SIST EN 13383-2:2019

(Main)Armourstone - Part 2: Test methods

Armourstone - Part 2: Test methods

This document specifies sampling and test methods for natural, artificial and recycled aggregates for use as armourstone. This document specifies the reference methods to be used for type testing and in case of dispute where an alternative method has been used. For other purposes, in particular factory production control, other methods may be used provided that an appropriate working relationship with the test method has been established.

Wasserbausteine - Teil 2: Prüfverfahren

Dieses Dokument legt Probenahme und Prüfverfahren für natürliche, künstliche und wiederaufbereitete Gesteinskörnungen für die Verwendung als Wasserbausteine fest. Dieses Dokument legt die Referenzverfahren fest, die für die Erstprüfung und in Streitfällen, in denen eine alternative Methode verwendet wurde, anzuwenden sind. Für andere Zwecke, speziell im Rahmen der werkseigenen Produktionskontrolle, dürfen andere Verfahren angewendet werden, sofern ein ausreichender Zusammenhang mit den Referenzverfahren nachgewiesen wurde.

Enrochements - Partie 2: Méthodes d'essai

Le présent document prescrit des méthodes d'échantillonnage et d'essai pour les granulats naturels, artificiels et recyclés destinés à être utilisés comme enrochements. Ce document précise les méthodes de référence à utiliser pour les essais de type et en cas de litige lorsqu'une méthode alternative a été utilisée. Pour d'autres fins, en particulier la maîtrise de la production des enrochements, il est permis d'utiliser d'autres méthodes, sous réserve qu'une relation valide et appropriée avec la méthode d'essai de référence ait été établie.

Kamen za obloge pri vodnih zgradbah in drugih gradbenih delih - 2. del: Preskusne metode

Ta evropski standard določa vzorčenje in preskusne metode za naravne, umetne ali reciklirane materiale za uporabo kot kamen za obloge pri vodnih zgradbah in drugih gradbenih delih. Ta evropski standard določa referenčne metode, ki se uporabljajo za tipsko preskušanje in v primeru spora, ko je bila uporabljena alternativna metoda. Za druge namene, zlasti za kontrolo proizvodnje v obratu, se lahko uporabijo druge metode, če obstaja primerna delovna povezava s preskusno metodo.

General Information

- Status

- Published

- Public Enquiry End Date

- 29-Mar-2017

- Publication Date

- 09-Sep-2019

- Technical Committee

- AGR - Aggregates

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 10-Jul-2019

- Due Date

- 14-Sep-2019

- Completion Date

- 10-Sep-2019

Relations

- Effective Date

- 01-Oct-2019

- Effective Date

- 18-Jan-2023

- Effective Date

- 24-Jun-2020

Overview

EN 13383-2:2019 - Armourstone, Part 2: Test methods (CEN) specifies sampling and laboratory test methods for natural, artificial and recycled aggregates used as armourstone (riprap, revetments and other enrochement works). It defines the reference methods to be used for type testing and for resolving disputes; for routine factory production control alternative validated methods may be used if an appropriate relationship to the reference method is demonstrated. This 2019 edition supersedes EN 13383-2:2002 and complements EN 13383-1 (specifications).

Key topics and technical requirements

The standard covers sampling, sample reduction, preparation and a comprehensive set of test procedures, including:

- Sampling principles and plans (including sampling from floating plant) and requirements for marking, packaging and registration of samples.

- Particle size distribution of coarse gradings (sieving methods and result expression).

- Mass distribution of light and heavy gradings - reference method and informative alternative (bulk weighing).

- Geometric characteristics such as the percentage of pieces with a length-to-thickness ratio > 3.

- Physical properties: particle density and water absorption (with precision guidance).

- Durability tests: resistance to freezing and thawing.

- Specific checks for steel slags: signs of “Sonnenbrand” (surface oxidation) and disintegration.

- Preparation for abrasion/wear tests - sample preparation requirements for the Micro-Deval test (EN 1097-1).

- Informative annexes (A–H) with worked examples (sampling registration, particle size curves), guidance on sampling schemes and precision data.

Definitions for grading categories are provided (for example, coarse grading nominal upper limit by sieve size ≥ 90 mm and ≤ 250 mm; light grading nominal upper limit mass 40–300 kg; heavy grading ≥ 1 000 kg).

Practical applications and users

EN 13383-2 is used by:

- Aggregate producers and quarry operators for type testing and quality validation of armourstone products.

- Testing laboratories and QA/QC teams for conformity testing and dispute resolution.

- Coastal, hydraulic and geotechnical engineers specifying durable armourstone for breakwaters, revetments, riverbank protection and flood defence works.

- Contractors and design consultants verifying materials against project specifications.

- Regulators and procurement bodies setting acceptance criteria for rock and recycled material used in enrochements.

Using this standard helps ensure reliable performance of armourstone in coastal and hydraulic structures and provides a consistent legal and technical basis for acceptance testing.

Related standards

- EN 13383-1 (Armourstone - Specifications)

- EN 932 series (sampling and general aggregate tests)

- EN 933 series (geometrical properties)

- EN 1097-1 (Micro-Deval abrasion)

- EN 1097-5 (water content determination)

Keywords: EN 13383-2, armourstone test methods, sampling, particle size distribution, Micro-Deval, aggregates, riprap, enrochements, CEN standard.

Frequently Asked Questions

SIST EN 13383-2:2019 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Armourstone - Part 2: Test methods". This standard covers: This document specifies sampling and test methods for natural, artificial and recycled aggregates for use as armourstone. This document specifies the reference methods to be used for type testing and in case of dispute where an alternative method has been used. For other purposes, in particular factory production control, other methods may be used provided that an appropriate working relationship with the test method has been established.

This document specifies sampling and test methods for natural, artificial and recycled aggregates for use as armourstone. This document specifies the reference methods to be used for type testing and in case of dispute where an alternative method has been used. For other purposes, in particular factory production control, other methods may be used provided that an appropriate working relationship with the test method has been established.

SIST EN 13383-2:2019 is classified under the following ICS (International Classification for Standards) categories: 91.100.15 - Mineral materials and products. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13383-2:2019 has the following relationships with other standards: It is inter standard links to SIST EN 13383-2:2002, oSIST prEN 13383-2:2021, oSIST prEN 13383-2:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13383-2:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-oktober-2019

Nadomešča:

SIST EN 13383-2:2002

Kamen za obloge pri vodnih zgradbah in drugih gradbenih delih - 2. del:

Preskusne metode

Armourstone - Part 2: Test methods

Wasserbausteine - Teil 2: Prüfverfahren

Enrochements - Partie 2: Méthodes d'essai

Ta slovenski standard je istoveten z: EN 13383-2:2019

ICS:

91.100.15 Mineralni materiali in izdelki Mineral materials and

products

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13383-2

EUROPEAN STANDARD

NORME EUROPÉENNE

June 2019

EUROPÄISCHE NORM

ICS 91.100.15 Supersedes EN 13383-2:2002

English Version

Armourstone, Part 2: Test methods

Enrochements - Partie 2: Méthodes d'essai Wasserbausteine - Teil 2: Prüfverfahren

This European Standard was approved by CEN on 13 August 2018.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13383-2:2019 E

worldwide for CEN national Members.

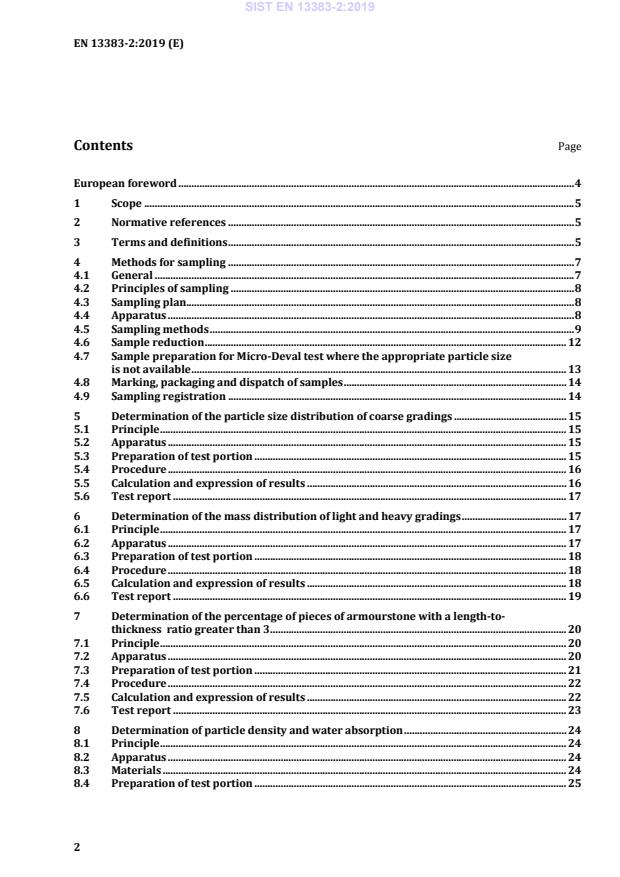

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Methods for sampling . 7

4.1 General . 7

4.2 Principles of sampling . 8

4.3 Sampling plan. 8

4.4 Apparatus . 8

4.5 Sampling methods . 9

4.6 Sample reduction . 12

4.7 Sample preparation for Micro-Deval test where the appropriate particle size

is not available . 13

4.8 Marking, packaging and dispatch of samples . 14

4.9 Sampling registration . 14

5 Determination of the particle size distribution of coarse gradings . 15

5.1 Principle . 15

5.2 Apparatus . 15

5.3 Preparation of test portion . 15

5.4 Procedure . 16

5.5 Calculation and expression of results . 16

5.6 Test report . 17

6 Determination of the mass distribution of light and heavy gradings . 17

6.1 Principle . 17

6.2 Apparatus . 17

6.3 Preparation of test portion . 18

6.4 Procedure . 18

6.5 Calculation and expression of results . 18

6.6 Test report . 19

7 Determination of the percentage of pieces of armourstone with a length-to-

thickness ratio greater than 3 . 20

7.1 Principle . 20

7.2 Apparatus . 20

7.3 Preparation of test portion . 21

7.4 Procedure . 22

7.5 Calculation and expression of results . 22

7.6 Test report . 23

8 Determination of particle density and water absorption . 24

8.1 Principle . 24

8.2 Apparatus . 24

8.3 Materials . 24

8.4 Preparation of test portion . 25

8.5 Test procedure . 25

8.6 Calculation and expression of results . 25

8.7 Test report . 26

9 Determination of resistance to freezing and thawing . 26

9.1 Principle . 26

9.2 Apparatus . 26

9.3 Materials . 28

9.4 Test portions . 28

9.5 Procedure . 29

9.6 Calculation and expression of results . 30

9.7 Test report . 30

10 Determination of signs of “Sonnenbrand” and disintegration of steel slags . 31

10.1 Principle . 31

10.2 Apparatus . 31

10.3 Materials . 31

10.4 Preparation of test portions . 32

10.5 Procedure . 32

10.6 Calculation and expression of results . 33

10.7 Test report . 33

Annex A (informative) Example of a sampling registration . 34

Annex B (informative) Example of a particle size distribution of a coarse grading . 36

Annex C (informative) Example of a mass distribution: reference method . 37

Annex D (informative) Example method for determination of mass distribution

(employing bulk weighing) . 39

D.1 Principle . 39

D.2 Apparatus . 39

D.3 Preparation of test portion . 39

D.4 Procedure . 39

D.5 Calculation and expression of results . 39

D.6 Test report . 40

Annex E (informative) Density of water . 43

Annex F (informative) Precision for determination of particle density and water

absorption (see Clause 8) . 44

Annex G (informative) Guidance on sampling for testing . 45

Annex H (informative) Guidance on sampling from floating plant . 50

H.1 General . 50

H.2 Sampling scheme 1 . 50

H.3 Sampling scheme 2 . 52

Bibliography . 55

European foreword

This document (EN 13383-2:2019) has been prepared by Technical Committee CEN/TC 154

“Aggregates”, the secretariat of which is held by BSI.

This document shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by month year of December 2019, and conflicting

national standards shall be withdrawn at the latest by month year of December 2019.

Attention is drawn to the possibility that some of the elements of this document may be the

subject of patent rights. CEN shall not be held responsible for identifying any or all such patent

rights.

This document supersedes EN 13383-2:2002.

In comparison with the previous version, the following changes have been made:

— changes and clarifications to the sampling and sample reduction clauses, including a new

informative Annex on sampling from waterborne plant

— introduction of requirements for sample preparation for the Micro-Deval test previously in

EN 13383-1.

— deletion of an unused wet sieving method for the determination of particle size distribution

of coarse gradings of armourstone

— removal to an informative annex of a previously normative alternative to the reference

method for determination of mass distribution of light and heavy gradings.

Otherwise the majority of the changes from the previous version are editorial.

EN 13383 Armourstone consists of the following parts:

— Part 1: Specifications

— Part 2: Test methods

1 Scope

This document specifies sampling and test methods for natural, artificial and recycled

aggregates for use as armourstone. This document specifies the reference methods to be used

for type testing and in case of dispute where an alternative method has been used. For other

purposes, in particular factory production control, other methods may be used provided that an

appropriate working relationship with the test method has been established.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition cited

applies. For undated references, the latest edition of the referenced document (including any

amendments) applies.

EN 932-1:1996, Tests for general properties of aggregates — Part 1: Methods for sampling

EN 932-5, Tests for general properties of aggregates — Part 5: Common equipment and

calibration

EN 933-1, Tests for geometrical properties of aggregates — Part 1: Determination of particle size

distribution — Sieving method

EN 933-2, Tests for geometrical properties of aggregates — Part 2: Determination of particle size

distribution — Test sieves, nominal size of apertures

EN 933-3, Tests for geometrical properties of aggregates — Part 3: Determination of particle

shape — Flakiness index

EN 1097-1:2011, Tests for mechanical and physical properties of aggregates — Part 1:

Determination of the resistance to wear (micro-Deval)

EN 1097-5, Tests for mechanical and physical properties of aggregates — Part 5: Determination of

the water content by drying in a ventilated oven

ISO 3310-2, Test sieves — Technical requirements and testing — Part 2: Test sieves of perforated

metal plate

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

armourstone grading

armourstone designation with a nominal lower and upper limit

Note 1 to entry: This designation accepts the presence of undersize and oversize pieces of armourstone.

3.2

nominal lower limit

mass or sieve size in a grading below which the armourstone pieces are considered to be

undersized

3.3

nominal upper limit

mass or sieve size in a grading above which the armourstone pieces are considered to be

oversized

3.4

coarse grading

designation of grading with a nominal upper limit defined by a sieve size ≥ 90 mm and ≤ 250 mm

3.5

light grading

designation of grading with a nominal upper limit defined by a mass ≥ 40 and ≤ 300 kg

3.6

heavy grading

designation of grading with a nominal upper limit defined by a mass ≥ 1 000 kg

3.7

fragment

aggregate pieces in the finest fraction of coarse gradings or the lightest fraction of light and

heavy gradings for which the particle size distribution or mass distribution requirements apply

Note 1 to entry: For further information on grading, see EN 13383–1:—, Annex B .

3.8

batch

production quantity, delivery quantity, partial delivery quantity (railway wagon-load, lorry-load,

ship's cargo) or a stockpile produced at one time under conditions that are presumed uniform

3.9

sampling plan

procedure of allocation, withdrawal and preparation of a sample or samples from a material to

yield the required information

3.10

sampling increment

quantity of material taken from a batch by one operation of the sampling apparatus

3.11

bulk sample

aggregation of the sampling increments

Under preparation. Stage at the time of publication: FprEN 13383–1:2017.

3.12

representative sample

sample created by taking sampling increments according to sampling plan, which makes it likely

that the quality of this sample corresponds to that of the batch

3.13

subsample

sample obtained from sampling increments or a bulk sample by means of a sample reduction

procedure

3.14

sampler

individual or a number of individuals working as a team, or an organisation, taking samples on a

routine basis

3.15

length

L

maximum dimension of a piece of armourstone as defined by the greatest distance apart of two

parallel planes tangential to the stone’s surface

3.16

thickness

T

minimum dimension of a piece of armourstone as defined by the least distance apart of two

parallel planes tangential to the stone’s surface

3.17

constant mass

successive weighings after drying at least 24 h apart not differing by more than 0,1 %

Note 1 to entry: In many cases, constant mass can be achieved after a test portion has been dried for a

pre-determined period in a specified oven at (110 ± 5) °C. Test laboratories can determine the time

required to achieve constant mass for specific types and sizes of sample dependent upon the drying

capacity of the oven used.

4 Methods for sampling

4.1 General

This clause describes methods for obtaining samples of armourstone from preparation and

processing plants including stocks and from silos, stockpiles and deliveries.

NOTE It is preferable for armourstone to be sampled at the quarry or during the loading for transport

(or unloading).

The aim of sampling is to obtain samples that are representative of the average properties of the

batch.

The methods described are also suitable for obtaining sampling increments, which are to be

tested separately.

Methods to be used for sample reduction are also given.

4.2 Principles of sampling

Proper and careful sampling and sample transport is a prerequisite for an analysis that will give

reliable results. The correct use of the specified apparatus and methods helps to avoid biased

sampling inclusive the possibility of human bias introduced by visual selection. Sampling

variation caused by the heterogeneity of the batch shall be reduced to an acceptable level by

taking an adequate number of sampling increments.

NOTE For guidance on numbers and sizes of samples and test portions for testing armourstone as

specified in this document, see Annex G.

Sampling increments are selected at random from all parts of the batch that the samples are to

represent. Armourstone from which no sampling increment can be taken (because it is not

accessible, or for some other practical reason) shall not be considered to be part of the batch

that is represented by the samples. For example, if sampling increments are taken from

armourstone discharged from a silo, the samples represent the armourstone that has been

discharged, not the armourstone remaining in the silo.

The sampler shall be informed of the aim of the sampling.

4.3 Sampling plan

A sampling plan shall be prepared, prior to sampling, taking into account the grading type, the

nature and size of the batch, the local circumstances and the purposes of sampling. It shall

include:

a) the type of the armourstone;

b) the aim of the sampling including a list of the properties to be tested;

c) the identification of the sampling points;

d) the mass or number of stones of sampling increments;

e) the number of sampling increments;

f) the sampling apparatus to be used;

g) the methods of sampling and sample reduction with reference to the clauses of this

document;

h) the relevant marking, packaging and dispatch of the samples.

4.4 Apparatus

4.4.1 Apparatus for sampling

4.4.1.1 Grab, fitted to either a crane or a hydraulic machine.

4.4.1.2 Bucket or fork, fitted to a wheeled loader or a hydraulic machine.

4.4.1.3 Truck, for receiving and/or transport of samples.

4.4.1.4 Lifting equipment and lifting aids, for stones that cannot be moved manually.

4.4.2 Apparatus for sample reduction and transport

4.4.2.1 A floor area, upon which samples can be deposited and tested. The floor shall be

sufficiently clean and close-textured to be able to distinguish and recover the material of the

sample from the floor material.

4.4.2.2 Shovels.

4.4.2.3 Rectangular sampling buckets, of sufficient size and of width not less than three

times the nominal upper grading limit.

4.4.2.4 Suitable plates and wires, for sample reduction.

4.4.2.5 Containers for transport, such as bags, buckets or other suitable containers.

4.5 Sampling methods

4.5.1 General

Regulations for safety and ergonomics shall be followed.

WARNING Some sampling methods will inevitably involve the samplers working close to

processing plant and moving vehicles. Those involved in the planning and execution of sampling

should work closely with the operational management to ensure safe working practices.

Mechanically selected gradings should preferably be sampled from a stationary conveyor belt or

from the stream of material. Sampling increments should be taken at regular intervals

throughout the period the batch is in motion. Gradings of which the pieces of armourstone are

individually handled may be sampled at the most convenient location.

Sampling from static batches should be avoided wherever possible since it is difficult to satisfy

the principle of taking sampling increments at random from all parts of the batch, and hence

segregation is likely to cause the sampling to produce biased results.

During sampling, grabs or other extraction equipment shall be filled to a minimum such that the

degree of filling does not adversely affect the representative nature of the sample or sampling

increment.

4.5.2 Sampling, for the determination of particle size distribution, mass distribution and

shape characteristics

4.5.2.1 Sampling of material in bucket conveyors, bucket loaders, or grabs

Each sampling increment shall consist of the entire contents of a grab or bucket.

When this gives too large a sampling increment, it should be reduced by one of the methods

described in 4.6.

4.5.2.2 Sampling at belt and chute discharge points

The period during which the sampling is to be done shall be divided into a number of equal

intervals, and a sampling increment shall be taken in the middle of each interval.

A sample increment shall be taken by catching the discharge stream in a loader bucket, making

sure that the complete cross-section of the stream of material is intercepted. At the beginning

and the ending of the sampling, the edge of the bucket shall pass the cross-section of the stream

as fast as possible.

Where appropriate, sampling should only be started after a preliminary run to ensure that

possible irregularities in the pass do not lead to unrepresentative samples.

Samples may also be taken at the discharge from a screen by the same method.

4.5.2.3 Sampling from stationary conveyor belts

Sampling should only be started after a preliminary run to ensure that possible irregularities in

the pass do not lead to unrepresentative samples.

All sampling increments shall be taken at the same sampling point. In every sampling increment,

all material between two cross-sections shall be taken. The distance between the cross-sections

shall be determined by the required quantity of the sampling increment.

4.5.2.4 Sampling from a silo

Sampling at a silo outlet shall be carried out in accordance with 4.5.2.2.

During filling of a silo the material segregates and as a result the finer material tends to be found

in the centre of the silo with the coarser material along the wall sides. Alternating loading and

discharging of a silo leads to a complex segregation pattern in the silo and this segregation

causes variations in the particle size distribution of the discharged material. The number of

sampling increments should be related to this variation.

4.5.2.5 Sampling from stockpiles

When sampling from a segregated stockpile, from which material is being collected for

transporting, a sampling increment shall be taken from the material which is being taken from

the stockpile. For this purpose, the contents of one or more loader buckets, grabs, lorries or any

other means of handling or transport shall be taken. The period during which the sampling is

done shall be divided into a number of equal intervals and a sampling increment shall be taken

in the middle of each interval.

If at the time of sampling no material of a segregated stockpile is undergoing routine removal,

the removal of material shall be simulated so as not to distort the representativity of the

sampling increment with the segregation effects associated with the initiation of stockpile

extraction. The sampling increments shall be taken at random or at equal distances around the

stockpile or part thereof to be sampled.

When sampling from a non-segregated stockpile, a sampling increment shall be taken as

indicated for a segregated stockpile or by taking a quantity of material from a random location

which is easily reached with the equipment available.

4.5.2.6 Sampling from floating equipment

When sampling cannot be performed during loading or unloading, sampling from floating

equipment should be performed with reference to Scheme 1 or Scheme 2 of Annex H.

4.5.2.7 Sampling from wheeled transport

Discharge the contents of the vehicle partially or completely in a manner, which produces an

evenly distributed longitudinal pile of material. Sampling increments shall be taken from across

the pile by removing, at random or at equally distributed locations, adequate quantities of

material whilst avoiding the possibly segregated material at the start and finish of the pile (see

Figure 1). Take the material in strips over the full width of the pile or in equal numbers of half

strips from the left and right hand side of the centre line of the pile.

Dimensions are approximate

Key

1 potential segregation area

Figure 1 — Sampling locations in a spread-discharged load

When a batch to be sampled consists of more than one load, the sampling increments shall be

taken from randomly selected loads using the method described above or taking each selected

load as a whole as an increment.

When one load contains insufficient material for one sample to be tested, several loads shall be

taken.

4.5.3 Sampling for the determination of physical, chemical, durability and other

properties

For the determination of physical, chemical, durability and other properties individual pieces of

armourstone excluding fragments shall be taken randomly as sampling increments, forming

together a bulk sample. For properties for which testing of aggregate is permitted, sampling

shall be carried out in accordance with EN 932-1.

Sampling increments consisting of individual pieces of armourstone shall be taken from the

batch to be tested and may be taken from the samples which have been taken for the

determination of the particle size or mass distribution.

Sampling increments shall be selected by one of the following methods:

a) using random numbers (see EN 932-1:1996, Annex D);

b) taking pieces of armourstone in a sequence of predetermined positions relative to a

randomly chosen starting point in a static batch;

c) taking pieces of armourstone from random sieve fractions or parts thereof during or after

the determination of the particle size distribution using two samplers, one being a

blindfolded selector and the other performing the actions;

d) taking pieces of armourstone at a time or number interval when the material to be sampled

is passing in a random sequence of the stones, for instance during the determination of the

mass distribution.

If individual pieces of armourstone are significantly larger than the minimum size or mass

required for the test(s) to be executed, a portion of appropriate size or mass may be obtained by

breaking a representative piece. (The objective is to obtain laboratory samples representative of

the batch to be tested but to have carried sample reduction at source so as to minimize transport

costs and reduce unnecessary sample reduction at the testing laboratory.)

4.6 Sample reduction

4.6.1 General

Wherever possible, samples shall be reduced to produce samples for testing of appropriate size

at the sampling location.

If a sampling increment of a coarse grading is too large as test portion, one of the procedures as

described in 4.6.2, 4.6.3 or 4.6.4 shall be used for the reduction of the sampling increment.

If a sampling increment of a light grading is too large for the preparation of the bulk sample, the

procedure as specified in 4.6.3 or 4.6.4 shall be used for the reduction of the sampling increment.

If a sampling increment of a heavy grading is too large for the preparation of the bulk sample,

the procedure as specified in 4.6.4 shall be used for the reduction of the sampling increment.

4.6.2 Reduction using buckets

Discharge the sample over one or more sample buckets.

When discharging a sample from a loader bucket, arrange the receiver bucket(s) to catch all the

material from a cross-sectional segment or from one side of an imaginary cross-sectional plane

in the centre of the loader bucket.

When discharging a sample from a grab, catch all the material from one symmetrical quarter or

half of the grab content in one or more buckets.

If further reduction is required, tip the bucket(s) containing the reduced sample over two

adjoining buckets and discard the contents of one bucket. Repeat this procedure until the

required size of test portion is obtained.

4.6.3 Reduction using plates or wires

Discharge the sample over one or two vertically set plates. The distance between two parallel set

plates shall be at least three times the sieve size of the nominal upper grading limit.

When discharging a sample from a loader bucket, take all the material from a cross-sectional

segment or from one side of an imaginary cross-sectional plane in the centre of the loader

bucket, discharged between two parallel and vertically set plates or at one side of a vertically set

plate.

When discharging a sample from a grab, take all the material from one symmetrical quarter or

half of the grab content, discharged between two vertically set plates at right angles to each

other or at one side of a vertically set plate.

When reducing a sample already discharged onto a floor area (4.4.2.1) use wires representing

imaginary separation planes.

For the reduction of a sample to approximately the half amount, stretch a wire as a separation

line over the sample. Where segregation is present in one direction of the deposited sample,

place the wire in the same direction (see Figure 2) and take the subsample by removing all

armourstone located, or for the largest part located, at one side of the imagined vertical plane

projected by the wire.

Figure 2 — Halving a sample by means of a Figure 3 — Dividing a sample with two

separation plane separation planes

For the reduction of a sample to less than the half amount, stretch two parallel wires as

separation lines over the sample, so that the desired subsample lies between the two lines.

Where segregation is present in one direction of the deposited sample, place the wires in the

same direction (see Figure 3) and take the subsample by removing all stones located, or for the

largest part located, between the imaginary vertical planes projected by the wires.

To facilitate the reduction procedure a sample to be reduced by using wires may be spread in a

layer of thickness not greater than twice the nominal upper size of the material.

Where no segregation of the material has occurred, the subsample may be limited to half the

separated strip.

4.6.4 Reduction using numbering

Each piece of armourstone in the sample shall be allocated an individual number in a

consecutive sequence covering the entire sample. Each piece of armourstone shall be marked

clearly and durably with the allocated number.

The subsample shall be taken by randomly selecting numbered pieces of armourstone until the

required size of test portion is obtained.

4.7 Sample preparation for Micro-Deval test where the appropriate particle size is

not available

The test portion shall be prepared in accordance with EN 1097-1:2011, Clause 6, with the

following variations:

4.7.1 The test portion shall be obtained by crushing at least six samples from separate pieces

of armourstone for which the masses do not differ by more than 25 %. The crushing shall be

carried out with a laboratory jaw crusher.

4.7.2 Flaky particles shall be removed by using bar sieves conforming to EN 933-3 as follows:

a) bar sieve of 6,3 mm for the fractions 10 mm to 11,2 mm (or 10 mm to 12,5 mm);

b) bar sieve of 8 mm for the fractions 11,2 mm to 14 mm (or 12,5 mm to 14 mm).

4.7.3 Cubical particles shall be removed by using bar sieves conforming to EN 933-3, as

retained particles on the 12,5 mm bar sieve for the fractions 11,2 to 14 mm (or 12,5 mm to

14 mm).

4.8 Marking, packaging and dispatch of samples

The laboratory samples or containers in which they are transported shall be clearly and durably

marked.

Marking shall include:

a) a unique code; or

b) identification of the laboratory samples, place of sampling, date of sampling and designation

of the material.

Laboratory samples shall be transported in such a way that pieces of armourstone are not

broken in transit.

4.9 Sampling registration

The sampler shall prepare a sampling registration for each laboratory sample or for each group

of laboratory samples from a single source.

The sampling registration shall refer to this part of this document and state:

a) the sampling registration identification (serial number);

b) the laboratory sample identification mark(s);

c) the date and place of sampling:

d) the grading type and the size of the batch;

e) the sampling point or identification of the batch sampled;

f) a reference to the sampling plan prepared in accordance with 4.3;

g) the name of the sampler;

h) any other relevant information.

NOTE An example of a sampling registration is given in Annex A.

5 Determination of the particle size distribution of coarse gradings

5.1 Principle

The test consists of dividing up and separating a material, by means of a series of sieves, into

several fractions of different sizes. The aperture sizes and the number of sieves shall be

appropriate for the nature of the sample and the accuracy required.

The cumulative mass of the pieces of armourstone passing each sieve shall be expressed as a

percentage of the total mass of the material.

5.2 Apparatus

5.2.1 All apparatus, unless otherwise stated, shall conform to the general requirements of

EN 932-5.

5.2.2 Steel rod sieves, with square openings of 250 mm, 180 mm, 125 mm, 90 mm, 63 mm,

45 mm, 31,5 mm, 22,4 mm, and 16 mm fitting on receivers, and single opening sieves, 500 mm

and 360 mm. Alternatively, for 125 mm, 90 mm and 63 mm square openings, perforated steel

plate sieves.

Steel bar sieves shall form right angled square openings, with dimensions equating to the

nominal sieve sizes with tolerances of ± 2,0 mm for the 500 mm, 360 mm,

250 mm, 180 mm and 125 mm sieves and ± 1,0 mm for the 90 mm, ± 0,6 mm for the

63 mm, ± 0,5 mm for the 45 mm, ± 0,4 mm for the 31,5 mm, ± 0,3 mm for the 22,4 mm,

and ± 0,27 mm for the 16 mm sieves. In all cases the 63 mm sieve shall be used.

Perforated steel plate sieves shall be in accordance with EN 933-2.

5.2.3 Test sieves, apertures conforming to ISO 3310-2 with apertures smaller than 63 mm.

, on which the sieves will fit.

5.2.4 Receivers, with a volume of at least 0,1 m

5.2.5 Weighing equipment, with a weighing capacity of at least 150 kg, accurate to ± 0,5 kg.

5.2.6 Shovels, and brushes.

5.2.7 A floor area, upon which the test portion can be deposited and tested. The floor shall be

sufficiently clean and close-textured to be able to distinguish and recover the material of the test

portion from the floor material.

5.3 Preparation of test portion

The sample shall be obtained from a bulk sample of six sampling increments taken out of a static

batch or three sampling increments obtained from a stream of material and reduced if necessary

in accordance with the requirements of Clause 4 to produce the required test portion.

The mass of the test portion in kilograms shall be at least twice the nominal upper limit of the

grading in millimetres.

5.4 Procedure

Place the sieves on the receivers.

Pass the sample in successive parts over the sieves.

Brush off, where present, any adhesive materials from the pieces of armourstone and catch the

fine material in the receiver under the 63 mm sieve.

Ensure that all pieces of armourstone which may pass the sieve in any orientation have so

passed before the retained material is placed on the subsequent sieve.

).

Remove the fraction which passes the 63 mm sieve and weigh its mass (m1

If this mass is greater than 80 kg, split the fraction, taking and weighing a representative part of

at least 40 kg (m ). Execute the split by discharging the homogenized material over two

adjoining receivers taking care to avoid any loss of material.

Sieve the fraction which passes the 63 mm sieve, or the representative part thereof, shall be in

accordance with EN 933-1.

Weigh the material retained on each sieve separately (M ) and weigh the fraction which passes

i

the sieve with the smallest aperture size (m ) to ± 0,5 kg.

5.5 Calculation and expression of results

Record the various masses on a test data sheet (see Annex B).

If the fraction which passed the 63 mm sieve has been split before being sieved further,

determine the values of M and m for the ISO 3310-2 test sieves by multiplying the individual

i 3

fractional masses by m /m .

1 2

Calculate as a percentage the mass (r) retained on each sieve to the nearest 0,1 % from the

i

following equation:

M

i

r × 100 (1)

i

ΣMm+

i

where

M is the mass of material retained on a sieve, in kilograms;

i

ΣM is the cumulative mass of material retained on all sieves, in kilograms;

i

m is the mass of material passing the sieve with the smallest aperture size, in

kilograms.

Calculate the cumulative percentage mass (R ) retained on each sieve to the nearest 0,1 %.

i

Calculate the cumulative percentage mass passing each sieve (P ) from Formula (2).

i

PR 100 − (2)

ii

Record to the nearest whole number.

=

=

5.6 Test report

5.6.1 Required data

The test report shall include the following information:

a) reference to this document;

b) identity of laboratory;

c) identification of the sample;

d) mass of test portion;

e) cumulative percentages of the masses passing each of the sieves, to the nearest whole

number;

f) date of test.

5.6.2 Optional data

The test report can include the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...