ASTM A691/A691M-09

(Specification)Standard Specification for Carbon and Alloy Steel Pipe, Electric-Fusion-Welded for High-Pressure Service at High Temperatures

Standard Specification for Carbon and Alloy Steel Pipe, Electric-Fusion-Welded for High-Pressure Service at High Temperatures

ABSTRACT

This specification covers carbon and alloy steel pipe, electric-fusion-welded with filler metal added, fabricated from pressure-vessel-quality plate of several analyses and strength levels and suitable for high-pressure service at high temperatures. Heat treatment may or may not be required to attain the desired mechanical properties. The pipes are classified according to steel grades and are designated in classes according to the type of heat treatment performed in the pipe manufacture, whether the weld is radiographically examined, and whether the pipe has been pressure tested. The steel welds shall be made either manually or automatically by an electric process involving the deposition of filler metal. The welded joints shall have positive reinforcement at the center of each side of the weld. The contour of this reinforcement shall be smooth, and the deposited metal shall be fused smoothly and uniformly into the plate surface. The joints shall undergo tension, bend and pressure tests. Unacceptable surface imperfections shall be removed by grinding or machining. The depression after grinding or machining shall be blended uniformly into the surrounding surface. Repair of weld and base metal defects shall be done by welding.

SCOPE

1.1 This specification covers carbon and alloy steel pipe, electric-fusion-welded with filler metal added, fabricated from pressure-vessel-quality plate of several analyses and strength levels and suitable for high-pressure service at high temperatures. Heat treatment may or may not be required to attain the desired mechanical properties or to comply with applicable code requirements. Supplementary requirements are provided for use when additional testing or examination is desired.

1.2 The specification nominally covers pipe 16 in. [400 mm] in outside diameter and larger with wall thicknesses up to 3 in. [75 mm] inclusive. Pipe having other dimensions may be furnished provided it complies with all other requirements of this specification.

1.3 Several grades and classes of pipe are provided.

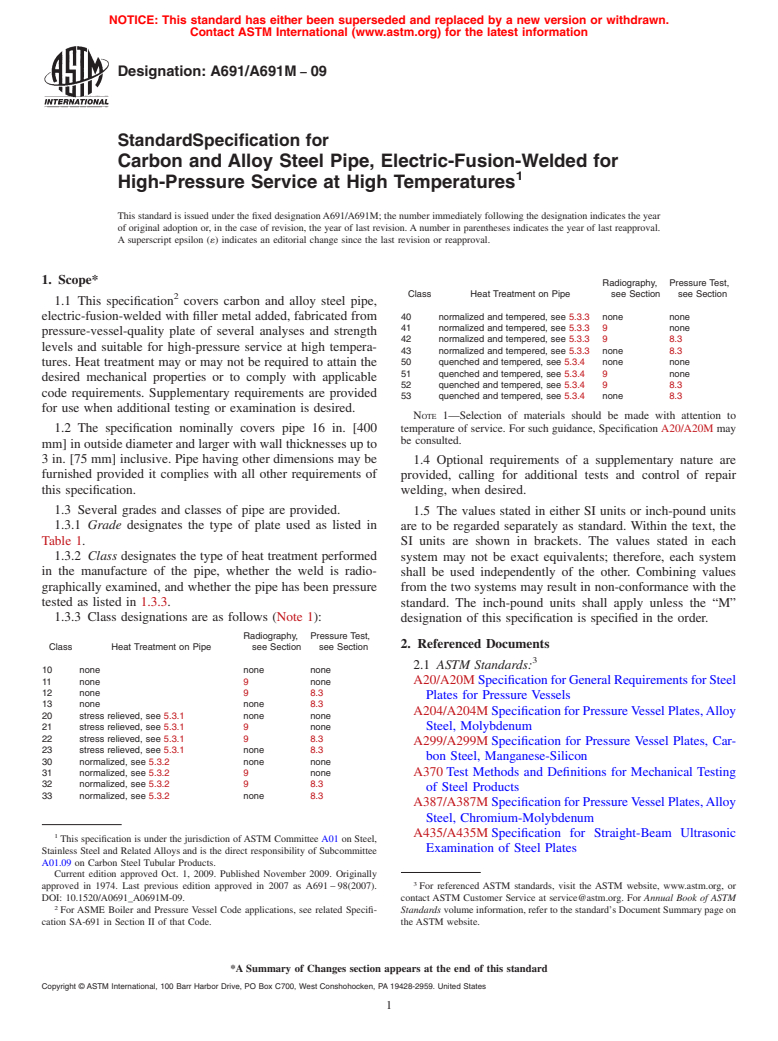

1.3.1 Grade designates the type of plate used as listed in Table 1.

1.3.2 Class designates the type of heat treatment performed in the manufacture of the pipe, whether the weld is radiographically examined, and whether the pipe has been pressure tested as listed in 1.3.3.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A691/A691M −09

StandardSpecification for

Carbon and Alloy Steel Pipe, Electric-Fusion-Welded for

1

High-Pressure Service at High Temperatures

This standard is issued under the fixed designationA691/A691M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

Radiography, Pressure Test,

Class Heat Treatment on Pipe see Section see Section

2

1.1 This specification covers carbon and alloy steel pipe,

electric-fusion-welded with filler metal added, fabricated from 40 normalized and tempered, see 5.3.3 none none

41 normalized and tempered, see 5.3.3 9 none

pressure-vessel-quality plate of several analyses and strength

42 normalized and tempered, see 5.3.3 9 8.3

levels and suitable for high-pressure service at high tempera-

43 normalized and tempered, see 5.3.3 none 8.3

tures. Heat treatment may or may not be required to attain the 50 quenched and tempered, see 5.3.4 none none

51 quenched and tempered, see 5.3.4 9 none

desired mechanical properties or to comply with applicable

52 quenched and tempered, see 5.3.4 9 8.3

code requirements. Supplementary requirements are provided

53 quenched and tempered, see 5.3.4 none 8.3

for use when additional testing or examination is desired.

NOTE 1—Selection of materials should be made with attention to

1.2 The specification nominally covers pipe 16 in. [400 temperature of service. For such guidance, Specification A20/A20M may

be consulted.

mm]inoutsidediameterandlargerwithwallthicknessesupto

3 in. [75 mm] inclusive. Pipe having other dimensions may be

1.4 Optional requirements of a supplementary nature are

furnished provided it complies with all other requirements of provided, calling for additional tests and control of repair

this specification.

welding, when desired.

1.3 Several grades and classes of pipe are provided. 1.5 The values stated in either SI units or inch-pound units

1.3.1 Grade designates the type of plate used as listed in

are to be regarded separately as standard. Within the text, the

Table 1. SI units are shown in brackets. The values stated in each

1.3.2 Class designates the type of heat treatment performed

system may not be exact equivalents; therefore, each system

in the manufacture of the pipe, whether the weld is radio- shall be used independently of the other. Combining values

graphically examined, and whether the pipe has been pressure from the two systems may result in non-conformance with the

tested as listed in 1.3.3.

standard. The inch-pound units shall apply unless the “M”

1.3.3 Class designations are as follows (Note 1): designation of this specification is specified in the order.

Radiography, Pressure Test,

2. Referenced Documents

Class Heat Treatment on Pipe see Section see Section

3

2.1 ASTM Standards:

10 none none none

A20/A20MSpecificationforGeneralRequirementsforSteel

11 none 9 none

12 none 98.3

Plates for Pressure Vessels

13 none none 8.3

A204/A204MSpecificationforPressureVesselPlates,Alloy

20 stress relieved, see 5.3.1 none none

21 stress relieved, see 5.3.1 9 none Steel, Molybdenum

22 stress relieved, see 5.3.1 9 8.3

A299/A299MSpecification for Pressure Vessel Plates, Car-

23 stress relieved, see 5.3.1 none 8.3

bon Steel, Manganese-Silicon

30 normalized, see 5.3.2 none none

31 normalized, see 5.3.2 9 none A370Test Methods and Definitions for Mechanical Testing

32 normalized, see 5.3.2 9 8.3

of Steel Products

33 normalized, see 5.3.2 none 8.3

A387/A387MSpecificationforPressureVesselPlates,Alloy

Steel, Chromium-Molybdenum

A435/A435MSpecification for Straight-Beam Ultrasonic

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Examination of Steel Plates

Stainless Steel and RelatedAlloysand is the direct responsibility of Subcommittee

A01.09 on Carbon Steel Tubular Products.

Current edition approved Oct. 1, 2009. Published November 2009. Originally

3

approved in 1974. Last previous edition approved in 2007 as A691–98(2007). For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/A0691_A0691M-09. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

For ASME Boiler and Pressure Vessel Code applications, see related Specifi- Standards volume information, refer to the standard’s Document Summary page on

cation SA-691 in Section II of that Code. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

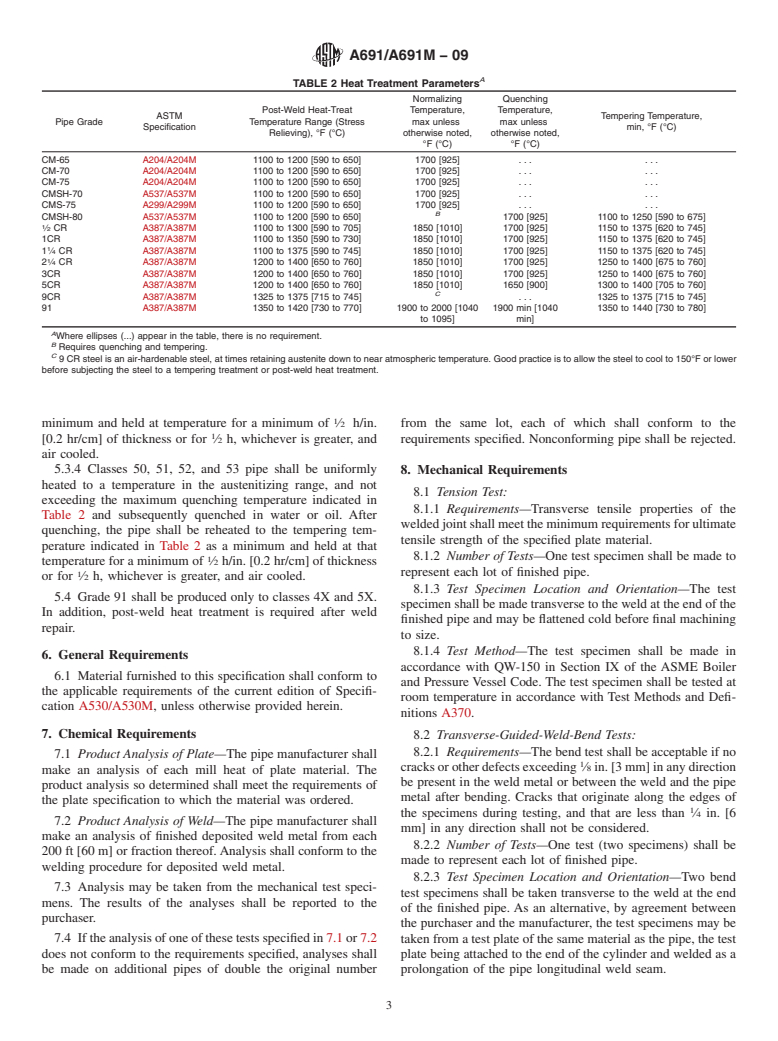

A691/A691M−09

TABLE 1 Plate Materials

A

ASTM Specification HB,

...

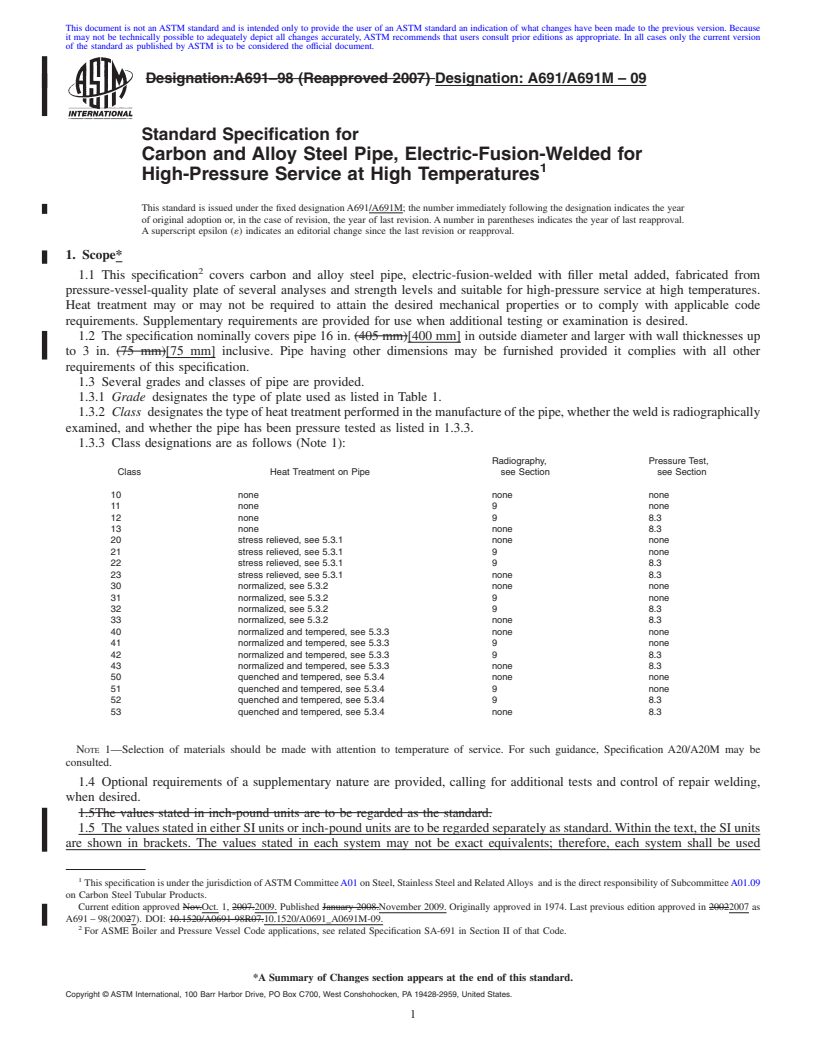

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A691–98 (Reapproved 2007) Designation: A691/A691M – 09

Standard Specification for

Carbon and Alloy Steel Pipe, Electric-Fusion-Welded for

1

High-Pressure Service at High Temperatures

This standard is issued under the fixed designationA691/A691M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

2

1.1 This specification covers carbon and alloy steel pipe, electric-fusion-welded with filler metal added, fabricated from

pressure-vessel-quality plate of several analyses and strength levels and suitable for high-pressure service at high temperatures.

Heat treatment may or may not be required to attain the desired mechanical properties or to comply with applicable code

requirements. Supplementary requirements are provided for use when additional testing or examination is desired.

1.2 The specification nominally covers pipe 16 in. (405 mm)[400 mm] in outside diameter and larger with wall thicknesses up

to 3 in. (75 mm)[75 mm] inclusive. Pipe having other dimensions may be furnished provided it complies with all other

requirements of this specification.

1.3 Several grades and classes of pipe are provided.

1.3.1 Grade designates the type of plate used as listed in Table 1.

1.3.2 Class designatesthetypeofheattreatmentperformedinthemanufactureofthepipe,whethertheweldisradiographically

examined, and whether the pipe has been pressure tested as listed in 1.3.3.

1.3.3 Class designations are as follows (Note 1):

Radiography, Pressure Test,

Class Heat Treatment on Pipe see Section see Section

10 none none none

11 none 9 none

12 none 9 8.3

13 none none 8.3

20 stress relieved, see 5.3.1 none none

21 stress relieved, see 5.3.1 9 none

22 stress relieved, see 5.3.1 9 8.3

23 stress relieved, see 5.3.1 none 8.3

30 normalized, see 5.3.2 none none

31 normalized, see 5.3.2 9 none

32 normalized, see 5.3.2 9 8.3

33 normalized, see 5.3.2 none 8.3

40 normalized and tempered, see 5.3.3 none none

41 normalized and tempered, see 5.3.3 9 none

42 normalized and tempered, see 5.3.3 9 8.3

43 normalized and tempered, see 5.3.3 none 8.3

50 quenched and tempered, see 5.3.4 none none

51 quenched and tempered, see 5.3.4 9 none

52 quenched and tempered, see 5.3.4 9 8.3

53 quenched and tempered, see 5.3.4 none 8.3

NOTE 1—Selection of materials should be made with attention to temperature of service. For such guidance, Specification A20/A20M may be

consulted.

1.4 Optional requirements of a supplementary nature are provided, calling for additional tests and control of repair welding,

when desired.

1.5The values stated in inch-pound units are to be regarded as the standard.

1.5 ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunits

are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used

1

ThisspecificationisunderthejurisdictionofASTMCommitteeA01onSteel,StainlessSteelandRelatedAlloys andisthedirectresponsibilityofSubcommitteeA01.09

on Carbon Steel Tubular Products.

Current edition approved Nov.Oct. 1, 2007.2009. Published January 2008.November 2009. Originally approved in 1974. Last previous edition approved in 20022007 as

A691–98(20027). DOI: 10.1520/A0691-98R07.10.1520/A0691_A0691M-09.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specification SA-691 in Section II of that Code.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

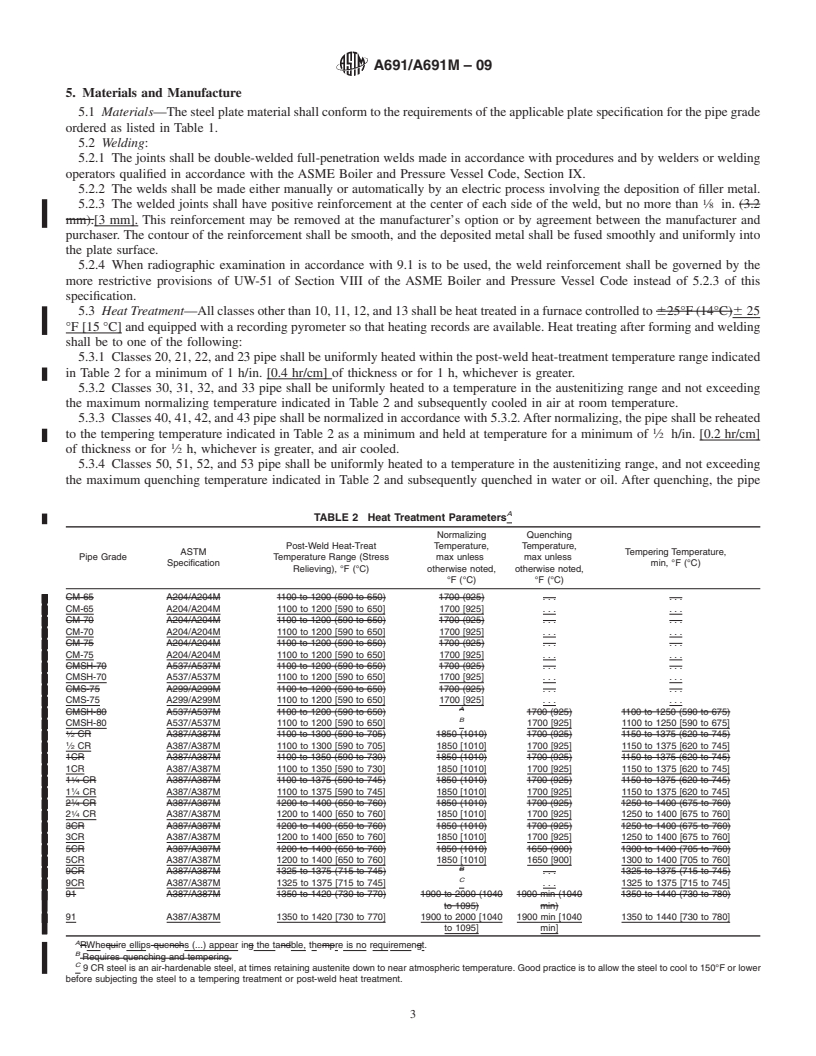

A691/A691M – 09

TABLE 1 Plate Materials

A

ASTM Specification HB, max

Pipe Grade Type of Steel

Number Grade

CM-65 carbon-molybdenum steel A204/A204M A 201

CM-70 carbon-molybdenum steel A204/A204M B 201

CM-75 carbon-molybdenum steel A204/A204M C 201

CMSH-70 carbon-manganese-silicon steel, normalized A537/A537M 1

CMS-75 carbon-manganese-silicon steel A299/A299M . . . . . .

CMSH-80 carbon-manganese-silicon steel, quenched and tempered A537/A537M 2

1 1 1

⁄2 CR ⁄2 % chromium, ⁄2 % molybdenum steel A387/A387M 2 201

1

1CR 1 % chromium, ⁄2 % molybdenum steel A387/A387M 12 201

1 1 1

1 ⁄4 CR 1 ⁄4 % chromium, ⁄2 % molybdenum steel A387/A387M 11 201

1 1

2 ⁄4 CR 2 ⁄4 % chromium, 1 % molybdenum steel A387/A387M 22 201

3CR 3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.