ASTM D2172-95

(Test Method)Standard Test Methods for Quantitative Extraction of Bitumen From Bituminous Paving Mixtures

Standard Test Methods for Quantitative Extraction of Bitumen From Bituminous Paving Mixtures

SCOPE

1.1 These test methods cover the quantitative determination of bitumen in hot-mixed paving mixtures and pavement samples. Aggregate obtained by these test methods may be used for sieve analysis using Test Method C 117 and Test Method C 136.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards are given in Section 7.

Note 1—The results obtained by these test methods may be affected by the age of the material tested, with older samples tending to yield slightly lower bitumen content. Best quantitative results are obtained when the test is made on mixtures and pavements shortly after their preparation. It is difficult to remove all the asphalt when some aggregates are used and some chlorides may remain within the mineral matter affecting the measured asphalt content.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2172 – 95

Standard Test Methods for

Quantitative Extraction of Bitumen From Bituminous Paving

Mixtures

This standard is issued under the fixed designation D 2172; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 604 Specification for Diatomaceous Silica Pigment

D 979 Practice for Sampling Bituminous Paving Mixtures

1.1 These test methods cover the quantitative determination

D 1461 Test Method for Moisture or Volatile Distillates in

of bitumen in hot-mixed paving mixtures and pavement

Bituminous Paving Mixtures

samples. Aggregate obtained by these test methods may be

D 1856 Test Method for Recovery of Asphalt from Solution

used for sieve analysis using Test Method C 117 and Test

by Abson Method

Method C 136.

D 2111 Test Methods for Specific Gravity of Halogenated

1.2 The values stated in inch-pound units are to be regarded

Organic Solvents and Their Admixtures

as the standard. The values given in parentheses are for

2.2 Federal Specifications:

information only.

O-T-620a (Int. Amd. 3) 1,1,1-Trichloroethane, Technical,

1.3 This standard does not purport to address all of the

Inhibited Methyl Chloroform)

safety concerns, if any, associated with its use. It is the

O-T-634 (latest) Trichloroethylene, Technical

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3. Summary of Test Methods

bility of regulatory limitations prior to use. Specific hazards are

3.1 The paving mixture is extracted with trichloroethylene,

given in Section 7.

1,1,1-trichloroethane or methylene chloride using the extrac-

NOTE 1—The results obtained by these test methods may be affected by

tion equipment applicable to the particular method. The bitu-

the age of the material tested, with older samples tending to yield slightly

men content is calculated by difference from the mass of the

lower bitumen content. Best quantitative results are obtained when the test

extracted aggregate, moisture content, and mineral matter in

is made on mixtures and pavements shortly after their preparation. It is

the extract. The bitumen content is expressed as mass percent

difficult to remove all the asphalt when some aggregates are used and

of moisture-free mixtures.

some chlorides may remain within the mineral matter affecting the

measured asphalt content.

4. Significance and Use

2. Referenced Documents

4.1 All of these test methods can be used for quantitative

2.1 ASTM Standards:

determinations of bitumen in hot-mixed paving mixtures and

C 117 Test Method for Materials Finer Than 75-μm (No. pavement samples for specification acceptance, service evalu-

200) Sieve in Mineral Aggregates by Washing

ation, control, and research. Each method prescribes the

C 128 Test Method for Specific Gravity and Absorption of

solvent or solvents and any other reagents that can be used in

Fine Aggregate

the test method. Test Method D 1856 requires that Method A be

C 136 Test Method for Sieve Analysis of Fine and Coarse

used when asphalt is recovered from solution.

Aggregates

5. Apparatus

C 670 Practice for Preparing Precision and Bias Statements

for Test Methods for Construction Materials 5.1 Oven, capable of maintaining the temperature at 230 6

D 70 Test Method for Specific Gravity of Semi-Solid Bitu-

9°F (110 6 5°C).

minous Materials 5.2 Pan, flat, 12 in. (305 mm) long, 8 in. (203 mm) wide,

and 1 in. (25 mm) deep.

5.3 Balance, or balances having an accuracy of at least

These test methods are under the jurisdiction of ASTM Committee D-4 on

0.01 % of the sample mass.

Road and Paving Materials and are the direct responsibilities of Subcommittee

D04.25 on Analysis of Bituminous Mixtures.

Current edition approved Nov. 10, 1995. Published January 1996. Originally Annual Book of ASTM Standards, Vol 06.03.

published as D 2172 – 63 T. Last previous edition D 2172 – 93. Annual Book of ASTM Standards, Vol 15.05.

2 6

Annual Book of ASTM Standards, Vol 04.02. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 04.03. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 2172

5.4 Hot Plate, electric, 700-W continuous or low, medium, 8.2.2 The size of the test sample shall be governed by the

and high settings. nominal maximum aggregate size of the mixture and shall

5.5 Small-Mouth Graduate, 1000 or 2000-mL capacity. conform to the mass requirement shown in Table 2 (Note 2):

Optional small-mouth graduate, 100-mL capacity.

NOTE 2—When the mass of the test specimen exceeds the capacity of

5.6 Ignition Dish, 125-mL capacity.

the equipment used (for a particular method), the test specimen may be

5.7 Desiccator.

divided into suitable increments, tested, and the results appropriately

5.8 Analytical Balance. combined for calculation of bitumen content (Section 12).

8.2.3 In addition, a test specimen is required for the deter-

6. Reagents

mination of moisture (Section 9) in the mixtures. Take this test

6.1 Purity of Reagents—Reagent grade chemicals shall be

specimen from the remaining sample of the mixture immedi-

used in all tests. Unless otherwise indicated, it is intended that

ately after obtaining the extraction test specimen.

all reagents shall conform to the specifications of the Commit-

7 NOTE 3—If recovery of bitumen from the solution obtained from the

tee on Analytical Reagents of the American Chemical Society,

extraction test is not required, the entire test specimen may be dried to

where such specifications are available. Other grades may be

constant mass in an oven at a temperature of 230 6 9°F (110 6 5°C) prior

used, provided it is first ascertained that the reagent is of

to extraction instead of determining the moisture content (Section 9).

sufficiently high purity to permit its use without lessening the

9. Moisture Content

accuracy of the determination.

6.2 Ammonium Carbonate Solution—Saturated solution of

9.1 Determine the moisture content of the mixture (see

reagent grade ammonium carbonate [(NH ) CO ].

4 2 3 8.2.2) in accordance using the procedure described in Test

6.3 Methylene Chloride, technical grade. Caution—see

Method D 1461.

Section 7.

9.2 Calculate the mass of water, W , (12.1) in the extraction

6.4 1,1,1-Trichloroethane, conforming to Federal Specifica-

test portion by multiplying mass percent water (9.1) by the

tion O-T-620a (Int. Amd. 3). Caution—see Section 7.

mass of the extraction test portion, W , (12.1).

6.5 Trichloroethylene, technical grade, Type 1, Federal

Specification O-T-634, latest revision. Caution—see Section

TEST METHOD A

7.

10. Apparatus

7. Hazards

10.1 In addition to the apparatus listed in Section 5, the

7.1 The solvents listed in Section 6 should be used only

following apparatus is required for Test Method A:

under a hood or with an effective surface exhaust system in a

10.1.1 Extraction Apparatus, consisting of a bowl approxi-

well-ventilated area, since they are all toxic to some degree as

mating that shown in Fig. 1 and an apparatus in which the bowl

indicated in Table 1:

may be revolved at controlled variable speeds up to 3600

r/min. The speed may be controlled manually or with a preset

speed control. The apparatus should be provided with a

TABLE 1 Solvent Toxicity

container for catching the solvent thrown from the bowl and a

Time-Weighted Average

drain for removing the solvent. The apparatus preferably shall

Solvent Concentration for 8-h exposure for

5-day week, ppm

be provided with explosion-proof features and installed in a

A

hood or an effective surface exhaust system to provide venti-

Methylene chloride 200

A

Trichloroethylene 100

lation.

A

1,1-Trichloroethane 350

NOTE 4—Similar apparatus of larger size may be used.

A

Threshold Limit Concentration Committee of the American Conference of

Governmental Hygienists, 1977 Values.

10.1.2 Filter Rings, felt or paper, to fit the rim of the bowl.

10.1.3 Low-ash paper filter rings may be used in place of the

felt filter ring (10.1.2). Such filter rings shall consist of low ash

8. Sampling

filter paper stock 0.05 6 0.005 in. thick. The nominal base

8.1 Obtain samples in accordance with Practice D 979.

weight of the paper shall be 330 6 30 lb for a ream (500

8.2 Preparation of Test Specimens:

sheets—25 by 38 in.). The ash content of the paper should not

8.2.1 If the mixture is not sufficiently soft to separate with a

exceed 0.2 % (approximately 0.034 g per ring).

spatula or trowel, place it in a large, flat pan and warm to 230

6 9°F (110 6 5°C) only until it can be handled or mixed. Split

TABLE 2 Size of Sample

or quarter the material until the mass of material required for

Nominal Maximum

test is obtained.

Minimum Mass of Sample,

Aggregate Size Standard, Sieve Size

kg

mm

4.75 (No. 4) 0.5

Reagent Chemicals, American Chemical Society Specifications, American 3

9.5 ⁄8 in. 1

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

12.5 ⁄2 in. 1.5

listed by the American Chemical Society, see Analar Standards for Laboratory

19.0 ⁄4 in. 2

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia 25.0 1 in. 3

and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville, 37.5 1 ⁄2 in. 4

MD.

D 2172

11. Procedure and dry on a steam bath and then, dry to constant mass in an

oven or on a hot plate at 2306 9°F (110 6 5°C). If

11.1 Determine the moisture content of the material in

trichloroethylene or trichloroethane is used as the extraction

accordance with Section 9.

solvent, the preliminary drying on a steam bath may be

11.2 Place a 650 to 2500-g test portion into a bowl. See

omitted. The mass of the extracted aggregate, W , is equal to

Annex A1 for alternative procedures to those prescribed herein

the mass of the aggregate in the pan plus the increase in mass

and in 11.5.

of the filter rings.

11.3 Cover the test portion in the bowl with trichloroethyl-

11.5.1 Use the following alternative procedure when low-

ene, 1,1,1-trichloroethane or methylene chloride and allow

ash filter rings are used: Place the aggregate and filter rings in

sufficient time for the solvent to disintegrate the test portion

a clean metal pan. Dry as specified above. Carefully fold the

(not over 1 h). Place the bowl containing the test portion and

dried filter ring and stand it on the aggregate. Burn the filter

the solvent in the extraction apparatus. Dry and determine the

ring by igniting with a bunsen burner or match. Determine the

mass of the filter ring and fit it around the edge of the bowl.

mass of the extracted aggregate in the pan, W .

Clamp the cover on the bowl tightly and place a beaker under

the drain to collect the extract.

NOTE 5—Since dry aggregate absorbs moisture when exposed to air

11.4 Start the centrifuge revolving slowly and gradually containing moisture, determine the mass of the extracted aggregate

immediately after cooling to a suitable temperature.

increase the speed to a maximum of 3600 r/min or until solvent

ceases to flow from the drain. Allow the machine to stop, add

11.6 Determine the amount of mineral matter in the extract

200 mL of trichloroethylene, 1,1,1-trichloroethane or methyl-

by any of the following test methods:

ene chloride and repeat the procedure. Use sufficient 200-mL

11.6.1 Ashing Method:

solvent additions (not less than three) so that the extract is not

11.6.1.1 Record the volume of the total extract in the

darker than a light straw color. Collect the extract and the

graduate (11.4). Determine the mass of an ignition dish. Agitate

washings in a suitable graduate.

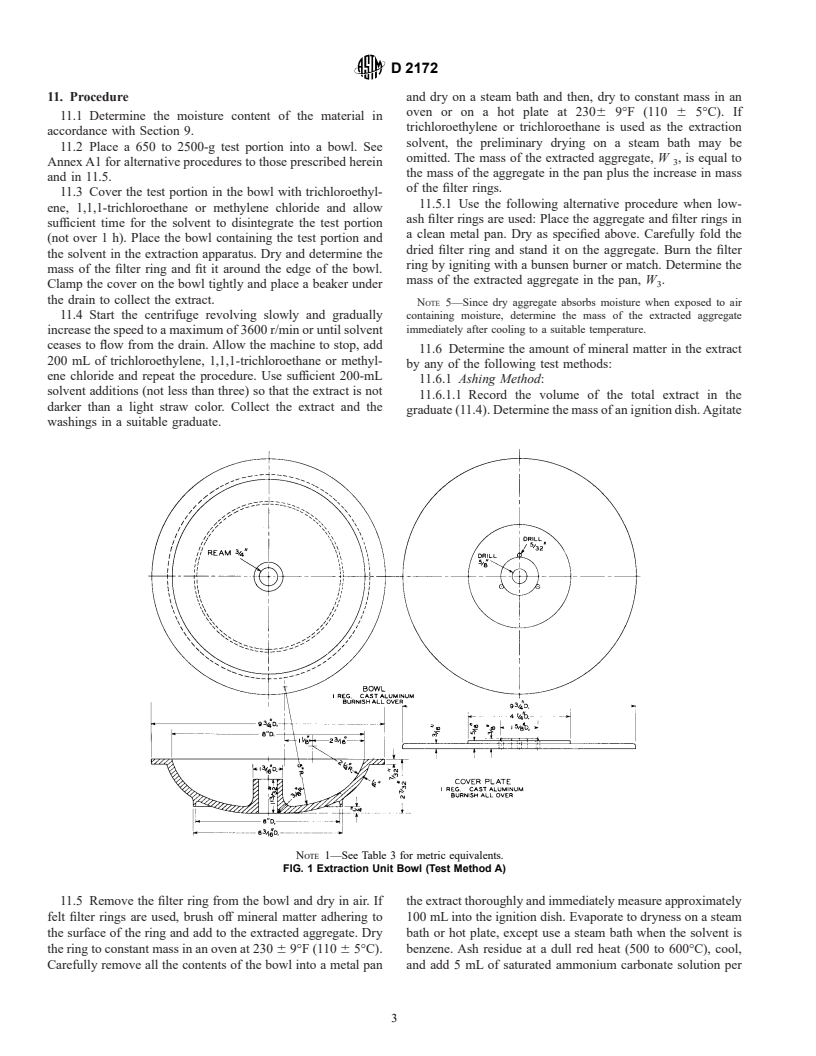

NOTE 1—See Table 3 for metric equivalents.

FIG. 1 Extraction Unit Bowl (Test Method A)

11.5 Remove the filter ring from the bowl and dry in air. If the extract thoroughly and immediately measure approximately

felt filter rings are used, brush off mineral matter adhering to 100 mL into the ignition dish. Evaporate to dryness on a steam

the surface of the ring and add to the extracted aggregate. Dry bath or hot plate, except use a steam bath when the solvent is

the ring to constant mass in an oven at 230 6 9°F (110 6 5°C). benzene. Ash residue at a dull red heat (500 to 600°C), cool,

Carefully remove all the contents of the bowl into a metal pan and add 5 mL of saturated ammonium carbonate solution per

D 2172

TABLE 3 Metric Equivalents for Figures

Inch-Pound Units, in. Metric Equivalent, cm Inch-Pound Units, in. Metric Equivalent, cm Inch-Pound Units, in. Metric Equivalent, cm

1 11 7

⁄8 0.32 1 ⁄16 4.3 5 ⁄8 14.9

3 3

⁄16 0.48 1 ⁄4 4.4 6 15.2

7 3 1

⁄32 0.56 2 ⁄16 5.5 6 ⁄8 15.5

1 7 3

⁄4 0.63 2 ⁄32 5.6 6 ⁄16 15.7

5 5 1

⁄16 0.79 2 ⁄16 5.9 6 ⁄4 15.9

3 1 1

⁄8 0.95 2 ⁄2 6.4 6 ⁄2 16.5

1 5 3

⁄2 1.27 2 ⁄8 6.9 7 ⁄8 18.7

5 13

⁄8 1.59 2 ⁄16 7.2 8 20.7

3 3

⁄4 1.9 3 7.6 9 ⁄4 24.7

1 2.5 3 ⁄4 9.6 10 25.4

1 1

1 ⁄8 2.86 4 10.2 10 ⁄8 25.7

3 1

1 ⁄16 3.02 4 ⁄4 10.8 12 30.5

1 ⁄32 3.57 5 12.7 14 35.5

1 7 1

1 ⁄2 3.8 5 ⁄16 13.8 14 ⁄2 37

1 ⁄8 4.1

gram of ash. Digest at room temperature for 1 h. Dry in an oven 11.6.3 Volumetric Method:

at 100°C to constant mass, cool in a desiccator, and determine 11.6.3.1 Place the extract in a previously tared and cali-

the mass. brated flask. Place the flask in a controlled-temperature bath

11.6.1.2 Calculate the mass of mineral matter in the total controlled to 0.2°F (60.1°C), and allow to come to the

volume of extract, W , as follows: temperature at which the flask was calibrated. When the

desired temperature has been reached, fill the flask with solvent

W 5 G@V /~V 2 V !# (1)

4 1 1 2

which has been kept at the same temperature. Bring the level of

where:

the liquid in the flask up to the neck, insert the stopper, making

G = ash in aliquot, g,

sure the liquid overflows the capillary, and remove from the

V = total volume, mL, and

1 bath. Wipe the flask dry, determine the mass to the nearest 0.1

V = volume after removing aliquot, mL.

g, and record this mass as the mass of flask plus extract. See

11.6.2 Centrifuge Method:

Annex A2 for a volumetric test method alternative procedure if

11.6.2.1 For this test method use any suitable high-speed

a controlled-temperature bath is not used as prescribed herein.

(3000 g or higher) centrifuge of the continuous-flow type.

11.6.3.2 Calculate the volume of asphalt and fines in the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.