ASTM D7756-11

(Test Method)Standard Test Method for Residues in Liquefied Petroleum (LP) Gases by Gas Chromatography with Liquid, On-Column Injection

Standard Test Method for Residues in Liquefied Petroleum (LP) Gases by Gas Chromatography with Liquid, On-Column Injection

SIGNIFICANCE AND USE

Control over the residue content as specified in Specification D1835 is of considerable importance in end-use applications of LPG. Oily residue in LPG is contamination which can occur during production, transportation, or storage.

This test method is quicker and much more sensitive than manual methods, such as Test Method D2158, which is based on evaporation of large sample volumes followed by visual or gravimetric estimation of residue content.

This test method provides enhanced sensitivity in measurements of heavier (oily) residues, with a quantification limit of 10 mg/kg total residue.

This test method gives both quantitative results and information about contaminant composition such as boiling point range and fingerprint, which can be very useful in tracing the source of a particular contaminant.

SCOPE

1.1 This test method covers the determination, by gas chromatography, of soluble hydrocarbon materials, sometimes called “oily residue,” which can be present in Liquefied Petroleum (LP) Gases and which are substantially less volatile than the LPG product.

1.2 This test method quantifies, in the range of 10 to 600 mg/kg (ppm mass), the residue with a boiling point between 174°C and 522°C (C10 to C40) in LPG. Higher boiling materials, or materials that adhere permanently to the chromatographic column, will not be detected.

1.3 Units—The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7756 −11

StandardTest Method for

Residues in Liquefied Petroleum (LP) Gases by Gas

Chromatography with Liquid, On-Column Injection

This standard is issued under the fixed designation D7756; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2598 Practice for Calculation of Certain Physical Proper-

ties of Liquefied Petroleum (LP) Gases from Composi-

1.1 This test method covers the determination, by gas

tional Analysis

chromatography, of soluble hydrocarbon materials, sometimes

D3700 Practice for Obtaining LPG Samples Using a Float-

called “oily residue,” which can be present in Liquefied

ing Piston Cylinder

Petroleum (LP) Gases and which are substantially less volatile

D6299 Practice for Applying Statistical Quality Assurance

than the LPG product.

and Control Charting Techniques to Evaluate Analytical

1.2 This test method quantifies, in the range of 10 to 600

Measurement System Performance

mg/kg (ppm mass), the residue with a boiling point between

D6667 Test Method for Determination of Total Volatile

174°C and 522°C (C to C ) in LPG. Higher boiling

10 40

Sulfur in Gaseous Hydrocarbons and Liquefied Petroleum

materials, or materials that adhere permanently to the chro-

Gases by Ultraviolet Fluorescence

matographic column, will not be detected.

E355 Practice for Gas ChromatographyTerms and Relation-

1.3 Units—The values stated in SI units are to be regarded ships

E594 Practice for Testing Flame Ionization Detectors Used

as standard. The values given in parentheses are for informa-

tion only. in Gas or Supercritical Fluid Chromatography

1.4 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1 Definitions of Terms Concerning Chromatography—

priate safety and health practices and determine the applica-

This test method makes reference to many common gas

bility of regulatory limitations prior to use.

chromatographicprocedures,terms,andrelationships.Detailed

definitions of these can be found in Practices E355 and E594.

2. Referenced Documents

3.2 Definitions of Terms Concerning Liquefied Petroleum

2.1 ASTM Standards:

Gases—This test method makes reference to the definitions of

D1265 Practice for Sampling Liquefied Petroleum (LP)

liquefied petroleum gases as described in Specification D1835.

Gases, Manual Method

D1835 Specification for Liquefied Petroleum (LP) Gases 3.3 Definitions of Terms Specific to This Standard:

D2158 Test Method for Residues in Liquefied Petroleum

3.3.1 high pressure liquefied gas injector, n—Sample intro-

(LP) Gases

duction device which injects liquefied gas samples under

D2163 Test Method for Analysis of Liquefied Petroleum

pressure and at room temperature directly onto the chromato-

(LP) Gases and Propene Concentrates by Gas Chromatog-

graphic column thereby maintaining the sample in liquid phase

raphy

during the injection process.

D2421 Practice for Interconversion of Analysis of C and

3.3.2 pressure station, n—Device that supplies high pres-

Lighter Hydrocarbons to Gas-Volume, Liquid-Volume, or

sure nitrogen to a suitable sample cylinder and therefore

Mass Basis

maintains sample in the liquid phase during the injection

procedure.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

4. Summary of Test Method

D02.H0 on Liquefied Petroleum Gas.

Current edition approved Oct. 1, 2011. Published November 2011. DOI:10.1520/

4.1 A sample cylinder of LPG is pressurized to 2500 kPa

D7756-11

(363 psi) using nitrogen or helium.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.2 TheinjectionsystemisflushedwithLPGinliquidphase

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. at room temperature.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7756 − 11

4.3 After flushing, the injection device is routed to the GC 6. Apparatus

injector port and LPG (25 milliseconds activation time equiva-

6.1 Gas Chromatograph (GC)—Gas chromatographic in-

lent to 30 µL) is introduced via a high pressure valve and

strument equipped with a Large Volume Cold on-Column

needle which is inserted into a large volume cold on-column

Injector (LVOCI), a linear temperature programmable column

injector.

oven, and a flame ionization detector (FID). The temperature

4.4 The gas chromatograph is equipped with a solvent vent

control shall be capable of obtaining a retention time repeat-

which routes most of the LPG light components out of the

ability of 0.05 min (3 s) throughout the scope of this analysis.

analyticalsystemandleavesbehindthecomponentsofinterest.

6.2 Data Acquisition—Any commercial integrator or com-

4.5 The oily residue to be determined is retained on a

puterized data acquisition system may be used for display of

pre-column.

the chromatographic detector signal and peak area integration.

4.6 After venting the LPG, the flow from the pre-column is

6.3 Solvent Vent—A controlled vent for venting the major

switchedtotheanalyticalcolumnandatemperatureprogramis

part of the matrix.

started.

6.4 Retention Gap—Uncoated stainless steel capillary. Suc-

4.7 Oily residue contaminants are separated and identified

cessfully used columns and conditions are given in Table 1.

based on differences in boiling point temperature.

6.5 Retaining Pre-Column—A column with a polydimeth-

4.8 Total residue is quantified using area summation of

ylsiloxane stationary phase. Successfully used columns and

components corresponding to the expected range of C to C

10 40

conditions are given in Table 1.

(174 to 522°C).

6.6 Analytical Column—A column with a polydimethylsi-

5. Significance and Use

loxane stationary phase. Successfully used columns and con-

ditions are given in Table 1.

5.1 Control over the residue content as specified in Speci-

fication D1835 is of considerable importance in end-use

6.7 Column Coupler—Coupling Device—Suitable for leak-

applications of LPG. Oily residue in LPG is contamination

free coupling of the retention gap to the retaining pre-column.

which can occur during production, transportation, or storage.

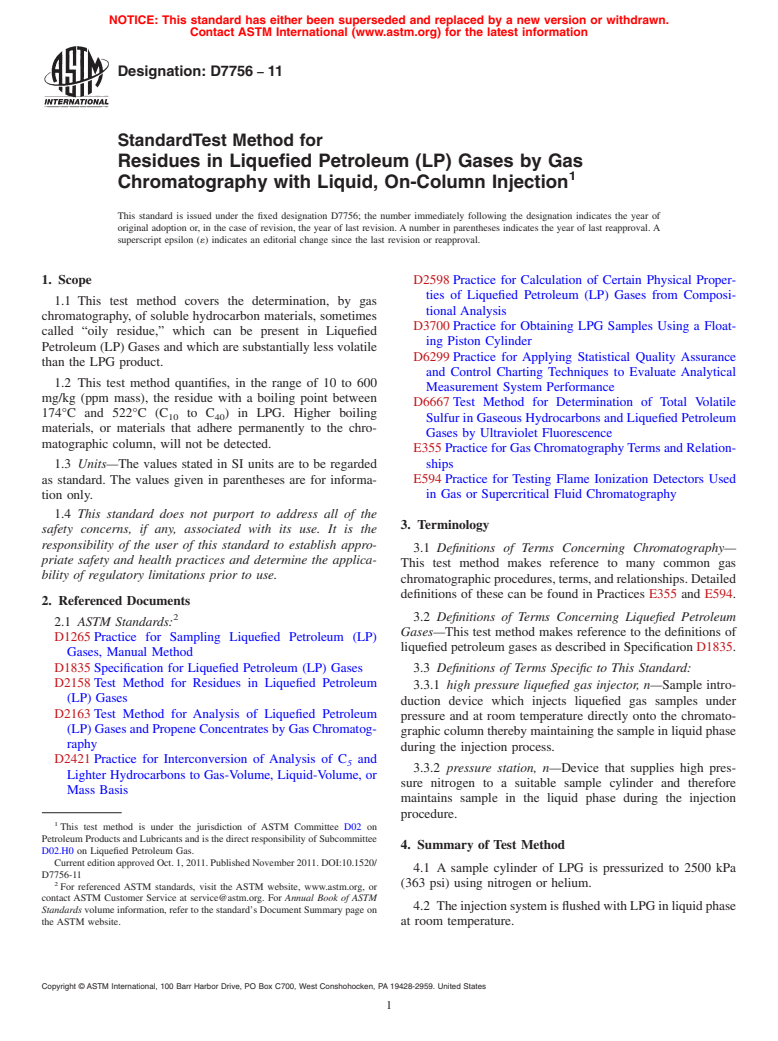

(SeeFig.1foraschematicoverviewofthecouplingsinsidethe

GC oven and the couplings to the solvent vent valve.)

5.2 This test method is quicker and much more sensitive

than manual methods, such as Test Method D2158, which is

6.8 Column Splitter—Splitter suitable for leak-free coupling

based on evaporation of large sample volumes followed by

oftheretainingpre-columntoonesideoftheanalyticalcolumn

visual or gravimetric estimation of residue content.

and the deactivated capillary on the other side. (See Fig. 1 for

a schematic overview of the couplings inside the GC oven and

5.3 This test method provides enhanced sensitivity in mea-

the couplings to the solvent vent valve.)

surements of heavier (oily) residues, with a quantification limit

of 10 mg/kg total residue.

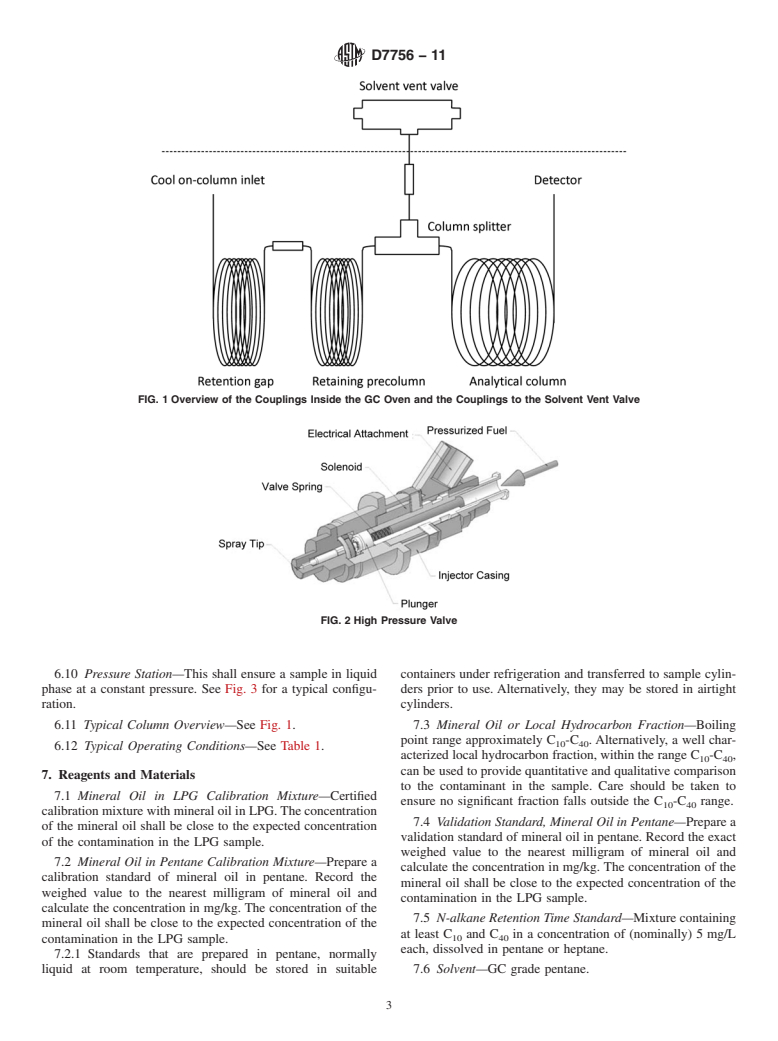

6.9 High Pressure Liquefied Gas Injector—A high pressure

5.4 This test method gives both quantitative results and valve directly connected to a needle which is inserted in the

information about contaminant composition such as boiling injection port of the GC, after which the valve is triggered in

point range and fingerprint, which can be very useful in tracing order to introduce a representative aliquot into the GC system

the source of a particular contaminant. without sample discrimination. (See Fig. 2.)

TABLE 1 Typical Operating Conditions

Oven program 35°C for 3 min

35 to 340°C at 25°C/min

340°C for 10 min

Inlet program Type: cool on-column

Temperature: 65°C for 3 min

55 to 340°C at 25°C/min

340°C for 9 min

Detector settings Air flow: 400 mL/min

Hydrogen flow: 40 mL/min

Make up gas flow: 45 mL/min

Temperature: 350°C

Data rate: 20 Hz

A

Column Retention gap: Sulfinert stainless steel capillary with inner diameter 0.53 mm and

length of 5 m

Retaining pre-column: 3 m 100%

Dimethylpolysiloxane: 0.53 mm, 2.65 µm

Analytical column: 100%

Dimethylpolysiloxane 30 m, 0.32 mm, 0.25 µm

Pressure station Sample flow: 2 mL/min

Nitrogen pressure: 2500 kPa

Nitrogen purge pressure: 500 kPa

Liquefied Gas Injector Injection: 25 ms

A

Sulfinert is a trademark of SilcoTek, 112 Benner Circle, Bellefonte, PA 16823, www.SilcoTek.com.

D7756 − 11

FIG. 1 Overview of the Couplings Inside the GC Oven and the Couplings to the Solvent Vent Valve

FIG. 2 High Pressure Valve

6.10 Pressure Station—This shall ensure a sample in liquid containers under refrigeration and transferred to sample cylin-

phase at a constant pressure. See Fig. 3 for a typical configu- ders prior to use. Alternatively, they may be stored in airtight

ration. cylinders.

6.11 Typical Column Overview—See Fig. 1. 7.3 Mineral Oil or Local Hydrocarbon Fraction—Boiling

point range approximately C -C . Alternatively, a well char-

10 40

6.12 Typical Operating Conditions—See Table 1.

acterized local hydrocarbon fraction, within the range C -C ,

10 40

can be used to provide quantitative and qualitative comparison

7. Reagents and Materials

to the contaminant in the sample. Care should be taken to

7.1 Mineral Oil in LPG Calibration Mixture—Certified

ensure no significant fraction falls outside the C -C range.

10 40

calibration mixture with mineral oil in LPG.The concentration

7.4 Validation Standard, Mineral Oil in Pentane—Prepare a

of the mineral oil shall be close to the expected concentration

validation standard of mineral oil in pentane. Record the exact

of the contamination in the LPG sample.

weighed value to the nearest milligram of mineral oil and

7.2 Mineral Oil in Pentane Calibration Mixture—Prepare a

calculate the concentration in mg/kg. The concentration of the

calibration standard of mineral oil in pentane. Record the

mineral oil shall be close to the expected concentration of the

weighed value to the nearest milligram of mineral oil and

contamination in the LPG sample.

calculate the concentration in mg/kg. The concentration of the

7.5 N-alkane Retention Time Standard—Mixture containing

mineral oil shall be close to the expected concentration of the

at least C and C in a concentration of (nominally) 5 mg/L

10 40

contamination in the LPG sample.

each, dissolved in pentane or heptane.

7.2.1 Standards that are prepared in pentane, normally

liquid at room temperature, should be stored in suitable 7.6 Solvent—GC grade pentane.

D7756 − 11

A Sample cylinder

B Sample line in

C Injection device

D Cool on column inlet

E Gas chromatograph

F Sample line out

G Rotometer

H Vaporizer

I Waste system

P Pressure gauge

FIG. 3 Typical Configuration of a Pressure Station

8. Hazards 9. Preparation of Apparatus

8.1 There is a significant fire hazard from LPG, and since

9.1 Gas Chromatograph—Install and verify performance in

the boiling point of LPG can be as low as -41°C, there is a risk

accordance with the manufacturer‘s instructions. Typical oper-

of freezing “burns.” Take appropriate safety precautions to

ating conditions are shown in Table 1.

prevent ignition or fire, and wear suitable protective equipment

9.2 Pressure Station—Install in accordance with the manu-

to protect against skin contact with LPG.

facturer‘s instructions. Purge sample and check carefully for

8.2 An appropriate laboratory ventilation system shall be

leaks.

used.

9.3 High Pressure Liquefied Gas Injector—Install in accor-

8.3 An appropriate waste line shall be installed. The pres-

dance with the manufacturer‘s instructions.

sure station and injector shall be connected to this line. The

waste line should vent outside the building.

9.4 Column Configuration—Install the columns as shown in

8.4 Pressure station, cylinder, injector, and controller shall

Fig. 1. Use low dead volume connections, and check for leaks.

be grounded appropriately.

D7756 − 11

10. Calibration of unknown samples under the assumption that all sample

components have the same response factor.

10.1 Perform a one point calibration at the startup of the

instrument, when the result of the validation sample falls 10.7 Analyze the validation sample using the liquefied gas

injector. Analyze the validation sample once per day of use

outside the acceptable SQC limits in accordance with Section

14 or after changes in the application hardware or gas supply, before the samples. Repeat the analysis when the result of the

validation sample falls outside the acceptable SQC limits in

or both.

accordance with Section 14.

10.2 Run a blank run, without sample injection. Cycle the

GC several times until the baseline is stable. A baseline is

11. Procedure

stable when the start and end signal (in pA) of two consecutive

11.1 Collect a representative sample according to Practice

blank runs are within 5%. An unstable baseline can be caused

D1265 or D3700.

by a leak, detector gases, or by high boiling point components

11.2 Connect the sample cylinder to the pressure station and

or materials that have not yet eluted from the column. The

pressurize to approximately 2500 6 200 kPa (363 6 29 psi). It

signal height (in pA) at the end of an analysis of a calibration,

is important to maintain and reproduce this pressure as closely

validation, or sample shall be equal or higher than the blank

as possible to ensure sample size injection repeatability.

baseline. A signal higher than 5% could indicate a poorly

conditioned column or the elution of sample components with 11.3 Openthecylinderatbothsidesandflushthesamplefor

a boiling point higher than 522°C. Refer to the datasheet of the approximately 3 min with a flow rate of about 5 mL/min.

column for instructions on conditioning the column.

11.4 Inject sample (trigger pulse 25 ms at 2500 kPa,

equivalent to approximately 30 µL).

10.3 Analyzethen-alkaneretentiontimestandard(7.6),and

establish the retention time for C and C . There should be

10 40 11.5 Analyze each sample in duplicate. If the difference

baseline separation between the solvent and the first normal

between the results of the two analyses is>5%, perform an

alkane peak (C ). If the separation is not sufficient, adjust the

10 extra analysis and average the two closest results.

temperature program, re-establish the baseline, and then reana-

11.6 Close the sample cylinder after injection an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.