ASTM A1031-04

(Specification)Standard Specification for Steel, Sheet and Strip, Heavy-Thickness Coils, Alloy, Drawing Steel and Structural Steel, Hot-Rolled

Standard Specification for Steel, Sheet and Strip, Heavy-Thickness Coils, Alloy, Drawing Steel and Structural Steel, Hot-Rolled

SCOPE

1.1 This specification covers hot-rolled, heavy thickness coils beyond the size limits of Specifications A 506 and A 507.

1.2 The product is available in three designations: Alloy, Drawing Steel, and Structural Steel.

1.3 Alloy steel is furnished to chemical composition requirements and is intended primarily for general or miscellaneous use where bending and moderate forming is a requirement.

1.4 Drawing steel is produced principally for applications involving severe cold plastic deformation such as deep drawn or severely formed parts.

1.4.1 Drawing steel may be furnished in several conditions, heat treatments, surface finishes, and edges, as specified herein.

1.5 Structural steel is furnished to chemical composition requirements and to specific mechanical property requirements which may include tension tests, hardness tests, or other commonly accepted mechanical tests.

1.5.1 The formability of structural steel decreases with increasing yield strength or hardness. Therefore, product design in relation to the mechanical properties of the grade used must be considered.

1.6 This material is available only in coils described as follows:ProductSize Limits, Coils OnlyWidth, in. (mm)Thickness, in. (mm)StripOver 8 to 12, incl0.230 to 1.000, incl(Over 200 to 300)(Over 6.0 to 25)SheetOver 12 to 48, incl0.230 to 1.000, incl(Over 300 to 1200)(Over 6.0 to 25)SheetOver 480.180 to 1.000, incl(Over 1200)(Over 4.5 to 25)

1.7 Sheet and strip in coils of sizes noted in are covered by this specification only with the following provisions:

1.7.1 The material is not to be converted into steel plates for structural or pressure vessel use unless tested in complete accordance with the appropriate sections of Specifications A 6/A 6M (plates provided from coils) or A 20/A 20M (plates produced from coils). A plate produced in this manner is no longer governed by this sheet steel specification and since this material is now plate, the appropriate plate standard must now apply.

1.7.2 The dimensional tolerances of Specification A 635/A 635M are applicable to material produced to this specification.

1.7.3 The material is to be fed directly from coils into a blanking press, drawing or forming operation, tube mill, rolling mill, or sheared or slit into blanks for subsequent drawing or forming.

1.8 The values stated in either inch-pound units and SI units (metric) are to be regarded separately as standard. Within the text the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of each other.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 1031 – 04

Standard Specification for

Steel, Sheet and Strip, Heavy-Thickness Coils, Alloy,

Drawing Steel and Structural Steel, Hot-Rolled

This standard is issued under the fixed designation A 1031; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope longer governed by this sheet steel specification and since this

material is now plate, the appropriate plate standard must now

1.1 This specification covers hot-rolled, heavy thickness

apply.

coils beyond the size limits of SpecificationsA 506 andA 507.

1.7.2 The dimensional tolerances of Specification A 635/

1.2 The product is available in three designations: Alloy,

A 635M are applicable to material produced to this specifica-

Drawing Steel, and Structural Steel.

tion.

1.3 Alloy steel is furnished to chemical composition re-

1.7.3 The material is to be fed directly from coils into a

quirements and is intended primarily for general or miscella-

blankingpress,drawingorformingoperation,tubemill,rolling

neous use where bending and moderate forming is a require-

mill, or sheared or slit into blanks for subsequent drawing or

ment.

forming.

1.4 Drawing steel is produced principally for applications

1.8 The values stated in either inch-pound units and SI units

involving severe cold plastic deformation such as deep drawn

(metric) are to be regarded separately as standard. Within the

or severely formed parts.

text the SI units are shown in brackets. The values stated in

1.4.1 Drawing steel may be furnished in several conditions,

each system are not exact equivalents; therefore, each system

heattreatments,surfacefinishes,andedges,asspecifiedherein.

must be used independently of each other.

1.5 Structural steel is furnished to chemical composition

requirements and to specific mechanical property requirements

2. Referenced Documents

which may include tension tests, hardness tests, or other

2.1 ASTM Standards:

commonly accepted mechanical tests.

A 6/A 6M Specification for General Requirements for

1.5.1 The formability of structural steel decreases with

Rolled Structural Steel Bars, Plates, Shapes, and Sheet

increasing yield strength or hardness. Therefore, product de-

Piling

sign in relation to the mechanical properties of the grade used

A 20/A 20M Specification for General Requirements for

must be considered.

Steel Plates for Pressure Vessels

1.6 This material is available only in coils described as

A 370 Test Methods and Definitions for MechanicalTesting

follows:

of Steel Products

Product Size Limits, Coils Only

A 505 Specification for Steel, Sheet and Strip, Alloy, Hot-

Width, in. (mm) Thickness, in. (mm)

Strip Over 8 to 12, incl 0.230 to 1.000, incl

Rolled and Cold-Rolled, General Requirements for

(Over 200 to 300) (Over 6.0 to 25)

A 506 Specification for Alloy and Structural Alloy Steel,

Sheet Over 12 to 48, incl 0.230 to 1.000, incl

Sheet and Strip, Hot-Rolled and Cold-Rolled

(Over 300 to 1200) (Over 6.0 to 25)

Sheet Over 48 0.180 to 1.000, incl

A 507 Specification for Drawing Alloy Steel, Sheet and

(Over 1200) (Over 4.5 to 25)

Strip, Hot-Rolled and Cold-Rolled

1.7 Sheet and strip in coils of sizes noted in 1.6 are covered A 635/A 635M Specification for Steel, Sheet and Strip,

by this specification only with the following provisions:

Heavy-ThicknessCoils,Carbon,CommercialSteel,Draw-

1.7.1 The material is not to be converted into steel plates for ing Steel, Structural, High-Strength Low-Alloy, and High-

structural or pressure vessel use unless tested in complete Strength Low-Alloy with Improved Formability, Hot-

accordance with the appropriate sections of Specifications Rolled, General Requirements for

A 6/A 6M (plates provided from coils) or A 20/A 20M (plates A 751 Test Methods, Practices, and Terminology for

produced from coils). A plate produced in this manner is no Chemical Analysis of Steel Products

1 2

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

A01.19 on Steel Sheet and Strip. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Jan. 1, 2004. Published January 2004. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A1031–04

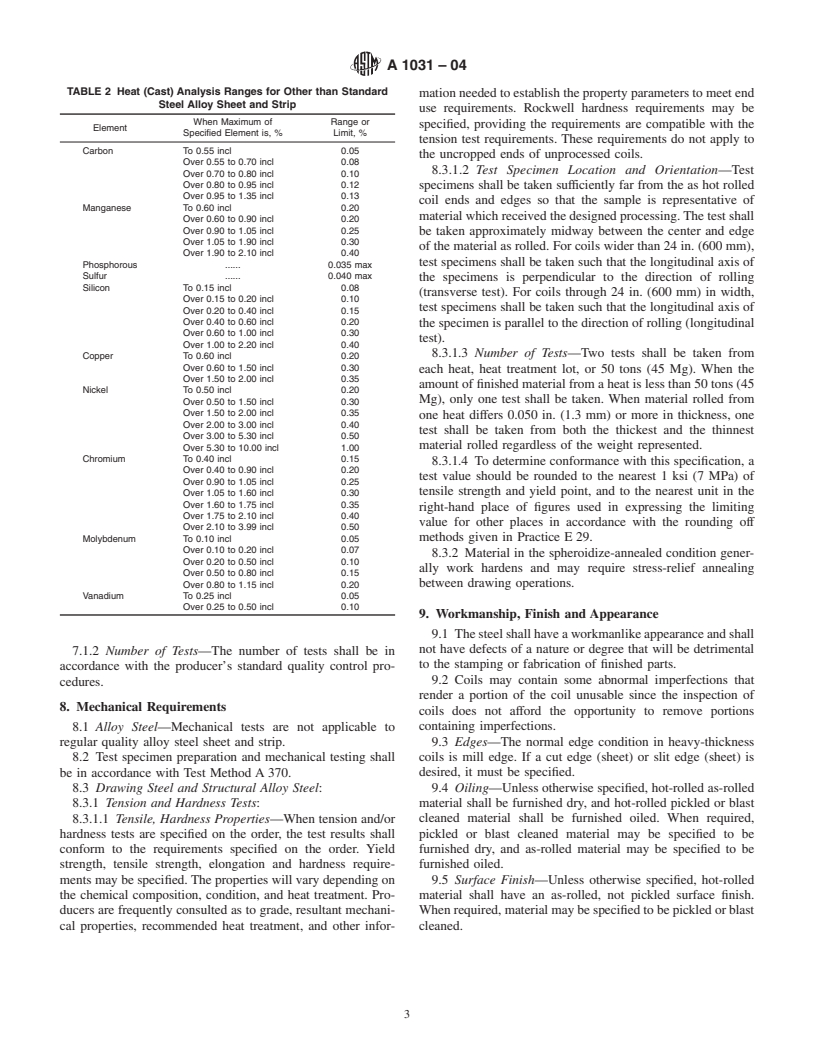

TABLE 1 Standard Steels Commonly Produced for Alloy Steel Sheet and Strip

A

Chemical Composition Ranges and Limits, % (Heat Analysis)

UNS SAE

B

Design. No.

CMn P S Si Ni Cr Mo

G41180 4118 0.18-0.23 0.70-0.90 0.035 0.035 0.15-0.30 . 0.40-0.60 0.08-0.15

G41300 4130 0.28-0.33 0.40-0.60 0.035 0.035 0.15-0.30 . 0.80-1.10 0.15-0.25

G41400 4140 0.38-0.43 0.75-1.00 0.035 0.035 0.15-0.30 . 0.80-1.10 0.15-0.25

G43400 4340 0.38-0.43 0.60-0.80 0.035 0.035 0.15-0.30 1.65-2.00 0.70-0.90 0.20-0.30

G51200 5120 0.17-0.22 0.70-0.90 0.035 0.035 0.15-0.30 . 0.70-0.90 .

G51400 5140 0.38-0.43 0.70-0.90 0.035 0.035 0.15-0.30 . 0.70-0.90 .

G51500 5150 0.48-0.53 0.70-0.90 0.035 0.035 0.15-0.30 . 0.70-0.90 .

G51600 5160 0.55-0.65 0.75-1.00 0.035 0.035 0.15-0.30 . 0.70-0.90 .

G86150 8615 0.13-0.18 0.70-0.90 0.035 0.035 0.15-0.30 0.40-0.70 0.40-0.60 0.15-0.25

G86200 8620 0.18-0.23 0.70-0.90 0.035 0.035 0.15-0.30 0.40-0.70 0.40-0.60 0.15-0.25

A

The chemical ranges and limits shown are subject to product analysis tolerances. See Specification A 505.

B

Other silicon ranges are available. Consult the producer.

72 in. maximum, coil weight 40 000 lb maximum; 200 000 lb for roll

E 29 Practice for Using Significant Digits in Test Data to

forming shapes; (SI units) ASTM A XXXX/XXXXM: Alloy, hot rolled

Determine Conformance with Specifications

sheet coils, grade SAE 4118, pickled and oiled, cut edge, 10 mm by 900

mm by coil; ID 600 mm, OD 1800 mm, maximum, coil weight 18 000 kg

3. General Requirements for Delivery

maximum; 90 000 kg for roll forming shapes.

3.1 Material furnished under this specification shall con-

form to the applicable requirements of Specification A 505,

5. Manufacture

current edition, unless otherwise provided herein.

5.1 Heat Treatment:

5.1.1 As-rolled,

4. Ordering Information

5.1.2 Annealed,

4.1 Orders for material under this specification shall include

5.1.2.1 Spheroidized Annealed,

the following information, as required, to adequately describe

(1) Drawing Steel—Unless otherwise specified on the

the desired material.

order, drawing steel will be furnished with a spheroidized

4.1.1 ASTM specification number and year of issue,

annealed heat treatment.

4.1.2 Classification of the material (hot-rolled sheet or

(2) If the material is to be heat treated by other than the

hot-rolled strip),

producer, the order shall so state. The material may be ordered

4.1.3 Chemical Composition (grade),

in the as-rolled condition, in such cases.

4.1.4 Condition—Material in accordance with this specifi-

5.1.2.2 Normalized, or

cation is furnished in the hot rolled condition. Pickled (or blast

5.1.2.3 Normalized-and-tempered.

cleaned) must be specified if required. Material ordered as

Pickled (or blast cleaned) will be oiled unless ordered dry,

6. Chemical Requirements

4.1.5 Heat treatment required, if any,

4.1.6 Type of edge must be specified for hot rolled sheet 6.1 The heat analysis of the steel shall conform to the

coils and strip coils, either mill edge or cut edge (sheet), mill requirements for the grade specified on the order.

edge or slit edge (strip), 6.2 Standard Alloy Steel grades listed in Table 1 are those

4.1.7 Dimensions(decimalthicknessandwidthofmaterial),

commonly produced for alloy steel sheet and strip. Other

4.1.7.1 As agreed upon between the purchaser and the standard steel grades are listed in Annex A1.

producer, material ordered to this specification will be supplied

6.3 Nonstandard Alloy Steel grades may be specified using

to meet the appropriate standard or restricted thickness toler- the ranges and limits shown in Table 2.

ances shown in Specification A 635/A 635M,

6.4 Structural Alloy Steel—The grade shall be specified as

outlined in 6.2 or 6.3. However, since different mechanical

NOTE 1—Not all producers are capable of meeting all the limitations of

properties may be expected for each of the many chemical

the thickness tolerance tables in Specification A 635/A 635M. The pur-

chaser should contact the producer regarding possible limitations prior to compositions and conditions (heat treatment) that may be

placing an order.

specified, consideration must be given to these factors in

selecting the chemical composition to be specified.

4.1.8 Coil size and weight requirements (must include

inside diameter, ID; outside diameter, OD), and maximum

7. Metallurgical Structure

weight,

4.1.9 Quantity (weight),

7.1 Microstructure:

4.1.10 Application (part identification and description),

7.1.1 Drawing Steel—A minimum of 75 % of the carbide

4.1.11 Special requirements (if required),

microstructureshallbeoftheglobulartypeformaterialwithan

4.1.12 Test reports (if required), and

ordered thickness of less than or equal to 0.400 in. (10 mm).

4.1.13 Cast or heat analysis (if required).

For material with an ordered thickness greater than 0.400 in.

(10mm),thepercentminimumglobularcarbidemicrostructure

NOTE 2—A typical ordering description is as follows: (inch pound

guarantee shall be by agreement between the purchaser and the

units)ASTMA XXXX/XXXXM:Alloy, hot rolled sheet coils, grade SAE

4118, pickled and oiled, cut edge, 0.500 by 40 in. by coil; ID 24 in., OD producer.

A1031–04

TABLE 2 Heat (Cast)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.