ASTM D2143-21

(Test Method)Standard Test Method for Cyclic Pressure Strength of Reinforced, Thermosetting Plastic Pipe

Standard Test Method for Cyclic Pressure Strength of Reinforced, Thermosetting Plastic Pipe

SIGNIFICANCE AND USE

5.1 The values obtained by this test method are applicable only to conditions that specifically duplicate the procedures used.

5.2 After the regression characteristics of a pipe material and manufacturing process have been determined by this test method, one pressure may be used for quality-control purposes. This pressure shall be one of the points used in the original determination and be agreed upon between the individuals concerned.

5.3 This test method deals with cyclic internal pressure performance of a pipe and omits creep and nonrecoverable deformation measurements.

5.4 For determination of the cyclic hydrostatic design basis using data from this test method see Practice D2992.

5.5 In the application of the following test requirements and recommendations it is assumed that test specimens of a given sample of pipe are truly representative of that material and manufacturing process. In tests conducted to show the effect of temperature and pressures on the life span of the pipe, great care must be taken to ensure that the specimens being tested are representative of the group being studied. Departure from this assumption could introduce discrepancies that are greater than those introduced by departure from the details of the procedure outlined in this test method.

SCOPE

1.1 This test method covers the determination of the failure characteristics of reinforced plastic pipe when subjected to cyclic internal hydraulic pressure. It is limited to pipe in which the ratio of outside diameter to wall thickness is 10:1 or more.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: There is no known ISO equivalent to this standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2143 − 21

Standard Test Method for

Cyclic Pressure Strength of Reinforced, Thermosetting

1

Plastic Pipe

This standard is issued under the fixed designation D2143; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

3.1 Definitions of Terms Specific to This Standard:

1.1 This test method covers the determination of the failure

3.1.1 failure—the transmission of the test fluid through the

characteristics of reinforced plastic pipe when subjected to

pipe wall in any manner, whether it be wall fracture, localized

cyclic internal hydraulic pressure. It is limited to pipe in which

leaking, or weeping at a distance greater than one diameter

the ratio of outside diameter to wall thickness is 10:1 or more.

from the end closure (specimens failing within one diameter of

1.2 The values stated in inch-pound units are to be regarded

the end closure shall be discarded).

as the standard. The values in parentheses are for information

3.1.2 failure detector—a devise that measures the electrical

only.

resistance between the test fluid and a conductive material,

1.3 This standard does not purport to address all of the

wrapped around the circumference of the test specimen, and

safety concerns, if any, associated with its use. It is the

which will indicate failure when 1) the resistance is lowered to

responsibility of the user of this standard to establish appro-

a range from 10 to 20 meg-ohm or 2) for the case of municipal

priate safety, health, and environmental practices and deter-

water, when the first drop of fluid has passed through the wall

mine the applicability of regulatory limitations prior to use.

of the specimen.

NOTE 1—There is no known ISO equivalent to this standard.

3.1.3 localized leaking—failure that occurs as small frac-

tures (one or more in a test specimen) that permit the test fluid

1.4 This international standard was developed in accor-

to be transferred at a rate that is measured by the failure

dance with internationally recognized principles on standard-

detector.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3.1.4 weeping—a general transmission of the test fluid

mendations issued by the World Trade Organization Technical

through the pipe, without visible fracture, at a sufficient rate to

Barriers to Trade (TBT) Committee.

be measured by the failure dectector, or in the case of larger

magnitudes of fluid transmission appear to be moisture con-

2. Referenced Documents densation on the specimen.

2

3.1.5 wall fracture—failure by a break in the pipe wall

2.1 ASTM Standards:

causing immediate loss of test fluid and continued loss at

D618 Practice for Conditioning Plastics for Testing

essentially no pressure.

D2992 Practice for Obtaining Hydrostatic or Pressure De-

sign Basis for “Fiberglass” (Glass-Fiber-Reinforced

4. Summary of Test Method

Thermosetting-Resin) Pipe and Fittings

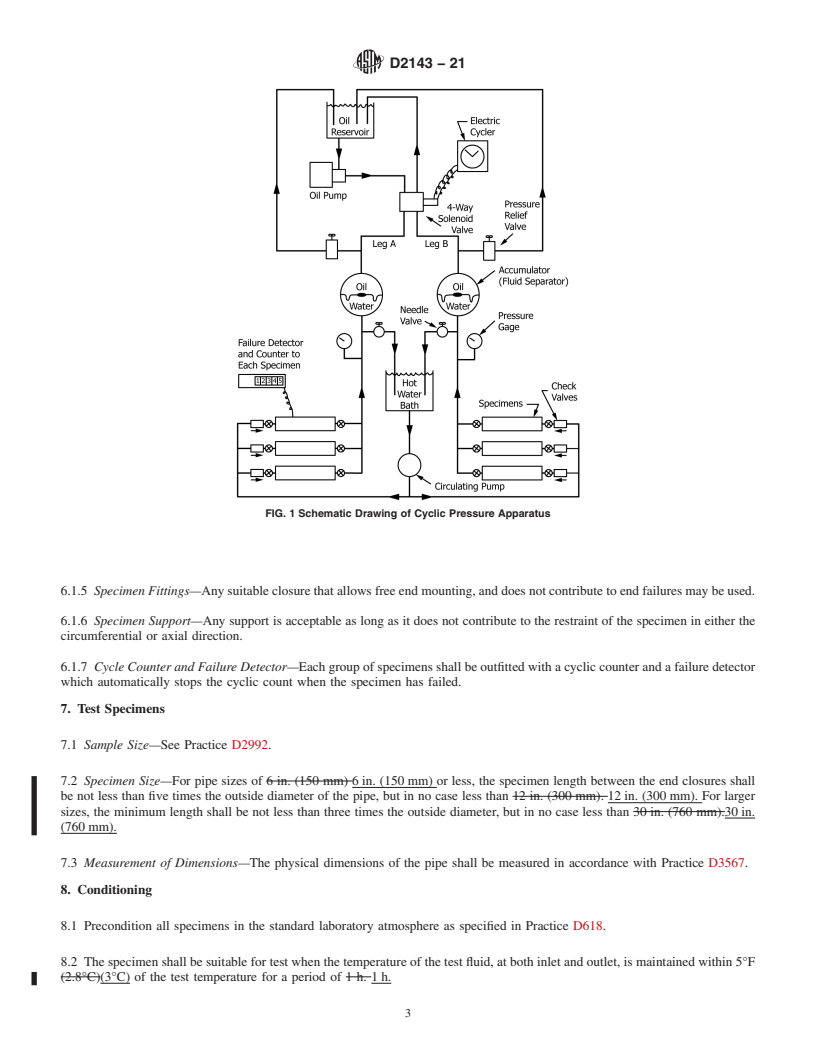

4.1 This test method consists of exposing pipe specimens to

D3567 Practice for Determining Dimensions of “Fiberglass”

(Glass-Fiber-Reinforced Thermosetting Resin) Pipe and cyclic internal pressures at several different pressure levels and

Fittings measuring the cycles to failure at these different levels. Test

temperatures are obtained by circulating salt water or munici-

pal water through the specimens.

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

5. Significance and Use

and is the direct responsibility of Subcommittee D20.23 on Reinforced Thermoset-

ting Resin Piping Systems and Chemical Equipment.

5.1 The values obtained by this test method are applicable

Current edition approved April 1, 2021. Published April 2021. Originally

only to conditions that specifically duplicate the procedures

approved in 1963. Last previous edition approved in 2015 as D2143 – 15. DOI:

used.

10.1520/D2143-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.2 After the regression characteristics of a pipe material

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and manufacturing process have been determined by this test

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. method,onepressuremaybeusedforquality-controlpurposes.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohoc

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2143 − 15 D2143 − 21

Standard Test Method for

Cyclic Pressure Strength of Reinforced, Thermosetting

1

Plastic Pipe

This standard is issued under the fixed designation D2143; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of the failure characteristics of reinforced plastic pipe when subjected to cyclic

internal hydraulic pressure. It is limited to pipe in which the ratio of outside diameter to wall thickness is 10:1 or more.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D2992 Practice for Obtaining Hydrostatic or Pressure Design Basis for “Fiberglass” (Glass-Fiber-Reinforced Thermosetting-

Resin) Pipe and Fittings

D3567 Practice for Determining Dimensions of “Fiberglass” (Glass-Fiber-Reinforced Thermosetting Resin) Pipe and Fittings

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 failure—the transmission of the test fluid through the pipe wall in any manner, whether it be wall fracture, localized leaking,

or weeping at a distance greater than one diameter from the end closure (specimens failing within one diameter of the end closure

shall be discarded).

3.1.2 failure detector—a devise that measures the electrical resistance between the test fluid and a conductive material, wrapped

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced Plastic

Thermosetting Resin Piping Systems and Chemical Equipment.

Current edition approved May 1, 2015April 1, 2021. Published June 2015April 2021. Originally approved in 1963. Last previous edition approved in 20102015 as

D2143 – 00D2143 – 15.(2010). DOI: 10.1520/D2143-15.10.1520/D2143-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2143 − 21

around the circumference of the test specimen, and which will indicate failure when 1) the resistance is lowered to a range from

10 to 20 meg-ohm or 2) for the case of municipal water, when the first drop of fluid has passed through the wall of the specimen.

3.1.3 localized leaking—failure that occurs as small fractures (one or more in a test specimen) that permit the test fluid to be

transferred at a rate that is measured by the failure detector.

3.1.4 weeping—a general transmission of the test fluid through the pipe, without visible fracture, at a sufficient rate to be measured

by the failure dectector, or in the case of larger magnitudes of fluid transmission appear to be moisture condensation on the

specimen.

3.1.5 wall fracture—failure by a break in the pipe wall causing immediate loss of test fluid and continued loss at essentially no

pressure.

4. Summary of Test Method

4.1 This test method consists of exposing pipe specimens to cyclic internal pressures at several different pressure levels and

measuring the cycles to failure at these different levels. Test temperatures are obtained by circulating salt water or municipal water

through the specimens.

5. Significance and Use

5.1 The values

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.