SIST EN 50411-3-3:2020

(Main)Fibre management systems and protective housings to be used in optical fibre communication systems - Product specifications - Part 3-3: Singlemode optical fibre fusion splice protectors

Fibre management systems and protective housings to be used in optical fibre communication systems - Product specifications - Part 3-3: Singlemode optical fibre fusion splice protectors

This European Standard contains the initial, start of life dimensional, optical, mechanical and environmental performance requirements, which a singlemode fusion splice protector need to meet in order for it to be categorised as an EN standard product.

LWL-Spleißkassetten und -Muffen für die Anwendung in LWL-Kommunikationssystemen - Produktnormen - Teil 3-3: Fusionsspleißschutze für Einmodenfasern

Organiseurs et boîtiers de fibres destinés à être utilisés dans les systèmes de communication par fibres optiques - Spécifications de produits - Partie 3-3: Protecteurs d’épissures par fusion de fibres optiques unimodales

1.1 Définition du produit

Le présent document contient les exigences de performances initiales, dimensionnelles, optiques, mécaniques et environnementales, de début de vie, auxquelles il est nécessaire qu’un protecteur d’épissure par fusion de fibres unimodales satisfasse, afin d'être classé comme entrant dans une norme EN de produit.

Bien que, dans le présent document, le produit soit qualifié pour les fibres unimodales de type B-652.D selon l’EN IEC 60793 2 50, il convient également pour la protection d’épissures par fusion de fibres multimodales avec une gaine en verre de 125 µm de diamètre et d’autres fibres unimodales avec une gaine en verre de 125 µm de diamètre.

1.2 Interopérabilité

Il est nécessaire que le protecteur d’épissure par fusion installé s’adapte à des cassettes d'épissures ou des plateaux d'épissures de fibres optiques. Le présent document spécifie les dimensions d’interface physique suivantes:

– profil transversal avec largeur, hauteur ou diamètre (en millimètres);

– longueur (en millimètres).

1.3 Performance attendue

Dans le présent document, la performance d’un protecteur d’épissure par fusion est donnée avec une sélection de fibres telle que spécifiée à l’Annexe A.

1.4 Environnement de fonctionnement

Les essais choisis, combinés avec leurs sévérités et leurs durées, sont représentatifs d’un environnement extérieur protégé, défini comme catégorie OP dans l’EN IEC 61753 1. Les essais de « montage et démontage » et « à la poussière » ne sont pas inclus, car ils ne sont pas applicables une fois le produit installé. Afin de garantir que le produit peut être utilisé dans des boîtiers extérieurs, des boîtes ou des armoires d’environnement urbain pour les catégories A, G ou S (tel que défini dans l’EN IEC 61753 1), la température inférieure spécifiée est étendue à −40 °C et une exigence relative à une immersion dans l’eau pour des conditions d’immersion temporaire a été ajoutée.

1.5 Fiabilité

Tandis que l'espérance de vie du produit en service prévue dans cet environnement est d’au moins 20 ans, la conformité à la présente spécification ne garantit pas la fiabilité du produit. Il convient que celle-ci soit estimée en utilisant un programme reconnu d'évaluation de la fiabilité.

1.6 Assurance de la qualité

La conformité à la présente spécification ne garantit pas la cohérence de fabrication du produit. Il convient qu’elle soit maintenue en utilisant un programme reconnu d'assurance de la qualité.

Sistemi za upravljanje z optičnimi vlakni in zaščitna ohišja za optične komunikacijske sisteme - Specifikacije izdelka - 3-3. del: Ščitniki spojev enorodovnih optičnih vlaken

Ta evropski standard vsebuje začetne dimenzijske, optične, mehanske in okoljske zahteve, ki jih mora na začetku svoje življenjske dobe izpolnjevati enorodni ščitnik spojev, da se lahko kategorizira kot izdelek v skladu s standardom EN.

General Information

- Status

- Published

- Public Enquiry End Date

- 31-Dec-2018

- Publication Date

- 11-Dec-2019

- Technical Committee

- MOC - Mobile Communications

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 06-Dec-2019

- Due Date

- 10-Feb-2020

- Completion Date

- 12-Dec-2019

Relations

- Effective Date

- 03-Dec-2019

- Effective Date

- 13-Mar-2018

Overview

EN 50411-3-3:2019 (CLC / CENELEC) specifies product requirements for singlemode optical fibre fusion splice protectors used in fibre management systems and protective housings. The standard defines the initial start-of-life dimensional, optical, mechanical and environmental performance criteria a fusion splice protector must meet to be classified as an EN standard product. It targets fusion splice protection for singlemode fibres (notably EN IEC 60793-2-50 type B-652.D) and is intended to ensure interoperability with splice cassettes and splice trays used in outdoor and enclosed environments.

Key topics and requirements

- Product definition & scope

- Singlemode fusion splice protectors (heat-shrink and crimp/clam-shell styles) for protecting fused fibres against dust and temporary flooding.

- Dimensional interoperability

- Cross-sectional profile (width/height/diameter) and nominal lengths are specified so protectors fit standard splice trays and cassettes.

- Performance requirements

- Optical: performance validated on representative singlemode fibres (Annex A).

- Mechanical & environmental: tests align with EN IEC 61753-1 Category OP and selected EN 61300 series methods.

- Environmental severities

- Extended temperature range for outdoor use (down to −40 °C) and provisions for temporary water immersion to simulate flooding.

- Test methods & pass/fail

- Includes vibration, shock, torsion, bending moment, cold, dry heat, change of temperature, damp heat cyclic, salt mist and water immersion; transient loss and active attenuation monitoring tests referenced.

- Variants & materials

- Multiple cross-section and length variants (single‑fibre and ribbon types) and material/colour/marking requirements (colour harmonized with EN 60304).

- Quality & reliability

- Standard states expected service life (≥20 years recommended) but recommends formal reliability and quality assurance programs for manufacturers.

Applications and users

- Who uses it

- Fibre optic component manufacturers, cable assembly shops, network equipment vendors, installers and test laboratories.

- Practical use

- Specifying, designing and accepting fusion splice protectors for access networks, FTTH, outdoor closures, street cabinets and indoor splice enclosures.

- Ensures compatibility with splice trays and predictable performance under real‑world environmental stresses.

Related standards

- EN IEC 60793-2-50 (singlemode fibre product spec)

- EN IEC 61753-1 (performance categories - Category OP referenced)

- EN 61300 series (basic test and measurement procedures)

- EN 60304 (colour coding for insulation)

EN 50411-3-3:2019 is essential when specifying certified, interoperable fusion splice protectors to ensure reliable protection and standardized performance across fibre optic installations.

Frequently Asked Questions

SIST EN 50411-3-3:2020 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Fibre management systems and protective housings to be used in optical fibre communication systems - Product specifications - Part 3-3: Singlemode optical fibre fusion splice protectors". This standard covers: This European Standard contains the initial, start of life dimensional, optical, mechanical and environmental performance requirements, which a singlemode fusion splice protector need to meet in order for it to be categorised as an EN standard product.

This European Standard contains the initial, start of life dimensional, optical, mechanical and environmental performance requirements, which a singlemode fusion splice protector need to meet in order for it to be categorised as an EN standard product.

SIST EN 50411-3-3:2020 is classified under the following ICS (International Classification for Standards) categories: 33.180.20 - Fibre optic interconnecting devices. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 50411-3-3:2020 has the following relationships with other standards: It is inter standard links to SIST EN 50411-3-3:2012, SIST EN 50411-3-3:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 50411-3-3:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2020

Nadomešča:

SIST EN 50411-3-3:2012

Sistemi za upravljanje z optičnimi vlakni in zaščitna ohišja za optične

komunikacijske sisteme - Specifikacije izdelka - 3-3. del: Ščitniki spojev

enorodovnih optičnih vlaken

Fibre management systems and protective housings to be used in optical fibre

communication systems - Product specifications - Part 3-3: Singlemode optical fibre

fusion splice protectors

LWL-Spleißkassetten und -Muffen für die Anwendung in LWL-Kommunikationssystemen

- Produktnormen - Teil 3-3: Fusionsspleißschutze für Einmodenfasern

Organiseurs et boîtiers de fibres destinés à être utilisés dans les systèmes de

communication par fibres optiques - Spécifications de produits - Partie 3-3: Protecteurs

d’épissures par fusion de fibres optiques unimodales

Ta slovenski standard je istoveten z: EN 50411-3-3:2019

ICS:

33.180.20 Povezovalne naprave za Fibre optic interconnecting

optična vlakna devices

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD EN 50411-3-3

NORME EUROPÉENNE

EUROPÄISCHE NORM

November 2019

ICS 33.180.20 Supersedes EN 50411-3-3:2011 and all of its

amendments and corrigenda (if any)

English Version

Fibre management systems and protective housings to be used

in optical fibre communication systems - Product specifications -

Part 3-3: Singlemode optical fibre fusion splice protectors

Organiseurs et boîtiers de fibres destinés à être utilisés LWL-Spleißkassetten und -Muffen für die Anwendung in

dans les systèmes de communication par fibres optiques - LWL-Kommunikationssystemen - Produktnormen - Teil 3-3:

Spécifications de produits - Partie 3-3: Protecteurs Fusionsspleißschutze für Einmodenfasern

d'épissures par fusion de fibres optiques unimodales

This European Standard was approved by CENELEC on 2019-09-30. CENELEC members are bound to comply with the CEN/CENELEC

Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC

Management Centre or to any CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CENELEC member into its own language and notified to the CEN-CENELEC Management Centre has the

same status as the official versions.

CENELEC members are the national electrotechnical committees of Austria, Belgium, Bulgaria, Croatia, Cyprus, the Czech Republic,

Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, the

Netherlands, Norway, Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

European Committee for Electrotechnical Standardization

Comité Européen de Normalisation Electrotechnique

Europäisches Komitee für Elektrotechnische Normung

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CENELEC All rights of exploitation in any form and by any means reserved worldwide for CENELEC Members.

Ref. No. EN 50411-3-3:2019 E

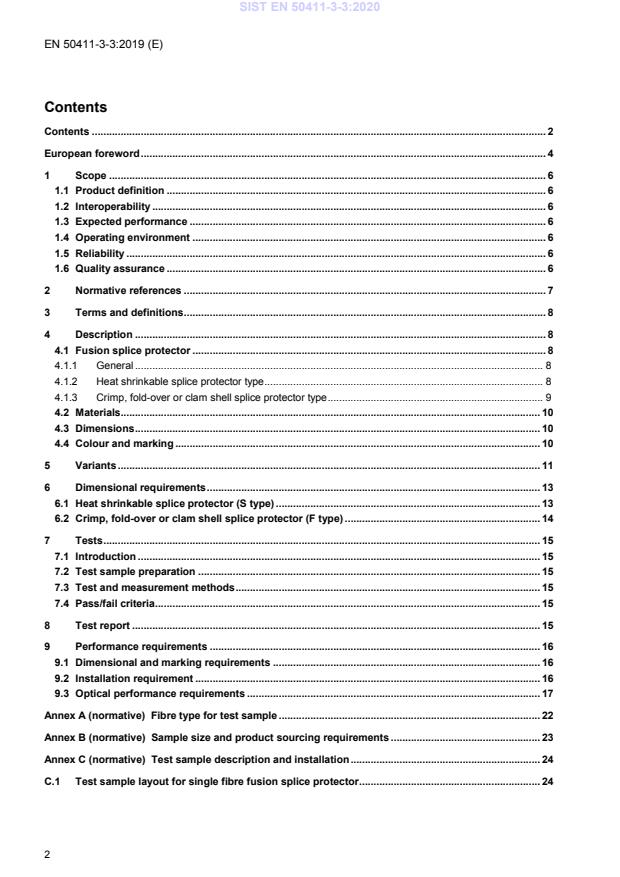

Contents

Contents . 2

European foreword . 4

1 Scope . 6

1.1 Product definition . 6

1.2 Interoperability . 6

1.3 Expected performance . 6

1.4 Operating environment . 6

1.5 Reliability . 6

1.6 Quality assurance . 6

2 Normative references . 7

3 Terms and definitions . 8

4 Description . 8

4.1 Fusion splice protector . 8

4.1.1 General . 8

4.1.2 Heat shrinkable splice protector type . 8

4.1.3 Crimp, fold-over or clam shell splice protector type . 9

4.2 Materials. 10

4.3 Dimensions . 10

4.4 Colour and marking . 10

5 Variants . 11

6 Dimensional requirements . 13

6.1 Heat shrinkable splice protector (S type) . 13

6.2 Crimp, fold-over or clam shell splice protector (F type) . 14

7 Tests . 15

7.1 Introduction . 15

7.2 Test sample preparation . 15

7.3 Test and measurement methods . 15

7.4 Pass/fail criteria . 15

8 Test report . 15

9 Performance requirements . 16

9.1 Dimensional and marking requirements . 16

9.2 Installation requirement . 16

9.3 Optical performance requirements . 17

Annex A (normative) Fibre type for test sample . 22

Annex B (normative) Sample size and product sourcing requirements . 23

Annex C (normative) Test sample description and installation . 24

C.1 Test sample layout for single fibre fusion splice protector . 24

C.2 Preparation of single fibre test samples . 25

C.3 Test sample layout for ribbon fibre fusion splice protector . 26

C.4 Preparation of ribbon fibre test samples. 26

Annex D (informative) Silicone band heat shrink fusion splice protectors . 28

Bibliography . 30

European foreword

This document (EN 50411-3-3:2019) has been prepared by CLC/TC 86BXA “Fibre optic interconnect, passive

and connectorised components”.

The following dates are fixed:

• latest date by which this document has to be (dop) 2020-09-30

implemented at national level by publication of an

identical national standard or by endorsement

• latest date by which the national standards conflicting (dow) 2020-09-30

with this document have to be withdrawn

This document supersedes EN 50411-3-3:2011 and all of its amendments and corrigenda (if any).

— terms and definitions are added;

— the EN 61753-1:2007 category U tests and test severities are replaced by the EN IEC 61753-1:2018

category OP test and test severities;

— a 23 mm length variant has been added to the variant XX3;

— the colour coding variant XX6 is harmonized with EN 60304;

— tolerance of height and width increased to ± 0,1 mm for variant S1-12 and ± 0,15 mm for S1-16

— requirement added of a transparent heatshrink splice protector to allow the visual centring of the fused

fibre area in the splice protector.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. CENELEC shall not be held responsible for identifying any or all such patent rights.

Fibre management systems and protective housings to be used in optical fibre communication

systems - Product specifications

Part 3-3: Singlemode optical fibre fusion splice protectors

Description Performance

Type: Fibre splice protector Application: EN 61753-1, Category OP

Style: Fusion

Operating 1 260 nm to 1 625 nm Attenuation grades: Not applicable

wavelength:

Fibre category: EN 60793-2-50 Return loss grades: Not applicable

Related documents:

EN IEC 60793-2-50 Optical fibres – Part 2-50: Product specifications – Sectional specification for class B

single-mode fibres (IEC 60793-2-50)

EN 61300 series Fibre optic interconnecting devices and passive components – Basic test and

measurement procedures (IEC 61300 series)

EN IEC 61753-1 Fibre optic interconnecting devices and passive components performance standard –

Part 1: General and guidance for performance standards (IEC 61753-1)

Outline and nominal dimensions:

Product as installed or fully recovered

W H L

S tS tyyppee

Type Fibre Available lengths

LL

mm mm mm

HH

F1 Single fibre 1,2 3,2 30

WW S1-12 Single fibre 1,25 1,25 15/20/25/30

S1-13 Single fibre 1,3 1,3 15/20/25/30

S1-16 Single fibre 1,6 1,5 15/20/25/30/40

S1-22

Single fibre 2,2 2,2 25/30/35/40/45

S1-24 Single fibre 2,4 2,4 20/23/25/35/40/45/60

F tF tyypepe

S1-26

Single fibre 2,6 2,6 23/35/40/45/60

S1-32 Single fibre 3,2 3,2 45/60

S1-35

LL Single fibre 3,5 3,5 45/60

HH

S1-37 Single fibre 3,7 3,7 68

WW

S2-37

Ribbon 4 3,7 3,5 40/45

S3-40 Ribbon 8 4,0 3,7 40/45

S4-45 Ribbon 12 4,5 4,0 25/30/40/45

1 Scope

1.1 Product definition

This document contains the initial, start of life dimensional, optical, mechanical and environmental

performance requirements, which a single mode fusion splice protector need to meet in order for it to be

categorized as an EN standard product.

Although, in this document, the product is qualified for EN IEC 60793-2-50 type B-652.D single mode fibres it

is also suitable for fusion splice protection of multimode fibre with 125 µm diameter glass cladding and other

single mode fibres with 125 µm diameter glass cladding.

1.2 Interoperability

The installed fusion splice protector needs to fit into optical fibre splice cassettes or splice trays. This

document specifies the following physical interface dimensions:

– cross sectional profile with width, height or diameter (in millimetres);

– length (in millimetres).

1.3 Expected performance

In this document, the performance of the fusion splice protector is given with selected fibres as specified in

Annex A.

1.4 Operating environment

The tests selected combined with the severities and durations are representative of an outdoor enclosed

environment defined as category OP in EN IEC 61753-1. The “assembly and disassembly” and the “dust” tests

are not included since they are not relevant once the product is installed. To ensure that the product can be

used in outdoor closures, boxes or street cabinets for categories A, G or S (as defined in EN IEC 61753-1) the

specified lower temperature is extended to −40 °C and a water immersion requirement for temporary flooding

conditions has been added.

1.5 Reliability

Whilst the anticipated service life expectancy of the product in this environment is at least 20 years,

compliance with this specification does not guarantee the reliability of the product. This should be predicted

using a recognized reliability assessment programme.

1.6 Quality assurance

Compliance with this specification does not guarantee the manufacturing consistency of the product. This

should be maintained using a recognized quality assurance programme.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

EN 60304, Standard colours for insulation for low-frequency cables and wires (IEC 60304)

EN IEC 60793-2-50, Optical fibres — Part 2-50: Product specifications — Sectional specification for class B

single-mode fibres (IEC 60793-2-50)

EN 61300-1, Fibre optic interconnecting devices and passive components - Basic test and measurement

procedures - Part 1: General and guidance (IEC 61300-1)

EN 61300-2-1, Fibre optic interconnecting devices and passive components - Basic test and measurement

procedures - Part 2-1: Tests - Vibration (sinusoidal) (IEC 61300-2-1)

EN IEC 61300-2-4, Fibre optic interconnecting devices and passive components — Basic test and

measurement procedures — Part 2-4: Tests — Fibre/cable retention (IEC 61300-2-4)

EN 61300-2-5, Fibre optic interconnecting devices and passive components - Basic test and measurement

procedures - Part 2-5: Tests – Torsion (IEC 61300-2-5)

EN 61300-2-7, Fibre optic interconnecting devices and passive components - Basic test and measurement

procedures - Part 2-7: Tests - Bending moment (IEC 61300-2-7)

EN 61300-2-9, Fibre optic interconnecting devices and passive components - Basic test and measurement

procedures - Part 2-9: Tests – Shock (IEC 61300-2-9)

EN 61300-2-17, Fibre optic interconnecting devices and passive components - Basic test and measurement

procedures - Part 2-17: Tests – Cold (IEC 61300-2-17)

EN 61300-2-18, Fibre optic interconnecting devices and passive components - Basic test and measurement

procedures - Part 2-18: Tests - Dry heat - High temperature endurance (IEC 61300-2-18)

EN 61300-2-22, Fibre optic interconnecting devices and passive components - Basic test and measurement

procedures - Part 2-22: Tests - Change of temperature (IEC 61300-2-22)

EN 61300-2-26, Fibre optic interconnecting devices and passive components - Basic test and measurement

procedures - Part 2-26: Tests - Salt mist (IEC 61300-2-26)

EN 61300-2-45, Fibre optic interconnecting devices and passive components - Basic test and measurement

procedures - Part 2-45: Tests - Durability test by water immersion (IEC 61300-2-45)

EN 61300-2-46, Fibre optic interconnecting devices and passive components — Basic test and measurement

procedures — Part 2-46: Tests — Damp heat cyclic (IEC 61300-2-46)

EN 61300-3-3, Fibre optic interconnecting devices and passive components - Basic test and measurement

procedures - Part 3-3: Examinations and measurements - Active monitoring of changes in attenuation and

return loss (IEC 61300-3-3)

EN 61300-3-28, Fibre optic interconnecting devices and passive components - Basic test and measurement

procedures - Part 3-28: Examinations and measurements - Transient loss (IEC 61300-3-28)

EN IEC 61753-1, Fibre optic interconnecting devices and passive components performance standard – Part 1:

General and guidance for performance standards (IEC 61753-1)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

live fibre

fibre optical circuit that is carrying an optical signal

[SOURCE: EN IEC 61756-1]

3.2

fibre splice

permanent or separable joint whose purpose is to couple optical power between two optical fibres, achieved by

either a fusion or a mechanical technique

[SOURCE: IEV 731-05-05 modified]

4 Description

4.1 Fusion splice protector

4.1.1 General

A single mode fibre fusion splice protector is a passive component, which provides mechanical and

environmental protection to a single fibre or ribbon fibre fusion splice. The fused fibres are protected against

ingress of dust or temporary flooding by a sealing material, generally a polymer material such as hot melt

adhesive or mastic.

The products described in this standard are based on various protection types:

– heat shrinkable splice protector;

– crimp or fold-over splice protector (also called clam shell splice protector).

4.1.2 Heat shrinkable splice protector type

Prior to splicing, the splice protector is put over one of the fibre or ribbon ends. After the fusion of the fibres,

the splice protector is placed over the spliced area. After visual centring over the fused area the splice

protector is shrunk using heating equipment.

A typical fusion splice protector is composed of three elements (see Figure 1).

Key:

1 a reinforcement member to give rigidity after the protector is installed in the heater;

2 an adhesive tube that will encapsulate the spliced region and bonds directly to the bare glass and primary or

secondary coating of the fibres;

3 a cross-linked polyethylene heat-shrinkable tube, which encloses the adhesive insert tube and the reinforcement

member.

Figure 1 — Heat shrinkable splice protector

4.1.3 Crimp, fold-over or clam shell splice protector type

The fused area of the optical fibre is centred and kept in place by adhesive strips and then the splice protector

is folded over and closed by the use of a crimping tool. In general the following elements are present:

— a rigid flat strip hinged in the centre;

— a compressible material adhered to the flat strip.

Figure 2 — Crimp, fold-over or clam shell splice protector

4.2 Materials

Materials which are not specified or which are not specifically described are left to the discretion of the

manufacturer. However, the following requirements shall be met:

– all materials that are likely to come in contact with personnel shall meet appropriate health and safety

regulations;

– the sealing materials shall be compatible with the fibre materials and/or the mechanical splice parts;

– the sealant or encapsulant material shall be free of dirt and air inclusions;

– all splice components shall be resistant to solvents and degreasing agents that are typically used to clean

and degrease fibres and cables (e.g. alcohols, white spirit and cable cleaners);

– exposed metallic parts shall be resistant to any corrosive influences they may encounter during the

lifetime of the product;

– exposed polymer materials shall be resistant to mould growth.

4.3 Dimensions

Outline dimensions are specified in Clause 6. All other dimensions are left to the discretion of the

manufacturer.

4.4 Colour and marking

Marking of the product or packaging shall be in the following order of precedence:

a) identification of supplier or manufacturer;

b) manufacturing date code: year/week;

c) manufacturer’s part number;

d) variant identification number.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...