a copper crimp ring around the

shown in Table 2 when tested in accordance with 11.6. outer circumference of the tubing forcing the tubing material

F2159–01

FIG. 1 Fitting Insert Dimensions and Tolerances

TABLE 4 Recommended Minimum Torque Requirements for

into annular spaces formed by ribs on the fitting. Insert fittings

Insert Torque (Break Off) Test

and crimp rings shall meet the dimensional and material

Minimum Torque,

requirements of this standard. PEX tubing shall meet the

Size

lbf/in (g/cm)

requirements of Specifications F 876 or F 877.The dimensions

⁄8 40 (7144)

and out-of-roundness of the crimp ring after it has been

⁄2 80 (14288)

crimped shall be in accordance with Table 3.

⁄4 120 (21432)

10.1.1 Crimping Procedure—Toaffixtheinsertfittingtothe

tubing with the crimp ring, the crimping procedure shall be as

follows: slide the crimp ring onto the tubing, insert the ribbed

checked to determine conformance to the after crimped dimen-

end of the fitting into the end of the tubing until the tubing

sional requirements of Table 3.

contacts the shoulder of the fitting or tube stop. The crimp ring

shall then be positioned on the tubing so the edge of the crimp

11. Test Methods

1 1

ring is ⁄8 in. to ⁄4 in. (3.2 to 6.4 mm) from the end of the tube.

11.1 Conditioning—Condition specimens at 73 6 4°F (23

The jaws of the crimping tool shall be centered over the crimp

6 2°C) and 50 6 5 % relative humidity for not less than 4 h

ring and the tool shall be held so that the crimping jaws are

prior to testing. Method D 618 shall be used to the extent

approximately perpendicular to the axis of the barb. The jaws

possible as a guide to other conditions.

of the crimping tool shall be closed around the crimp ring,

11.2 Test Conditions—Conduct the tests in the standard

compressing the crimp ring onto the tubing. The crimp ring

laboratory atmosphere at 73 6 4°F (23 6 2°C) and 5065%

shall not be crimped more than once. Each crimp shall be

relativehumidityunlessotherwisespecifiedinthetestmethods

or in this specification.

TABLE 3 Crimp Ring Dimensions After Crimping on Tube/Fitting

11.3 Sampling—A sample of the fittings, crimp rings, and

Assembly

PEX tubing sufficient to determine conformance with this

A,B

Nominal Tube Size Final Crimped Outside Diameter

specification shall be taken at random.

Insert End Minimum, in. (mm) Maximum, in. (mm)

3 11.4 Dimensions—Any randomly selected fitting or fittings

⁄8 0.580 (14.7) 0.595 (15.1)

⁄2 0.700 (17.8) 0.715 (24.4)

and crimp ring or crimp rings shall be used to determine

⁄4 0.945 (24.0) 0.960 (24.4)

dimensions. Measurements shall be made in accordance with

A

For all diameters except for the area of scoring caused by the crimping tool.

Method D 2122. Determine the diameters by making measure-

B

The maximum out-of-roundness as measured by the difference between the

ments at four locations spaced at approximately 45° apart

minimum crimped outside diameter and the maximum crimped outside diameter

shall not exceed 0.006 in. (0.150 mm). around the circumference.

F2159–01

11.5 Burst Pressure—Determine the minimum burst pres- 11.7.4 Procedure—Pressurize the specimen assembly with

sure in accordance with Test Method D 1599 on at least six air to 100 6 10 psi (690 6 69 kPa) and check for leaks.

assemblies for each temperature in Table 1. Leakage or Eliminate any leaks before the thermocycle test is started.

separation at any of the joints tested, or from the fitting itself, Thermally cycle the specimen assembly either manually or

at less than the minimum burst requirements for the tempera- automatically and under a constant internal pressure of 100 6

tures specified in Table 1 shall constitute a failure in this test. 10 psi (690 6 69 kPa), alternately between 60 6 4°F (16 6

11.6 Sustained Hydrostatic Pressure—Performthetestonat 2°C) and 180 6 4°F (82 6 2°C) by means of immersion in

least six assemblies in accordance with Test Method D 1598, water using the following test cycle (Note 2):

except for the following:

Water immersion at 180°F 2 min minimum

Air immersion at ambient 2 min maximum

11.6.1 Test temperature shall be 180 6 4°F (82 6 2°C).

Water immersion at 60°F 2 min minimum

11.6.2 The external test environment shall be air or water.

Air immersion at ambient 2 min maximum

11.6.3 Fill the specimens with water at a temperature of at

NOTE 2—If the test must be interrupted before completion, samples are

least 120°F (50°C).

to be kept at room temperature until the test is restarted.

11.6.4 Leakage or separation at any joint tested at less than

11.7.4.1 Upon completion of 1000 cycles, visually inspect

1000 h at the sustained pressure as given in Table 2 shall

for leaks while under the test pressure. Any evidence of

constitute failure in this test.

leakage at the fittings or separation of the fittings from the

11.7 Thermocycling:

tubing constitutes failure.

11.7.1 Summary of Test Method—This test method de-

11.7.4.2 If no failures are evident, the specimen assembly

scribes a pass-fail test for thermally cycling assemblies com-

shall immediately be tested for joint integrity (hydrostatic

prised of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.