ASTM C1266-95

(Test Method)Standard Test Method for Flow Characteristics of Preformed Tape Sealants

Standard Test Method for Flow Characteristics of Preformed Tape Sealants

SCOPE

1.1 This test method describes a laboratory procedure for determining the flow characteristics of preformed tape sealants after a specified time, temperature, and load.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are provided for information purposes only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: C 1266 – 95

Standard Test Method for

1

Flow Characteristics of Preformed Tape Sealants

This standard is issued under the fixed designation C 1266; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope the flow characteristics of a tape sealant under controlled

temperature and aging conditions with a specified load.

1.1 This test method describes a laboratory procedure for

determining the flow characteristics of preformed tape sealants

6. Apparatus

after a specified time, temperature, and load.

6.1 Aluminum Plates, four, each 6.35 by 76.2 by 101.6 mm

1.2 The values stated in SI units are to be regarded as the

(0.25 by 3.00 by 4.00 in.).

standard. The inch-pound units given in parentheses are

6.2 Lead Weights, two, each 3.63 kg (8.0 lb) with dimen-

provided for information purposes only.

sions large enough to cover the entire assembly, but not

1.3 This standard does not purport to address all of the

overhanging the assembly.

safety concerns, if any, associated with its use. It is the

6.3 Mechanical Convection Oven, capable of maintaining a

responsibility of the user of this standard to establish appro-

temperature of 88 6 1°C (190 6 2°F).

priate safety and health practices and determine the applica-

6.4 Steel Spacers, six, each 76.2 by 5.08 by 5.08 6 0.05 mm

bility of regulatory limitations prior to use.

(3.00 by 0.20 by 0.20 6 0.002 in.).

2. Referenced Documents 6.5 Thickness Gage, having a total capacity of at least 76.2

mm (3.00 in.) graduated in 0.025 mm (0.001 in.) divisions. The

2.1 ASTM Standards:

2

gage shall be equipped to provide a 57 g (2 oz) load over a

C 717 Terminology of Building Seals and Sealants

minimum contact area of 6.35 mm (0.25 in.).

3. Terminology

6.6 Laboratory Press, at room temperature, to compress the

preformed sealant tape to the proper material thickness.

3.1 Definitions—The definitions of the following terms used

6.7 Stop Watch, to measure the timed intervals specified in

in this test method are found in Terminology C 717: com-

the laboratory procedure.

pound, seal, sealant, substrate and tape sealant.

6.8 Laboratory Precision Balance (capable of weighing to

4. Summary of Test Method

0.1 mg) to measure the weight of the individual spherical balls

of tape.

4.1 The tape sealant to be tested is rolled into spherical balls

of equal weight. Four spherical balls are placed between two

7. Sampling

aluminum plates, which are then compressed. A standard

7.1 Samples to be tested shall be taken from a fresh roll of

weight is placed on the test assembly for1hat room

tape sealant taken directly from a randomly selected commer-

temperature. The height of the test assembly is measured to

cial container as supplied by the manufacturer, after first

determine the rebound of the sample. The test assembly is then

removing and discarding approximately the first 0.61 (2 ft) of

placed in an 88°C (190°F) oven with the standard weight on it.

the roll.

After 24 h the height of the test assembly is measured again to

determine the flow of the sample.

8. Standard Test Conditions

5. Significance and Use 8.1 Unless otherwise specified by those authorizing the test,

standard conditions of temperature and relative humidity shall

5.1 Tape sealants are tacky, deformable solids, which are

be 236 2°C (73.4 6 3.6°F) and 50 6 5 % respectively.

used under compression between two or more surfaces of

similar or dissimilar substrates in a variety of sealing applica-

9. Test Assembly Preparation

tions. These tapes are normally supplied in a roll form with a

9.1 A total of two assemblies per tape are to be prepared.

release paper interlever and are hand pressed against a fixed

9.1.1 Prepare a test assembly as follows:

substrate. This procedure is designed to give an indication of

9.1.1.1 Clean two aluminum plates with isopropyl alcohol

(IPA) or other suitable solvent.

1

This test method is under the jurisdiction of ASTM Committee C-24 on

9.1.1.2 Using a marking pen, draw intersecting diagonals on

Building Seals and Sealants and is the direct responsibility of Subcommittee C24.50

one side of both metal plates. On each plate mark four points

on Tape Sealants.

32 mm (1.25 in.) from the intersection of the diagonals as

Current edition approved April 15, 1995. Published June 1995.

2

Annual Book of ASTM Standards, Vol 04.07. shown in Fig. 1. These become the top surfaces.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C 1266

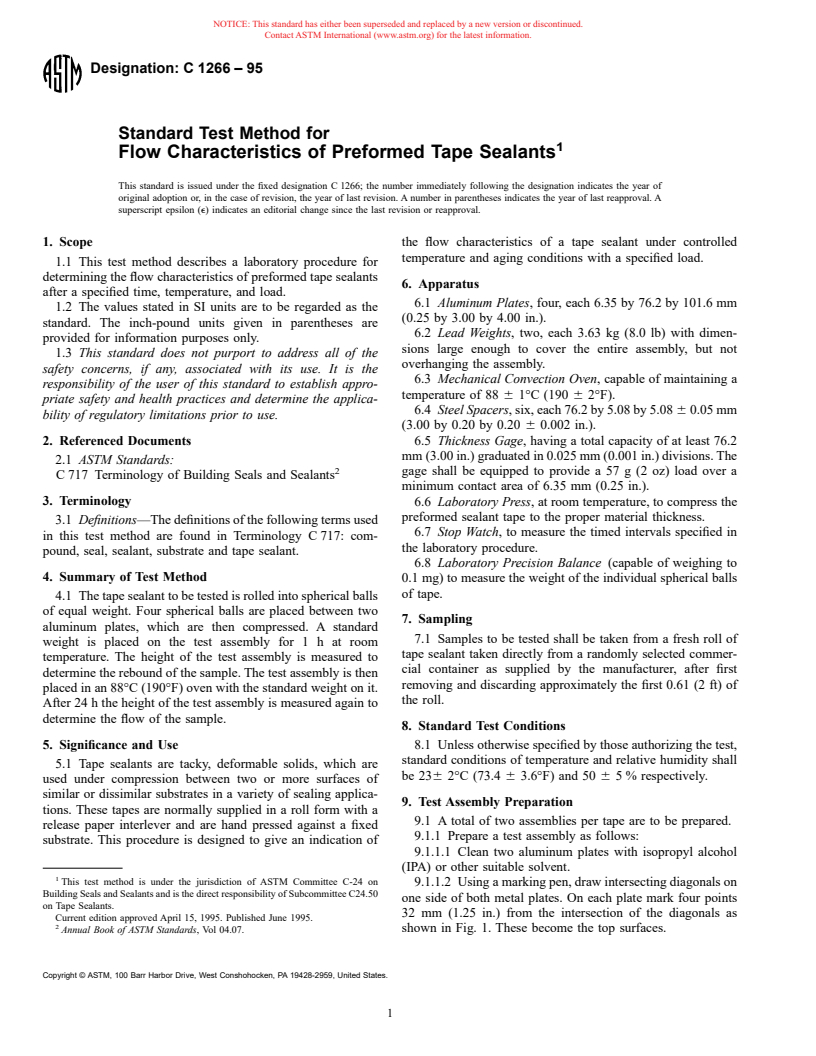

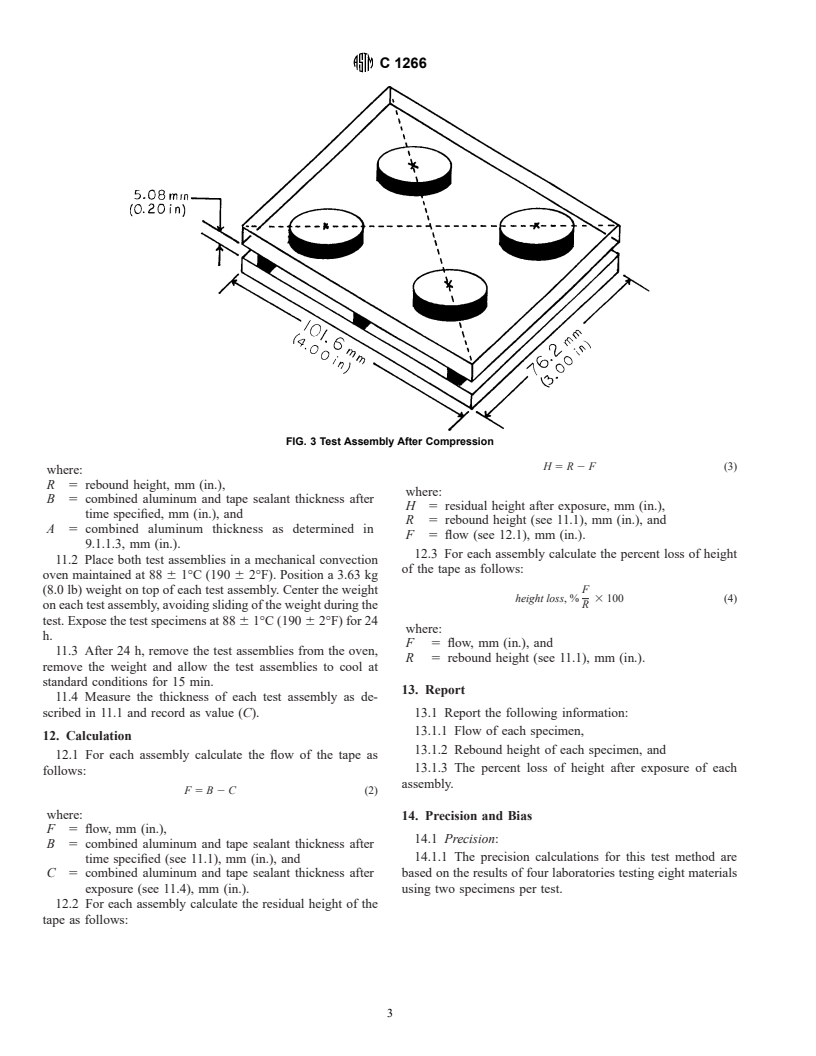

9.1.1.5 Place each of the four—4 g spherical balls of tape

sealant at quarter points (31.75 mm (1.25 in.) from the

intersection of the diagonals) of the diagonals on one of the

metal plates.

9.1.1.6 Place three steel spacers on the aluminum plate, one

in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.