SIST EN 1090-2:2018/kprA1:2024

(Amendment)Execution of steel structures and aluminium structures - Part 2: Technical requirements for steel structures

Execution of steel structures and aluminium structures - Part 2: Technical requirements for steel structures

This European Standard specifies requirements for execution of structural steelwork as structures or as manufactured components, produced from:

- hot rolled, structural steel products up to and including grade S700;

- cold formed components and sheeting up to and including grade S700 (unless coming within the scope of prEN 1090-4);

- hot finished or cold formed austenitic, austenitic-ferritic and ferritic stainless steel products;

- hot finished or cold formed structural hollow sections, including standard range and custom-made rolled products and hollow sections manufactured by welding.

For components produced from cold formed components, and cold formed structural hollow sections that are within the scope of prEN 1090-4, the requirements of prEN 1090-4 take precedence over corresponding requirements in this European Standard.

This European Standard can also be used for structural steel grades up to and including S960, provided that conditions for execution are verified against reliability criteria and any necessary additional requirements are specified.

This European Standard specifies requirements, which are mostly independent of the type and shape of the steel structure (e.g. buildings, bridges, plated or latticed components) including structures subjected to fatigue or seismic actions. Certain requirements are differentiated in terms of execution classes.

This European Standard applies to structures designed according to the relevant part of the EN 1993 series. Sheet piling, displacement piles and micropiles designed to EN 1993-5 are intended to be executed in accordance with respectively EN 12063, EN 12699 and EN 14199. This European Standard only applies to the execution of waling, bracing, and connections.

This European Standard applies to steel components in composite steel and concrete structures designed according to the relevant part of the EN 1994 series.

This European Standard can be used for structures designed according to other design rules provided that conditions for execution comply with them and any necessary additional requirements are specified.

This European Standard includes the requirements for the welding of reinforcing steels to structural steels. This European Standard does not include requirements for the use of reinforcing steels for reinforced concrete applications.

Ausführung von Stahltragwerken und Aluminiumtragwerken - Teil 2: Technische Regeln für die Ausführung von Stahltragwerken

Exécution des structures en acier et des structures en aluminium - Partie 2: Exigences techniques pour les structures en acier

Izvedba jeklenih in aluminijastih konstrukcij - 2. del: Tehnične zahteve za izvedbo jeklenih konstrukcij - Dopolnilo A1

General Information

- Status

- Not Published

- Public Enquiry End Date

- 18-Dec-2022

- Technical Committee

- KON - Structures

- Current Stage

- 5020 - Formal vote (FV) (Adopted Project)

- Start Date

- 05-Dec-2023

- Due Date

- 23-Jan-2024

- Completion Date

- 18-Jan-2024

Relations

- Effective Date

- 01-Jul-2024

- Effective Date

- 08-Dec-2021

Overview

EN 1090-2:2018/FprA1 - Execution of steel structures and aluminium structures (Part 2) - sets the technical requirements for execution of structural steelwork across a wide range of steel products. It covers hot‑rolled and cold‑formed structural steels (normally up to grade S700, and optionally up to S960 subject to additional verification), stainless steels, and structural hollow sections (both hot‑finished and welded). The amendment prA1 updates definitions, welding rules, high‑strength steel provisions and several inspection and fabrication tolerances.

Key topics and requirements

- Scope of materials: hot rolled structural steels, cold‑formed components and sheeting, austenitic/austenitic‑ferritic/ferritic stainless steels, and hot‑ or cold‑formed hollow sections. prEN 1090‑4 takes precedence for some cold‑formed items.

- Execution classes (EXC): differentiated requirements depending on structural importance and risk (e.g., fatigue, seismic loading).

- Welding and fabrication:

- Specific welding requirements, including use of EN ISO 17660‑1 for welded reinforcing steels to structural steels.

- For high‑strength steels, weld quality management is required to meet EN ISO 3834‑2 and additional controls on preheat, interpass temperatures, cooling times and filler metal selection.

- Provisions on back‑gouging, grinding, and avoidance of hydrogen‑induced cracking for high‑strength steels.

- Inspection, testing and traceability: hold‑points, witness testing (if specified), and requirements for material certification (including heat analysis when yield > 460 MPa).

- Fabrication tolerances and shaping: requirements for bending, hot forming, punching/drilling, machining of cut edges and applicable tolerance classes for shells and platework.

- Special conditions: application to structures subject to fatigue or seismic actions, and to steel components in composite steel–concrete structures.

Applications and users

Who uses EN 1090-2:2018/FprA1:

- Structural fabricators and welders implementing shop and site execution procedures

- Structural engineers and designers referencing execution requirements for buildings, bridges and lattice/plated components

- Quality managers and conformity assessment bodies for CE marking of fabricated structural components

- Steel producers and suppliers providing material certificates and recommendations for welding/cutting Practical use cases include execution of load‑bearing steelwork in buildings and bridges, fabrication of hollow section members, connections subject to fatigue/seismic loads, and composite steel‑concrete elements.

Related standards

- EN 1993 series (design of steel structures)

- EN 1994 series (composite steel‑concrete structures)

- EN 10210 / EN 10219 (structural hollow section product standards; parts 3 referenced for high‑strength steels)

- EN ISO 3834 (welding quality management)

- EN ISO 5817 (weld acceptance levels)

- EN ISO 17660‑1 (welding of reinforcing steel)

- prEN 1090‑4 (cold‑formed components where applicable)

Keywords: EN 1090‑2:2018, EN 1090, execution of steel structures, welding requirements, high‑strength steels, EXC classes, fabrication tolerances, structural hollow sections.

Frequently Asked Questions

SIST EN 1090-2:2018/kprA1:2024 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Execution of steel structures and aluminium structures - Part 2: Technical requirements for steel structures". This standard covers: This European Standard specifies requirements for execution of structural steelwork as structures or as manufactured components, produced from: - hot rolled, structural steel products up to and including grade S700; - cold formed components and sheeting up to and including grade S700 (unless coming within the scope of prEN 1090-4); - hot finished or cold formed austenitic, austenitic-ferritic and ferritic stainless steel products; - hot finished or cold formed structural hollow sections, including standard range and custom-made rolled products and hollow sections manufactured by welding. For components produced from cold formed components, and cold formed structural hollow sections that are within the scope of prEN 1090-4, the requirements of prEN 1090-4 take precedence over corresponding requirements in this European Standard. This European Standard can also be used for structural steel grades up to and including S960, provided that conditions for execution are verified against reliability criteria and any necessary additional requirements are specified. This European Standard specifies requirements, which are mostly independent of the type and shape of the steel structure (e.g. buildings, bridges, plated or latticed components) including structures subjected to fatigue or seismic actions. Certain requirements are differentiated in terms of execution classes. This European Standard applies to structures designed according to the relevant part of the EN 1993 series. Sheet piling, displacement piles and micropiles designed to EN 1993-5 are intended to be executed in accordance with respectively EN 12063, EN 12699 and EN 14199. This European Standard only applies to the execution of waling, bracing, and connections. This European Standard applies to steel components in composite steel and concrete structures designed according to the relevant part of the EN 1994 series. This European Standard can be used for structures designed according to other design rules provided that conditions for execution comply with them and any necessary additional requirements are specified. This European Standard includes the requirements for the welding of reinforcing steels to structural steels. This European Standard does not include requirements for the use of reinforcing steels for reinforced concrete applications.

This European Standard specifies requirements for execution of structural steelwork as structures or as manufactured components, produced from: - hot rolled, structural steel products up to and including grade S700; - cold formed components and sheeting up to and including grade S700 (unless coming within the scope of prEN 1090-4); - hot finished or cold formed austenitic, austenitic-ferritic and ferritic stainless steel products; - hot finished or cold formed structural hollow sections, including standard range and custom-made rolled products and hollow sections manufactured by welding. For components produced from cold formed components, and cold formed structural hollow sections that are within the scope of prEN 1090-4, the requirements of prEN 1090-4 take precedence over corresponding requirements in this European Standard. This European Standard can also be used for structural steel grades up to and including S960, provided that conditions for execution are verified against reliability criteria and any necessary additional requirements are specified. This European Standard specifies requirements, which are mostly independent of the type and shape of the steel structure (e.g. buildings, bridges, plated or latticed components) including structures subjected to fatigue or seismic actions. Certain requirements are differentiated in terms of execution classes. This European Standard applies to structures designed according to the relevant part of the EN 1993 series. Sheet piling, displacement piles and micropiles designed to EN 1993-5 are intended to be executed in accordance with respectively EN 12063, EN 12699 and EN 14199. This European Standard only applies to the execution of waling, bracing, and connections. This European Standard applies to steel components in composite steel and concrete structures designed according to the relevant part of the EN 1994 series. This European Standard can be used for structures designed according to other design rules provided that conditions for execution comply with them and any necessary additional requirements are specified. This European Standard includes the requirements for the welding of reinforcing steels to structural steels. This European Standard does not include requirements for the use of reinforcing steels for reinforced concrete applications.

SIST EN 1090-2:2018/kprA1:2024 is classified under the following ICS (International Classification for Standards) categories: 91.080.13 - Steel structures. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1090-2:2018/kprA1:2024 has the following relationships with other standards: It is inter standard links to SIST EN 1090-2:2018+A1:2024, SIST EN 1090-2:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1090-2:2018/kprA1:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

SIST EN 1090-2:2018/oprA1:2022

01-december-2022

Izvedba jeklenih in aluminijastih konstrukcij - 2. del: Tehnične zahteve za izvedbo

jeklenih konstrukcij - Dopolnilo A1

Execution of steel structures and aluminium structures - Part 2: Technical requirements

for steel structures

Ausführung von Stahltragwerken und Aluminiumtragwerken - Teil 2: Technische Regeln

für die Ausführung von Stahltragwerken

Exécution des structures en acier et des structures en aluminium - Partie 2: Exigences

techniques pour les structures en acier

Ta slovenski standard je istoveten z: EN 1090-2:2018/prA1

ICS:

91.080.13 Jeklene konstrukcije Steel structures

SIST EN 1090-2:2018/oprA1:2022 en,fr,de

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

SIST EN 1090-2:2018/oprA1:2022

SIST EN 1090-2:2018/oprA1:2022

DRAFT

EUROPEAN STANDARD

EN 1090-2:2018

NORME EUROPÉENNE

EUROPÄISCHE NORM

prA1

September 2022

ICS 91.080.13

English Version

Execution of steel structures and aluminium structures -

Part 2: Technical requirements for steel structures

Exécution des structures en acier et des structures en Ausführung von Stahltragwerken und

aluminium - Partie 2: Exigences techniques pour les Aluminiumtragwerken - Teil 2: Technische Regeln für

structures en acier die Ausführung von Stahltragwerken

This draft amendment is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee CEN/TC 135.

This draft amendment A1, if approved, will modify the European Standard EN 1090-2:2018. If this draft becomes an amendment,

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for inclusion of

this amendment into the relevant national standard without any alteration.

This draft amendment was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1090-2:2018/prA1:2022 E

worldwide for CEN national Members.

SIST EN 1090-2:2018/oprA1:2022

EN 1090-2:2018/prA1:2022 (E)

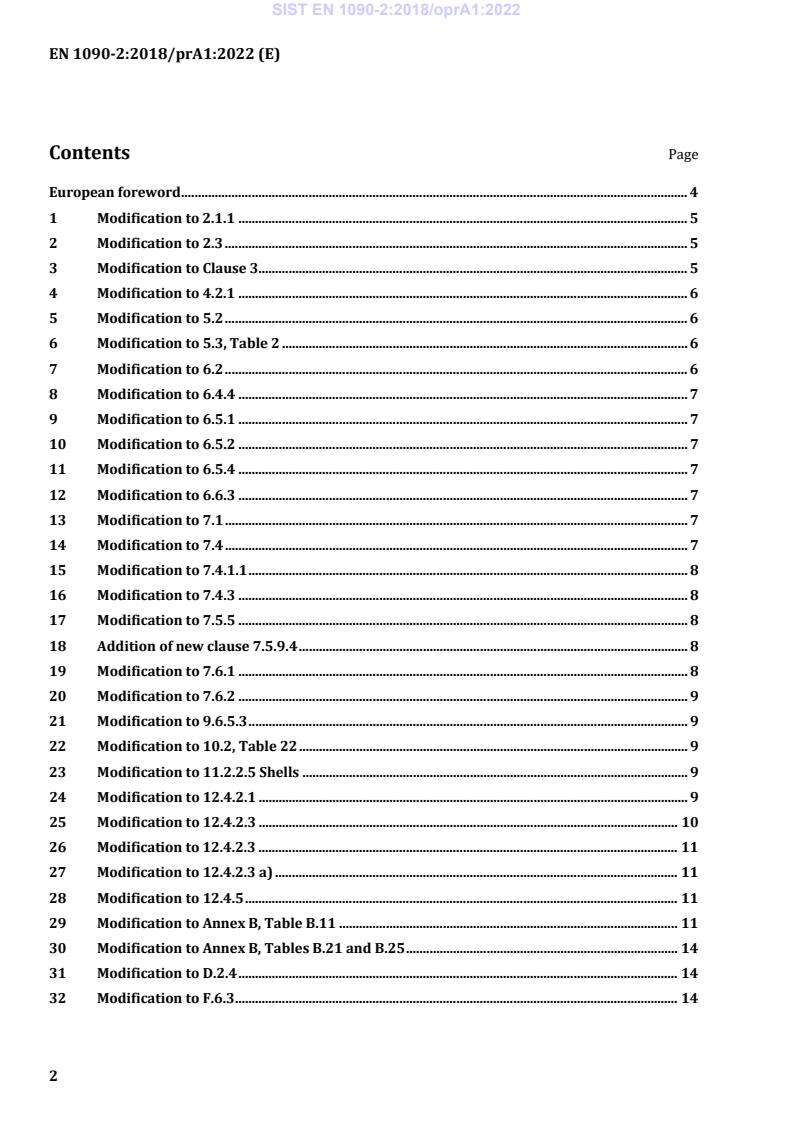

Contents Page

European foreword . 4

1 Modification to 2.1.1 . 5

2 Modification to 2.3 . 5

3 Modification to Clause 3. 5

4 Modification to 4.2.1 . 6

5 Modification to 5.2 . 6

6 Modification to 5.3, Table 2 . 6

7 Modification to 6.2 . 6

8 Modification to 6.4.4 . 7

9 Modification to 6.5.1 . 7

10 Modification to 6.5.2 . 7

11 Modification to 6.5.4 . 7

12 Modification to 6.6.3 . 7

13 Modification to 7.1 . 7

14 Modification to 7.4 . 7

15 Modification to 7.4.1.1 . 8

16 Modification to 7.4.3 . 8

17 Modification to 7.5.5 . 8

18 Addition of new clause 7.5.9.4 . 8

19 Modification to 7.6.1 . 8

20 Modification to 7.6.2 . 9

21 Modification to 9.6.5.3 . 9

22 Modification to 10.2, Table 22 . 9

23 Modification to 11.2.2.5 Shells . 9

24 Modification to 12.4.2.1 . 9

25 Modification to 12.4.2.3 . 10

26 Modification to 12.4.2.3 . 11

27 Modification to 12.4.2.3 a) . 11

28 Modification to 12.4.5 . 11

29 Modification to Annex B, Table B.11 . 11

30 Modification to Annex B, Tables B.21 and B.25 . 14

31 Modification to D.2.4 . 14

32 Modification to F.6.3 . 14

SIST EN 1090-2:2018/oprA1:2022

EN 1090-2:2018/prA1:2022 (E)

33 Modification to F.7.2 . 15

34 Modication to Annex G, clause G.5 . 15

SIST EN 1090-2:2018/oprA1:2022

EN 1090-2:2018/prA1:2022 (E)

European foreword

This document (EN 1090-2:2018/prA1:2022) has been prepared by Technical Committee CEN/TC 135

“Execution of steel structures and aluminium structures”, the secretariat of which is held by SN.

This document is currently submitted to the CEN Enquiry.

SIST EN 1090-2:2018/oprA1:2022

EN 1090-2:2018/prA1:2022 (E)

1 Modification to 2.1.1

After "EN 10210-2, Hot finished structural hollow sections of non-alloy and fine grain steels - Part 2:

Tolerances, dimensions and sectional properties",

Add:

"EN 10210-3, Hot finished steel structural hollow sections of non-alloy and fine grain steels - Part 3 :

Technical delivery conditions for high strength and weather resistant steels".

After "EN 10219-2, Cold formed welded structural hollow sections of non-alloy and fine grain steels - Part

2: Tolerances, dimensions and sectional properties"

Add:

"EN 10219-3, Cold formed welded steel structural hollow sections of non-alloy and fine grain steels - Part

3 : Technical delivery conditions for high strength and weather resistant steels".

2 Modification to 2.3

Add in Clause 2.3 after EN ISO 13916:

"EN ISO 13920, Welding - General tolerances for welded constructions - Dimensions for lengths and angles

- Shape and position (ISO 13920)".

Delete [25] in the bibliography.

Replace:

"EN ISO 17660 (all parts), Welding - Welding of reinforcing steel (ISO 17660 series)"

with:

"EN ISO 17660-1, Welding - Welding of reinforcing steel - Part 1: Load bearing welded joints (ISO 17660-

1)".

3 Modification to Clause 3

Replace:

"3.4

constructor

person or organization executing the works"

with:

"3.4

constructor

person or organization responsible for the execution of the works."

Add after 3.15.4:

“3.16

high-strength steels

materials with the mechanical properties for hollow sections, flat and long steel products with minimum

yield strength greater than 460 MPa

SIST EN 1090-2:2018/oprA1:2022

EN 1090-2:2018/prA1:2022 (E)

Note 1 to entry: High-strength steels in this standard are divided into four categories, which are used to

differenciate quality requirements (see Table HSS).

Table HSS — Categories of High-Strength Steels

a

Steel grades Thermomechanically rolled Quenched and tempered

> S460 and

A1 A2

≤ S700

> S700 and

B1 B2

≤ S960

a

S500W can be treated as S460W.

“.

4 Modification to 4.2.1

Replace:

"f) specified hold-points or requirement to witness inspections or tests, and any consequent access

requirements."

with:

"f) if specified, hold-points or requirement to witness inspections or tests, and any consequent access

requirements.".

5 Modification to 5.2

nd

In Table 1, 1st column, 2 line: add a new footnote "g":

g

"

"Structural steels (Tables 2 and 3)

In the last line, add:

g

" When yield strength greater than 460 MPa is specified and used in welded structural steel, the

chemical composition (heat analysis) for the following 14 elements shall be required and certified: C, Si,

Mn, P, S, Al, N , Cr, Cu, Mo, Ni, Nb, Ti, V and the designation in accordance with EN 10027.".

6 Modification to 5.3, Table 2

Add at the bottom of Table 2:

"The national product standards/recommendations or manufacturers guidelines must consider".

th

9 line: replace "EN 10210-1" with "EN 10210-3"

th

10 line: replace "EN 10219-1" with "EN 10219-3"

7 Modification to 6.2

th

5 paragraph, replace:

"Soft or low stress stamps may be used for stainless steels unless otherwise specified."

with:

“Appropriate soft or low stress stamps may be used for stainless steels unless otherwise specified.”.

SIST EN 1090-2:2018/oprA1:2022

EN 1090-2:2018/prA1:2022 (E)

8 Modification to 6.4.4

Add at the end of 6.4.4:

For all steel categories listed in 3.16 Table HSS, it will be checked with the steel manufacturer whether

preheating of the material is necessary for thermal cutting. As an alternative, the cut edges may be

machined to remove the hardened layer and thus ensure the parent metal properties.

9 Modification to 6.5.1

st

1 paragraph, replace:

"Steel may be bent, pressed or forged to the required shape by either a hot or cold forming process,

provided the properties are not reduced below those specified."

with:

"Steel may be bent, pressed or forged to the required shape, by either a hot or cold forming process,

provided the properties conform to those specified.".

10 Modification to 6.5.2

st

1 paragraph, replace:

"Shaping by hot forming shall conform to the requirements relating to hot forming in the relevant product

standard and to the recommendations of the steel manufacturer."

with:

"Shaping by hot forming shall conform to the requirements relating to hot forming in the relevant product

standard and to the recommendations of the steel producer.".

11 Modification to 6.5.4

Remove all the text of paragraphs "b)", "e)" and "f)".

Renumber the retained paragraphs in "a)" to "g)".

12 Modification to 6.6.3

Add at the end of 6.6.3:

“For all steel categories listed in 3.16 Table HSS, it shall be checked with the steel manufacturer whether

punching is acceptable. Otherwise, drilling or machining is necessary.”.

13 Modification to 7.1

rd

In 7.1 (3 paragraph) replace "EN ISO 17660 series" with "EN ISO 17660-1".

Add at t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...