ASTM C1202-08

(Test Method)Standard Test Method for Electrical Indication of Concrete's Ability to Resist Chloride Ion Penetration

Standard Test Method for Electrical Indication of Concrete's Ability to Resist Chloride Ion Penetration

SIGNIFICANCE AND USE

This test method covers the laboratory evaluation of the electrical conductance of concrete samples to provide a rapid indication of their resistance to chloride ion penetration. In most cases the electrical conductance results have shown good correlation with chloride ponding tests, such as AASHTO T259, on companion slabs cast from the same concrete mixtures (Refs 1-5).

This test method is suitable for evaluation of materials and material proportions for design purposes and research and development.

Sample age has significant effects on the test results, depending on the type of concrete and the curing procedure. Most concretes, if properly cured, become progressively and significantly less permeable with time.

This test method was developed originally for evaluations of alternative materials, but in practice its use has evolved to applications such as quality control and acceptance testing. In such cases it is imperative that the curing procedures and the age at time of testing be clearly defined.

Table 1 provides a qualitative relationship between the results of this test and the chloride ion penetrability of concrete.

Care should be taken in interpreting results of this test when it is used on surface-treated concretes, for example, concretes treated with penetrating sealers. The results from this test on some such concretes indicate low resistance to chloride ion penetration, while 90-day chloride ponding tests on companion slabs show a higher resistance.

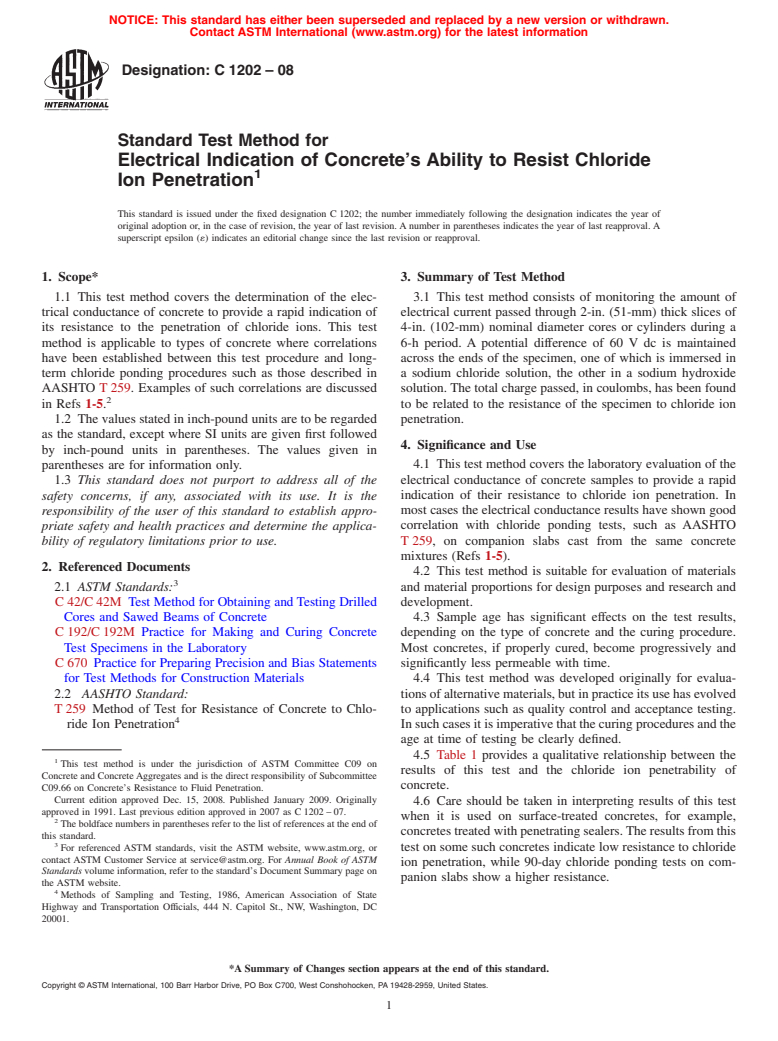

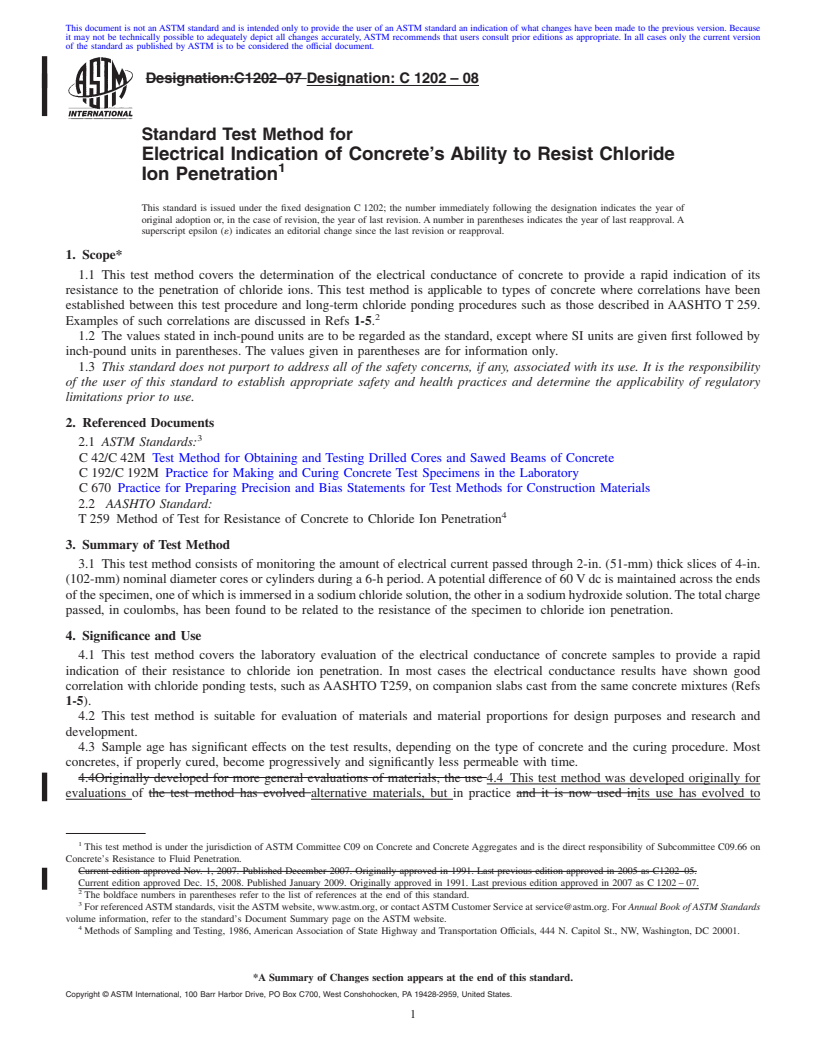

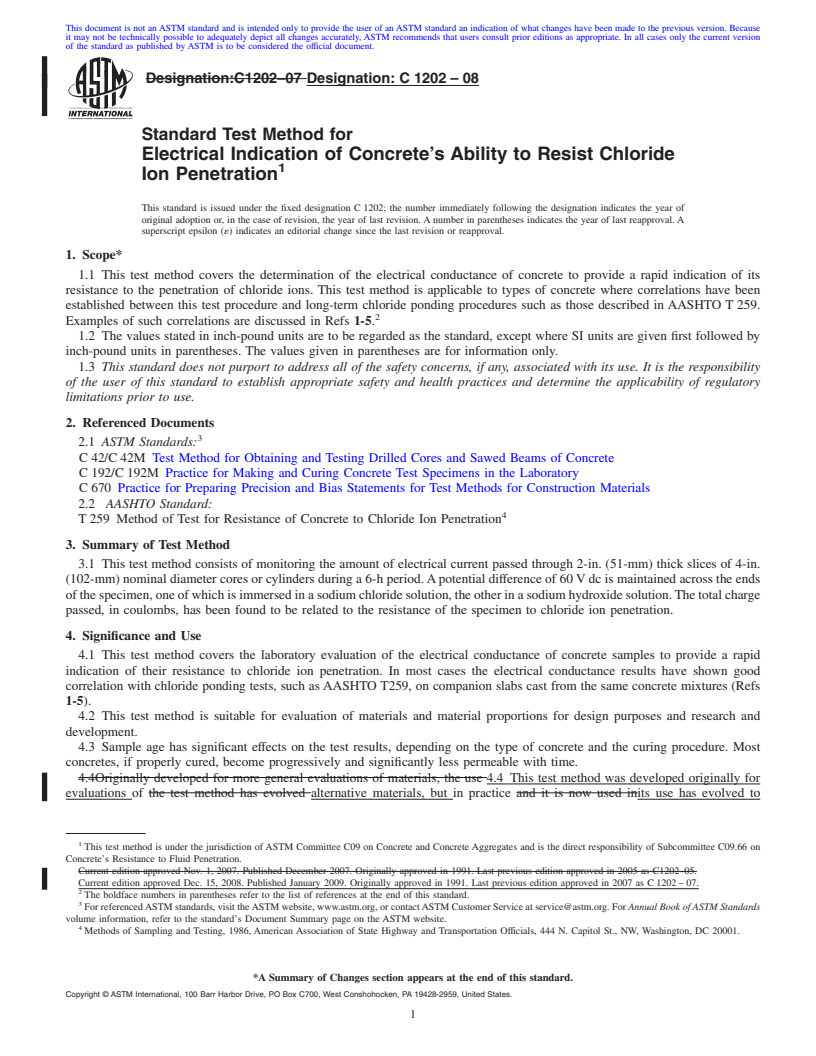

The details of the test method apply to 4-in. (102-mm) nominal diameter specimens. This includes specimens with actual diameters ranging from 3.75 in. (95 mm) to 4.0 in. (102 mm). Other specimen diameters may be tested with appropriate changes in the applied voltage cell design (see 7.5 and Fig. 1).

For specimen diameters other than 3.75 in. (95 mm), the test result value for total charge passed must be adjusted following the procedure in 11.2. For specimens with diameters less than 3.75 in. (95 ...

SCOPE

1.1 This test method covers the determination of the electrical conductance of concrete to provide a rapid indication of its resistance to the penetration of chloride ions. This test method is applicable to types of concrete where correlations have been established between this test procedure and long-term chloride ponding procedures such as those described in AASHTO T 259. Examples of such correlations are discussed in Refs 1-5.

1.2 The values stated in inch-pound units are to be regarded as the standard, except where SI units are given first followed by inch-pound units in parentheses. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1202–08

Standard Test Method for

Electrical Indication of Concrete’s Ability to Resist Chloride

1

Ion Penetration

This standard is issued under the fixed designation C 1202; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Summary of Test Method

1.1 This test method covers the determination of the elec- 3.1 This test method consists of monitoring the amount of

trical conductance of concrete to provide a rapid indication of electrical current passed through 2-in. (51-mm) thick slices of

its resistance to the penetration of chloride ions. This test 4-in. (102-mm) nominal diameter cores or cylinders during a

method is applicable to types of concrete where correlations 6-h period. A potential difference of 60 V dc is maintained

have been established between this test procedure and long- across the ends of the specimen, one of which is immersed in

term chloride ponding procedures such as those described in a sodium chloride solution, the other in a sodium hydroxide

AASHTO T 259. Examples of such correlations are discussed solution. The total charge passed, in coulombs, has been found

2

in Refs 1-5. to be related to the resistance of the specimen to chloride ion

1.2 The values stated in inch-pound units are to be regarded penetration.

as the standard, except where SI units are given first followed

4. Significance and Use

by inch-pound units in parentheses. The values given in

4.1 This test method covers the laboratory evaluation of the

parentheses are for information only.

1.3 This standard does not purport to address all of the electrical conductance of concrete samples to provide a rapid

indication of their resistance to chloride ion penetration. In

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- most cases the electrical conductance results have shown good

correlation with chloride ponding tests, such as AASHTO

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. T 259, on companion slabs cast from the same concrete

mixtures (Refs 1-5).

2. Referenced Documents

4.2 This test method is suitable for evaluation of materials

3

2.1 ASTM Standards: and material proportions for design purposes and research and

C 42/C 42M Test Method for Obtaining and Testing Drilled development.

Cores and Sawed Beams of Concrete 4.3 Sample age has significant effects on the test results,

C 192/C 192M Practice for Making and Curing Concrete depending on the type of concrete and the curing procedure.

Test Specimens in the Laboratory Most concretes, if properly cured, become progressively and

C 670 Practice for Preparing Precision and Bias Statements significantly less permeable with time.

for Test Methods for Construction Materials 4.4 This test method was developed originally for evalua-

2.2 AASHTO Standard: tionsofalternativematerials,butinpracticeitsusehasevolved

T 259 Method of Test for Resistance of Concrete to Chlo- to applications such as quality control and acceptance testing.

4

ride Ion Penetration In such cases it is imperative that the curing procedures and the

age at time of testing be clearly defined.

4.5 Table 1 provides a qualitative relationship between the

1

This test method is under the jurisdiction of ASTM Committee C09 on

results of this test and the chloride ion penetrability of

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

concrete.

C09.66 on Concrete’s Resistance to Fluid Penetration.

Current edition approved Dec. 15, 2008. Published January 2009. Originally

4.6 Care should be taken in interpreting results of this test

approved in 1991. Last previous edition approved in 2007 as C 1202 – 07.

when it is used on surface-treated concretes, for example,

2

The boldface numbers in parentheses refer to the list of references at the end of

concretes treated with penetrating sealers.The results from this

this standard.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or test on some such concretes indicate low resistance to chloride

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ion penetration, while 90-day chloride ponding tests on com-

Standards volume information, refer to the standard’s Document Summary page on

panion slabs show a higher resistance.

the ASTM website.

4

Methods of Sampling and Testing, 1986, American Association of State

Highway and Transportation Officials, 444 N. Capitol St., NW, Washington, DC

20001.

*A Summary of Changes section appears at the end of this st

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1202–07 Designation:C1202–08

Standard Test Method for

Electrical Indication of Concrete’s Ability to Resist Chloride

1

Ion Penetration

This standard is issued under the fixed designation C 1202; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of the electrical conductance of concrete to provide a rapid indication of its

resistance to the penetration of chloride ions. This test method is applicable to types of concrete where correlations have been

established between this test procedure and long-term chloride ponding procedures such as those described in AASHTO T 259.

2

Examples of such correlations are discussed in Refs 1-5.

1.2 The values stated in inch-pound units are to be regarded as the standard, except where SI units are given first followed by

inch-pound units in parentheses. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

C 42/C 42M Test Method for Obtaining and Testing Drilled Cores and Sawed Beams of Concrete

C 192/C 192M Practice for Making and Curing Concrete Test Specimens in the Laboratory

C 670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

2.2 AASHTO Standard:

4

T 259 Method of Test for Resistance of Concrete to Chloride Ion Penetration

3. Summary of Test Method

3.1 This test method consists of monitoring the amount of electrical current passed through 2-in. (51-mm) thick slices of 4-in.

(102-mm) nominal diameter cores or cylinders during a 6-h period.Apotential difference of 60 V dc is maintained across the ends

ofthespecimen,oneofwhichisimmersedinasodiumchloridesolution,theotherinasodiumhydroxidesolution.Thetotalcharge

passed, in coulombs, has been found to be related to the resistance of the specimen to chloride ion penetration.

4. Significance and Use

4.1 This test method covers the laboratory evaluation of the electrical conductance of concrete samples to provide a rapid

indication of their resistance to chloride ion penetration. In most cases the electrical conductance results have shown good

correlation with chloride ponding tests, such as AASHTO T259, on companion slabs cast from the same concrete mixtures (Refs

1-5).

4.2 This test method is suitable for evaluation of materials and material proportions for design purposes and research and

development.

4.3 Sample age has significant effects on the test results, depending on the type of concrete and the curing procedure. Most

concretes, if properly cured, become progressively and significantly less permeable with time.

4.4Originally developed for more general evaluations of materials, the use 4.4 This test method was developed originally for

evaluations of the test method has evolved alternative materials, but in practice and it is now used inits use has evolved to

1

This test method is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.66 on

Concrete’s Resistance to Fluid Penetration.

Current edition approved Nov. 1, 2007. Published December 2007. Originally approved in 1991. Last previous edition approved in 2005 as C1202–05.

Current edition approved Dec. 15, 2008. Published January 2009. Originally approved in 1991. Last previous edition approved in 2007 as C 1202 – 07.

2

The boldface numbers in parentheses refer to the list of references at the end of this standard.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Methods of Sampling and Testing, 1986, American Association of State Highway and Transportation Officials, 444 N. Capitol St., NW, Washington, DC 20001.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, Un

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1202–07 Designation:C1202–08

Standard Test Method for

Electrical Indication of Concrete’s Ability to Resist Chloride

1

Ion Penetration

This standard is issued under the fixed designation C 1202; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of the electrical conductance of concrete to provide a rapid indication of its

resistance to the penetration of chloride ions. This test method is applicable to types of concrete where correlations have been

established between this test procedure and long-term chloride ponding procedures such as those described in AASHTO T 259.

2

Examples of such correlations are discussed in Refs 1-5.

1.2 The values stated in inch-pound units are to be regarded as the standard, except where SI units are given first followed by

inch-pound units in parentheses. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

C 42/C 42M Test Method for Obtaining and Testing Drilled Cores and Sawed Beams of Concrete

C 192/C 192M Practice for Making and Curing Concrete Test Specimens in the Laboratory

C 670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

2.2 AASHTO Standard:

4

T 259 Method of Test for Resistance of Concrete to Chloride Ion Penetration

3. Summary of Test Method

3.1 This test method consists of monitoring the amount of electrical current passed through 2-in. (51-mm) thick slices of 4-in.

(102-mm) nominal diameter cores or cylinders during a 6-h period.Apotential difference of 60 V dc is maintained across the ends

ofthespecimen,oneofwhichisimmersedinasodiumchloridesolution,theotherinasodiumhydroxidesolution.Thetotalcharge

passed, in coulombs, has been found to be related to the resistance of the specimen to chloride ion penetration.

4. Significance and Use

4.1 This test method covers the laboratory evaluation of the electrical conductance of concrete samples to provide a rapid

indication of their resistance to chloride ion penetration. In most cases the electrical conductance results have shown good

correlation with chloride ponding tests, such as AASHTO T259, on companion slabs cast from the same concrete mixtures (Refs

1-5).

4.2 This test method is suitable for evaluation of materials and material proportions for design purposes and research and

development.

4.3 Sample age has significant effects on the test results, depending on the type of concrete and the curing procedure. Most

concretes, if properly cured, become progressively and significantly less permeable with time.

4.4Originally developed for more general evaluations of materials, the use 4.4 This test method was developed originally for

evaluations of the test method has evolved alternative materials, but in practice and it is now used inits use has evolved to

1

This test method is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.66 on

Concrete’s Resistance to Fluid Penetration.

Current edition approved Nov. 1, 2007. Published December 2007. Originally approved in 1991. Last previous edition approved in 2005 as C1202–05.

Current edition approved Dec. 15, 2008. Published January 2009. Originally approved in 1991. Last previous edition approved in 2007 as C 1202 – 07.

2

The boldface numbers in parentheses refer to the list of references at the end of this standard.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Methods of Sampling and Testing, 1986, American Association of State Highway and Transportation Officials, 444 N. Capitol St., NW, Washington, DC 20001.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, Un

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.